Improving Fatigue Performance of GFRP Composite Using Carbon Nanotubes

Abstract

:1. Introduction

2. Experimental Methods

2.1. Materials

2.2. Preparing of Epoxy-MWCNTs Nanocomposites

2.3. GFRP Fabrications and Specimens Preparation

2.4. Test Methods

2.4.1. Static Tension Test

2.4.2. Cyclic Tension Test

2.4.3. Microstructure Characterization

3. Results and Discussion

3.1. Tensile Strength

| Specimen number | Tensile strength (MPa) | ||

|---|---|---|---|

| Neat | 0.5 wt% MWCNTs | 1.0 wt% MWCNTs | |

| 1 | 690 | 891 | 680 |

| 2 | 783 | 763 | 595 |

| 3 | 729 | 1058 | 909 |

| 4 | 657 | 931 | 699 |

| 5 | 650 | 876 | 688 |

| Mean | 703 | 904 | 714 |

| Standard deviation | 55 | 107 | 117 |

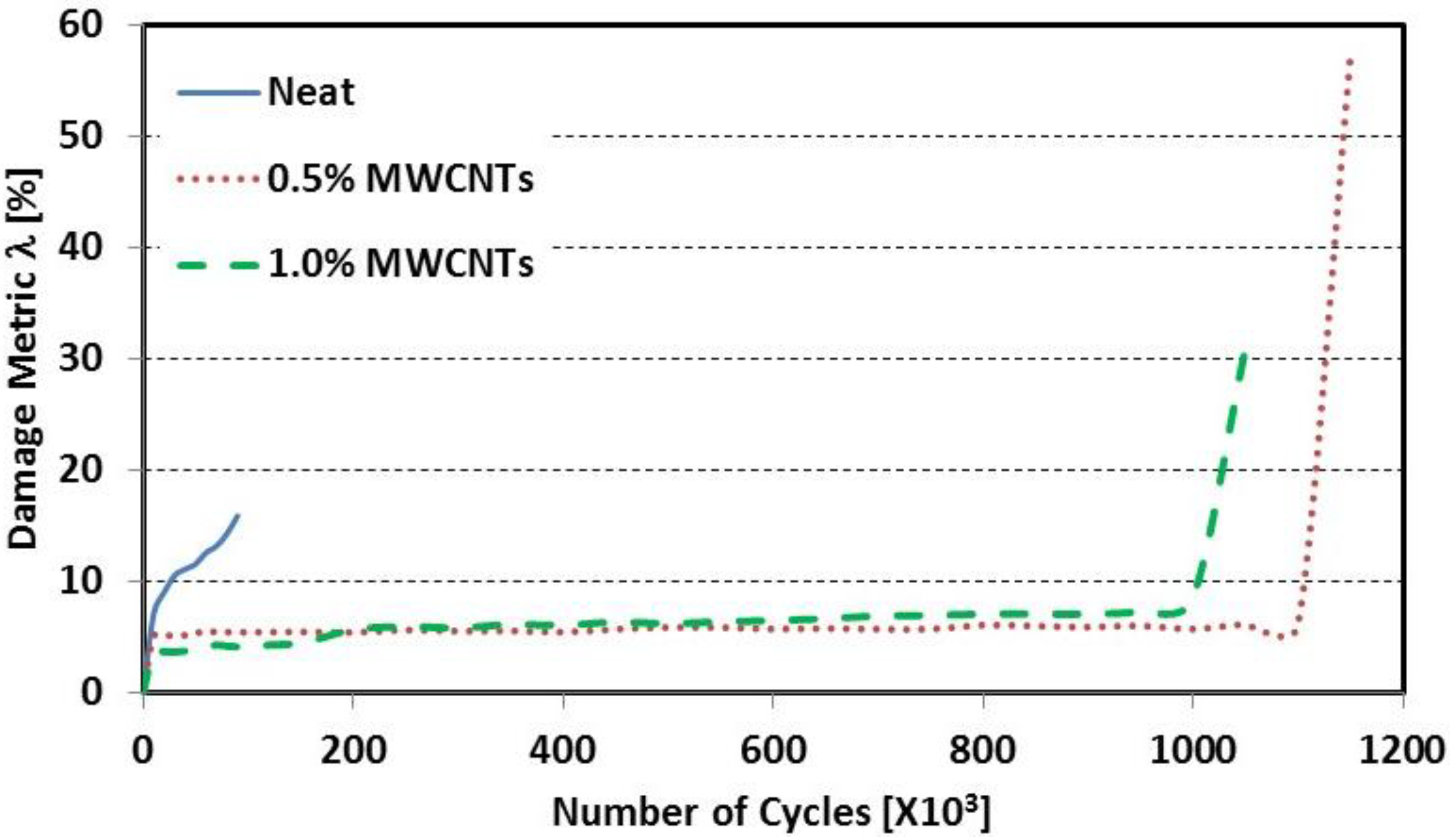

3.2. Damage Evolution

| Specimen number | Fatigue life (number of cycles until failure) | ||

|---|---|---|---|

| Neat | 0.5 wt% MWCNTs | 1.0 wt% MWCNTs | |

| 1 | 85,138 | 531,006 | 637,398 |

| 2 | 92,111 | 2,082,378 | 702,837 |

| 3 | 79,543 | 585,078 | 1,125,000 |

| 4 | 87,472 | 1,094,855 | 1,246,330 |

| 5 | 93,301 | 1,144,095 | 1,042,000 |

| Mean | 87,513 | 1,087,482 | 950,713 |

| Standard deviation | 5,563 | 623,526 | 267,258 |

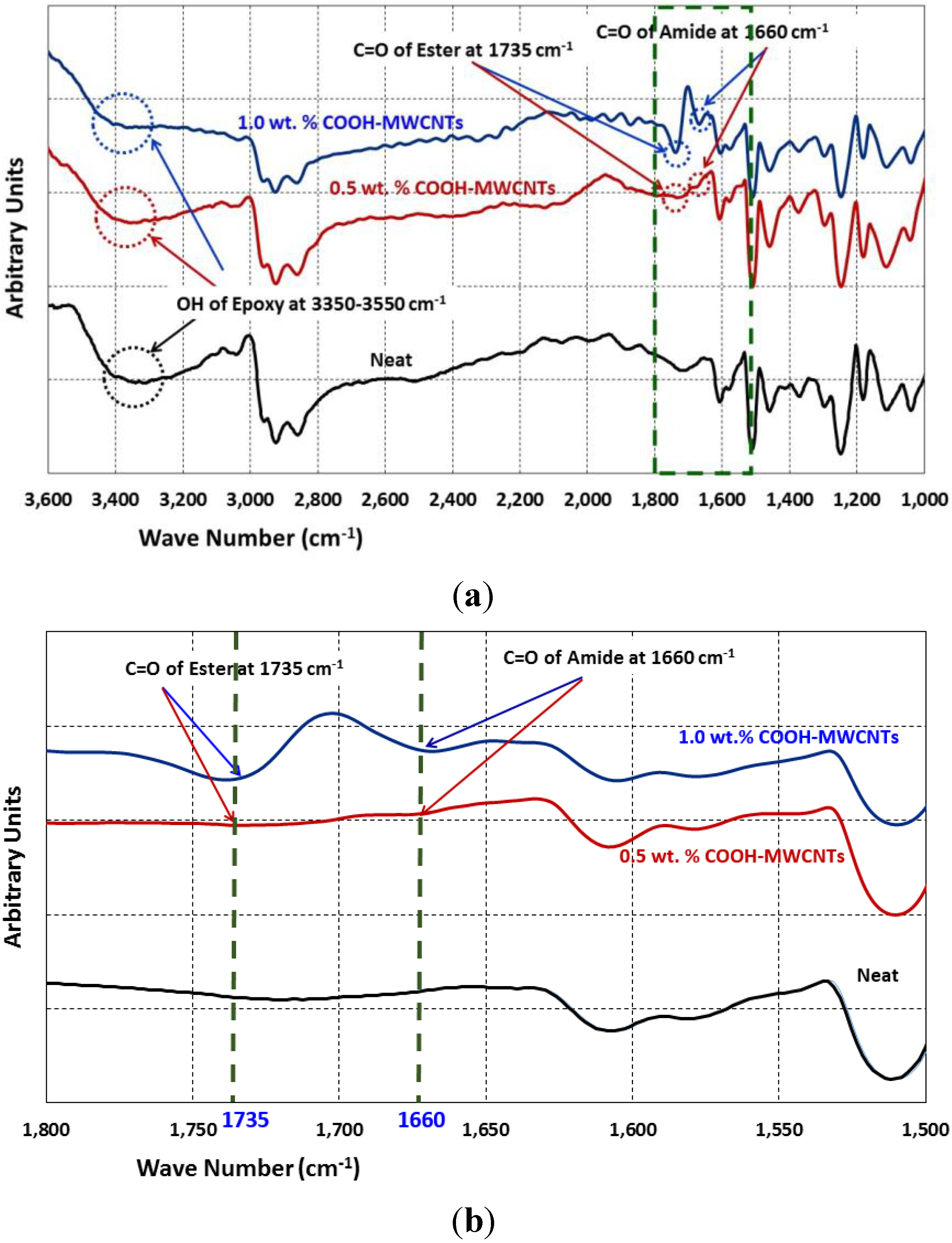

3.3. Microstructure Characterization

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Einde, L.V.D.; Zhao, L.; Seible, F. Use of FRP composites in civil structural applications. Constr. Build. Mater. 2013, 17, 389–403. [Google Scholar] [CrossRef]

- Hollaway, L.C. The evolution of and the way forward for advanced polymer composites in the civil infrastructure. Constr. Build. Mater. 2003, 17, 365–378. [Google Scholar] [CrossRef]

- Wight, R.G.; Erik, M.A.; Shgu, C.T.; Tanovic, R.; Heffernan, P.J. Development of FRP short-span deployable bridge—Experimental results. J. Bridge Eng. 2006, 11, 489–498. [Google Scholar] [CrossRef]

- Park, K.; Yu, Y.; Shin, H. Span length variance effect on the fatigue life of FRP bridge deck. Adv. Mater. Sci. Eng. 2013, 2013, 1–10. [Google Scholar]

- Wu, Z.; Wang, X.; Iwashita, K.; Sasaki, T.; Hamaguchi, Y. Tensile fatigue behaviour of FRP and hybrid FRP sheets. Compos. Part B 2010, 41, 396–402. [Google Scholar] [CrossRef]

- Kumar, P.K.; Chandrashekhara, K.; Nanni, A. Structural performance of a FRP bridge deck. Constr. Build. Mater. 2004, 18, 35–49. [Google Scholar] [CrossRef]

- Zheng, Y.; Guoyou, Y.; Yungfeng, P. Investigation of ultimate strengths of concrete bridge deck slabs reinforced with GFRP bars. Constr. Build. Mater. 2012, 28, 482–492. [Google Scholar] [CrossRef]

- Brown, D.L.; Berman, J.W. Fatigue and strength evaluation of two glass fiber reinforced polymer bridge decks. J. Bridge Eng. Am. Soc. Civ. Eng. 2010, 15, 290–301. [Google Scholar]

- Noël, M.; Soudki, K. Fatigue behavior of GFRP reinforcing bars in air and in concrete. J. Compos. Constr. 2014, 18, 1–8. [Google Scholar] [CrossRef]

- Kim, J.K.; Mai, Y.W. Engineered Interfaces in Fiber Reinforced Composites, 1st ed.; Elsevier: Oxford, UK, 1998. [Google Scholar]

- Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures; ACI Committee: Farmington Hills, MI, USA, 2008; ACI Committee 440.2R-08.

- Canadian Standard Association (CSA) S6. Canadian Highway Bridge Design Code; CSA: Mississauga, ON, Canada, 2010. [Google Scholar]

- Agubra, V.; Owuor, P.; Hosur, M. Influence of nanoclay dispersion methods on the mechanical behavior of E-Glass/Epoxy nanocomposites. Nanomaterials 2013, 2, 550–563. [Google Scholar] [CrossRef]

- Aboubakr, S.H.; Kandil, U.F.; Reda Taha, M.M. Creep of epoxy-clay nanocomposite adhesive at the FRP interface: A multi-scale investigation. Int. J. Adhes. Adhes. 2014, 54, 1–12. [Google Scholar] [CrossRef]

- Meng, Q.; Wang, C.H.; Saber, N.; Kuan, H.C.; Dai, J.; Friedrich, K.; Ma, J. Nanosilica-toughened polymer adhesives. Mater. Des. 2014, 61, 75–86. [Google Scholar] [CrossRef]

- Kim, H.; Miura, Y.; Macosko, C.W. Graphene/polyurethane nanocomposites for improved gas barrier and electrical conductivity. Chem. Mater. 2010, 22, 3441–3450. [Google Scholar] [CrossRef]

- Wang, S.; Qiu, J. Enhancing thermal conductivity of glass fiber/polymer composites through carbon nanotubes incorporation. Compos. Part B Eng. 2010, 41, 533–536. [Google Scholar] [CrossRef]

- Manjunatha, C.M.; Bojja, R.; Jangannathan, N.; Kinloch, A.J.; Taylor, A.C. Enhanced fatigue behavior of a glass fiber reinforced hybrid particles modified epoxy nanocomposite under WISPERX spectrum load sequence. Int. J. Fatigue 2013, 54, 25–31. [Google Scholar] [CrossRef]

- Wang, S.; Qiu, J. Modifying epoxy resin via M-chloroperbenzoic acid epoxidized carbon nanotubes. J. Appl. Polym. Sci. 2009, 112, 3322–3326. [Google Scholar] [CrossRef]

- Wang, S.; Liang, R.; Wang, B.; Zhang, C. Addition of diethyltoluenediamines onto carbon nanotubes for efficient load-transfer in the nanocomposites. Polym. Compos. 2009, 30, 1050–1057. [Google Scholar] [CrossRef]

- Qiu, J.; Zhang, C.; Wang, B.; Liang, R. Carbon nanotube integrated multifunctional multiscale composites. Nanotechnology 2008, 18, 1–11. [Google Scholar]

- Soliman, E.; Al-Haik, M.; Reda Taha, M.M. On and off-axis tension behavior of fiber reinforced polymer (FRP) composites incorporating multi-walled carbon nanotubes. J. Compos. Mater. 2012, 46, 1661–1675. [Google Scholar] [CrossRef]

- Pandey, G.; Woltersd, M.; Thostenson, E.T. Localized functionally modified glass fibers with carbon nanotube networks for crack sensing in composites using time domain reflectometry. Carbon 2012, 50, 3816–3825. [Google Scholar] [CrossRef]

- Naghashpour, A.; Hoa, S.V. In-situ monitoring of through-thickness strain in glass fiber/epoxy composite laminates using carbon nanotube sensors. Compos. Sci. Technol. 2013, 78, 41–47. [Google Scholar] [CrossRef]

- Wang, S.; Liang, Z.; Liu, T.; Wang, B.; Zhang, C. Effective amino-functionalization of carbon nanotubes for reinforcing epoxy polymer composites. Nanotechnology 2006, 17, 1551–1557. [Google Scholar] [CrossRef]

- Wang, S.; Liang, R.; Wang, B.; Zhang, C. Load-transfer in functionalized carbon nanotubes/polymer composites. Chem. Phys. Lett. 2008, 457, 371–375. [Google Scholar] [CrossRef]

- Zhu, J.; Kim, J.; Peng, H.; Margrave, J.L.; Khabashesku, V.N.; Barrera, E.V. Improving the dispersion and integration of single-walled carbon nanotubes in epoxy composites through functionalization. Nano Lett. 2003, 3, 1107–1113. [Google Scholar] [CrossRef]

- Osorio, A.G.; Silveira, I.C.L.; Bueno, V.L.; Bergmann, C.P. H2SO4/HNO3/HCl—Functionalization and its effect on dispersion of carbon nanotubes in aqueous media. Appl. Surf. Sci. 2008, 255, 2485–2489. [Google Scholar] [CrossRef]

- Ma, P.C.; Siddiqui, N.A.; Marom, G.; Kim, J.K. Dispersion and functionalization of carbon nanotubes for polymer-based nanocomposites: A review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1345–1367. [Google Scholar] [CrossRef]

- Advani, S.G.; Fan, Z. Dispersion, bonding and orientation of carbon nanotubes in polymer matrices. In Processing and Properties of Nanocomposites; World Scientific Publishing Co., Pte. Ltd.: Hackensack, NJ, USA, 2007. [Google Scholar]

- Standard Guide for Preparation of Flat Composite Panels with Processing Guidelines for Specimen Preparation; ASTM International: West Conshohocken, PA, USA, 2007; ASTM D5687/D5687M-07.

- Standard Test Methods for Constituent Content of Composite Materials; ASTM International: West Conshohocken, PA, USA, 2006; ASTM D3171-06.

- Test Method for Tensile Properties of Polymer Matrix Composite Materials; ASTM International: West Conshohocken, PA, USA, 2008; ASTM D3039M-08.

- Standard Test Method for Tension-Tension Fatigue of Polymer Matrix Composite Materials; ASTM International: West Conshohocken, PA, USA, 2012; ASTM D3479/D3479M-12.

- Griffiths, P.; de Hasseth, J.A. Fourier Transform Infrared Spectrometry, 2nd ed.; Wiley-Blackwell: Hoboken, NJ, USA, 2007. [Google Scholar]

- Kuo, C.M.; Takahashi, K.; Chou, T.W. Effect of fiber waviness on the nonlinear elastic behavior of flexible composites. J. Compos. Mater. 1988, 22, 1004–1025. [Google Scholar] [CrossRef]

- Peel, L.D.; Jensen, D.W. The response of fiber-reinforced elastomers under simple tension. J. Compos. Mater 2001, 35, 96–137. [Google Scholar] [CrossRef]

- Chou, T.W. Microstructural Design of Fiber Composites; Cambridge University Press: Cambridge, UK, 2005. [Google Scholar]

- Greenhalgh, E.S. Failure Analysis and Fractography of Polymer Composites; Woodhead Publishing: Cambridge, UK, 2009. [Google Scholar]

- Kumar, M.S.; Raghavendra, K.; Venkataswamy, M.A.; Ramachandra, H.V. Fractographic analysis of tensile failures of aerospace grade composites. Mater. Res. 2012, 15, 990–997. [Google Scholar] [CrossRef]

- Bieniaś, J.; Surowska, B. The mechanical properties and failure analysis of selected fibre metal laminates. Compos. Theory Pract. 2012, 13, 220–224. [Google Scholar]

- Lemaitre, J.; Desmorat, R. Engineering Damage Mechanics: Ductile, Creep, Fatigue and Brittle Failures; Springer: Heidelberg, Germany, 2005. [Google Scholar]

- Tomblin, J.; Seneviratne, W. Determining the Fatigue Life of Component Aircraft Structures Using Life and Load-Enhancement Factors; Federal Aviation Administration: Washington, DC, USA, 2011. [Google Scholar]

- Strong, A.B. Fundamentals of Composites Manufacturing: Materials, Methods and Applications; Society of Manufacturing Engineers: Dearborn, MI, USA, 2008. [Google Scholar]

- Kim, W.-J.; Kang, S.-O.; Ah, C.S.; Lee, Y.-W.; Ha, D.H.; Choi, I.S.; Yun, W.S. Functionalization of shortened SWCNTs using esterification. Bull. Korean Chem. Soc. 2004, 25, 1301–1302. [Google Scholar] [CrossRef]

- Zhang, T.; Xu, M.; He, L.; Xi, K.; Gu, M.; Jiang, Z. Synthesis, characterization and cytotoxicity of phosphoryl choline-grafted water-soluble carbon nanotubes. Carbon 2008, 45, 1782–1791. [Google Scholar] [CrossRef]

- Gojny, F.H.; Wichmann, M.; Fiedler, B.; Schulte, K. Influence of different carbon nanotubes on the mechanical properties of epoxy matrix composites—A comparative study. Compos. Sci. Technol. 2005, 65, 2300–2313. [Google Scholar] [CrossRef]

- Suresh, S. Fatigue of Materials, 2nd ed.; Cambridge University Press: Cambridge, UK, 1998. [Google Scholar]

- Reda Taha, M.M.; Taha, E.O.; Genedy, M. Monitoring fatigue damage propagation in GFRP using carbon nanotubes. In Proceedings of the American Society for Composites 29th Technical Conference, 16th US-Japan Conference on Composite Materials, San Diego, CA, USA, 8–10 September 2014; DEStech Publications, Inc.: Lancaster, PA, USA, 2014. [Google Scholar]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Genedy, M.; Daghash, S.; Soliman, E.; Taha, M.M.R. Improving Fatigue Performance of GFRP Composite Using Carbon Nanotubes. Fibers 2015, 3, 13-29. https://doi.org/10.3390/fib3010013

Genedy M, Daghash S, Soliman E, Taha MMR. Improving Fatigue Performance of GFRP Composite Using Carbon Nanotubes. Fibers. 2015; 3(1):13-29. https://doi.org/10.3390/fib3010013

Chicago/Turabian StyleGenedy, Moneeb, Sherif Daghash, Eslam Soliman, and Mahmoud M. Reda Taha. 2015. "Improving Fatigue Performance of GFRP Composite Using Carbon Nanotubes" Fibers 3, no. 1: 13-29. https://doi.org/10.3390/fib3010013

APA StyleGenedy, M., Daghash, S., Soliman, E., & Taha, M. M. R. (2015). Improving Fatigue Performance of GFRP Composite Using Carbon Nanotubes. Fibers, 3(1), 13-29. https://doi.org/10.3390/fib3010013