Fabrication and Characterization of Polymer Optical Fibers Doped with Perylene-Derivatives for Fluorescent Lighting Applications

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Absorption and Emission Bands

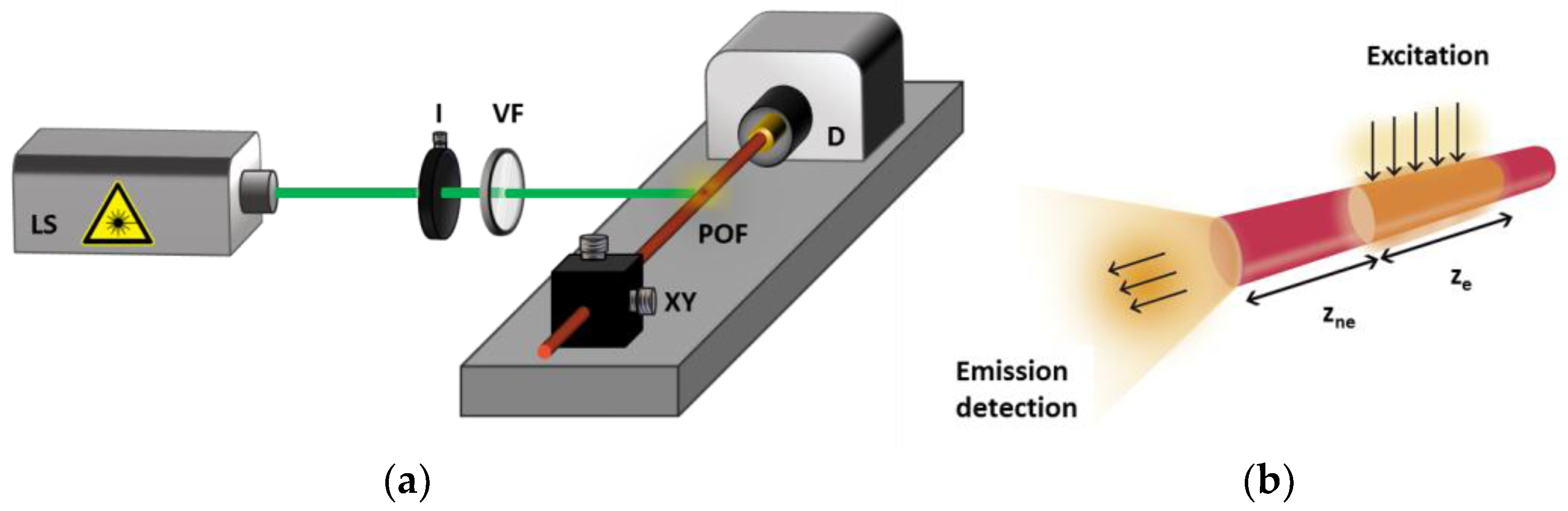

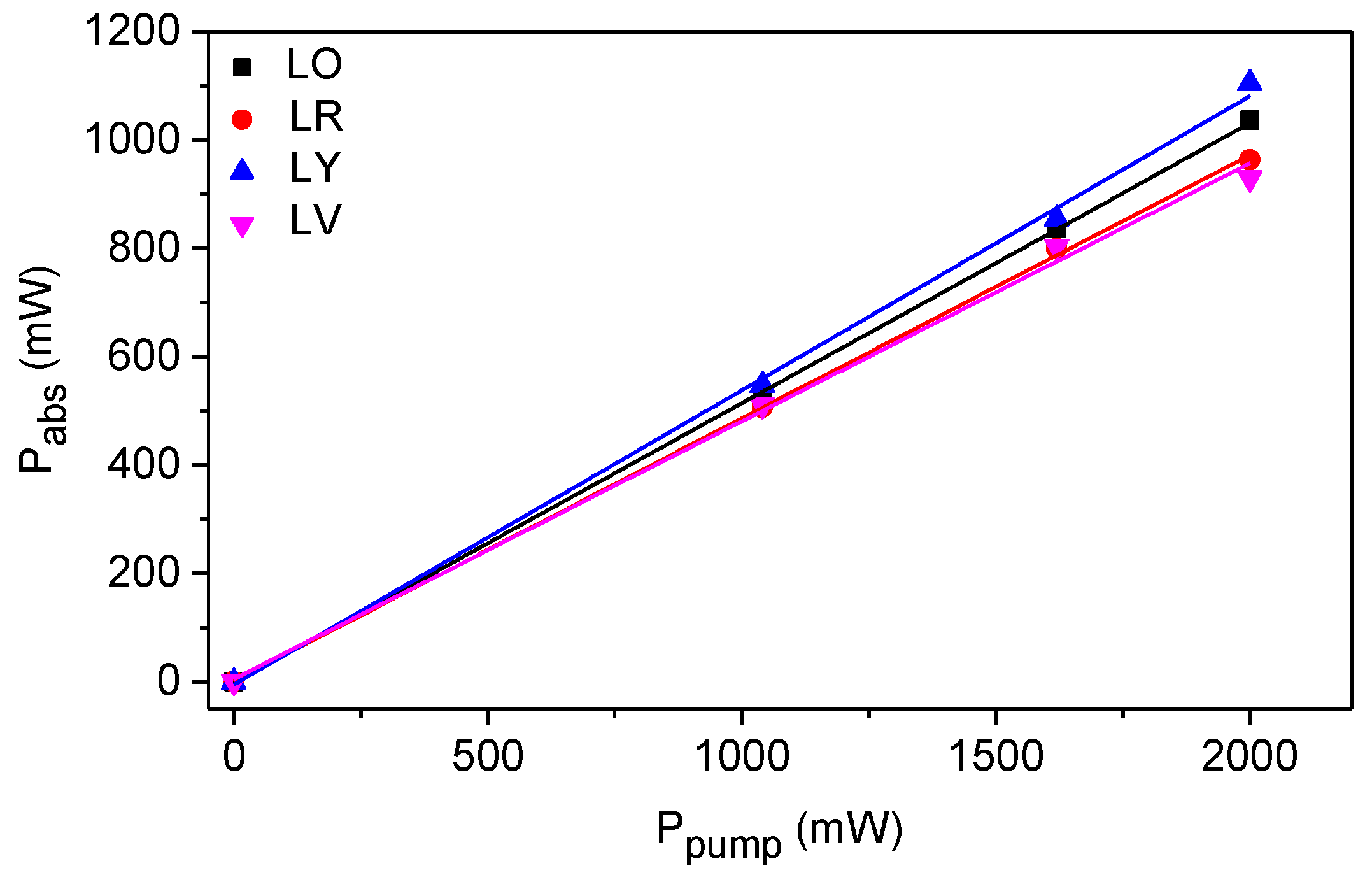

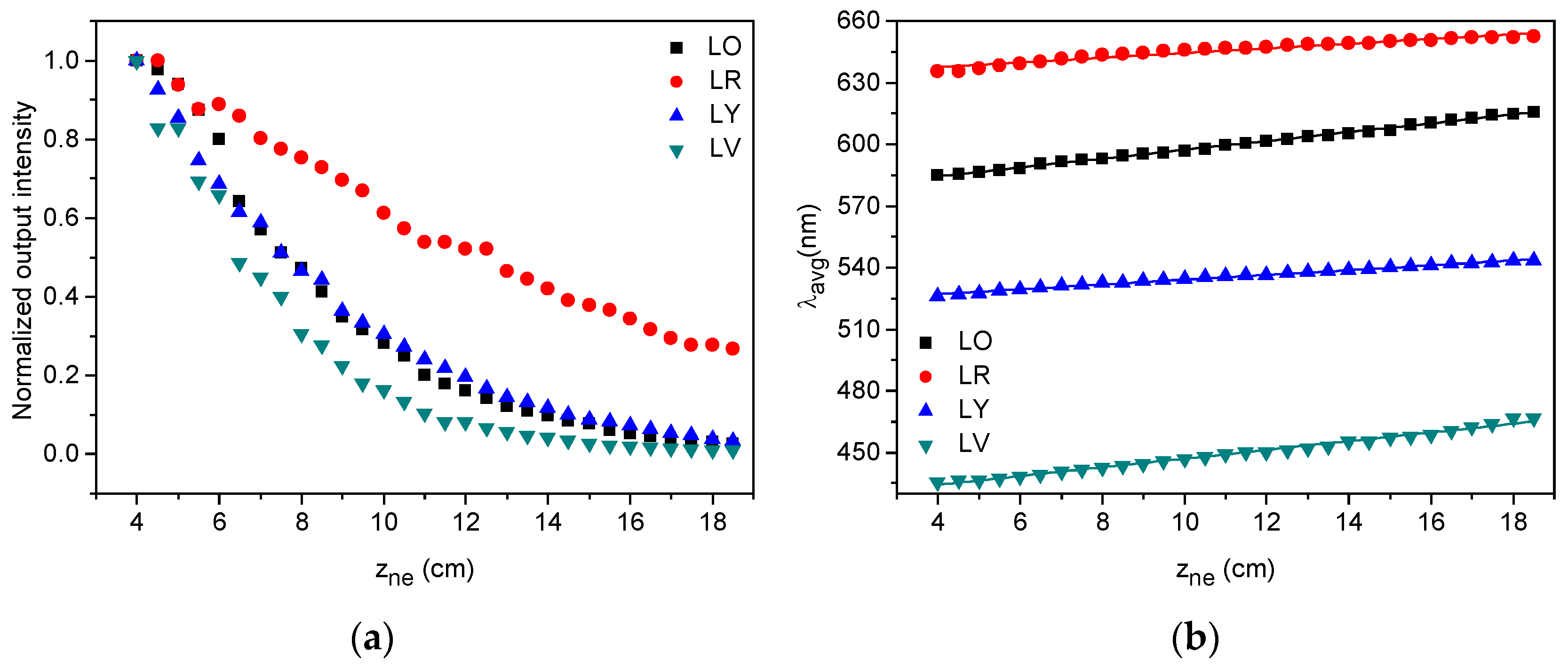

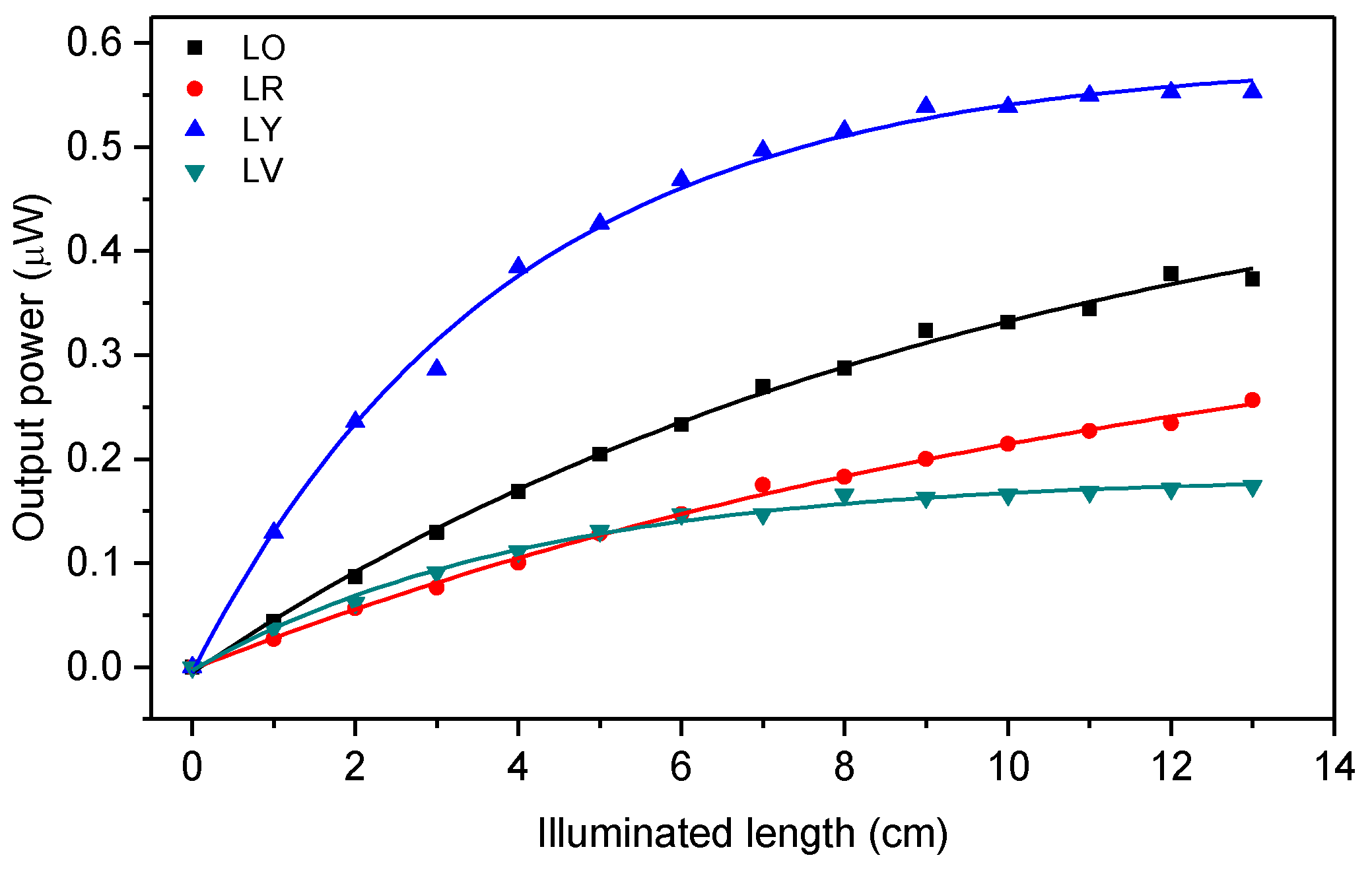

3.2. Side Illumination Coupling Efficiency

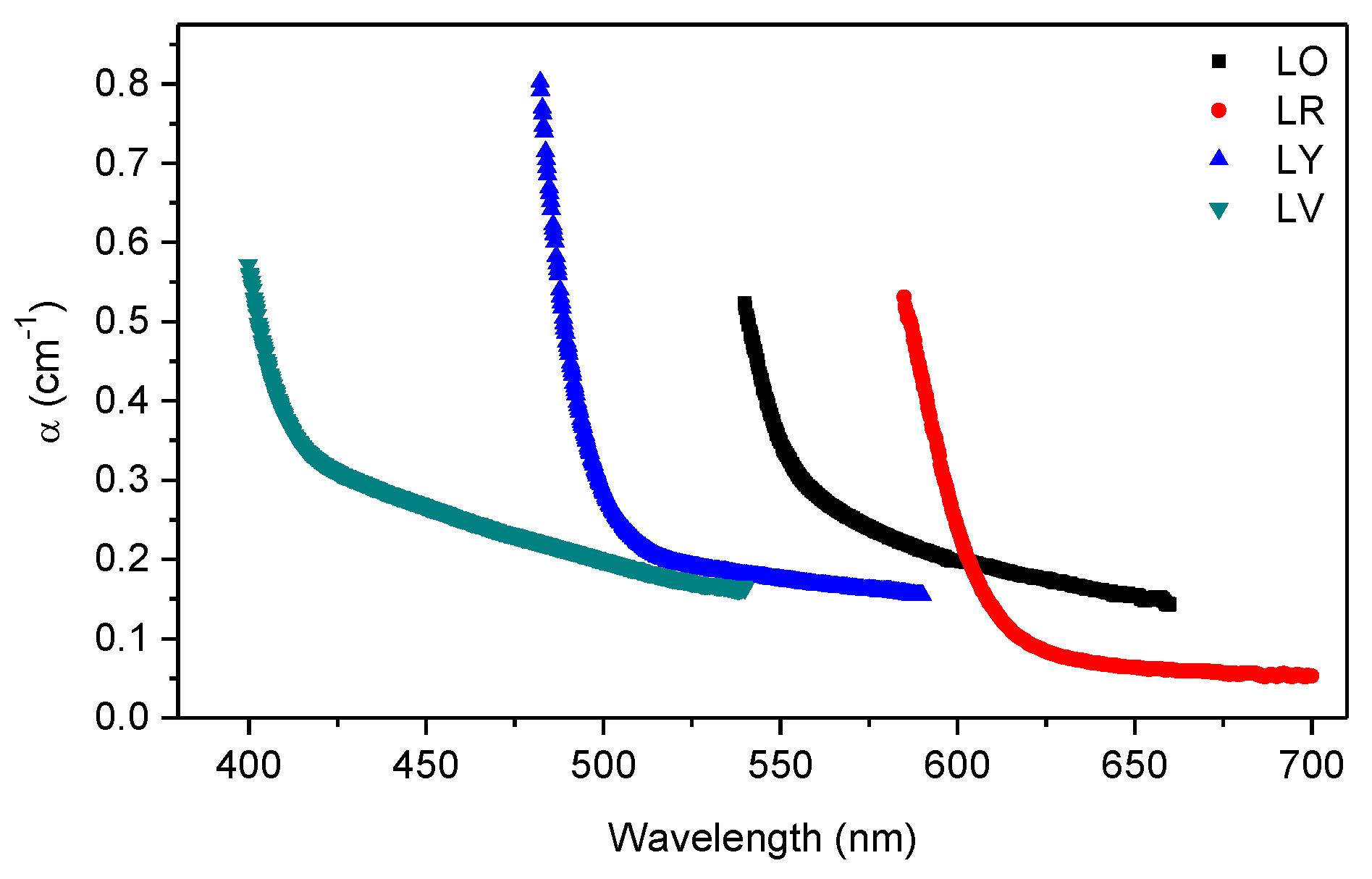

3.3. Optical Losses

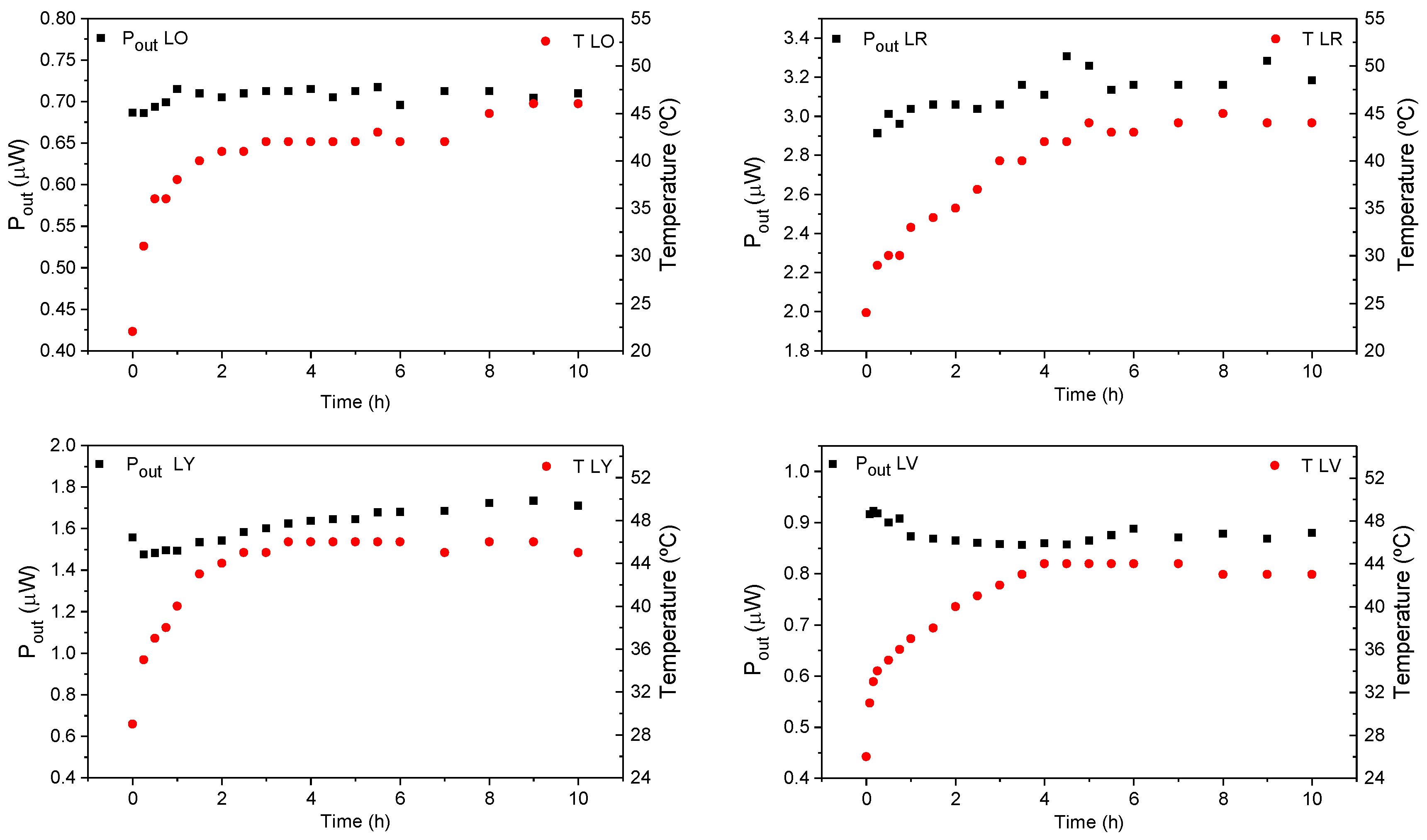

3.4. Analysis under Solar Simulator

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Koike, Y.; Ishigure, T.; Nihei, E. High-bandwidth graded-index polymer optical fiber. J. Lightwave Technol. 1995, 13, 1475–1489. [Google Scholar] [CrossRef]

- Zubia, J.; Garitaonaindía, G.; Arrúe, J. Passive device based on plastic optical fibers to determine the indices of refraction of liquids. Appl. Opt. 2000, 39, 941–946. [Google Scholar] [CrossRef] [PubMed]

- Arrue, J.; Jiménez, F.; Ayesta, I.; Illarramendi, M.A.; Zubia, J. Polymer-optical-fiber lasers and amplifiers doped with organic dyes. Polymers (Basel) 2011, 3, 1162–1180. [Google Scholar] [CrossRef]

- Liang, H.; Zheng, Z.; Li, Z.; Xu, J.; Chen, B.; Zhao, H.; Zhang, Q.; Ming, H. Fabrication and amplification of Rhodamine B-doped step-index polymer optical fiber. J. Appl. Polym. Sci. 2004, 93, 681–685. [Google Scholar] [CrossRef]

- Parola, I.; Illarramendi, M.A.; Arrue, J.; Ayesta, I.; Jiménez, F.; Zubia, J.; Tagaya, A.; Koike, Y. Characterization of the optical gain in doped polymer optical fibres. J. Lumin. 2016, 177, 1–8. [Google Scholar] [CrossRef]

- Kobayashi, T.; Blau, W.J.; Tillmann, H.; Hörhold, H.-H. Blue amplified spontaneous emission from a stilbenoid-compound-doped polymer optical fiber. Opt. Lett. 2001, 26, 1952–1954. [Google Scholar] [CrossRef] [PubMed]

- Kobayashi, T.; Blau, W.J.; Tillmann, H.; Hörhold, H.H. Light amplification and lasing in a stilbenoid compound-doped glass-clad polymer optical fiber. IEEE J. Quantum Electron. 2003, 39, 664–672. [Google Scholar] [CrossRef]

- Camposeo, A.; Di Benedetto, F.; Stabile, R.; Neves, A.A.; Cingolani, R.; Pisignano, D. Laser emission from electrospun polymer nanofibers. Small 2009, 5, 562–566. [Google Scholar] [CrossRef] [PubMed]

- Camposeo, A.; Persano, L.; Pisignano, D. Light-emitting electrospun nanofibers for nanophotonics and optoelectronics. Macromol. Mater. Eng. 2013, 298, 487–503. [Google Scholar] [CrossRef]

- Meng, C.; Xiao, Y.; Wang, P.; Zhang, L.; Liu, Y.; Tong, L. Quantum-dot-doped polymer nanofibers for optical sensing. Adv. Mater. 2011, 23, 3770–3774. [Google Scholar] [CrossRef] [PubMed]

- Yang, Q.; Jiang, X.; Gu, F.; Ma, Z.; Zhang, J.; Tong, L. Polymer micro or nanofibers for optical device applications. J. Appl. Polym. Sci. 2008, 110, 1080–1084. [Google Scholar] [CrossRef]

- Quochi, F.; Cordella, F.; Mura, A.; Bongiovanni, G.; Balzer, F.; Rubahn, H.-G. Gain amplification and lasing properties of individual organic nanofibers. Appl. Phys. Lett. 2006, 88, 041106. [Google Scholar] [CrossRef]

- Song, J.; Chen, M.; Olesen, M.B.; Wang, C.; Havelund, R.; Li, Q.; Xie, E.; Yang, R.; Bøggild, P.; Wang, C.; et al. Direct electrospinning of Ag/polyvinylpyrrolidone nanocables. Nanoscale 2011, 3, 4966–4971. [Google Scholar] [CrossRef] [PubMed]

- Wang, P.; Zhang, L.; Xia, Y.; Tong, L.; Xu, X.; Ying, Y. Polymer Nano fibers Embedded with Aligned Gold Nanorods: A new platform for plasmonic studies and optical sensing. Nano Lett. 2012, 12, 3145–3150. [Google Scholar] [CrossRef] [PubMed]

- Lolla, D.; Lolla, M.; Abutaleb, A.; Shin, H.U.; Reneker, D.H.; Chase, G.G. Fabrication, polarization of electrospun polyvinylidene fluoride electret fibers and effect on capturing nanoscale solid aerosols. Materials (Basel) 2016, 9, 671. [Google Scholar] [CrossRef]

- Huang, X.; Han, S.; Huang, W.; Liu, X. Enhancing solar cell efficiency: The search for luminescent materials as spectral converters. Chem. Soc. Rev. 2013, 42, 173–201. [Google Scholar] [CrossRef] [PubMed]

- Colantuono, G.; Buckley, A.; Erdelyi, R. Ray-optics modelling of rectangular and cylindrical 2-layer solar concentrators. J. Lightwave Technol. 2013, 31, 1033–1044. [Google Scholar] [CrossRef]

- McIntosh, K.R.; Yamada, N.; Richards, B.S. Theoretical comparison of cylindrical and square-planar luminescent solar concentrators. Appl. Phys. B 2007, 88, 285–290. [Google Scholar] [CrossRef]

- Wang, T.; Yu, B.; Chen, B.; Hu, Z.; Luo, Y.; Zou, G.; Zhang, Q. A theoretical model of a cylindrical luminescent solar concentrator with a dye-doping coating. J. Opt. 2013, 15, 055709. [Google Scholar] [CrossRef]

- Chen, J.-Y.; Chiu, Y.-C.; Shih, C.-C.; Wu, W.-C.; Chen, W.-C. Electrospun nanofibers with dual plasmonic-enhanced luminescent solar concentrator effects for high-performance organic photovoltaic cells. J. Mater. Chem. A 2015, 3, 15039–15048. [Google Scholar] [CrossRef]

- Rowan, B.C.; Wilson, L.R.; Richards, B.S. Advanced material concepts for luminescent solar concentrators. IEEE J. Sel. Top. Quantum Electron. 2008, 14, 1312–1322. [Google Scholar] [CrossRef]

- Earp, A.A.; Franklin, J.B.; Smith, G.B. Absorption tails and extinction in luminescent solar concentrators. Sol. Energy Mater. Sol. Cells 2011, 95, 1157–1162. [Google Scholar] [CrossRef]

- Cerdán, L.; Costela, A.; Durán-Sampedro, G.; García-Moreno, I.; Calle, M.; Juan-y-Seva, M.; de Abajo, J.; Turnbull, G.A. New perylene-doped polymeric thin films for efficient and long-lasting lasers. J. Mater. Chem. 2012, 22, 8938–8947. [Google Scholar] [CrossRef]

- Mansour, A.; El-Shaarawy, M.; El-Bashir, S.; El-Mansy, M.; Hammam, M. Optical study of perylene dye doped poly(methyl methacrylate) as fluorescent solar collector. Polym. Int. 2002, 51, 393–397. [Google Scholar] [CrossRef]

- Correia, S.F.H.; Lima, P.P.; André, P.S.; Ferreira, M.R.S.; Carlos, L.A.D. High-efficiency luminescent solar concentrators for flexible waveguiding photovoltaics. Sol. Energy Mater. Sol. Cells 2015, 138, 51–57. [Google Scholar] [CrossRef]

- Wang, C.; Abdul-Rahman, H.; Rao, S.P. Daylighting can be fluorescent: Development of a fiber solar concentrator and test for its indoor illumination. Energy Build. 2010, 42, 717–727. [Google Scholar] [CrossRef]

- Bikandi, I.; Illarramendi, M.A.; Zubia, J.; Arrue, J.; Jiménez, F. Side-illumination fluorescence critical angle: Theory and application to F8BT-doped polymer optical fibers. Opt. Express 2012, 20, 4630–4644. [Google Scholar] [CrossRef] [PubMed]

- Illarramendi, M.A.; Aldabaldetreku, G.; Bikandi, I.; Zubia, J.; Durana, G.; Berganza, A. Scattering in step-index polymer optical fibers by side-illumination technique: Theory and application. JOSA B 2012, 29, 1316–1329. [Google Scholar] [CrossRef]

- Ayesta, I.; Illarramendi, M.A.; Arrue, J.; Parola, I.; Jiménez, F.; Zubia, J.; Tagaya, A.; Koike, Y. Optical characterization of doped thermoplastic and thermosetting polymer-Optical-Fibers. Polymers (Basel) 2017, 9, 90. [Google Scholar] [CrossRef]

- Parola, I.; Illarramendi, M.A.; Zubia, J.; Arrospide, E.; Durana, G.; Guarrotxena, N.; García, O.; Evert, R.; Zaremba, D.; Johannes, H.-H.; et al. Polymer optical fibers doped with organic materials as luminescent solar concentrators. Proc. SPIE 2017, 10101, 101010Z. [Google Scholar] [CrossRef]

- Illarramendi, M.A.; Zubia, J.; Bazzana, L.; Durana, G.; Aldabaldetreku, G.; Sarasua, J.R. Spectroscopic characterization of plastic optical fibers doped with fluorene oligomers. J. Lightwave Technol. 2009, 27, 3220–3226. [Google Scholar] [CrossRef]

- Videira, J.J.; Bilotti, E.; Chatten, A.J. Cylindrical and square fibre luminescent solar concentrators: Experimental and simulation comparisons. In Proceedings of the 2014 IEEE 40th Photovoltaic Specialist Conference, Denver, CO, USA, 8–13 June 2014; pp. 2280–2285. [Google Scholar]

- Müller, G.R.J.; Meiners, C.; Enkelmann, V.; Geerts, Y.; Müllen, K. Liquid crystalline perylene-3,4-dicarboximide derivatives with high thermal and photochemical stability. J. Mater. Chem. 1998, 8, 61–64. [Google Scholar] [CrossRef]

| Sample | Tg (°C) | Mn (g/mol) | Mw (g/mol) | PDI |

|---|---|---|---|---|

| PMMA | 93.5 | 44,900 | 77,677 | 1.73 |

| Fiber | α* (cm−1) | R2 | Lsat (cm) |

|---|---|---|---|

| LO | 0.10 | 0.997 | 53 |

| LR | 0.07 | 0.997 | 76 |

| LY | 0.24 | 0.996 | 25 |

| LV | 0.20 | 0.993 | 20 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Parola, I.; Arrospide, E.; Recart, F.; Illarramendi, M.A.; Durana, G.; Guarrotxena, N.; García, O.; Zubia, J. Fabrication and Characterization of Polymer Optical Fibers Doped with Perylene-Derivatives for Fluorescent Lighting Applications. Fibers 2017, 5, 28. https://doi.org/10.3390/fib5030028

Parola I, Arrospide E, Recart F, Illarramendi MA, Durana G, Guarrotxena N, García O, Zubia J. Fabrication and Characterization of Polymer Optical Fibers Doped with Perylene-Derivatives for Fluorescent Lighting Applications. Fibers. 2017; 5(3):28. https://doi.org/10.3390/fib5030028

Chicago/Turabian StyleParola, Itxaso, Eneko Arrospide, Federico Recart, María Asunción Illarramendi, Gaizka Durana, Nekane Guarrotxena, Olga García, and Joseba Zubia. 2017. "Fabrication and Characterization of Polymer Optical Fibers Doped with Perylene-Derivatives for Fluorescent Lighting Applications" Fibers 5, no. 3: 28. https://doi.org/10.3390/fib5030028