Jute Based Bio and Hybrid Composites and Their Applications

Abstract

:1. Introduction

2. Structure, Morphology, and Chemical Composition of Jute

3. Mechanical Properties of Jute Fiber

4. Surface Treatments of Jute Fiber

Physical Modification Methods

5. Fiber Modification Techniques

5.1. Improvement in Jute Fiber and Matrix Adhesion

5.2. Moisture Absorption Properties

5.3. Thermal Degradation and Fire Resistance Properties

6. Processing Methods for Jute-Based Composites

6.1. Hand Lay-Up Technique

6.2. Resin Transfer Molding

6.3. Pultrusion

6.4. Extrusion

7. Hybrid Jute Bio-Composite

7.1. Hybridization with Natural Fibers

7.2. Hybridization with Synthetic Fibers

8. Limitations of Jute Fiber

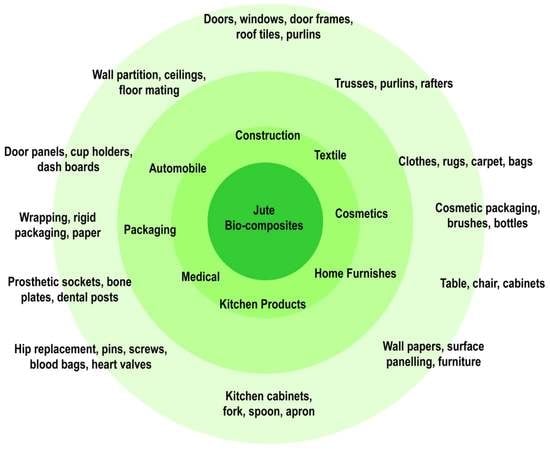

9. Applications

10. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- dos Santos Rosa, D.; Lenz, D.M. Biocomposites: Influence of matrix nature and additives on the properties and biodegradation behaviour. Biodegrad. Eng. Technol. 2013. [Google Scholar] [CrossRef]

- Satyanarayana, K.G.; Arizaga, G.G.; Wypych, F.; Arizaga, G.G.C. Biodegradable composites based on lignocellulosic fibers—An overview. Prog. Polym. Sci. 2009, 34, 982–1021. [Google Scholar] [CrossRef]

- Väisänen, T.; Das, O.; Tomppo, L. A review on new bio-based constituents for natural fiber-polymer composites. J. Clean. Prod. 2017, 149, 582–596. [Google Scholar] [CrossRef]

- John, M.J.; Thomas, S. Biofibres and biocomposites. Carbohydr. Polym. 2008, 71, 343–364. [Google Scholar] [CrossRef]

- Burrola-Núñez, H.; Herrera-Franco, P.J.; Rodríguez-Félix, D.E.; Soto-Valdez, H.; Madera-Santana, T.J. Surface modification and performance of jute fibers as reinforcement on polymer matrix: An overview. J. Nat. Fibers 2018, 1–17. [Google Scholar] [CrossRef]

- Iman, M.; Maji, T.K. Jute: An Interesting Lignocellulosic Fiber for New Generation Applications. Lignocellul. Polym. Compos. 2014, 3, 453–475. [Google Scholar]

- Kozlowski, R.; Wladyka-Przybylak, M. Uses of natural fiber reinforced plastics. In Natural Fibers, Plastics and Composites; Springer: Berlin, Germany, 2004; pp. 249–274. [Google Scholar]

- Satyanarayana, K.G.; Flores-Sahagun, T.H.; Bowman, P. Lignocellulosic Materials of Brazil—Their Characterization and Applications in Polymer Composites and Art Works. In Lignocellulosic Composite Materials; Springer: Berlin, Germany, 2018; pp. 1–96. [Google Scholar]

- Welcome to the World of Jute and Kenaf—IJSG. Available online: http://www.jute.org/plant.htm (accessed on 27 June 2018).

- Mir, R.R.; Rustgi, S.; Sharma, S.; Singh, R.; Goyal, A.; Kumar, J.; Gaur, A.; Tyagi, A.K.; Khan, H.; Sinha, M.K.; et al. A preliminary genetic analysis of fibre traits and the use of new genomic SSRs for genetic diversity in jute. Euphytica 2008, 161, 413–427. [Google Scholar] [CrossRef]

- Li, X.; Tabil, L.G.; Panigrahi, S. Chemical Treatments of Natural Fiber for Use in Natural Fiber-Reinforced Composites: A Review. J. Polym. Environ. 2007, 15, 25–33. [Google Scholar] [CrossRef]

- Pickering, K.; Efendy, M.A.; Le, T. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef] [Green Version]

- Wang, P.; Chen, F.; Zhang, H.; Meng, W.; Sun, Y.; Liu, C. Large-scale preparation of jute-fiber-reinforced starch-based composites with high mechanical strength and optimized biodegradability. Starch Stärke 2017, 69, 1700052. [Google Scholar] [CrossRef]

- Jahan, M.S.; Saeed, A.; He, Z.; Ni, Y. Jute as raw material for the preparation of microcrystalline cellulose. Cellulose 2011, 18, 451–459. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Lopes, F.P.D.; Ferreira, A.S.; Nascimento, D.C.O. Natural-fiber polymer-matrix composites: Cheaper, tougher, and environmentally friendly. JOM 2009, 61, 17–22. [Google Scholar] [CrossRef]

- Suddell, B.C.; Evans, W.J.; Isaac, D.H.; Crosky, A. A survey into the application of natural fiber composites in the automotive industry. In Proceedings of the 4th International Symposium on Natural Polymers and Composites—ISNAPol, São Pedro, SP, Brazil, 10–11 April 2002; pp. 455–461. [Google Scholar]

- Pickering, K.L. Properties and Performance of Natural-Fibre Composites; Elsevier: Amsterdam, The Netherlands, 2008. [Google Scholar]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- PressReader.com—Connecting People Through News. Available online: https://www.pressreader.com/philippines/manila-bulletin/20170619/281938837908620 (accessed on 11 May 2018).

- Top Jute Producing Countries in the World. In: World Atlas. Available online: https://www.worldatlas.com/articles/top-jute-producing-countries-in-the-world.html (accessed on 11 May 2018).

- Chaudhary, V.; Bajpai, P.K.; Maheshwari, S. Studies on Mechanical and Morphological Characterization of Developed Jute/Hemp/Flax Reinforced Hybrid Composites for Structural Applications. J. Nat. Fibers 2018, 15, 80–97. [Google Scholar] [CrossRef]

- Abraham, E.; Deepa, B.; Pothan, L.; Jacob, M.; Thomas, S.; Cvelbar, U.; Anandjiwala, R. Extraction of nanocellulose fibrils from lignocellulosic fibres: A novel approach. Carbohydr. Polym. 2011, 86, 1468–1475. [Google Scholar] [CrossRef]

- Vilay, V.; Mariatti, M.; Taib, R.M.; Todo, M. Effect of fiber surface treatment and fiber loading on the properties of bagasse fiber–reinforced unsaturated polyester composites. Compos. Sci. Technol. 2008, 68, 631–638. [Google Scholar] [CrossRef]

- Roe, P.J.; Ansell, M.P. Jute-reinforced polyester composites. J. Mater. Sci. 1985, 20, 4015–4020. [Google Scholar] [CrossRef]

- Biagiotti, J.; Puglia, D.; Kenny, J.M. A review on natural fibre-based composites-part I: Structure, processing and properties of vegetable fibres. J. Nat. Fibers 2004, 1, 37–68. [Google Scholar] [CrossRef]

- Jawaid, M.; Khalil, H.A. Cellulosic/synthetic fibre reinforced polymer hybrid composites: A review. Carbohydr. Polym. 2011, 86, 1–18. [Google Scholar] [CrossRef]

- Reddy, N.; Yang, Y. Biofibers from agricultural byproducts for industrial applications. Trends Biotechnol. 2005, 23, 22–27. [Google Scholar] [CrossRef] [Green Version]

- Guillén, F.; Martínez, M.J.; Gutiérrez, A.; Del Rio, J.C. Biodegradation of lignocellu-losics: Microbial, chemical, and enzymatic aspects of the fungal attack of lignin. Int. Microbiol. 2005, 8, 195–204. [Google Scholar]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Progress report on natural fiber reinforced composites. Macromol. Mater. Eng. 2014, 299, 9–26. [Google Scholar] [CrossRef]

- Khalil, H.A.; Davoudpour, Y.; Islam, M.N.; Mustapha, A.; Sudesh, K.; Dungani, R.; Jawaid, M. Production and modification of nanofibrillated cellulose using various mechanical processes: A review. Carbohydr. Polym. 2014, 99, 649–665. [Google Scholar] [CrossRef] [PubMed]

- Kalia, S.; Dufresne, A.; Cherian, B.M.; Kaith, B.S.; Avérous, L.; Njuguna, J.; Nassiopoulos, E. Cellulose-Based Bio- and Nanocomposites: A Review. Int. J. Polym. Sci. 2011. [Google Scholar] [CrossRef]

- Khalil, H.A.; Bhat, A.; Yusra, A.I. Green composites from sustainable cellulose nanofibrils: A review. Carbohydr. Polym. 2012, 87, 963–979. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Hinrichsen, G. Biofibers, biodegradable polymers and biocomposites: An overview. Macromol. Mater. Eng. 2000, 276, 1–24. [Google Scholar] [CrossRef]

- Akil, H.M.; Cheng, L.W.; Ishak, Z.M.; Abu Bakar, A.; Rahman, M.A. Water absorption study on pultruded jute fibre reinforced unsaturated polyester composites. Compos. Sci. Technol. 2009, 69, 1942–1948. [Google Scholar] [CrossRef]

- Klemm, D.; Philipp, B.; Heinze, T.; Heinze, U.; Wagenknecht, W. General considerations on structure and reactivity of cellulose: Section 2.1–2.1. Wiley Online Library 2004, 4. [Google Scholar] [CrossRef]

- Gopinath, A.; Kumar, M.S.; Elayaperumal, A. Experimental Investigations on Mechanical Properties of Jute Fiber Reinforced Composites with Polyester and Epoxy Resin Matrices. Procedia Eng. 2014, 97, 2052–2063. [Google Scholar] [CrossRef]

- Célino, A.; Freour, S.; Jacquemin, F.; Casari, P. The hygroscopic behavior of plant fibers: A review. Front. Chem. 2014, 1. [Google Scholar] [CrossRef]

- Fratzl, P. Cellulose and collagen: From fibres to tissues. Curr. Opin. Colloid Interface Sci. 2003, 8, 32–39. [Google Scholar] [CrossRef]

- Roy, S.; Lutfar, L.B. 3—Bast fibres: Jute. In Handbook of Natural Fibres; Kozłowski, R.M., Ed.; Woodhead Publishing: Sawston, UK, 2012; pp. 24–46. [Google Scholar]

- Jayamani, E.; Hamdan, S.; Rahman, M.R.; Bin Bakri, M.K. Comparative Study of Dielectric Properties of Hybrid Natural Fiber Composites. Procedia Eng. 2014, 97, 536–544. [Google Scholar] [CrossRef] [Green Version]

- Yan, L.; Kasal, B.; Huang, L. A review of recent research on the use of cellulosic fibres, their fibre fabric reinforced cementitious, geo-polymer and polymer composites in civil engineering. Compos. Part B Eng. 2016, 92, 94–132. [Google Scholar] [CrossRef]

- Hansen, C.M.; Björkman, A. The Ultrastructure of Wood from a Solubility Parameter Point of View. Holzforsch Int. J. Biol. Chem. Phys. Technol. Wood 2009, 52, 335–344. [Google Scholar] [CrossRef]

- Rowell, R.M.; Han, J.S.; Rowell, J.S. Characterization and factors effecting fiber properties. Nat. Polym. Agrofibers Based Compos. 2000, 2000, 115–134. [Google Scholar]

- Norgren, M.; Edlund, H. Lignin: Recent advances and emerging applications. Curr. Opin. Colloid Interface Sci. 2014, 19, 409–416. [Google Scholar] [CrossRef]

- Kumar, M.N.S.; Mohanty, A.K.; Erickson, L.; Misra, M. Lignin and Its Applications with Polymers. J. Biobased Mater. Bioenergy 2009, 3, 1–24. [Google Scholar] [CrossRef]

- Gurunathan, T.; Mohanty, S.; Nayak, S.K. A review of the recent developments in biocomposites based on natural fibres and their application perspectives. Compos. Part A Appl. Sci. Manuf. 2015, 77, 1–25. [Google Scholar] [CrossRef]

- Mishra, V.; Biswas, S. Physical and Mechanical Properties of Bi-directional Jute Fiber Epoxy Composites. Procedia Eng. 2013, 51, 561–566. [Google Scholar] [CrossRef] [Green Version]

- Thwe, M.M.; Liao, K. Durability of bamboo-glass fiber reinforced polymer matrix hybrid composites. Compos. Sci. Technol. 2003, 63, 375–387. [Google Scholar] [CrossRef]

- Fu, S.-Y.; Xu, G.; Mai, Y.-W. On the elastic modulus of hybrid particle/short-fiber/polymer composites. Compos. Part B Eng. 2002, 33, 291–299. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Sarasini, F.; Tirilló, J.; Calabrese, L. Salt-fog spray aging of jute-basalt reinforced hybrid structures: Flexural and low velocity impact response. Compos. Part B Eng. 2017, 116, 99–112. [Google Scholar] [CrossRef]

- Ho, M.-P.; Wang, H.; Lee, J.-H.; Ho, C.-K.; Lau, K.-T.; Leng, J.; Hui, D. Critical factors on manufacturing processes of natural fibre composites. Compos. Part B Eng. 2012, 43, 3549–3562. [Google Scholar] [CrossRef]

- Chollakup, R.; Tantatherdtam, R.; Ujjin, S.; Sriroth, K. Pineapple leaf fiber reinforced thermoplastic composites: Effects of fiber length and fiber content on their characteristics. J. Appl. Polym. Sci. 2011, 119, 1952–1960. [Google Scholar] [CrossRef]

- Lodha, P.; Netravali, A.N. Characterization of interfacial and mechanical properties of “green” composites with soy protein isolate and ramie fiber. J. Mater. Sci. 2002, 37, 3657–3665. [Google Scholar] [CrossRef]

- Mishra, H.K.; Dash, B.N.; Tripathy, S.S.; Padhi, B.N. A study on mechanical performance of jute-epoxy composites. Polym. Technol. Eng. 2000, 39, 187–198. [Google Scholar] [CrossRef]

- Abdullah-Al-Kafi; Abedin, M.Z.; Beg, M.D.H.; Pickering, K.L.; Khan, M.A. Study on the mechanical properties of jute/glass fiber-reinforced unsaturated polyester hybrid composites: Effect of surface modification by ultraviolet radiation. J. Reinf. Plast. Compos. 2006, 25, 575–588. [Google Scholar] [CrossRef]

- Ahmed, K.S.; Vijayarangan, S. Tensile, flexural and interlaminar shear properties of woven jute and jute-glass fabric reinforced polyester composites. J. Mater. Process. Technol. 2008, 207, 330–335. [Google Scholar] [CrossRef]

- Ahmed, K.S.; Vijayarangan, S.; Rajput, C. Mechanical Behavior of Isothalic Polyester-based Untreated Woven Jute and Glass Fabric Hybrid Composites. J. Reinf. Plast. Compos. 2006, 25, 1549–1569. [Google Scholar] [CrossRef]

- Gibeop, N.; Lee, D.; Prasad, C.; Toru, F.; Kim, B.S.; Song, J.I. Effect of plasma treatment on mechanical properties of jute fiber/poly (lactic acid) biodegradable composites. Adv. Compos. Mater. 2013, 22, 389–399. [Google Scholar] [CrossRef]

- Zamri, M.H.; Akil, H.M.; Bakar, A.A.; Ishak, Z.A.M.; Cheng, L.W. Effect of water absorption on pultruded jute/glass fiber-reinforced unsaturated polyester hybrid composites. J. Compos. Mater. 2012, 46, 51–61. [Google Scholar] [CrossRef]

- Goriparthi, B.K.; Suman, K.; Rao, N.M. Effect of fiber surface treatments on mechanical and abrasive wear performance of polylactide/jute composites. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1800–1808. [Google Scholar] [CrossRef]

- Rezaur Rahman, M.; Hasan, M.; Monimul Huque, M.; Nazrul Islam, M. Physico-mechanical properties of jute fiber reinforced polypropylene composites. J. Reinf. Plast. Compos. 2010, 29, 445–455. [Google Scholar] [CrossRef]

- Boopalan, M.; Umapathy, M.J.; Jenyfer, P. A Comparative Study on the Mechanical Properties of Jute and Sisal Fiber Reinforced Polymer Composites. Silicon 2012, 4, 145–149. [Google Scholar] [CrossRef]

- Joshy, M.K.; Mathew, L.; Joseph, R. Influence of Fiber Surface Modification on the Mechanical Performance of Isora-Polyester Composites. Int. J. Polym. Mater. 2008, 58, 2–20. [Google Scholar] [CrossRef]

- Lilholt, H.; Lawther, J.M. 1.10—Natural Organic Fibers. In Comprehensive Composite Materials; Kelly, A., Zweben, C., Eds.; Pergamon: Oxford, UK, 2000; pp. 303–325. [Google Scholar]

- Rowell, R.M.; Sanadi, A.R.; Caulfield, D.F.; Jacobson, R.E. Utilization of natural fibers in plastic composites: Problems and opportunities. Lignocellul. Plast Compos. 1997, 13, 23–51. [Google Scholar]

- Stokke, D.D.; Wu, Q.; Han, G. Introduction to Wood and Natural Fiber Composites; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Ramesh, M.; Palanikumar, K.; Reddy, K.H. Mechanical property evaluation of sisal–jute–glass fiber reinforced polyester composites. Compos. Part B Eng. 2013, 48, 1–9. [Google Scholar] [CrossRef]

- Ramesh, M.; Palanikumar, K.; Reddy, K.H. Comparative Evaluation on Properties of Hybrid Glass Fiber-Sisal/Jute Reinforced Epoxy Composites. Procedia Eng. 2013, 51, 745–750. [Google Scholar] [CrossRef]

- Kalia, S.; Kaith, B.; Kaur, I. Pretreatments of natural fibers and their application as reinforcing material in polymer composites—A review. Polym. Eng. Sci. 2009, 49, 1253–1272. [Google Scholar] [CrossRef]

- Wambua, P.; Ivens, J.; Verpoest, I. Natural fibres: Can they replace glass in fibre reinforced plastics? Compos. Sci. Technol. 2003, 63, 1259–1264. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Lopes, F.P.D.; Barbosa, A.P.; Bevitori, A.B.; Da Silva, I.L.A.; Da Costa, L.L. Natural Lignocellulosic Fibers as Engineering Materials—An Overview. Met. Mater. Trans. A 2011, 42, 2963–2974. [Google Scholar] [CrossRef]

- Satyanarayana, K.; Guimarães, J.; Wypych, F. Studies on lignocellulosic fibers of Brazil. Part I: Source, production, morphology, properties and applications. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1694–1709. [Google Scholar] [CrossRef]

- Dufresne, A. Cellulose-based composites and nanocomposites. In Monomers, Polymers and Composites from Renewable Resources; Elsevier: Amsterdam, The Netherlands, 2008; pp. 401–418. [Google Scholar]

- Dittenber, D.B.; GangaRao, H.V. Critical review of recent publications on use of natural composites in infrastructure. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1419–1429. [Google Scholar] [CrossRef]

- Dicker, M.P.; Duckworth, P.F.; Baker, A.B.; François, G.; Hazzard, M.K.; Weaver, P.M. Green composites: A review of material attributes and complementary applications. Compos. Part A Appl. Sci. Manuf. 2014, 56, 280–289. [Google Scholar] [CrossRef]

- Rathore, A.; Pradhan, M.; Pradhan, M. Hybrid Cellulose Bionanocomposites from banana and jute fibre: A Review of Preparation, Properties and Applications. Mater. Today Proc. 2017, 4, 3942–3951. [Google Scholar] [CrossRef]

- Cheung, H.-Y.; Ho, M.-P.; Lau, K.-T.; Cardona, F.; Hui, D. Natural fibre-reinforced composites for bioengineering and environmental engineering applications. Compos. Part B Eng. 2009, 40, 655–663. [Google Scholar] [CrossRef]

- Zini, E.; Scandola, M. Green composites: An overview. Polym. Compos. 2011, 32, 1905–1915. [Google Scholar] [CrossRef]

- Tripathi, P.; Gupta, V.K.; Dixit, A.; Mishra, R.K.; Sharma, S. Development and characterization of low cost jute, bagasse and glass fiber reinforced advanced hybrid epoxy composites. AIMS Mater. Sci. 2018, 5, 320–337. [Google Scholar] [CrossRef]

- Jha, K.; Samantaray, B.B.; Tamrakar, P. A Study on Erosion and Mechanical Behavior of Jute/E-Glass Hybrid Composite. Mater. Today Proc. 2018, 5, 5601–5607. [Google Scholar] [CrossRef]

- Anand, P.; Rajesh, D.; Kumar, M.S.; Raj, I.S. Investigations on the performances of treated jute/Kenaf hybrid natural fiber reinforced epoxy composite. J. Polym. Res. 2018, 25, 94. [Google Scholar] [CrossRef]

- Motaleb, K.A. Improvement of Mechanical Properties by Alkali Treatment on Pineapple and Jute Fabric Reinforced Polyester Resin Composites. Int J. Compos. Mater. 2018, 8, 32–37. [Google Scholar]

- Athijayamani, A.; Thiruchitrambalam, M.; Natarajan, U.; Pazhanivel, B. Effect of moisture absorption on the mechanical properties of randomly oriented natural fibers/polyester hybrid composite. Mater. Sci. Eng. A 2009, 517, 344–353. [Google Scholar] [CrossRef]

- Kozlowski, R.; Władyka-Przybylak, M.; Władyka-Przybylak, M. Flammability and fire resistance of composites reinforced by natural fibers. Polym. Adv. Technol. 2008, 19, 446–453. [Google Scholar] [CrossRef]

- Mohanty, A.; Khan, M.A.; Hinrichsen, G. Surface modification of jute and its influence on performance of biodegradable jute-fabric/Biopol composites. Compos. Sci. Technol. 2000, 60, 1115–1124. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Drzal, L.T. Surface modifications of natural fibers and performance of the resulting biocomposites: An overview. Compos. Interfaces 2001, 8, 313–343. [Google Scholar] [CrossRef]

- Braga, R.; Magalhaes, P. Analysis of the mechanical and thermal properties of jute and glass fiber as reinforcement epoxy hybrid composites. Mater. Sci. Eng. C 2015, 56, 269–273. [Google Scholar] [CrossRef] [PubMed]

- Khan, M.A.; Haque, N.; Al-Kafi, A.; Alam, M.N.; Abedin, M.Z. Jute Reinforced Polymer Composite by Gamma Radiation: Effect of Surface Treatment with UV Radiation. Polym. Technol. Eng. 2006, 45, 607–613. [Google Scholar] [CrossRef]

- Khan, R.A.; Khan, M.A.; Khan, A.H.; Hossain, M.A. Effect of gamma radiation on the performance of jute fabrics-reinforced polypropylene composites. Radiat. Phys. Chem. 2009, 78, 986–993. [Google Scholar]

- Islam, T.; Khan, R.A.; Khan, M.A.; Rahman, M.A.; Fernandez-Lahore, M.; Huque, Q.M.I.; Islam, R.; Lahore, H.M.F. Physico-Mechanical and Degradation Properties of Gamma-Irradiated Biocomposites of Jute Fabric-Reinforced Poly(caprolactone). Polym. Technol. Eng. 2009, 48, 1198–1205. [Google Scholar] [CrossRef]

- Hassan, M.M.; Islam, M.R.; Shehrzade, S.; Khan, M.A. Influence of Mercerization Along with Ultraviolet (UV) and Gamma Radiation on Physical and Mechanical Properties of Jute Yarn by Grafting with 3-(Trimethoxysilyl) Propylmethacrylate (Silane) and Acrylamide Under UV Radiation. Polym. Technol. Eng. 2003, 42, 515–531. [Google Scholar] [CrossRef]

- Seki, Y.; Sarikanat, M.; Sever, K.; Erden, S.; Gulec, H.A. Effect of the low and radio frequency oxygen plasma treatment of jute fiber on mechanical properties of jute fiber/polyester composite. Fibers Polym. 2010, 11, 1159–1164. [Google Scholar] [CrossRef]

- Yuan, X.; Jayaraman, K.; Bhattacharyya, D. Effects of plasma treatment in enhancing the performance of woodfibre-polypropylene composites. Compos. Part A Appl. Sci. Manuf. 2004, 35, 1363–1374. [Google Scholar] [CrossRef]

- Pang, Y.; Cho, D.; Han, S.O.; Park, W.H. Interfacial shear strength and thermal properties of electron beam-treated henequen fibers reinforced unsaturated polyester composites. Macromol. Res. 2005, 13, 453–459. [Google Scholar] [CrossRef]

- Ji, S.G.; Hwang, J.H.; Cho, D.; Kim, H.-J. Influence of electron beam treatment of jute on the thermal properties of random and two-directional jute/poly(lactic acid) green composites. J. Adhes. Sci. Technol. 2013, 27, 1359–1373. [Google Scholar] [CrossRef]

- Signori, F.; Pelagaggi, M.; Bronco, S.; Righetti, M.C. Amorphous/crystal and polymer/filler interphases in biocomposites from poly(butylene succinate). Thermochim. Acta 2012, 543, 74–81. [Google Scholar] [CrossRef]

- John, M.J.; Anandjiwala, R.D. Recent developments in chemical modification and characterization of natural fiber-reinforced composites. Polym. Compos. 2008, 29, 187–207. [Google Scholar] [CrossRef]

- Fiore, V.; Di Bella, G.; Valenza, A. The effect of alkaline treatment on mechanical properties of kenaf fibers and their epoxy composites. Compos. Part B Eng. 2015, 68, 14–21. [Google Scholar] [CrossRef]

- Pukánszky, B. Influence of interface interaction on the ultimate tensile properties of polymer composites. Composites 1990, 21, 255–262. [Google Scholar] [CrossRef]

- Liu, X. Surface modification and micromechanical properties of jute fiber mat reinforced polypropylene composites. Express Polym. Lett. 2007, 1, 299–307. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Drzal, L.T.; Misra, M. Novel hybrid coupling agent as an adhesion promoter in natural fiber reinforced powder polypropylene composites. J. Mater. Sci. Lett. 2002, 21, 1885–1888. [Google Scholar] [CrossRef]

- Mwaikambo, L.Y.; Ansell, M.P. Chemical modification of hemp, sisal, jute, and kapok fibers by alkalization. J. Appl. Polym. Sci. 2002, 84, 2222–2234. [Google Scholar] [CrossRef]

- Corrales, F.; Vilaseca, F.; Llop, M.F.; Gironès, J.; Méndez, J.A.; Mutjé, P. Chemical modification of jute fibers for the production of green-composites. J. Hazard. Mater. 2007, 144, 730–735. [Google Scholar] [CrossRef]

- Basak, R.; Choudhury, P.; Pandey, K.M. Impacts of Temperature Disparity on Surface Modification of Short Jute Fiber-Reinforced Epoxy Composites. IOP Conf. Ser. Mater. Sci. Eng. 2017, 225, 12114. [Google Scholar] [CrossRef] [Green Version]

- Thakur, M.K.; Gupta, R.K.; Thakur, V.K. Surface modification of cellulose using silane coupling agent. Carbohydr. Polym. 2014, 111, 849–855. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gassan, J.; Bledzki, A.K. Effect of cyclic moisture absorption desorption on the mechanical properties of silanized jute-epoxy composites. Polym. Compos. 1999, 20, 604–611. [Google Scholar] [CrossRef]

- Battegazzore, D.; Frache, A.; Carosio, F. Sustainable and High Performing Biocomposites with Chitosan/Sepiolite Layer-by-Layer Nanoengineered Interphases. ACS Sustain. Chem. Eng. 2018, 6, 9601–9605. [Google Scholar] [CrossRef]

- Vlaev, L.; Turmanova, S.; Dimitrova, A. Kinetics and thermodynamics of water adsorption onto rice husks ash filled polypropene composites during soaking. J. Polym. Res. 2009, 16, 151–164. [Google Scholar] [CrossRef]

- Benard, P.; Kroener, E.; Vontobel, P.; Kaestner, A.; Carminati, A. Water percolation through the root-soil interface. Adv. Water Resour. 2016, 95, 190–198. [Google Scholar] [CrossRef]

- Wang, Y.; Wei, Q.; Wang, S.; Chai, W.; Zhang, Y. Structural and water diffusion of poly(acryl amide)/poly(vinyl alcohol) blend films: Experiment and molecular dynamics simulations. J. Mol. Graph. Model. 2017, 71, 40–49. [Google Scholar] [CrossRef]

- Claus, H. Laccases: Structure, reactions, distribution. Micron 2004, 35, 93–96. [Google Scholar] [CrossRef]

- Liu, R.; Dong, A.; Fan, X.; Yu, Y.; Yuan, J.; Wang, P.; Wang, Q.; Cavaco-Paulo, A. Enzymatic Hydrophobic Modification of Jute Fibers via Grafting to Reinforce Composites. Appl. Biochem. Biotechnol. 2016, 178, 1612–1629. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Riva, S. Laccases: Blue enzymes for green chemistry. Trends Biotechnol. 2006, 24, 219–226. [Google Scholar] [CrossRef] [PubMed]

- Dong, A.; Yu, Y.; Yuan, J.; Wang, Q.; Fan, X. Hydrophobic modification of jute fiber used for composite reinforcement via laccase-mediated grafting. Appl. Surf. Sci. 2014, 301, 418–427. [Google Scholar] [CrossRef]

- Hu, R.-H.; Sun, M.-Y.; Lim, J.-K. Moisture absorption, tensile strength and microstructure evolution of short jute fiber/polylactide composite in hygrothermal environment. Mater. Des. 2010, 31, 3167–3173. [Google Scholar] [CrossRef]

- Hong, C.K.; Kim, N.; Kang, S.L.; Nah, C.; Lee, Y.-S.; Cho, B.-H.; Ahn, J.-H. Mechanical properties of maleic anhydride treated jute fibre/polypropylene composites. Plast. Rubber Compos. 2008, 37, 325–330. [Google Scholar] [CrossRef]

- Mouritz, A.P.; Gibson, A.G. Fire Properties of Polymer Composite Materials; Springer Science & Business Media: Berlin, Germany, 2007. [Google Scholar]

- Dasari, A.; Yu, Z.-Z.; Cai, G.-P.; Mai, Y.-W. Recent developments in the fire retardancy of polymeric materials. Prog. Polym. Sci. 2013, 38, 1357–1387. [Google Scholar] [CrossRef]

- Chapple, S.; Anandjiwala, R. Flammability of Natural Fiber-reinforced Composites and Strategies for Fire Retardancy: A Review. J. Thermoplast. Compos. Mater. 2010, 23, 871–893. [Google Scholar] [CrossRef]

- Wang, W.; Sain, M.; Cooper, P. Hygrothermal weathering of rice hull/HDPE composites under extreme climatic conditions. Polym. Degrad. Stab. 2005, 90, 540–545. [Google Scholar] [CrossRef]

- A Review: Natural Fiber Composites Selection in View of Mechanical, Light Weight, and Economic Properties Ahmad 2014 Macromolecular Materials and Engineering—Wiley Online Library. Available online: http://onlinelibrary.wiley.com/doi/10.1002/mame.201400089/full (accessed on 7 December 2017).

- Hollaway, L. A review of the present and future utilisation of FRP composites in the civil infrastructure with reference to their important in-service properties. Constr. Build. Mater. 2010, 24, 2419–2445. [Google Scholar] [CrossRef]

- Stark, N.M.; White, R.H.; Mueller, S.A.; Osswald, T.A. Evaluation of various fire-retardants for use in wood flour–polyethylene composites. Polym. Degrad. Stab. 2010, 95, 1903–1910. [Google Scholar] [CrossRef]

- Ngo, T.D.; Ton-That, M.T.; Hu, W. Innovative and Sustainable Approaches to Enhance Fire Resistance of Cellulosic Fibers for Green Polymer Composites. SAMPE J. 2013, 49, 31–37. [Google Scholar]

- Manfredi, L.B.; Rodriguez, E.; Wladyka-Przybylak, M.; Vazquez, A. Thermal Properties and Fire Resistance of Jute-Reinforced Composites. Compos. Interfaces 2010, 17, 663–675. [Google Scholar] [CrossRef]

- Horrocks, A.R.; Kandola, B.K.; Kandola, B. Flammability and fire resistance of composites. In Design and Manufacture of Textile Composites; Elsevier: Amsterdam, The Netherlands, 2005; pp. 330–363. [Google Scholar]

- Sinha, E.; Rout, S.K. Influence of fibre-surface treatment on structural, thermal and mechanical properties of jute fibre and its composite. Bull. Mater. Sci. 2009, 32, 65–76. [Google Scholar] [CrossRef]

- Nam, T.H.; Ogihara, S.; Nakatani, H.; Kobayashi, S.; Song, J.I. Mechanical and thermal properties and water absorption of jute fiber reinforced poly(butylene succinate) biodegradable composites. Adv. Compos. Mater. 2012, 21, 241–258. [Google Scholar] [CrossRef]

- Suppakarn, N.; Jarukumjorn, K. Mechanical properties and flammability of sisal/PP composites: Effect of flame retardant type and content. Compos. Part B Eng. 2009, 40, 613–618. [Google Scholar] [CrossRef]

- Sain, M.; Park, S.; Suhara, F.; Law, S. Flame retardant and mechanical properties of natural fibre–PP composites containing magnesium hydroxide. Polym. Degrad. Stab. 2004, 83, 363–367. [Google Scholar] [CrossRef]

- Morgan, A.B.; Gilman, J.W. An overview of flame retardancy of polymeric materials: Application, technology, and future directions. Fire Mater. 2013, 37, 259–279. [Google Scholar] [CrossRef]

- Fatima, S.; Mohanty, A.; Mohanty, A. Acoustical and fire-retardant properties of jute composite materials. Appl. Acoust. 2011, 72, 108–114. [Google Scholar] [CrossRef]

- Battegazzore, D.; Alongi, J.; Duraccio, D.; Frache, A. Reuse and Valorisation of Hemp Fibres and Rice Husk Particles for Fire Resistant Fibreboards and Particleboards. J. Polym. Environ. 2018, 26, 3731–3744. [Google Scholar] [CrossRef]

- Matkó, S.; Toldy, A.; Keszei, S.; Anna, P.; Bertalan, G.; Marosi, G. Flame retardancy of biodegradable polymers and biocomposites. Polym. Degrad. Stab. 2005, 88, 138–145. [Google Scholar] [CrossRef]

- Hapuarachchi, T.D.; Ren, G.; Fan, M.; Hogg, P.J.; Peijs, T. Fire Retardancy of Natural Fibre Reinforced Sheet Moulding Compound. Appl. Compos. Mater. 2007, 14, 251–264. [Google Scholar] [CrossRef]

- Schartel, B.; Hull, T.R.; Hull, R. Development of fire-retarded materials—Interpretation of cone calorimeter data. Fire Mater. 2007, 31, 327–354. [Google Scholar] [CrossRef]

- Bajpai, P.K.; Ahmad, F.; Chaudhary, V.; Martínez, L.M.T.; Kharissova, O.V.; Kharisov, B.I. Processing and Characterization of Bio-Composites; Springer: Berlin, Germany, 2017; pp. 1–18. [Google Scholar]

- Biocomposites Reinforced with Natural Fibers: 2000–2010—ScienceDirect. Available online: http://www.sciencedirect.com/science/article/pii/S0079670012000391 (accessed on 18 December 2017).

- Le Duc, A.; Vergnes, B.; Budtova, T. Polypropylene/natural fibres composites: Analysis of fibre dimensions after compounding and observations of fibre rupture by rheo-optics. Compos. Part Appl. Sci. Manuf. 2011, 42, 1727–1737. [Google Scholar] [CrossRef]

- Bledzki, A.; Jaszkiewicz, A.; Murr, M.; Sperber, V.; Lützendgrf, R.; Reußmann, T.; Lützendorf, R. Processing techniques for natural- and wood-fibre composites. In Properties and Performance of Natural-Fibre Composites; Elsevier: Amsterdam, The Netherlands, 2008; pp. 163–192. [Google Scholar]

- Bledzki, A.K.; Specht, K.; Cescutti, G.; Müssig, M. Comparison of different compounding processes by an analysis of fibres degradation. In Proceedings of the 3rd International Conference on Eco-Composites, Stockholm, Sweden, 20–21 June 2005; p. 3. [Google Scholar]

- Chaitanya, S.; Singh, I. Processing of PLA/sisal fiber biocomposites using direct-and extrusion-injection molding. Mater. Manuf. Process. 2017, 32, 468–474. [Google Scholar] [CrossRef]

- Huda, M.; Drzal, L.; Ray, D.; Mohanty, A.; Mishra, M. Natural-fiber composites in the automotive sector. In Properties and Performance of Natural-Fibre Composites; Elsevier: Amsterdam, The Netherlands, 2008; pp. 221–268. [Google Scholar]

- Azaman, M.; Sapuan, S.; Sulaiman, S.; Zainudin, E.; Abdan, K.; Sapuan, M.S. An investigation of the processability of natural fibre reinforced polymer composites on shallow and flat thin-walled parts by injection moulding process. Mater. Des. 2013, 50, 451–456. [Google Scholar] [CrossRef]

- Leong, Y.; Thitithanasarn, S.; Yamada, K.; Hamada, H. Compression and injection molding techniques for natural fiber composites. In Natural Fibre Composites; Elsevier: Amsterdam, The Netherlands, 2014; pp. 216–232. [Google Scholar]

- Thakur, V.K.; Thakur, M.K. Processing and characterization of natural cellulose fibers/thermoset polymer composites. Carbohydr. Polym. 2014, 109, 102–117. [Google Scholar] [CrossRef]

- Stringer, L. Optimization of the wet lay-up/vacuum bag process for the fabrication of carbon fibre epoxy composites with high fibre fraction and low void content. Composites 1989, 20, 441–452. [Google Scholar] [CrossRef]

- Yuhazri, M.; Sihombing, H. A comparison process between vacuum infusion and hand lay-up method toward kenaf/polyester composite. Int. J. Basic Appl. Sci. 2010, 10, 63–66. [Google Scholar]

- Rouison, D.; Sain, M.; Couturier, M. Resin transfer molding of natural fiber reinforced composites: Cure simulation. Compos. Sci. Technol. 2004, 64, 629–644. [Google Scholar] [CrossRef]

- Kang, M.K.; Lee, W.I.; Hahn, H. Formation of microvoids during resin-transfer molding process. Compos. Sci. Technol. 2000, 60, 2427–2434. [Google Scholar] [CrossRef]

- Peng, X.; Fan, M.; Hartley, J.; Al-Zubaidy, M. Properties of natural fiber composites made by pultrusion process. J. Compos. Mater. 2012, 46, 237–246. [Google Scholar] [CrossRef]

- Akil, H.M.; Santulli, C.; Sarasini, F.; Tirillò, J.; Valente, T. Environmental effects on the mechanical behaviour of pultruded jute/glass fibre-reinforced polyester hybrid composites. Compos. Sci. Technol. 2014, 94, 62–70. [Google Scholar] [CrossRef]

- Almeida, J.H.S., Jr.; Amico, S.C.; Botelho, E.C.; Amado, F.D.R. Hybridization effect on the mechanical properties of curaua/glass fiber composites. Compos. Part B Eng. 2013, 55, 492–497. [Google Scholar] [CrossRef]

- Nunna, S.; Chandra, P.R.; Shrivastava, S.; Jalan, A. A review on mechanical behavior of natural fiber based hybrid composites. J. Reinf. Plast. Compos. 2012, 31, 759–769. [Google Scholar] [CrossRef]

- Boopalan, M.; Niranjanaa, M.; Umapathy, M. Study on the mechanical properties and thermal properties of jute and banana fiber reinforced epoxy hybrid composites. Compos. Part B Eng. 2013, 51, 54–57. [Google Scholar] [CrossRef]

- Fiore, V.; Calabrese, L. Effect of Stacking Sequence and Sodium Bicarbonate Treatment on Quasi-Static and Dynamic Mechanical Properties of Flax/Jute Epoxy-Based Composites. Materials 2019, 12, 1363. [Google Scholar] [CrossRef]

- Jawaid, M.; Khalil, H.A.; Abu Bakar, A.; Khanam, P.N. Chemical resistance, void content and tensile properties of oil palm/jute fibre reinforced polymer hybrid composites. Mater. Des. 2011, 32, 1014–1019. [Google Scholar] [CrossRef]

- Jawaid, M.; Khalil, H.A.; Abu Bakar, A. Mechanical performance of oil palm empty fruit bunches/jute fibres reinforced epoxy hybrid composites. Mater. Sci. Eng. A 2010, 527, 7944–7949. [Google Scholar] [CrossRef]

- Shanmugam, D.; Thiruchitrambalam, M. Static and dynamic mechanical properties of alkali treated unidirectional continuous Palmyra Palm Leaf Stalk Fiber/jute fiber reinforced hybrid polyester composites. Mater. Des. 2013, 50, 533–542. [Google Scholar] [CrossRef]

- Scalici, T.; Badagliacco, D.; Enea, D.; Alaimo, G.; Valenza, A.; Fiore, V. Aging resistance of bio-epoxy jute-basalt hybrid composites as novel multilayer structures for cladding. Compos. Struct. 2017, 160, 1319–1328. [Google Scholar]

- Shubhra, Q.T.; Alam, A.K.M.M.; Beg, M.D.H.; Khan, M.A.; Gafur, M.A. Mechanical and degradation characteristics of natural silk and synthetic phosphate glass fiber reinforced polypropylene composites. J. Compos. Mater. 2011, 45, 1305–1313. [Google Scholar] [CrossRef]

- Yang, Y.; Ota, T.; Morii, T.; Hamada, H. Mechanical property and hydrothermal aging of injection molded jute/polypropylene composites. J. Mater. Sci. 2011, 46, 2678–2684. [Google Scholar] [CrossRef]

- Velmurugan, R.; Manikandan, V. Mechanical properties of palmyra/glass fiber hybrid composites. Compos. Part A Appl. Sci. Manuf. 2007, 38, 2216–2226. [Google Scholar] [CrossRef]

- Ahmed, K.S.; Vijayarangan, S.; Naidu, A. Elastic properties, notched strength and fracture criterion in untreated woven jute–glass fabric reinforced polyester hybrid composites. Mater. Des. 2007, 28, 2287–2294. [Google Scholar] [CrossRef]

- Aquino, E.M.F.; Sarmento, L.P.S.; Oliveira, W.; Silva, R.V. Moisture Effect on Degradation of Jute/Glass Hybrid Composites. J. Reinf. Plast. Compos. 2007, 26, 219–233. [Google Scholar] [CrossRef]

- Selver, E.; Ucar, N.; Gulmez, T. Effect of stacking sequence on tensile, flexural and thermomechanical properties of hybrid flax/glass and jute/glass thermoset composites. J. Ind. Text. 2018, 48, 494–520. [Google Scholar] [CrossRef]

- Manikandan, N.; Morshed, M.N.; Karthik, R.; Al Azad, S.; Deb, H.; Rumi, T.M.; Ahmed, M.R. Improvement of mechanical properties of natural fiber reinforced jute/polyester epoxy composite through meticulous alkali treatment. Am. J. Curr. Org. Chem. 2017, 3, 9–18. [Google Scholar]

- Ku, H.; Wang, H.; Pattarachaiyakoop, N.; Trada, M. A review on the tensile properties of natural fiber reinforced polymer composites. Compos. Part B Eng. 2011, 42, 856–873. [Google Scholar] [CrossRef] [Green Version]

- Shalwan, A.; Yousif, B.; Yousif, B. In State of Art: Mechanical and tribological behaviour of polymeric composites based on natural fibres. Mater. Des. 2013, 48, 14–24. [Google Scholar] [CrossRef]

- Faruk, O. Cars from Jute and Other Bio-Fibers, 2009. Available online: http://docplayer.net/48269780-Cars-from-jute-and-other-bio-fibers.html. (accessed on 28 December 2018).

- Karus, M.; Kaup, M.; Lohmeyer, D. Study on markets and prices for natural fibres (Germany and EU). In Proceedings of the 3rd International Symposium Bioresource Hemp, Wolfsburg, Germany, 13–16 September 2000. [Google Scholar]

- Netravali, A.N.; Chabba, S. Composites get greener. Mater. Today 2003, 6, 22–29. [Google Scholar] [CrossRef]

| Fiber Source | Fiber Type | Annual Production (103 Tonnes) |

|---|---|---|

| Jute | Bast and Core fiber | 3600 |

| Bamboo | Wood fiber | 30,000 |

| Sugar cane | Wood or Stem fiber | 75,000 |

| Grass | Grass fiber | 700–750 |

| Ramie | Bast fiber | 100–110 |

| Abaca | Leaf fiber | 70–90 |

| Hemp | Bast and Core fiber | 200–220 |

| Sisal | Leaf fiber | 370–380 |

| Coir | Seed fiber | 600–650 |

| Kenaf | Bast and Core fiber | 950–990 |

| Flax | Bast fiber | 830 |

| Mechanical Properties of Jute Fiber | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Density (g/cm3) | Diameter (µm) | Micro-Fibrillar Angle (°) | Moisture Content (%) | Tensile Strength (MPa) | Tensile Modulus (GPa) | Specific Strength (MPa/g·m−3) (S/ρ) | Specific Modulus (GPa/g·m−3) (E/ρ) | Elongation at Break (%) | References |

| 1.3–1.5 | - | - | - | 200–770 | 20–55 | 310–625 | 2–37 | - | [33,63,64,65,66] |

| 1.3–1.45 | - | - | - | 393–780 | 13–30 | - | - | 1.9 | [67,68] |

| 1.3–1.45 | 20–200 | - | - | 393–773 | 13–26.5 | - | - | 7–8 | [69] |

| - | - | - | - | 320–800 | 8–78 | - | - | - | [36,40] |

| 1.3 | - | - | - | 393–773 | 26.5 | - | - | 1.5–1.8 | [70] |

| - | 25–30 | - | - | 400–800 | 10–30 | - | - | 1.5–1.8 | [2] |

| - | 25–30 | 7–9 | - | 393–800 | 13–27 | - | - | 0.7 | [71,72] |

| 1.3–1.5 | - | 8 | - | 393–800 | 13–26.5 | - | - | 1.2–1.8 | [73] |

| 1.3–1.49 | 20–200 | 8 | 15.5–13.7 | 320–800 | 8–78 | - | 30 | 1–1.8 | [74] |

| 1.23 | 5–25 | - | 12 | 187–773 | 20–55 | 140–320 | 14–39 | 1.5–3.1 | [2,46,75,76] |

| 1.3–1.5 | - | - | 12 | 393–800 | 10–55 | 300–610 | 7.1–39 | 1.5–1.8 | [33,77,78] |

| Jute Composite | Fabrication Method | Key Parameters and Findings | Mechanical Properties | Surface Treatments and Effects on Mechanical Properties | References |

|---|---|---|---|---|---|

| Jute/epoxy | Hand lay-up | Void content decreased and mechanical properties increased with the increase in jute fiber content in composite. | Properties like hardness, impact strength and tensile strength increased with the increase in jute fiber content due to improved fiber/matrix adhesion with better interlocking. Inclusion of fibers increases modulus of composite, increasing overall hardness. | - | [47] |

| Glass/jute fiber reinforced epoxy composite | Hand lay-up | Flexural load separated fibers from matrix upon failure. | Jute–glass fiber composite had tensile strength up to 63 MPa and flexural load up to 1.03 KN. | - | [68] |

| Jute fiber reinforced with epoxy and polyester matrices | Compression molding | 20 wt % jute fibers and 80 wt % matrix materials were used with fiber length of 2–3 mm. | Jute epoxy composite had higher tensile strength, flexural strength and tensile modulus due to better stress distribution and fiber/matrix adhesion. | 5% NaOH (alkali treated) jute fiber composites showed better tensile strengths and flexural strengths than 10% NaOH treated composites. | [36] |

| Jute/glass fiber reinforced epoxy composite | Hand lay-up | 64–69% of epoxy resin, 18–31% of jute fibers, 0–19% of glass fibers were used in fabrication of different samples. | Increase in glass fiber content increased mechanical properties of composite. Composite with 64% epoxy resin, 18% of jute fibers and 19% of glass fiber had better tensile strength while flexural strength had not any significant change. Greater jute content led to rapid mass loss and increased moisture absorption. | - | [79] |

| Polylactide and jute composite | Solvent casting method | Samples with 50 wt % of jute were fabricated. | Tensile strength, tensile modulus, Izod impact strength, flexural strength and modulus for untreated jute/polylactide were 158 MPa, 5.3 GPa, 60 KJ/m2, 180 MPa and 10.5 GPa respectively. Untreated samples had greater Izod impact strength and thermal stability due to fiber pull out mechanism. While treated samples had fractured fibers which require less energy than pull out mechanism. | Samples were modified by alkali, silane, peroxide and permanganate surface treatments. Silane treated samples had elevated values for tensile strength and modulus, flexural strength and modulus. Surface treatments increase surface roughness which in turn increases fiber/matrix adhesion and inter-locking. Surface treatment alters fiber structure and can chemically modify mechanical properties, increasing mechanical properties of composite. | [60] |

| Jute fiber/polypropylene composite | Extrusion | 30 wt % of fiber loading had optimum mechanical properties. | Tensile strength showed decreasing trend as increase in jute fiber content increased the area of fiber/matrix interface, while tensile modulus increased due to obstruction in stress propagation by micro spaces. Flexural strength and modulus increased up to 30wt % fiber loading. Impact strength showed an increasing trend as larger force is required to pull out fibers up till 30 wt % of jute contents. | Urea treatment improved properties such as fiber/matrix adhesion, tensile strength and modulus, flexural strength and modulus and impact strength | [61] |

| Jute reinforced epoxy composite | Hand lay-up | Different mechanical and water absorption properties were studied for treated and untreated samples. | Tensile strength and flexural strength of untreated jute fiber epoxy composite were 46.7 and 62.4 MPa respectively. | Alkali treatment increased tensile strength by 108% and flexural strength by 28%. | [62] |

| Jute/glass epoxy composite | Hand lay-up | Jute and glass fibers were used in epoxy matrix to fabricate composite. | Hardness values increased with the increase in glass fiber content. Glass fibers have high hardness values which increase hardness of composite. Tensile strength showed increasing trend with the increase in glass fiber composition. Natural fibers enhanced degradability properties. and glass fibers enhanced brittleness. | Strength of composite increased by 11% when fibers were treated with NaOH. Tensile strength for treated composite increased due to removal of fiber components such as hemicellulose, lignin along with amorphous and crystalline parts of fibers. | [80] |

| Jute/Epoxy glass composite | Hand lay-up | Homogenous thickness of samples was obtained through compression technique. | Jute/E-glass composite showed better tensile strength than pure jute-based composite due to better stress transfer. Jute fibers increased toughness and decreased brittleness. While epoxy glass improved erosion wear properties. | Jute fibers were alkali treated to get rid of lignin, hemicellulose, and cellulose from the surface of fibers. | [81] |

| Jute/kenaf fibers reinforced epoxy composite | Hand lay-up | Samples were prepared using 56% of jute and kenaf fibers, 40% of epoxy, and 4% of hardeners. | Flexural strength, impact strength, tensile and compressive strength of treated fibers had enhanced values as compared untreated fibers composite. | Surface treatment of kenaf and jute fibers removed hemi-cellulose, pectin and other non-cellulosic matter. Surface treatment increased surface area, reduced moisture absorption and improved roughness of fibers for better fiber/matrix adhesion. | [82] |

| Jute reinforced polyester resin | Hand lay-up | Composite samples were manufactured through hand lay-up techniques and were tested for different mechanical properties. | Values of tensile strength, elongation at break and Young’s modulus for untreated jute composite are 12.61 MPa, 20.96%, 84.63 MPa, respectively. | 7% NaOH treated sample exhibited highest values of tensile strength, elongation at break and Young’s modulus with increase of 48.69%, 87.5%, and 62.94% respectively from untreated sample. NaOH treatment makes surface rough, improving fiber/matrix adhesion which enhances mechanical properties. | [83] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ashraf, M.A.; Zwawi, M.; Taqi Mehran, M.; Kanthasamy, R.; Bahadar, A. Jute Based Bio and Hybrid Composites and Their Applications. Fibers 2019, 7, 77. https://doi.org/10.3390/fib7090077

Ashraf MA, Zwawi M, Taqi Mehran M, Kanthasamy R, Bahadar A. Jute Based Bio and Hybrid Composites and Their Applications. Fibers. 2019; 7(9):77. https://doi.org/10.3390/fib7090077

Chicago/Turabian StyleAshraf, Muhammad Ahsan, Mohammed Zwawi, Muhammad Taqi Mehran, Ramesh Kanthasamy, and Ali Bahadar. 2019. "Jute Based Bio and Hybrid Composites and Their Applications" Fibers 7, no. 9: 77. https://doi.org/10.3390/fib7090077