Modeling and Analysis of the Soil Vapor Extraction Equipment for Soil Remediation

Abstract

:1. Introduction

- (1)

- A mathematical model of key SVE power and control components is established, and the influence of parameters of key components is analyzed, laying the foundation for decontamination efficiency evaluation and efficient equipment control.

- (2)

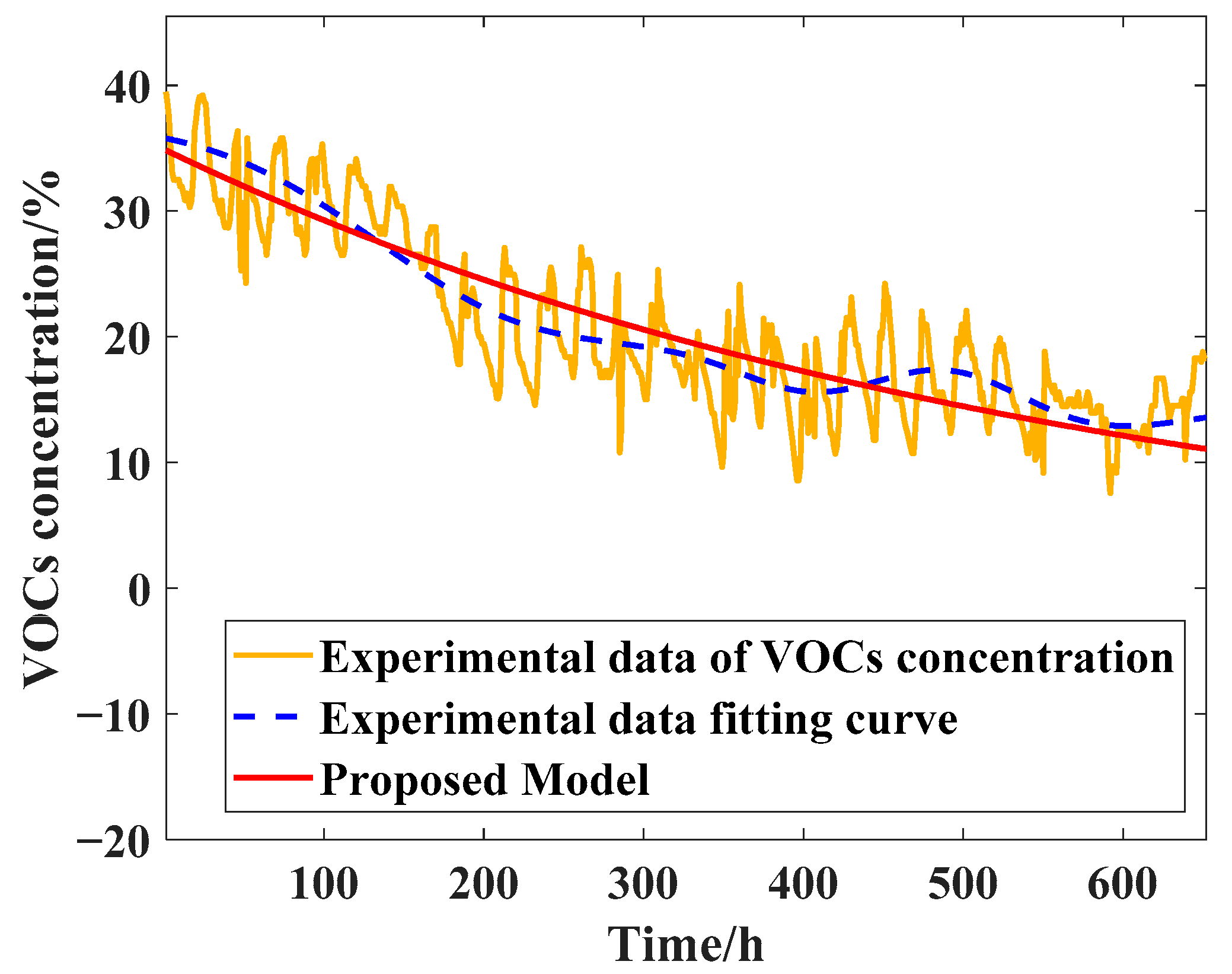

- An SVE intermittent operation strategy is proposed, the effectiveness of the strategy is verified using simulations, and the effectiveness of the model and strategy is verified using 3 months of engineering experiments.

2. Modeling of SVE Equipment

2.1. Model of Valve

2.2. Model of Droplet Separator

2.3. Model of Motor and Fan

3. Numerical Simulation of the SVE Equipment Model

3.1. Finite Element Simulation of Soil

3.2. Simulation with MATLAB/Simulink

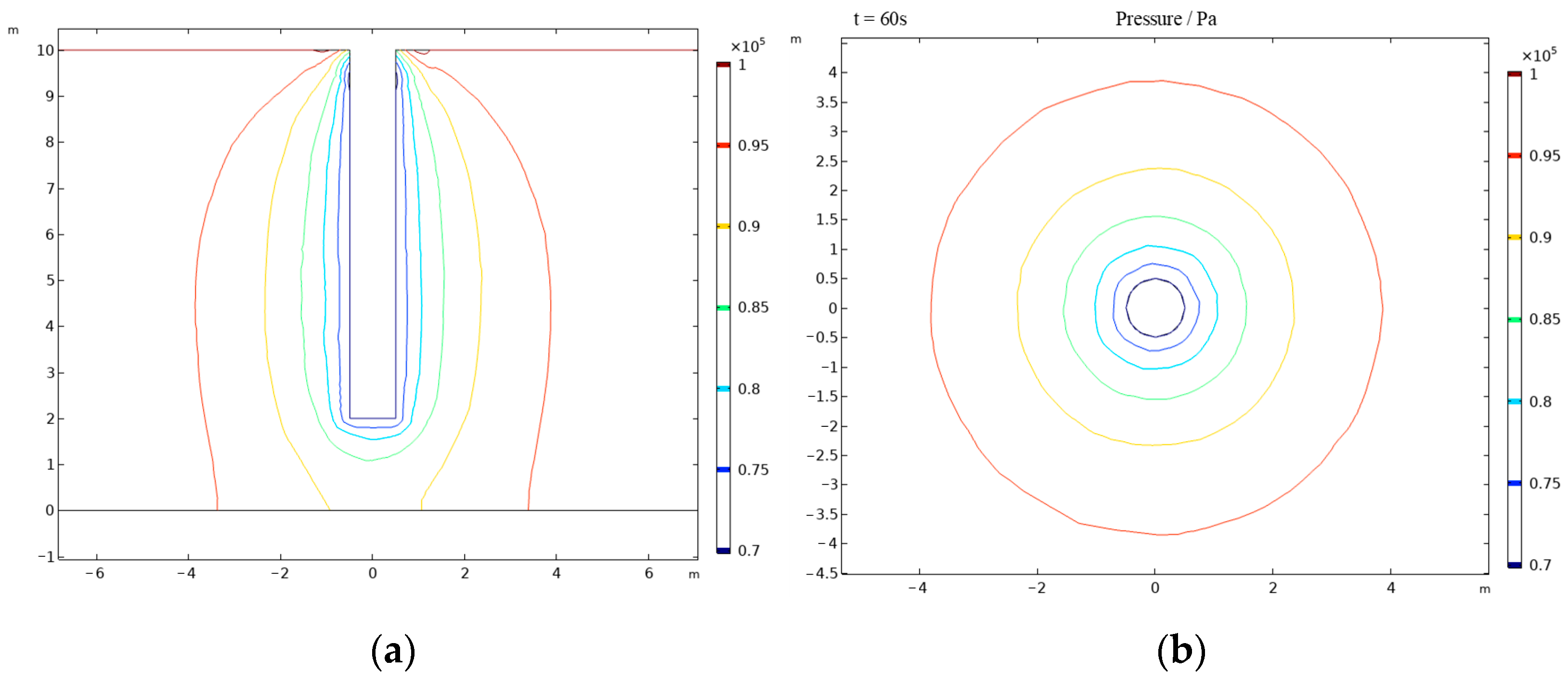

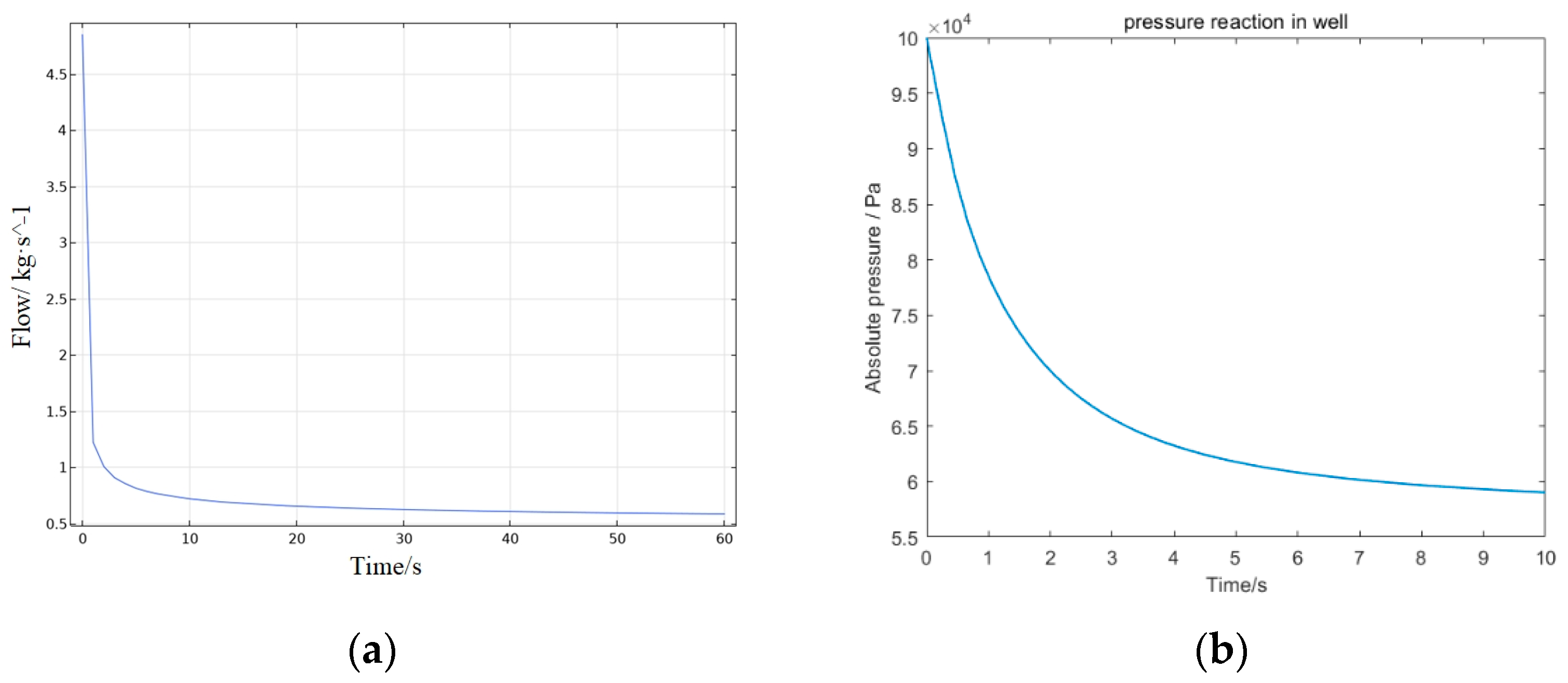

3.3. Pressure Distribution and Flow in Soil

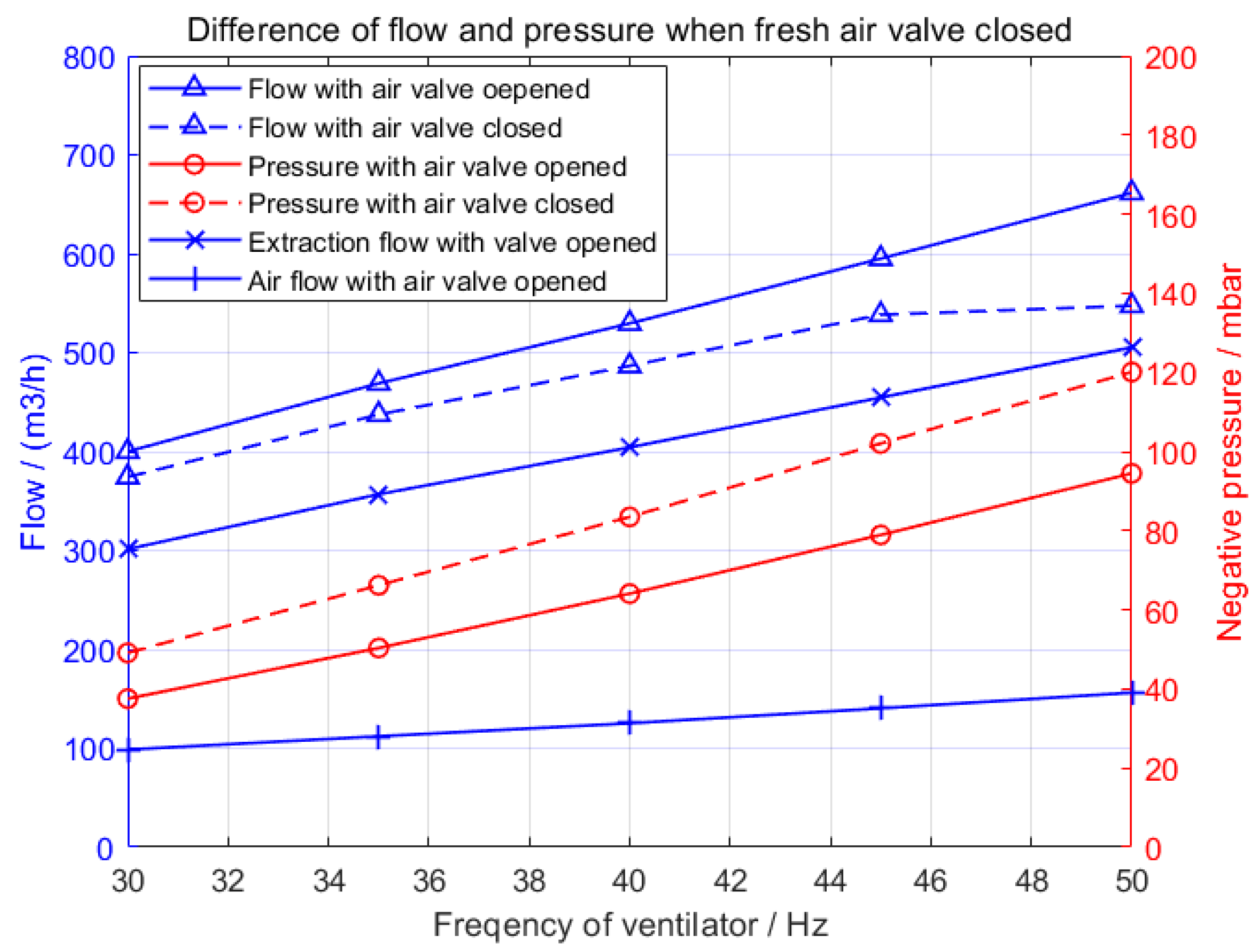

3.4. Influence of Fan Frequency and Valve Opening Ratio

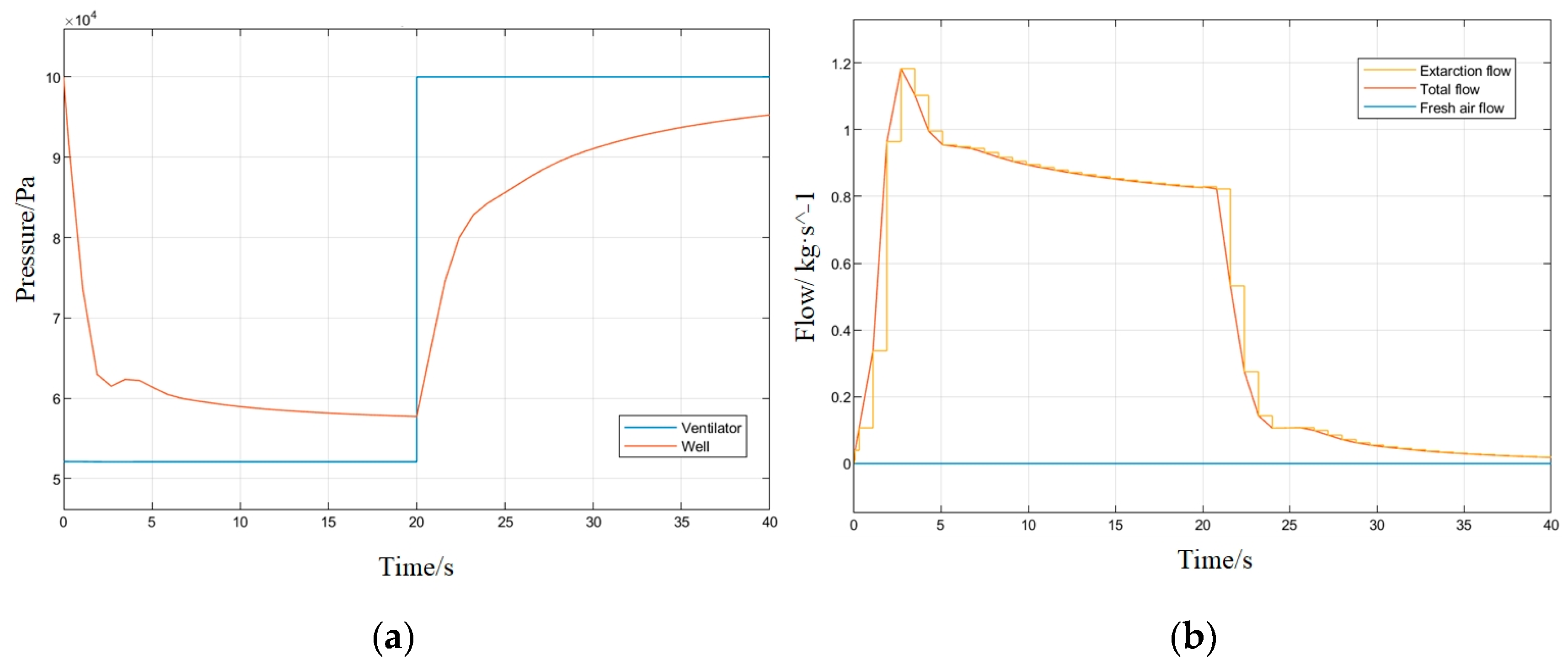

3.5. Intermittent Extraction Strategy

4. Field Experiments and Results

4.1. Field Experiments

4.2. Analysis of Equipment Testing Results

4.3. Analysis of Operation Experimental Results

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ye, S.; Zeng, G.; Wu, H.; Zhang, C.; Liang, J.; Dai, J.; Liu, Z.; Xiong, W.; Wan, J.; Wan, J.; et al. Co-occurrence and interactions of pollutants, and their impacts on soil remediation—A review. Crit. Rev. Environ. Sci. Technol. 2017, 47, 1528–1553. [Google Scholar] [CrossRef]

- Ossai, I.C.; Ahmed, A.; Hassan, A.; Hamid, F.S. Remediation of soil and water contaminated with petroleum hydrocarbon: A review. Environ. Technol. Innov. 2020, 17, 100526. [Google Scholar] [CrossRef]

- Wei, K.H.; Ma, J.; Xi, B.D.; Yu, M.D.; Cui, J.; Chen, B.L.; Li, Y.; Gu, Q.-B.; He, X.-S. Recent progress on in-situ chemical oxidation for the remediation of petroleum contaminated soil and groundwater. J. Hazard. Mater. 2022, 432, 128738. [Google Scholar] [CrossRef] [PubMed]

- Cao, W.; Zhang, L.; Miao, Y.; Qiu, L. Research progress in the enhancement technology of soil vapor extraction of volatile petroleum hydrocarbon pollutants. Environ. Sci. Process. Impacts 2021, 23, 1650–1662. [Google Scholar] [CrossRef] [PubMed]

- Qin, C.Y.; Zhao, Y.S.; Zheng, W.; Li, Y.S. Study on influencing factors on removal of chlorobenzene from unsaturated zone by soil vapor extraction. J. Hazard. Mater. 2010, 176, 294–299. [Google Scholar] [CrossRef]

- Brusseau, M.L.; Rohay, V.; Truex, M.J. Analysis of soil vapor extraction data to evaluate mass-transfer constraints and estimate source-zone mass flux. Groundw. Monit. Remediat. 2010, 30, 57–64. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Farhan, S.; Holsen, T.M.; Budiman, J. Interaction of soil air permeability and soil vapor extraction. J. Environ. Eng. 2001, 127, 32–37. [Google Scholar] [CrossRef]

- Yu, Y.; Liu, L.; Yang, C.; Kang, W.; Yan, Z.; Zhu, Y.; Wang, J.; Zhang, H. Removal kinetics of petroleum hydrocarbons from low-permeable soil by sand mixing and thermal enhancement of soil vapor extraction. Chemosphere 2019, 236, 124319. [Google Scholar] [CrossRef]

- Yasumoto, K.; Kawabata, J. Evaluation of in-situ air permeability test for designing of soil vapor extraction. In Groundwater Updates; Springer: Tokyo, Japan, 2000; pp. 393–397. [Google Scholar]

- Høier, C.K.; Sonnenborg, T.O.; Jensen, K.H.; Kortegaard, C.; Nasser, M.M. Experimental investigation of pneumatic soil vapor extraction. J. Contam. Hydrol. 2007, 89, 29–47. [Google Scholar] [CrossRef] [PubMed]

- Albergaria JT, Maria da Conceição M, and Delerue-Matos C, Soil vapor extraction in sandy soils: Influence of airflow rate. Chemosphere 2008, 73, 1557–1561. [CrossRef]

- Sun, M.; Ouyang, X.; Mattila, J.; Yang, H.; Hou, G. One Novel Hydraulic Actuating System for the Lower-Body Exoskeleton. Chin. J. Mech. Eng. 2021, 34, 31. [Google Scholar] [CrossRef]

- Labianca, C.; De Gisi, S.; Picardi, F.; Todaro, F.; Notarnicola, M. Remediation of a petroleum hydrocarbon-contaminated site by soil vapor extraction: A full-scale case study. Appl. Sci. 2020, 10, 4261. [Google Scholar] [CrossRef]

- Yoon, H.; Oostrom, M.; Wietsma, T.W.; Werth, C.J.; Valocchi, A.J. Numerical and experimental investigation of DNAPL removal mechanisms in a layered porous medium by means of soil vapor extraction. J. Contam. Hydrol. 2009, 109, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Ouoba, S.; Bénet, J.C. Numerical modeling and simulation of water transfer in soil with low water contents. Int. J. Environ. Sci. Technol. 2022, 1–12. [Google Scholar] [CrossRef]

- Ding, Y.; Zhang, Y.; Deng, Z.; Song, H.; Wang, J.; Guo, H. An innovative method for soil vapor extraction to improve extraction and tail gas treatment efficiency. Sci. Rep. 2022, 12, 6495. [Google Scholar] [CrossRef]

- Fen, C.S.; Chan, C.; Cheng, H.C. Assessing a response surface-based optimization approach for soil vapor extraction system design. J. Water Resour. Plan. Manag. 2009, 135, 198. [Google Scholar] [CrossRef]

- Kacem, M. Models for soil vapor extraction and multiphase extraction design and monitoring. In Diagnostic Techniques in Industrial Engineering; Springer: Cham, Switzerland, 2018; pp. 171–190. [Google Scholar]

- Zhao, L.; Zytner, R.G. Three-dimensional numerical model for soil vapor extraction. J. Contam. Hydrol. 2013, 147, 82–95. [Google Scholar]

- Carroll, K.C.; Oostrom, M.; Truex, M.J.; Rohay, V.J.; Brusseau, M.L. Assessing performance and closure for soil vapor extraction: Integrating vapor discharge and impact to groundwater quality. J. Contam. Hydrol. 2012, 128, 71–82. [Google Scholar] [CrossRef]

- Shi, H.; Li, J.; Guo, L.; Mei, X. Control Performance Evaluation of Serial Urology Manipulator by Virtual Prototyping. Chin. J. Mech. Eng. 2021, 34, 25. [Google Scholar] [CrossRef]

- Esslimani, K.; Kacem, M.; Boudouch, O.; Elkacmi, R.; Benadda, B. Influence of the presence of clay and water on the efficiency of soil vapor extraction in sand laboratory columns. Remediat. J. 2022, 33, 63–76. [Google Scholar] [CrossRef]

- Johnson, C.D.; Byrnes, M.E. Hanford 200-PW-1 Operable Unit Soil Vapor Extraction Endpoint Evaluation. Remplex Semin. Present. Jan. 2021, 26, 2021. [Google Scholar]

- Zhang, Y.; Li, K.; Xu, M.; Liu, J.; Yue, H. Medical Grabbing Servo System with Friction Compensation Based on the Differential Evolution Algorithm. Chin. J. Mech. Eng. 2021, 34, 107. [Google Scholar] [CrossRef]

- Wang, N.; Liu, Q.; Shi, Y.; Wang, S.; Zhang, X.; Han, C.; Wang, Y.; Cai, M. Modeling and Simulation of an Invasive Mild Hypothermic Blood Cooling System. Chin. J. Mech. Eng. 2021, 34, 23. [Google Scholar] [CrossRef]

- Shi, Y.; Rui, S.; Xu, S.; Wang, N.; Wang, Y. COMSOL Modeling of Heat Transfer in SVE Process. Environments 2022, 9, 58. [Google Scholar] [CrossRef]

- Jin, Z. Numerical Simulation Study on Multi-well Overlapping Effect of Soil Vapor Extraction. Master’s Thesis, Guangdong University of Technology, Guangzhou, China, 2017. [Google Scholar]

- Barnes, D.L. Estimation of operation time for soil vapor extraction systems. J. Environ. Eng. 2003, 129, 873–878. [Google Scholar] [CrossRef]

- Modeling the Rebounding of Contaminant Concentrations in Subsurface Gaseous Phase during Intermittent Soil Vapor Extraction Operation. J. Chin. Inst. Environ. Eng. 2007, 17, 11–19.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, Y.; Zhao, S.; Diao, Z.; Ye, Y.; Wang, Q.; Wang, Y. Modeling and Analysis of the Soil Vapor Extraction Equipment for Soil Remediation. Electronics 2023, 12, 151. https://doi.org/10.3390/electronics12010151

Shi Y, Zhao S, Diao Z, Ye Y, Wang Q, Wang Y. Modeling and Analysis of the Soil Vapor Extraction Equipment for Soil Remediation. Electronics. 2023; 12(1):151. https://doi.org/10.3390/electronics12010151

Chicago/Turabian StyleShi, Yan, Shijian Zhao, Zhuo Diao, Yuan Ye, Qiansuo Wang, and Yixuan Wang. 2023. "Modeling and Analysis of the Soil Vapor Extraction Equipment for Soil Remediation" Electronics 12, no. 1: 151. https://doi.org/10.3390/electronics12010151