Basic Mechanisms of Single-Event Occurrence in Silicon Carbide Semiconductor under Terrestrial Atmospheric Neutron Irradiation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials Properties

2.2. Atmospheric Neutron Source

2.3. Classification of Neutron Interactions

2.4. Direct Calculation of the Number of Interactions

2.5. Geant4 Simulation Details

3. Results

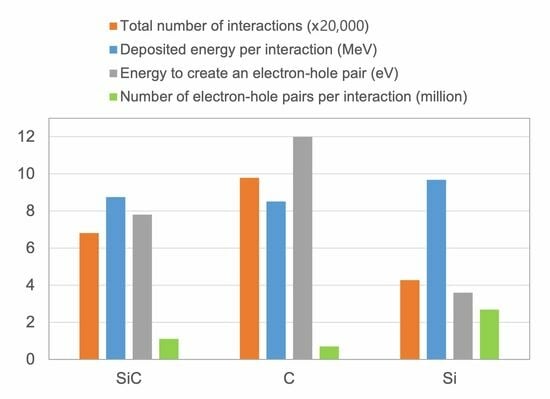

3.1. Number of Interactions

3.2. Number and Nature of Secondary Products

3.3. Energy, LET and Range of Secondary Products

3.4. Deposited Energy

3.5. Generation of Electron–Hole Pairs and Deposited Charge

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dimitrijev, S.; Jamet, P. Advances in SiC power MOSFET technology. Microelectron. Reliab. 2003, 43, 225–233. [Google Scholar] [CrossRef]

- Hudgins, J.L.; Simin, G.S.; Santi, E.; Khan, M.A. An assessment of wide bandgap semiconductors for power devices. IEEE Trans. Power Electron. 2003, 18, 907–914. [Google Scholar] [CrossRef]

- Östling, M.; Ghandi, R.; Zetterling, C.M. SiC power devices—Present status, applications and future perspective. In Proceedings of the 23rd IEEE International Symposium on Power Semiconductor Devices and ICs, San Diego, CA, USA, 23–26 May 2011. [Google Scholar]

- La Via, F.; Alquier, D.; Giannazzo, F.; Kimoto, T.; Neudeck, P.; Ou, H.; Roncaglia, A.; Saddow, S.E.; Tudisco, S. Emerging SiC Applications beyond Power Electronic Devices. Micromachines 2023, 14, 1200. [Google Scholar] [CrossRef] [PubMed]

- Papanasam, E.; Prashanth Kumar, B.; Chanthini, B.; Manikandan, E.; Agarwal, L. A Comprehensive Review of Recent Progress, Prospect and Challenges of Silicon Carbide and its Applications. Silicon 2022, 14, 12887–12900. [Google Scholar]

- Ou, H.; Shi, X.; Lu, Y.; Kollmuss, M.; Steiner, J.; Tabouret, V.; Syväjärvi, M.; Wellmann, P.; Chaussende, D. Novel Photonic Applications of Silicon Carbide. Materials 2023, 16, 1014. [Google Scholar] [CrossRef] [PubMed]

- Coutinho, J.; Torres, V.J.B.; Capan, I.; Brodar, T.; Eres, Z.; Bernat, R.; Radulovic, V. Silicon carbide diodes for neutron detection. Nucl. Inst. Methods Phys. Res. A 2020, 986, 164793. [Google Scholar] [CrossRef]

- Bernat, R.; Capan, I.; Bakrac, L.; Brodar, T.; Makino, T.; Ohshima, T.; Pastuovic, Z.; Sarbutt, A. Response of 4h-SiC detectors to ionizing particles. Crystals 2021, 11, 10. [Google Scholar] [CrossRef]

- Shenai, K.; Galloway, K.F.; Schrimpf, R.D. The effects of space radiation exposure on power MOSFETs: A review. Int. J. High Speed Electron. Syst. 2004, 14, 445–463. [Google Scholar] [CrossRef]

- Galloway, K.F.; Witulski, A.F.; Schrimpf, R.D.; Sternberg, A.L.; Ball, D.R.; Javanainen, A.; Reed, R.A.; Sierawski, B.D.; Lauenstein, J.-M. Failure Estimates for SiC Power MOSFETs in Space Electronics. Aerospace 2018, 5, 67. [Google Scholar] [CrossRef]

- Pearton, S.J.; Aitkaliyeva, A.; Xian, M.; Ren, F.; Khachatrian, A.; Ildefonso, A.; Islam, Z.; Rasel, M.A.J.; Haque, A.; Polyakov, A.Y.; et al. Review—Radiation Damage in Wide and Ultra-Wide Bandgap Semiconductors. ECS J. Solid State Sci. Technol. 2021, 10, 055008. [Google Scholar] [CrossRef]

- Kumar, A.; Moradpour, M.; Losito, M.; Franke, W.-T.; Ramasamy, S.; Baccoli, R.; Gatto, G. Wide Band Gap Devices and Their Application in Power Electronics. Energies 2022, 15, 9172. [Google Scholar] [CrossRef]

- Prado, E.O.; Bolsi, P.C.; Sartori, H.C.; Pinheiro, J.R. An Overview about Si, Superjunction, SiC and GaN Power MOSFET Technologies in Power Electronics Applications. Energies 2022, 15, 5244. [Google Scholar] [CrossRef]

- Langpoklakpam, C.; Liu, A.-C.; Chu, K.-H.; Hsu, L.-H.; Lee, W.-C.; Chen, S.-C.; Sun, C.-W.; Shih, M.-H.; Lee, K.-Y.; Kuo, H.-C. Review of Silicon Carbide Processing for Power MOSFET. Crystals 2022, 12, 245. [Google Scholar] [CrossRef]

- Yuan, X.; Laird, I.; Walder, S. Opportunities, Challenges, and Potential Solutions in the Application of Fast-Switching SiC Power Devices and Converters. IEEE Trans. Power Electron. 2021, 36, 3925–3945. [Google Scholar] [CrossRef]

- Lee, K.K.; Ohshima, T.; Itoh, H. Radiation Response of p-Channel 6H-SiC MOSFETs Fabricated Using Pyrogenic Conditions. Mater. Sci. Forum 2002, 389–393, 1097–1100. [Google Scholar] [CrossRef]

- Nishijima, T.; Ohshima, T.; Lee, K.K. Investigation of the Radiation Hardness on Semiconductor Devices using the Ion Micro-Beam. Nucl. Instrum. Meth. B 2002, 190, 329–334. [Google Scholar] [CrossRef]

- Lee, K.K.; Ohshima, T.; Itoh, H. Performance of Gamma Irradiated p-Channel 6H-SiC MOSFETs: High Total Dose. IEEE Trans. Nucl. Sci. 2003, 50, 194–200. [Google Scholar]

- Ohshima, T.; Onoda, S.; Iwamoto, N.; Makino, T.; Arai, M.; Tanak, Y. Radiation Response of Silicon Carbide Diodes and Transistors. In Physics and Technology of Silicon Carbide Devices; Hijikata, Y., Ed.; IntechOpen: London, UK, 2012; pp. 379–402. [Google Scholar]

- Akturk, A.; McGarrity, J.M.; Goldsman, N.; Lichtenwalner, D.; Hull, B.; Grider, D.; Wilkins, R. Terrestrial Neutron-Induced Failures in Silicon Carbide Power MOSFETs and Diodes. IEEE Trans. Nucl. Sci. 2018, 65, 1248–1254. [Google Scholar] [CrossRef]

- Ball, D.R.; Sierawski, B.D.; Galloway, K.F.; Johnson, R.A.; Alles, M.L.; Sternberg, A.L.; Witulski, A.F.; Reed, R.A.; Schrimpf, R.D.; Javanainen, A.; et al. Estimating Terrestrial Neutron-Induced SEB Cross Sections and FIT Rates for High-Voltage SiC Power MOSFETs. IEEE Trans. Nucl. Sci. 2019, 66, 337–343. [Google Scholar] [CrossRef]

- Asai, H.; Nashiyama, I.; Sugimoto, K.; Shiba, K.; Sakaide, Y.; Ishimaru, Y.; Okazaki, Y.; Noguchi, K.; Morimura, T. Tolerance Against Terrestrial Neutron-Induced Single-Event Burnout in SiC MOSFETs. IEEE Trans. Nucl. Sci. 2014, 61, 3109–3114. [Google Scholar] [CrossRef]

- Martinella, C.; Alia, R.G.; Stark, R.; Coronetti, A.; Cazzaniga, C.; Kastriotou, M.; Kadi, Y.; Gaillard, R.; Grossner, U.; Javanainen, A. Impact of Terrestrial Neutrons on the Reliability of SiC VD-MOSFET Technologies. IEEE Trans. Nucl. Sci. 2021, 68, 634–641. [Google Scholar] [CrossRef]

- Akturk, A.; McGarrity, J.M.; Goldsman, N.; Lichtenwalner, D.J.; Hull, B.; Grider, D.; Wilkins, R. Predicting Cosmic Ray-Induced Failures in Silicon Carbide Power Devices. IEEE Trans. Nucl. Sci. 2019, 66, 1828–1832. [Google Scholar] [CrossRef]

- Principato, F.; Altieri, S.; Abbene, L.; Pintacuda, F. Accelerated Tests on Si and SiC Power Transistors with Thermal, Fast and Ultra-Fast Neutrons. Sensors 2020, 20, 3021. [Google Scholar] [CrossRef] [PubMed]

- Yazdi, M.B.; Schmeidl, M.; Wu, X.; Neyer, T. A concise study of neutron irradiation effects on power MOSFETs and IGBTs. Microelectron. Reliab. 2016, 62, 74–78. [Google Scholar] [CrossRef]

- Ngwashi, D.K.; Phung, L.V. Recent review on failures in silicon carbide power MOSFETs. Microelectron. Reliab. 2021, 123, 114169. [Google Scholar] [CrossRef]

- Munteanu, D.; Autran, J.L. Susceptibility of Group-IV and III-V Semiconductor-based Electronics to Atmospheric Neutrons Explored by Geant4 Numerical Simulations. In Numerical Simulations; Rao, S., Ed.; IntechOpen: London, UK, 2018; pp. 117–134. [Google Scholar]

- Autran, J.L.; Munteanu, D. Radiation Response of Group-IV and III-V Semiconductors Subjected to D–D and D–T Fusion Neutrons. In New Advances in Semiconductors; Cavalheiro, A.A., Ed.; IntechOpen: London, UK, 2022; pp. 1–21. [Google Scholar]

- Munteanu, D.; Autran, J.L. Modeling and Simulation of Single-Event Effects in Digital Devices and ICs. IEEE Trans. Nucl. Sci. 2008, 55, 1854–1878. [Google Scholar] [CrossRef]

- Agostinelli, S.; Allison, J.; Amako, K.; Apostolakis, J.; Araujo, H.; Arce, P.; Asai, M.; Axen, D.; Banerjee, S.; Barrand, G.; et al. Geant4—A simulation toolkit. Nucl. Instrum. Meth. A 2003, 506, 250–303. [Google Scholar] [CrossRef]

- Allison, J.; Amako, K.; Apostolakis, J.; Arce, P.; Asai, M.; Aso, T.; Bagli, E.; Bagulya, A.; Banerjee, S.; Barrand, G.; et al. Recent developments in Geant4. Nucl. Instrum. Meth. A 2016, 835, 186–225. [Google Scholar] [CrossRef]

- Geant4 General Particle Source (GPS). Available online: https://www.fe.infn.it/u/paterno/Geant4_tutorial/slides_further/GPS/GPS_manual.pdf (accessed on 20 August 2023).

- Geant4 version 4.9.4. Available online: http://geant4.in2p3.fr/IMG/pdf_PhysicsLists.pdf (accessed on 20 August 2023).

- Autran, J.L.; Munteanu, D. Atmospheric Neutron Radiation Response of III-V Binary Compound Semiconductors. IEEE Trans. Nucl. Sci. 2020, 67, 1428–1435. [Google Scholar] [CrossRef]

- Autran, J.L.; Munteanu, D. Soft Errors: From Particles to Circuits; Taylor & Francis/CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- Goldhagen, P. Cosmic-Ray Neutrons on the Ground and in the Atmosphere. MRS Bull. 2003, 28, 131–135. [Google Scholar] [CrossRef]

- Gordon, M.S.; Goldhagen, P.; Rodbell, K.P.; Zabel, T.H.; Tang, H.H.K.; Clem, J.M.; Bailey, P. Measurement of the Flux and Energy Spectrum of Cosmic-Ray Induced Neutrons on the Ground. IEEE Trans. Nucl. Sci. 2004, 51, 3427–3434. [Google Scholar] [CrossRef]

- Rinard, P. Neutron Interactions with Matter. Los Alamos Technical Report. 1991. Available online: https://www.lanl.gov/org/ddste/aldgs/sst-training/_assets/docs/PANDA/Neutron%20Interactions%20with%20Matter%20Ch.%2012%20p.%20357-378.pdf (accessed on 20 August 2023).

- TENDL-2021. TALYS-Based Evaluated Nuclear Data Library. Available online: https://tendl.web.psi.ch/tendl_2021/tendl2021.html (accessed on 20 August 2023).

- Autran, J.L.; Serre, S.; Semikh, S.; Munteanu, D.; Gasiot, G.; Roche, P. Soft-Error Rate Induced by Thermal and Low Energy Neutrons in 40 nm SRAMs. IEEE Trans. Nucl. Sci. 2012, 59, 2658–2665. [Google Scholar] [CrossRef]

- Serre, S.; Semikh, S.; Uznanski, S.; Autran, J.L.; Munteanu, D.; Gasiot, G.; Roche, P. Geant4 Analysis of n-Si Nuclear Reactions From Different Sources of Neutrons and Its Implication on Soft-Error Rate. IEEE Trans. Nucl. Sci. 2012, 59, 714–722. [Google Scholar] [CrossRef]

- Baker, D.E. Graphite as a neutron moderator and reflector material. Nucl. Eng. Des. 1971, 14, 413–444. [Google Scholar] [CrossRef]

- Gaillard, R. Single Event Effects: Mechanisms and Classification. In Soft Errors in Modern Electronic Systems; Nicolaidis, M., Ed.; Springer: New York, NY, USA, 2011. [Google Scholar]

- Ziegler, J.F.; Ziegler, M.D.; Biersack, J.P. SRIM—The stopping and range of ions in matter. Nucl. Instrum. Meth. B 2010, 268, 1818–1823. [Google Scholar] [CrossRef]

- Available online: http://srim.org (accessed on 20 August 2023).

- Seifert, N.; Jahinuzzaman, S.; Velamala, J.; Ascazubi, R.; Patel, N.; Gill, B.; Basile, J.; Hicks, J. Soft Error Rate Improvements in 14-nm Technology Featuring Second-Generation 3D Tri-Gate Transistor. IEEE Trans. Nucl. Sci. 2012, 62, 2570–2577. [Google Scholar] [CrossRef]

- JESD89B; Measurement and Reporting of Alpha Particle and Terrestrial Cosmic Ray-Induced Soft Errors in Semiconductor Devices. Revision of JESD89A. JEDEC: Arlington, VA, USA, 2021.

| Symbol | Atomic Number | Nuclide | Natural Abundance |

|---|---|---|---|

| C | 6 | 6-C-12 | 98.93% |

| 6-C-13 | 1.07% | ||

| Si | 14 | 14-Si-28 | 92.20% |

| 14-Si-29 | 4.70% | ||

| 14-Si-30 | 3.10% |

| Semiconductor | Bandgap @ 300 K Eg (eV) | Number of Atoms per cm3 (×1022) | Density (g/cm3) | Electron–Hole Pair Creation Energy Eeh (eV) |

|---|---|---|---|---|

| C (diamond) | 5.47 | 17.6 | 3.515 | 12 |

| Si | 1.124 | 5 | 2.329 | 3.6 |

| SiC | 3.23 | 9.64 | 3.21 | 7.8 |

| Material | Multiplicity = 1 | Multiplicity ≥ 2 | Multiplicity ≥ 4 |

|---|---|---|---|

| C | 85.78% | 14.22% | 2.56% |

| Si | 82.13% | 17.87% | 2.98% |

| SiC | 83.74% | 16.26% | 2.70% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Munteanu, D.; Autran, J.-L. Basic Mechanisms of Single-Event Occurrence in Silicon Carbide Semiconductor under Terrestrial Atmospheric Neutron Irradiation. Electronics 2023, 12, 4468. https://doi.org/10.3390/electronics12214468

Munteanu D, Autran J-L. Basic Mechanisms of Single-Event Occurrence in Silicon Carbide Semiconductor under Terrestrial Atmospheric Neutron Irradiation. Electronics. 2023; 12(21):4468. https://doi.org/10.3390/electronics12214468

Chicago/Turabian StyleMunteanu, Daniela, and Jean-Luc Autran. 2023. "Basic Mechanisms of Single-Event Occurrence in Silicon Carbide Semiconductor under Terrestrial Atmospheric Neutron Irradiation" Electronics 12, no. 21: 4468. https://doi.org/10.3390/electronics12214468