Modulation of Diamond PN Junction Diode with Double-Layered n-Type Diamond by Using TCAD Simulation

Abstract

:1. Introduction

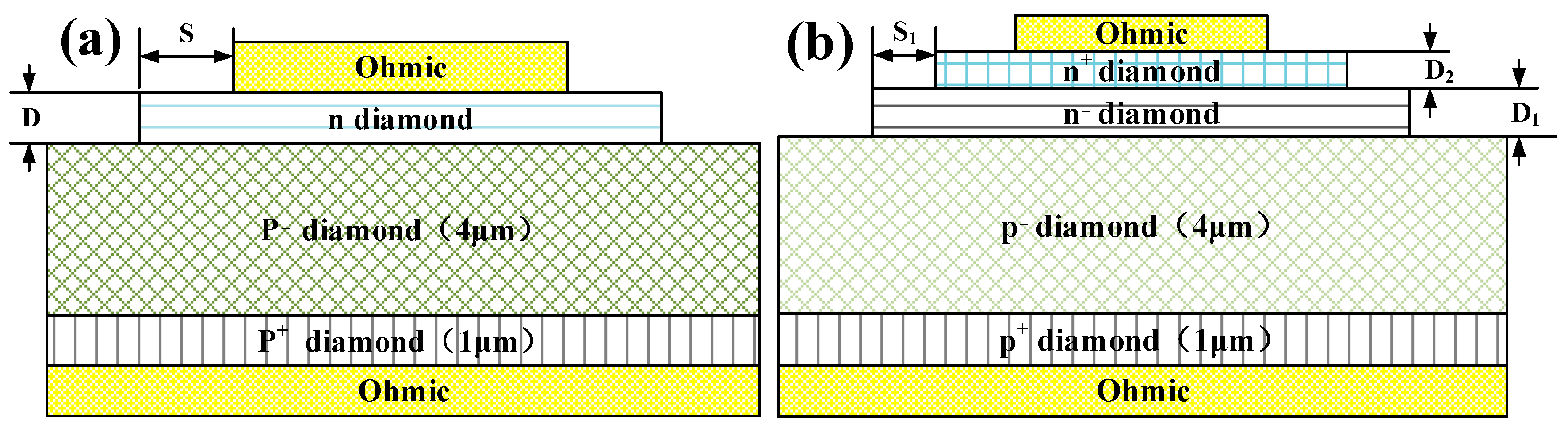

2. Design Models and Calibration

3. Results and Discussions

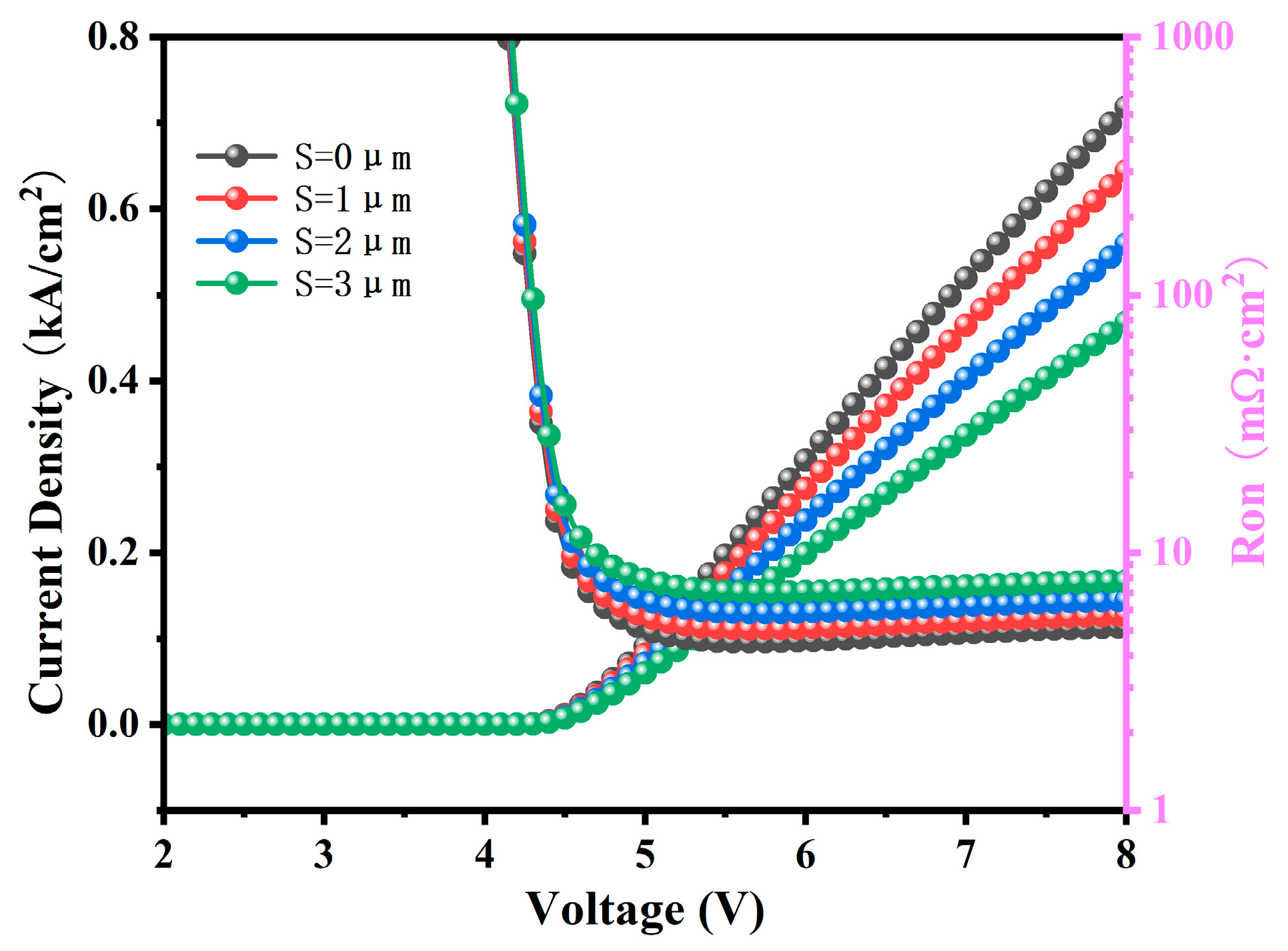

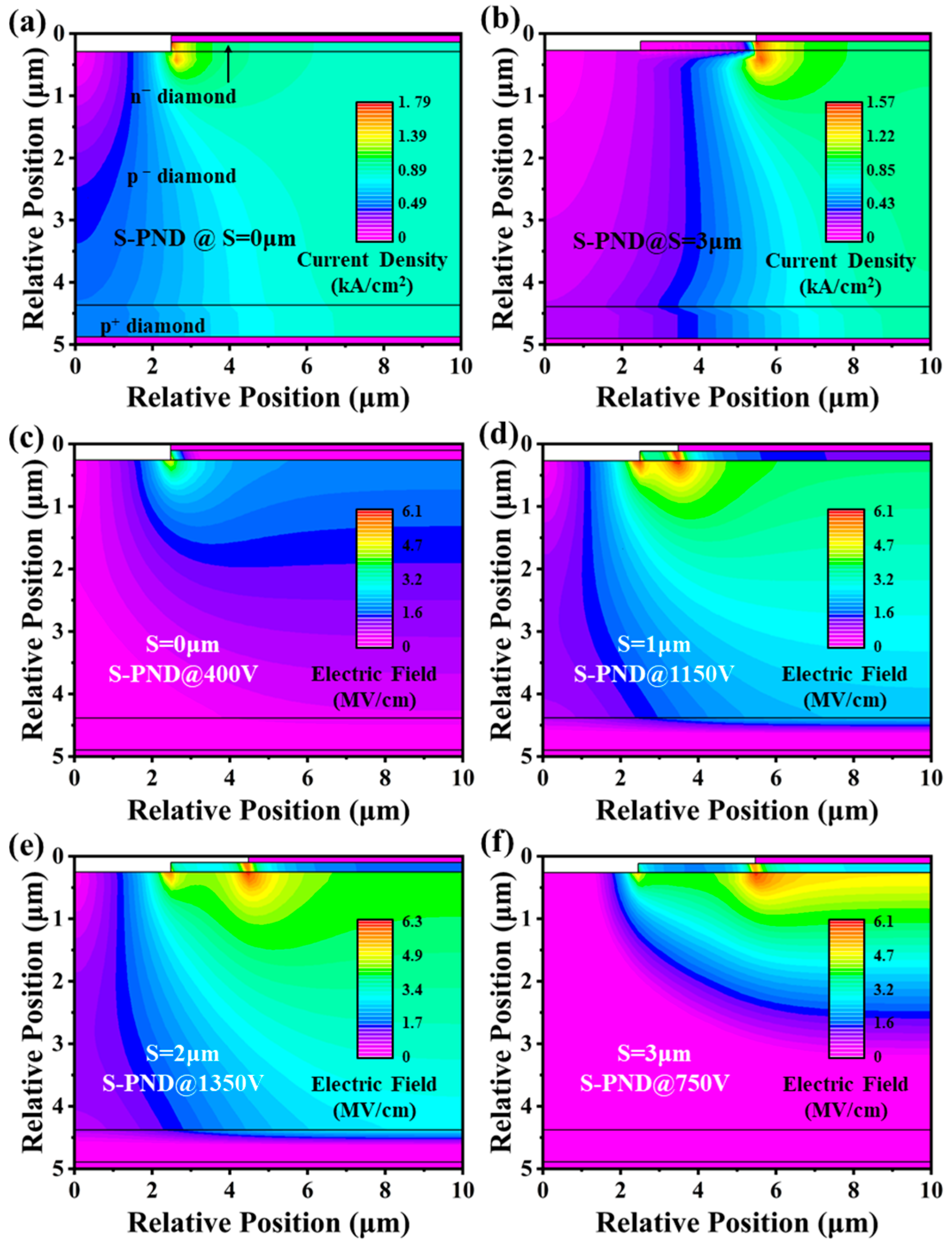

3.1. Modulation of the Structure Parameters for the S-PND

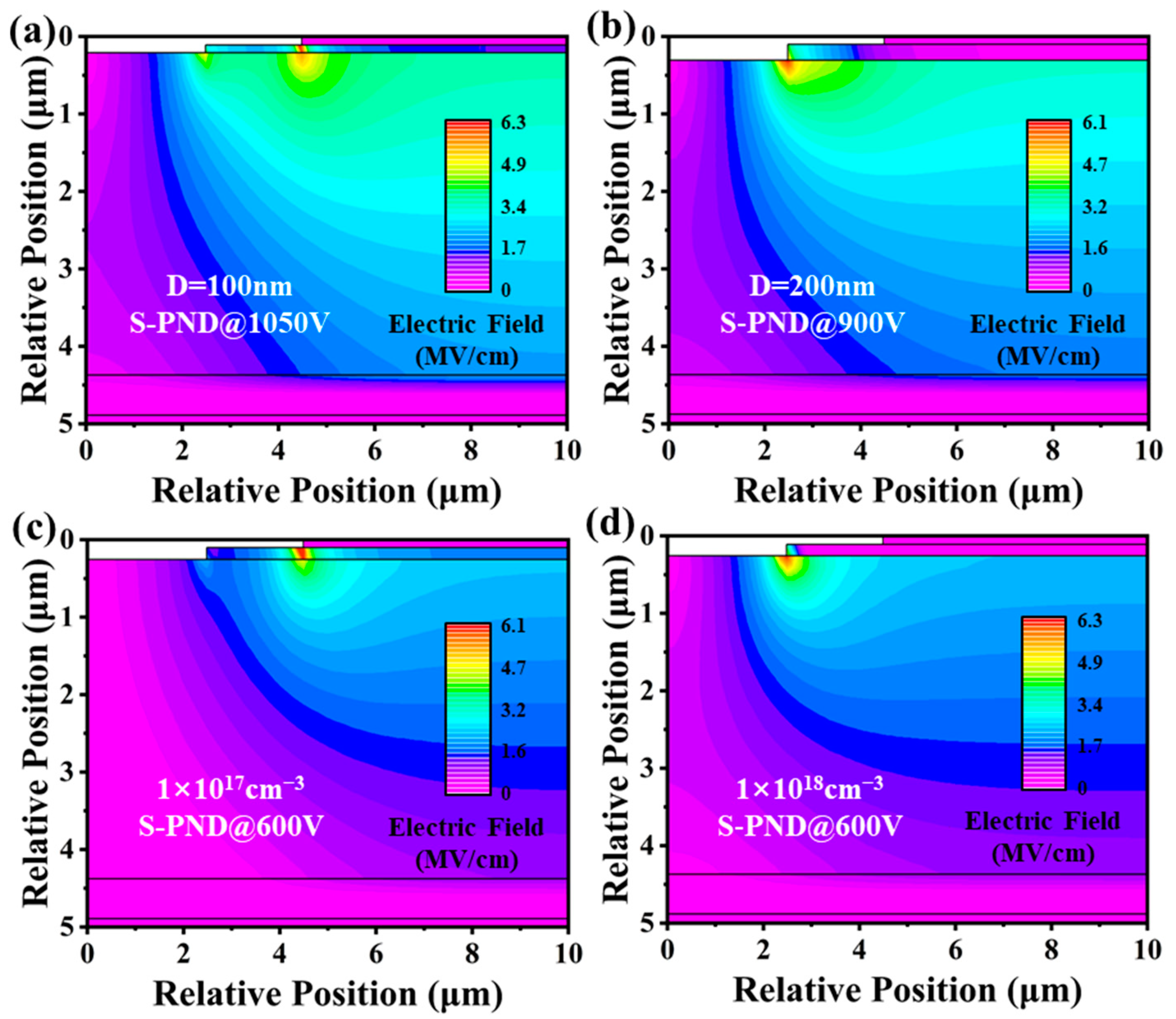

3.2. The Effects of Structure Parameters on the D-PND

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hower, P.L.; Pendharkar, S.; Efland, T. Current status and future trends in silicon power devices. In Proceedings of the 2010 International Electron Devices Meeting, San Francisco, CA, USA, 6–8 December 2010; pp. 13.11.11–13.11.14. [Google Scholar]

- Millán, J.; Godignon, P.; Perpiñà, X.; Pérez-Tomás, A.; Rebollo, J. A Survey of Wide Bandgap Power Semiconductor Devices. IEEE Trans. Power Electron. 2014, 29, 2155–2163. [Google Scholar] [CrossRef]

- Zhang, Y.; Dadgar, A.; Palacios, T. Gallium nitride vertical power devices on foreign substrates: A review and outlook. J. Phys. D Appl. Phys. 2018, 51, 273001. [Google Scholar] [CrossRef]

- Yang, H.; Ma, Y.; Dai, Y. Progress of structural and electronic properties of diamond: A mini review. Funct. Diam. 2022, 1, 150–159. [Google Scholar] [CrossRef]

- Zhang, X.; Liao, F.; Huang, X.; Yao, D.; Du, Z.; Ma, X.; Chen, Y.; Liu, J. Design of a 6 kV Beta-Ga2O3 PN Heterojunction Diode with Etched Double-Layered NiO with a Figure of Merit of 10 GW cm−2. ECS J. Solid State Sci. Technol. 2022, 11, 045012. [Google Scholar] [CrossRef]

- Umezawa, H. Recent advances in diamond power semiconductor devices. Mater. Sci. Semicond. Process. 2018, 78, 147–156. [Google Scholar] [CrossRef]

- Zhang, J.; Dong, P.; Dang, K.; Zhang, Y.; Yan, Q.; Xiang, H.; Su, J.; Liu, Z.; Si, M.; Gao, J.; et al. Ultra-wide bandgap semiconductor Ga2O3 power diodes. Nat. Commun. 2022, 13, 3900. [Google Scholar] [CrossRef] [PubMed]

- Ma, S.; Kumaresan, Y.; Dahiya, A.S.; Lorenzelli, L.; Dahiya, R.S. Flexible Tactile Sensors Using AlN and MOSFETs Based Ultra-Thin Chips. IEEE Sens. J. 2023, 23, 23988–23994. [Google Scholar] [CrossRef]

- Maeda, T.; Page, R.; Nomoto, K.; Toita, M.; Xing, H.G.; Jena, D. AlN quasi-vertical Schottky barrier diode on AlN bulk substrate using Al0.9Ga0.1N current spreading layer. Appl. Phys. Express 2022, 15, 061007. [Google Scholar] [CrossRef]

- Amaratunga, G.A.J. A Dawn for Carbon Electronics? Science 2002, 297, 1657–1658. [Google Scholar] [CrossRef]

- Isberg, J.; Hammersberg, J.; Johansson, E.; Wikström, T.; Twitchen, D.J.; Whitehead, A.J.; Coe, S.E.; Scarsbrook, G.A. High Carrier Mobility in Single-Crystal Plasma-Deposited Diamond. Science 2002, 297, 1670–1672. [Google Scholar] [CrossRef]

- Inyushkin, A.V.; Taldenkov, A.N.; Ralchenko, V.G.; Bolshakov, A.P.; Koliadin, A.V.; Katrusha, A.N. Thermal conductivity of high purity synthetic single crystal diamonds. Phys. Rev. B 2018, 97, 144305. [Google Scholar] [CrossRef]

- Shimaoka, T.; Koizumi, S.; Kaneko, J.H. Recent progress in diamond radiation detectors. Funct. Diam. 2022, 1, 205–220. [Google Scholar] [CrossRef]

- Twitchen, D.J.; Whitehead, A.J.; Coe, S.E.; Isberg, J.; Hammersberg, J.; Wikstrom, T.; Johansson, E. High-voltage single-crystal diamond diodes. IEEE Trans. Electron Devices 2004, 51, 826–828. [Google Scholar] [CrossRef]

- Umezawa, H.; Nagase, M.; Kato, Y.; Shikata, S.-i. High temperature application of diamond power device. Diam. Relat. Mater. 2012, 24, 201–205. [Google Scholar] [CrossRef]

- Li, G.; Li, D.; Mu, C.; Wang, Q.; Lv, X.; Li, L.; Zou, G. Effect of step-flow modulation on the large-size single crystal diamond through mosaic growth. Funct. Diam. 2023, 3, 2279057. [Google Scholar] [CrossRef]

- Xie, W.-L.; Lv, X.-Y.; Wang, Q.-L.; Li, L.-A.; Zou, G.-T. Relationship between spatial position of seed and growth mode in single-crystal diamond grown with an enclosed-type holder. Chin. Phys. B 2022, 31, 108106. [Google Scholar] [CrossRef]

- Li, D.; Wang, Q.; Lv, X.; Li, L.; Zou, G. Reduction of dislocation density in single crystal diamond by Ni-assisted selective etching and CVD regrowth. J. Alloys Compd. 2023, 960, 170890. [Google Scholar] [CrossRef]

- Makino, T.; Tanimoto, S.; Hayashi, Y.; Kato, H.; Tokuda, N.; Ogura, M.; Takeuchi, D.; Oyama, K.; Ohashi, H.; Okushi, H.; et al. Diamond Schottky-pn diode with high forward current density and fast switching operation. Appl. Phys. Lett. 2009, 94, 262101. [Google Scholar] [CrossRef]

- Li, D.; Wang, T.; Lin, W.; Zhu, Y.; Wang, Q.; Lv, X.; Li, L.; Zou, G. Design of vertical diamond Schottky barrier diode with a novel beveled junction termination extension. Diam. Relat. Mater. 2022, 128, 109300. [Google Scholar] [CrossRef]

- Li, Q.; Wang, J.; Shao, G.; Chen, G.; He, S.; Zhang, Q.; Zhang, S.; Wang, R.; Fan, S.; Wang, H.X. Breakdown Voltage Enhancement of Vertical Diamond Schottky Barrier Diode with Annealing Method and AlO Field Plate Structure. IEEE Electron. Device Lett. 2022, 43, 1937–1940. [Google Scholar] [CrossRef]

- Makino, T.; Kato, H.; Tokuda, N.; Ogura, M.; Takeuchi, D.; Oyama, K.; Tanimoto, S.; Okushi, H.; Yamasaki, S. Diamond Schottky-pn diode without trade-off relationship between on-resistance and blocking voltage. Phys. Status Solidi a 2010, 207, 2105–2109. [Google Scholar] [CrossRef]

- Ikeda, K.; Umezawa, H.; Ramanujam, K.; Shikata, S.-i. Thermally Stable Schottky Barrier Diode by Ru/Diamond. Appl. Phys. Express 2009, 2, 011202. [Google Scholar] [CrossRef]

- Zhou, J.; He, L.; Li, X.; Pu, T.; Li, L.; Ao, J.-P. Vertical GaN Schottky barrier diodes with area-selectively deposited p-NiO guard ring termination structure. Superlattices Microstruct. 2021, 151, 106820. [Google Scholar] [CrossRef]

- Lombardi, E.B.; Mainwood, A. A first principles study of lithium, sodium and aluminum in diamond. Diam. Relat. Mater. 2008, 17, 1349–1352. [Google Scholar] [CrossRef]

- Hu, X.J.; Li, R.B.; Shen, H.S.; Dai, Y.B.; He, X.C. Electrical and structural properties of boron and phosphorus co-doped diamond films. Carbon 2004, 42, 1501–1506. [Google Scholar] [CrossRef]

- Gao, N.; Gao, L.L.; Yu, H.Y. First-principles study of N and S co-doping in diamond. Diam. Relat. Mater. 2023, 132, 109651. [Google Scholar] [CrossRef]

- Katayama-Yoshida, H.; Nishimatsu, T.; Yamamoto, T.; Orita, N. Codoping method for the fabrication of low-resistivity wide band-gap semiconductors in p-type GaN, p-type AlN and n-type diamond: Prediction versus experiment. J. Phys. -Condens. Matter 2001, 13, 8901–8914. [Google Scholar] [CrossRef]

- Pinault-Thaury, M.-A.; Temgoua, S.; Gillet, R.; Bensalah, H.; Stenger, I.; Jomard, F.; Issaoui, R.; Barjon, J. Phosphorus-doped (113) CVD diamond: A breakthrough towards bipolar diamond devices. Appl. Phys. Lett. 2019, 114, 112106. [Google Scholar] [CrossRef]

- Gong, H.H.; Chen, X.H.; Xu, Y.; Ren, F.-F.; Gu, S.L.; Ye, J.D. A 1.86-kV double-layered NiO/β-Ga2O3 vertical p–n heterojunction diode. Appl. Phys. Lett. 2020, 117, 022104. [Google Scholar] [CrossRef]

- Li, G.; Mu, C.; Lin, W.; Li, D.; Lv, X.; Wang, Q.; Li, L.; Zou, G. Simulation study of vertical diamond Schottky barrier diode with field plate assisted junction termination extension. Mater. Today Commun. 2023, 35, 105968. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, T.; Pu, T.; Cheng, S.; Li, X.; Li, L.; Ao, J. Hybrid-anode structure designed for a high-performance quasi-vertical GaN Schottky barrier diode. Chin. Phys. B 2022, 31, 057702. [Google Scholar] [CrossRef]

- Miyata, K.; Nishimura, K.; Kobashi, K. Device simulation of submicrometer gate p+-i-p+ diamond transistors. IEEE Trans. Electron Devices 1995, 42, 2010–2014. [Google Scholar] [CrossRef]

- Cai, G.; Mu, C.; Li, J.; Li, L.; Cheng, S.; Wang, Q.; Han, X. Vertical Diamond p-n Junction Diode with Step Edge Termination Structure Designed by Simulation. Micromachines 2023, 14, 1667. [Google Scholar] [CrossRef] [PubMed]

| S (μm) | Von (V) | Ron (mΩ·cm2) | Vbd (V) | BFOM (GW/cm2) |

|---|---|---|---|---|

| 0 | 5.7 | 4.51 | 400 | 0.04 |

| 1 | 5.7 | 5.06 | 1150 | 0.26 |

| 2 | 5.7 | 5.86 | 1350 | 0.31 |

| 3 | 5.7 | 7.04 | 750 | 0.08 |

| D (nm) | Electron Density (550 K) | Ron (mΩ·cm2) | Vbd (V) | BFOM (GW/cm2) |

|---|---|---|---|---|

| 100 | 5 × 1017 cm−3 | 5.32 | 1050 | 0.21 |

| 150 | 1 × 1017 cm−3 | 8.47 | 500 | 0.03 |

| 150 | 5 × 1017 cm−3 | 5.86 | 1350 | 0.31 |

| 150 | 1 × 1018 cm−3 | 4.52 | 600 | 0.08 |

| 200 | 5 × 1017 cm−3 | 6.52 | 900 | 0.13 |

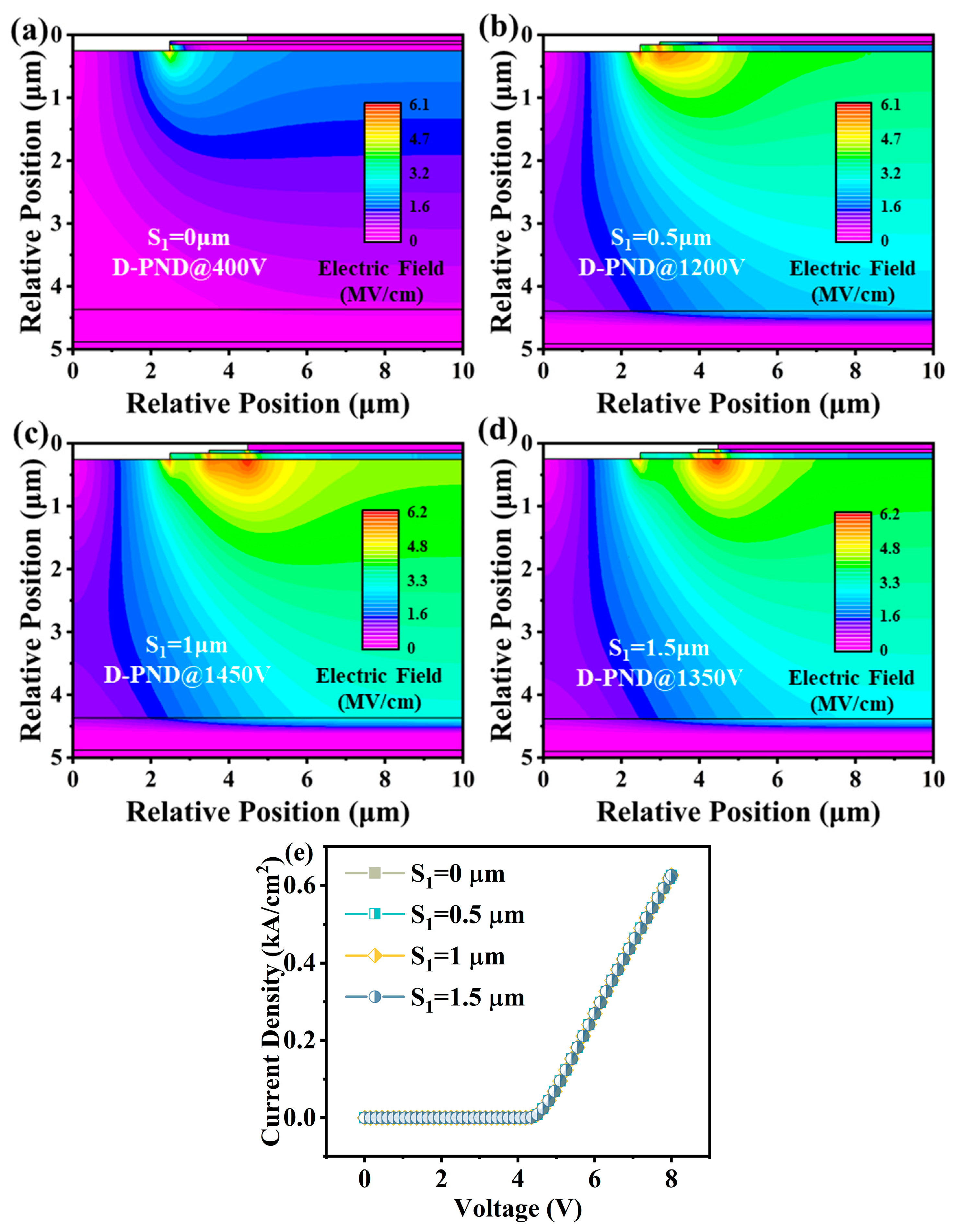

| S1 (μm) | Ron (mΩ·cm2) | Vbd (V) | BFOM (GW/cm2) |

|---|---|---|---|

| 0 | 5.08 | 400 | 0.03 |

| 0.5 | 5.08 | 1200 | 0.28 |

| 1 | 5.08 | 1450 | 0.42 |

| 1.5 | 5.08 | 1350 | 0.36 |

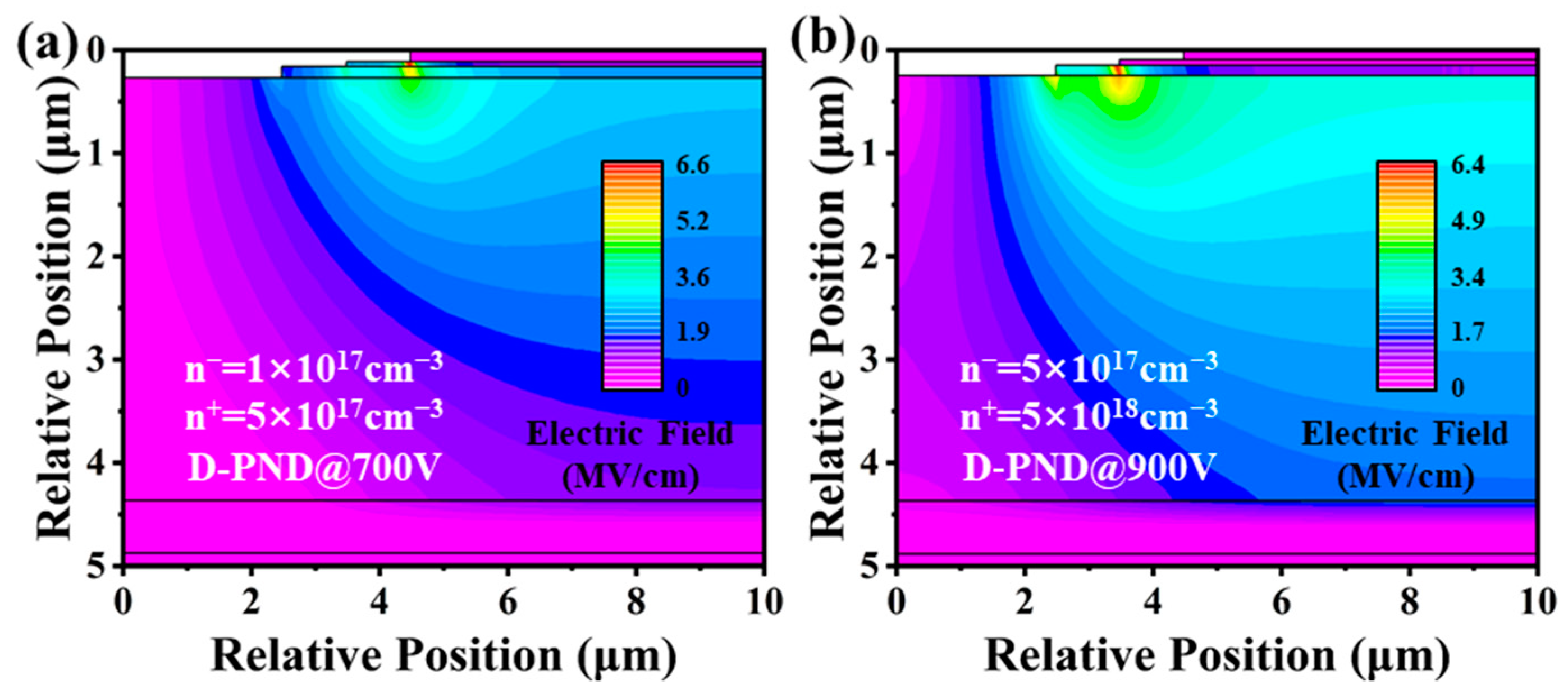

| n− Electron Density (550 K) | n+ Electron Density (550 K) | Ron (mΩ·cm2) | Vbd (V) | BFOM (GW/cm2) |

|---|---|---|---|---|

| 1 × 1017 cm−3 | 5 × 1017 cm−3 | 6.76 | 700 | 0.07 |

| 1 × 1017 cm−3 | 1 × 1018 cm−3 | 6.07 | 1050 | 0.18 |

| 1 × 1017 cm−3 | 5 × 1018 cm−3 | 4.51 | 400 | 0.02 |

| 5 × 1017 cm−3 | 1 × 1018 cm−3 | 5.08 | 1450 | 0.42 |

| 5 × 1017 cm−3 | 5 × 1018 cm−3 | 3.56 | 900 | 0.23 |

| 1 × 1018 cm−3 | 5 × 1018 cm−3 | 3.06 | 500 | 0.08 |

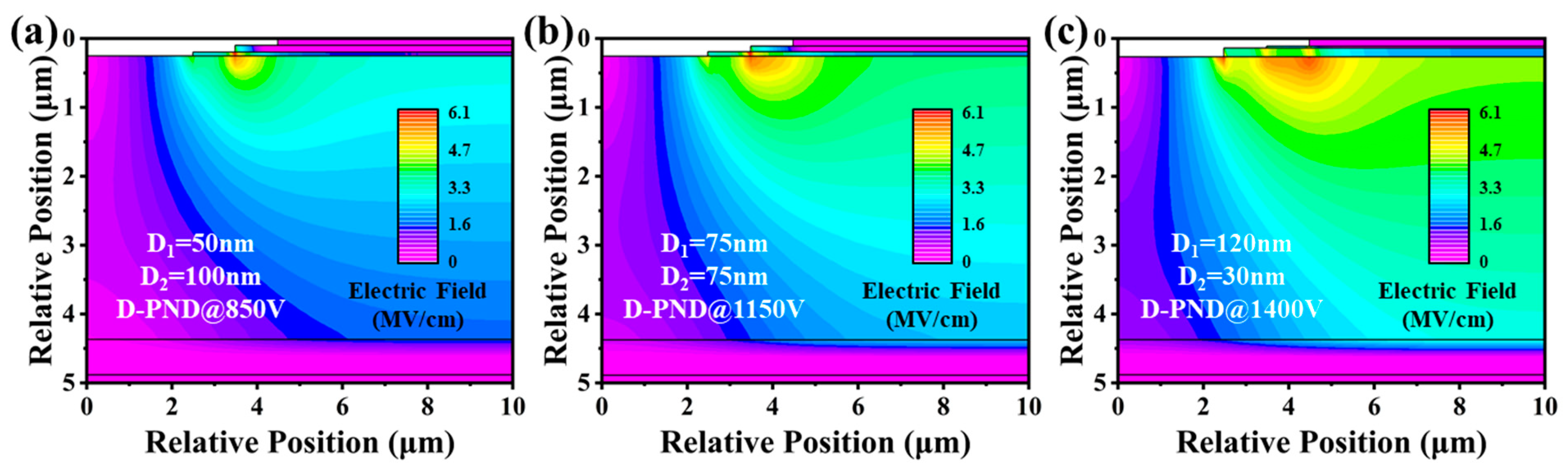

| D1 (nm) | D2 (nm) | Ron (mΩ·cm2) | Vbd (V) | BFOM (GW/cm2) |

|---|---|---|---|---|

| 50 | 100 | 4.94 | 850 | 0.15 |

| 75 | 75 | 5.03 | 1150 | 0.26 |

| 100 | 50 | 5.08 | 1450 | 0.41 |

| 120 | 30 | 5.33 | 1400 | 0.37 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mu, C.; Li, G.; Lv, X.; Wang, Q.; Li, H.; Li, L.; Zou, G. Modulation of Diamond PN Junction Diode with Double-Layered n-Type Diamond by Using TCAD Simulation. Electronics 2024, 13, 1703. https://doi.org/10.3390/electronics13091703

Mu C, Li G, Lv X, Wang Q, Li H, Li L, Zou G. Modulation of Diamond PN Junction Diode with Double-Layered n-Type Diamond by Using TCAD Simulation. Electronics. 2024; 13(9):1703. https://doi.org/10.3390/electronics13091703

Chicago/Turabian StyleMu, Caoyuan, Genzhuang Li, Xianyi Lv, Qiliang Wang, Hongdong Li, Liuan Li, and Guangtian Zou. 2024. "Modulation of Diamond PN Junction Diode with Double-Layered n-Type Diamond by Using TCAD Simulation" Electronics 13, no. 9: 1703. https://doi.org/10.3390/electronics13091703