Research on the Parameter Test and Identification Method of Electromechanical Transient Model for PV Power Generation

Abstract

:1. Introduction

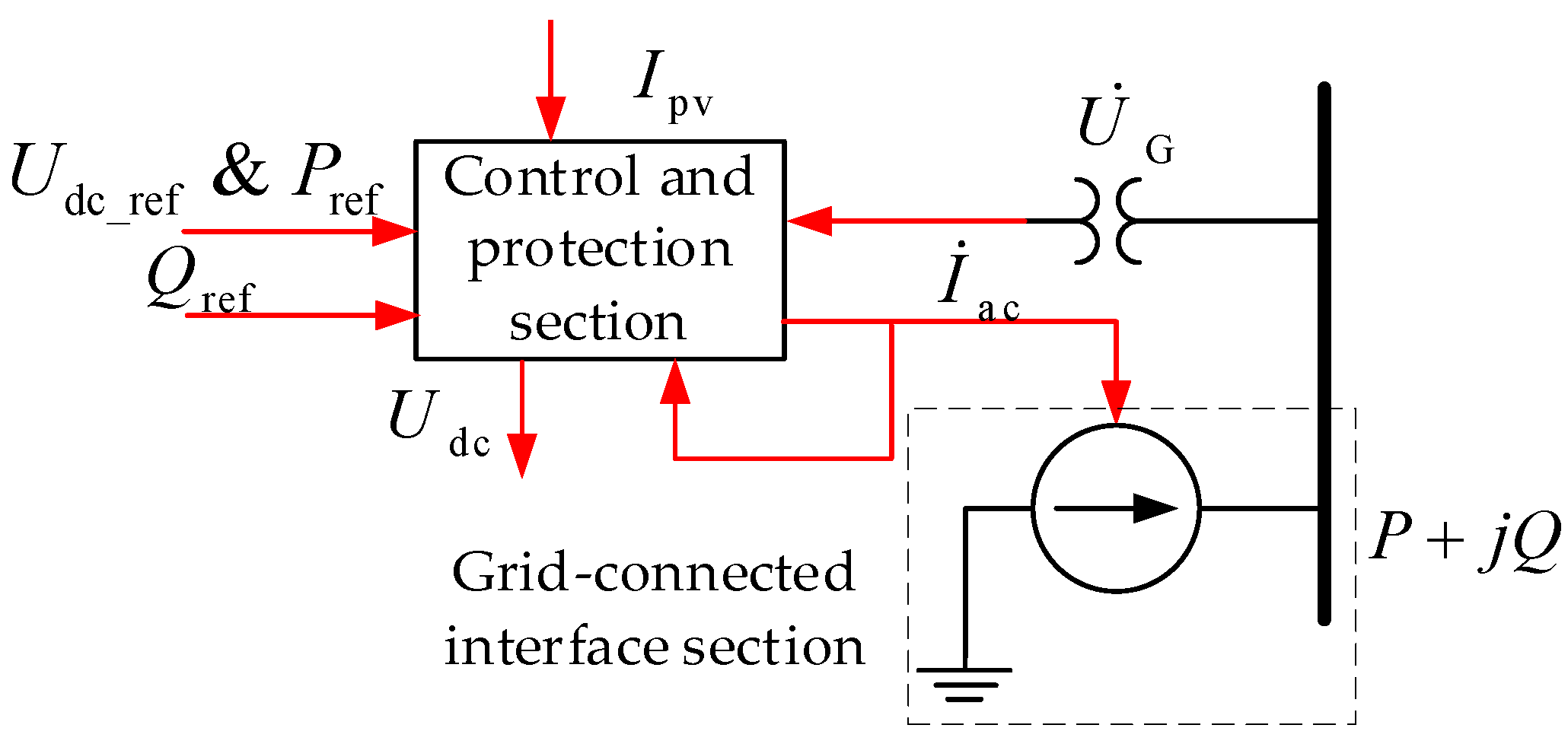

2. Electromechanical Transient Model Structure

2.1. Typical Structure of the PV Power Station

2.2. Model Framework

2.3. PV Array Model

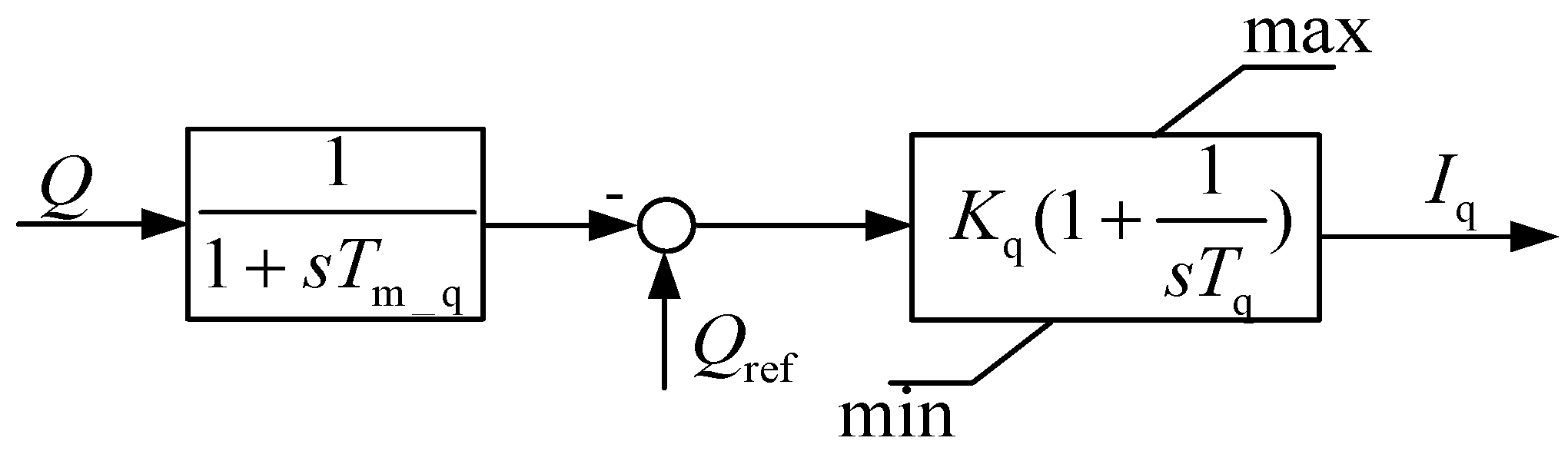

2.4. Inverter Control Model

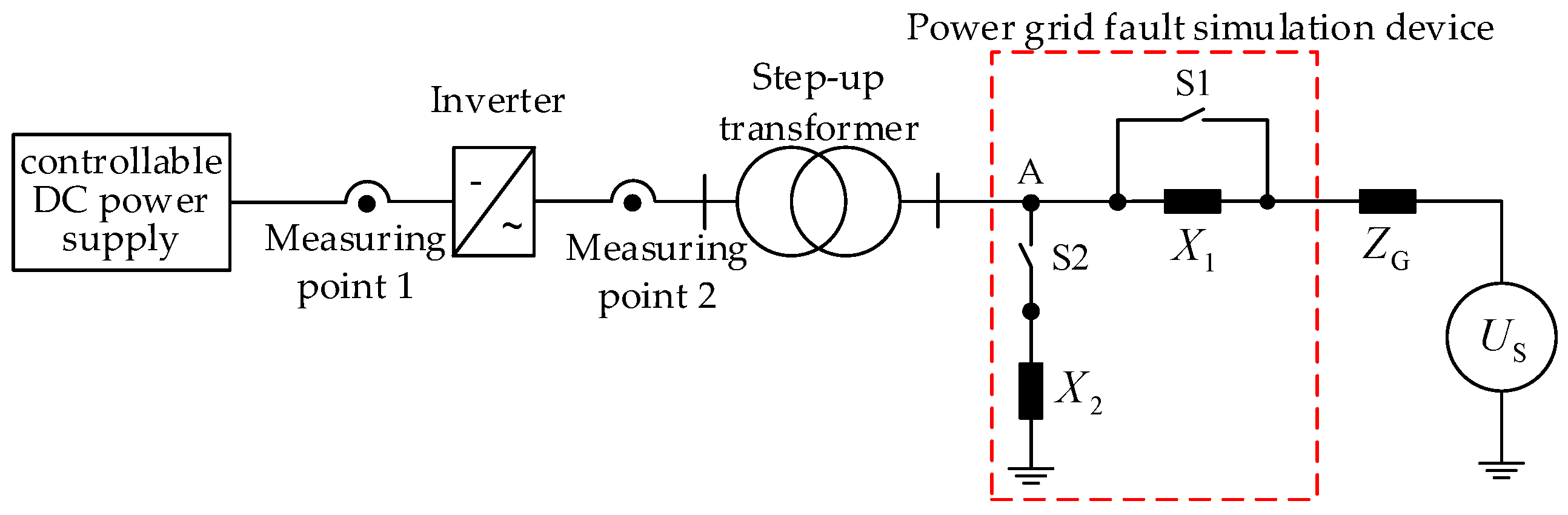

3. Transient Characteristic Test

3.1. Test Principle

3.2. Verification Conditions

- (1)

- Power range: high power output state, P ≥ 0.8 Pp, P is the output active power of the PV power generation unit, Pp is the peak power of the PV power generation unit; intermediate power grade output state, 0.5 Pp ≤ P ≤ 0.7 Pp; low power output state, 0.1 Pp ≤ P ≤ 0.3 Pp.

- (2)

- Fault type: the working conditions of the electromechanical transient model parameters of the PV power generation unit include a three-phase symmetric fault and a two-phase asymmetric fault.

- (3)

- Test data: the instantaneous values of voltage and current on the DC side and AC side of the inverter are measured synchronously.

3.3. AC Small Disturbance Test

- (1)

- The model parameter test should be selected when the output of the inverter is within the high power output range;

- (2)

- exit the inverter MPPT control mode and enter the constant voltage control mode. The reference value of DC voltage is set to 1 p.u. to stable operation;

- (3)

- set the voltage drop (or rise) of the AC side of the inverter to 0.95 and 0.9 p.u. (or 1.05 and 1.1 p.u.), respectively, and the stable operation of the inverter lasts 2 s;

- (4)

- restore the AC side voltage of the inverter to 1 p.u. until stable operation of the inverter.

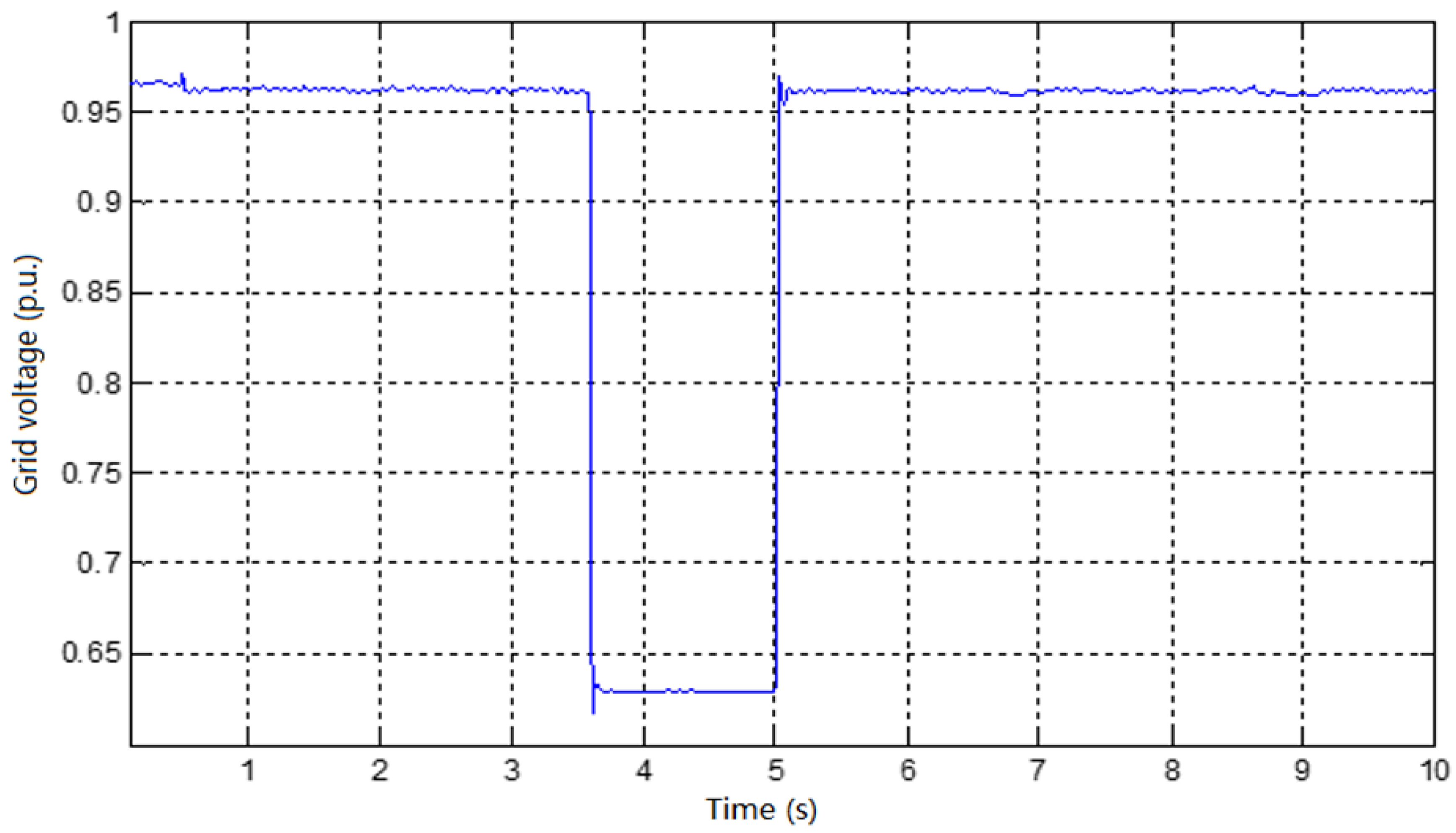

3.4. AC Large Disturbance Test

- (1)

- The model parameter test should be carried out when inverter output is within the high power output range;

- (2)

- exit the inverter MPPT control mode and enter the constant voltage control mode. The reference value of DC voltage is set to 1 p.u. to stable operation;

- (3)

- set the voltage drop of the AC side of the inverter to 0.85 p.u. until stable operation of the inverter, and set the voltage drop of the AC side of the inverter to 0.6, 0.4, 0.2, and 0 p.u. until stable operation of the inverter;

- (4)

- restore the AC side voltage of the inverter to 0.85 p.u. until stable operation of the inverter;

- (5)

- restore the AC side voltage of the inverter to 1 p.u. until stable operation of the inverter.

4. Model Parameter Identification

4.1. Preprocessing of Test Data

- (1)

- Low-pass filter: due to the influence of the on-site test environment, the test data contained a large number of harmonics, which needed to be filtered. In this paper, a first-order low-pass filter was selected. The selection of filter parameters affects the amplitude and phase angle of the measured data. Therefore, the amplitude and phase angle difference caused by the filter must be considered when calculating the output power of the PV power generation unit according to the filtered voltage and current.

- (2)

- Extract the positive sequence component of the fundamental wave: the object of parameter identification is the effective value of the fundamental positive sequence component of each parameter. Therefore, after filtering the high-order harmonic components, extract the fundamental positive sequence components of the voltage and current, then calculate the active power and reactive power output of the PV power generation unit.

- (3)

- Power calculation: the active power and reactive power output of the PV power generation unit are calculated according to the filtered instantaneous values of voltage and current. Among them, the phase difference between voltage and current needs to compensate the phase difference between line voltage and phase current and the phase difference caused by the filter. At the same time, the module calculates the effective values of voltage and current.

- (4)

- Reduce the sampling rate: to ensure the validity of the comparison between test data and simulation data, all data should be in the same dimension, time scale, and resolution format. The disturbance test data are the instantaneous values, and the previously processed data still have a high sampling rate (for example, 100 kHz), while the simulation step of power system transient calculation is millisecond class (for example, 20 ms). Therefore, the average value of the test data is calculated within a simulation step to obtain the test comparison data, and the test data are processed to per unit values.

4.2. Identification Method

5. Model Validation

5.1. Model Simulation

5.2. Model Evaluation

- Period A: before fault, 2 s before voltage disturbance is the beginning of period A, and the beginning time of voltage disturbance is the end of period A.

- Period B: during the fault period, the end of period A is the beginning of period B, and the start of voltage disturbance clearing is the end of period B.

- Period C: after the fault, the end of period B is the beginning of period C, and the 2 s after the active power of PV unit starts to output stably is the end of period C.

- Average deviation of the steady state interval: F1.

- Average deviation of the transient interval: F2.

- Maximum deviation of the steady state interval: F3.

6. Case Study

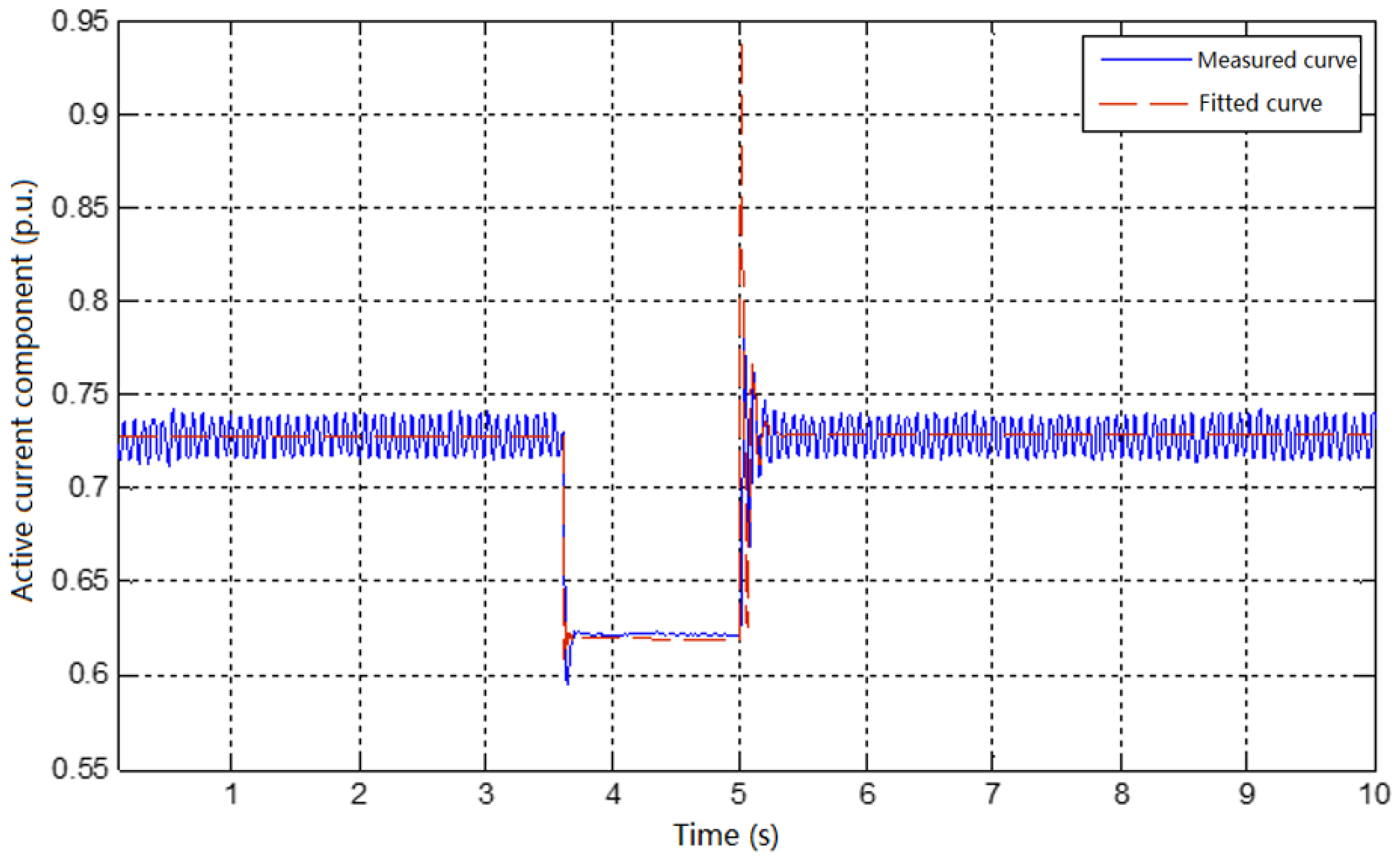

6.1. Parameter Identification under Small Disturbance Mode of the Grid Voltage

- (1)

- Make the output of the inverter reach more than 0.7 p.u. of its rated output power;

- (2)

- After the inverter enters into steady-state operation, the circuit breaker S2 is closed through the grid fault simulation device, and makes the AC side voltage of the inverter drop to near 0.925 p.u.;

- (3)

- The test data are the instantaneous values of DC voltage at measuring point 1 and AC voltage and current at measuring point 2. The voltage and current transformers are used to transmit the measurement signal to the multi-channel wave-recorder to ensure the synchronization of the test data of each channel in time.

6.2. Parameter Identification under Large Disturbance Mode of the Grid Voltage

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Symbol | Definition | Unit |

| Light intensity corresponding to standard test conditions | W/m2 | |

| Ambient temperature corresponding to standard test conditions | °C | |

| Active power control command of PV power station | kW | |

| Reactive power control command of PV power station | kvar | |

| Active power output of PV inverter | kW | |

| Reactive power output of PV inverter | kW | |

| Interface voltage of PV inverter | V | |

| DC voltage of PV inverter | V | |

| Current output of PV array | A | |

| Current output of PV inverter | A | |

| DC reference voltage of PV inverter | V | |

| Active power reference of PV inverter | kW | |

| Reactive power reference of PV inverter | kvar | |

| Active current component of PV inverter | A | |

| Reactive current component of PV inverter | A | |

| Proportional coefficient of active current control | ||

| Time constant of integral link of active current control | s | |

| Proportional coefficient of reactive current control | ||

| Time constant of integral link of reactive current control | s | |

| Inertia time constant of reactive current control | s | |

| AC rated voltage of PV inverter | V | |

| AC rated current of PV inverter | A | |

| Active current support coefficient of inverter in fault ride through | ||

| Reactive current support coefficient of inverter in fault ride through |

References

- Sun, Y.; Xiao, H.; Xie, S. Parameter Solution and Verification of Solar Cells. Power Electron. 2009, 43, 44–47. (In Chinese) [Google Scholar]

- Ai, Y.; Liu, Q.; Han, C.; Ding, J.Y. Photovoltaic MPPT Strategy Based on Improved Perturbation and Observation Method. J. Wuhan Univ. 2020, 53, 339–344. (In Chinese) [Google Scholar]

- Zhang, R.; Zhai, D.; Zhang, Y. MPPT Technology Combining Prediction Model and Disturbance Observation Algorithm. Power Supply Technol. 2020, 44, 429–434. (In Chinese) [Google Scholar]

- Yuan, W.; Wang, T.; Diallo, D.; Delpha, C. A Fault Diagnosis Strategy Based on Multilevel Classification for a Cascaded Photovoltaic Grid-Connected Inverter. Electronics 2020, 9, 429. [Google Scholar] [CrossRef] [Green Version]

- Ko, J.S.; Huh, J.H.; Kim, J.C. Overview of Maximum Power Point Tracking Methods for PV System in Micro Grid. Electronics 2020, 9, 816. [Google Scholar] [CrossRef]

- Lee, H.J.; Yoon, K.H.; Shin, J.W.; Kim, J.C.; Cho, S.M. Optimal Parameters of Volt-Var Function in Smart Inverters for Improving System Performance. Energies 2020, 13, 2294. [Google Scholar] [CrossRef]

- Chiandone, M.; Campaner, R.; Bosich, D.; Sulligoi, G. A Coordinated Voltage and Reactive Power Control Architecture for Large PV Power Plants. Energies 2020, 13, 2441. [Google Scholar] [CrossRef]

- Liao, Z.; Liu, G.; Mei, C. An Improved Non-linear Engineering Mahtematic Model for Silicon Solar Cell. J. Jiangsu University 2010, 31, 442–447. (In Chinese) [Google Scholar]

- Wang, F.; Lin, Z.; Ke, G.; Qiang, L.; Lu, D.; Yong, H. Research on engineering analytical model of solar cells. Trans. China Electrotech. Soc. 2011, 26, 211–216. [Google Scholar]

- Nan, N.; Zhou, S.Q.; Li, Y.D. PV cell modeling based on Bezier function. Power Syst. Technol. 2015, 39, 2195–2200. [Google Scholar]

- Xu, Y.; Gao, Z.; Zhu, X.R. Parameter identification method of phootovoltaic array based on shuffled frog leaping algorithm. Acta Enerciae Solaris Sinica 2019, 40, 1903–1911. [Google Scholar]

- Chatterjee, A.; Keyhani, A.; Kapoor, D. Identification of photovoltaic source models. IEEE Trans. Energy Convers. 2011, 26, 883–889. [Google Scholar] [CrossRef]

- Jing, J.S.; Low, K.S. Photovoltaic model identification using particle swarm optimization with inverse barrier constraint. IEEE Trans. Power Electron. 2012, 27, 3975–3983. [Google Scholar]

- Cheng, Z.; Dong, M.; Yang, T.; Han, L. Extraction of solar cell based on self-adaptive chaos particle swarm optimization algorithm. Trans. China Electrotech. Soc. 2014, 29, 245–252. [Google Scholar]

- Shen, F.; Yin, B.; Sun, W.G. Single-neuron adaptive PID control in MPPT of photovoltaic generation. Proc. CSUEPSA 2017, 29, 89–95. [Google Scholar]

- Hu, G.T.; Zhong, C.C.; Zhang, W.J. Application of BP neural network based on model identification in photovoltaic system MPPT. Comput. Meas. Control 2017, 25, 213–216. [Google Scholar]

- Yang, D.H.; Liu, Y.; Wang, Y.; Xie, W.H. Research on MPPT control algorithm of photovoltaic system by binary ant colony algorithm and fuzzy neural network. J. Electr. Eng. 2017, 12, 41–46. [Google Scholar]

- Zhang, X.Q.; Liu, Y.G.; Zou, Y.Q.; Zhang, C.F. An enchanted photovoltaic MPPT approach based on adaptive neural network control. Acta Energiae Solaris Sinica. 2017, 40, 3091–3102. [Google Scholar]

- Wang, H.; Yi, H.; Peng, J.; Wang, G.; Liu, Y.; Jiang, H.; Liu, W. Deterministic and probabilistic forecasting of photovoltaic power based on deep convolutional neural network. Energy Convers. Manag. 2017, 153, 409–422. [Google Scholar] [CrossRef]

- Zhao, K.N.; Pu, T.J.; Wang, X.Y.; Li, Y. Probabilistic forecasting for photovoltaic power based on improved bayesian neural network. Power Syst. Technol. 2019, 43, 4377–4386. [Google Scholar]

- Tan, J.W. Research on Dynamic Modeling of Photovoltaic Power System. Master’s Thesis, North China Electric Power University, Beijing, China, March 2019. [Google Scholar]

- Liu, Y.Z.; Zhao, D.W.; Zhang, L.; Zhu, L.Z.; Chen, N. Modeling and simulation of the solar photovoltaic systems for grid studies considering the negative sequence control strategy. In Proceedings of the International Conference on Renewable Power Generation, Beijing, China, 17–18 October 2015. [Google Scholar]

- Qu, L.; Zhu, L.; Ge, L.; Sun, M. Research on multi-time scale modeling of photovoltaic power plant. In Proceedings of the International Conference on Renewable Power Generation, Beijing, China, 17–18 October 2015. [Google Scholar]

- Ju, P. Theory and Method of Power System Modeling, 1st ed.; Science Press: Beijing, China, 2010; pp. 145–169. [Google Scholar]

- Li, Y.J.; Zhang, K. Theory and Application of System Identification, 1st ed.; National Defense Industry Press: Beijing, China, 2006; pp. 56–59. [Google Scholar]

- Shi, T.; Yang, H.; Zhang, N.; Hua, G. Research on verification method of electromechanical transient simulation model of battery energy storage system. In Proceedings of the 2020 2nd Asia Energy and Electrical Engineering Symposium, Chengdu, China, 30 May 2020. [Google Scholar]

| Identification Parameters | Damped Least Squares |

|---|---|

| Kd | 0.00269 |

| Td | 0.11447 |

| Period | Deviation Type | Deviation Value |

|---|---|---|

| Period A | Average Deviation | 0.002178 |

| Maximum Deviation | 0.0048 | |

| Period B | Average Deviation | 0.000343 |

| Period C | Average Deviation | 0.000492 |

| Maximum Deviation | 0.0030 | |

| Whole Process | Weighted Average Deviation | 0.000571 |

| Identification Parameters | Damped Least Squares |

|---|---|

| KLVLC | 1.55 |

| Kp | 1.05 |

| Period | Deviation Type | Deviation Value |

|---|---|---|

| Period A | Average Deviation | 0.000813 |

| Maximum Deviation | 0.001898 | |

| Period B | Average Deviation | 0.06815 |

| Period C | Average Deviation | 0.03441 |

| Maximum Deviation | 0.314974 | |

| Whole Process | Weighted Average Deviation | 0.051292 |

| Period | Deviation Type | Deviation Value |

|---|---|---|

| Period A | Average Deviation | 0.0004 |

| Maximum Deviation | 0.016228 | |

| Period B | Average Deviation | 0.005467 |

| Period C | Average Deviation | 0.00156 |

| Maximum Deviation | 0.028566 | |

| Whole Process | Weighted Average Deviation | 0.003788 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, T.; Qu, L.; Ge, L. Research on the Parameter Test and Identification Method of Electromechanical Transient Model for PV Power Generation. Electronics 2020, 9, 1184. https://doi.org/10.3390/electronics9081184

Shi T, Qu L, Ge L. Research on the Parameter Test and Identification Method of Electromechanical Transient Model for PV Power Generation. Electronics. 2020; 9(8):1184. https://doi.org/10.3390/electronics9081184

Chicago/Turabian StyleShi, Tao, Linan Qu, and Luming Ge. 2020. "Research on the Parameter Test and Identification Method of Electromechanical Transient Model for PV Power Generation" Electronics 9, no. 8: 1184. https://doi.org/10.3390/electronics9081184