Hybrid System Combining Ice-Phobic Coating and Electrothermal Heating for Wing Ice Protection

Abstract

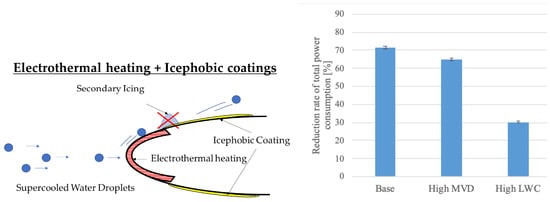

:1. Introduction: Hybrid Ice-Phobic Coating and Electrothermal Heating Wing Ice Protection System (ICE-WIPS)

2. Icing Wind Tunnel and Test Models

2.1. ICE-WIPS Validation at KAIT Icing Wind Tunnel

2.2. ICE-WIPS Demonstration at Icing Research Tunnel

2.3. ICE-WIPS Model

2.4. Power Consumption Estimation

3. Validation Test at KAIT Icing Wind Tunnel

3.1. Test Conditions

3.2. Reduction in Power Consumption by ICE-WIPS

4. Demonstration Test at Large-Scale Icing Wing Tunnel

4.1. Test Condition

4.2. Demonstration Results

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Papadakis, M.; Wong, S.H.; Yeong, H.W.; Wong, S.C.; Vu, G. Icing Tests of a Wing Model with a Hot-Air Ice Protection System. In Proceedings of the AIAA Atmospheric and Space Environments Conference, Toronto, ON, Canada, 2−5 August 2010. [Google Scholar]

- Pellissier, M.P.C.; Habashi, W.G.; Pueyo, A. Optimization via FENSAP-ICE of Aircraft Hot-Air Anti-Icing Systems. J. Aircr. 2011, 48, 265–276. [Google Scholar] [CrossRef]

- Addy Jr, H.E.; Orchard, D.; Wright, W.B.; Oleskiw, M. Altitude Effects on Thermal Ice Protection System performance; A Study of an Alternative Approach; NASA/TM: Washington, DC, USA, 2016; p. 219081. [Google Scholar]

- Pourbagian, M.; Habashi, W.G. CFD-Based Optimization of Electro-Thermal Wing Ice Protection Systems in De-Icing Mode. In Proceedings of the 51st AIAA Aerospace Sciences Meeting Including the New Horizons Forum and Aerospace Exposition, Grapevine, TX, USA, 7−10 January 2013. [Google Scholar]

- Mohseni, M.; Amirfazli, A. A novel electro-thermal anti-icing system for fiber-reinforced polymer composite airfoils. Cold Reg. Sci. Technol. 2013, 87, 47–58. [Google Scholar] [CrossRef]

- Guo, P.; Zheng, Y.; Wen, M.; Song, C.; Lin, Y.; Jiang, L. Icephobic/Anti-Icing Properties of Micro/Nanostructured Surfaces. Adv. Mater. 2012, 24, 2642–2648. [Google Scholar] [CrossRef] [PubMed]

- Ruan, M.; Li, W.; Wang, B.; Deng, B.; Ma, F.; Yu, Z. Preparation and Anti-icing Behavior of Superhydrophobic Surfaces on Aluminum Alloy Substrates. Langmuir 2013, 29, 8482–8491. [Google Scholar] [CrossRef] [PubMed]

- Ganne, A.; Lebed, V.O.; Gavrilov, A.I. Combined wet chemical etching and anodic oxidation for obtaining the superhydrophobic meshes with anti-icing performance. Colloids Surf. A Physicochem. Eng. Asp. 2016, 499, 150–155. [Google Scholar] [CrossRef]

- Zhan, X.; Yan, T.; Zhang, Q.; Chen, F. A novel superhydrophobic hybrid nanocomposite material prepared by surface-initiated AGET ATRP and its anti-icing properties. J. Mater. Chem. A 2014, 2, 9390–9399. [Google Scholar] [CrossRef]

- Menini, R.; Farzaneh, M. Elaboration of Al2O3/PTFE icephobic coatings for protecting aluminum surfaces. Surf. Coat. Technol. 2009, 203, 1941–1946. [Google Scholar] [CrossRef]

- Boinovich, L.B.; Emelyanenko, A.M.; Ivanov, V.K.; Pashinin, A.S. Durable Icephobic Coating for Stainless Steel. ACS Appl. Mater. Interfaces 2013, 5, 2549–2554. [Google Scholar] [CrossRef] [PubMed]

- Menini, R.; Farzaneh, M. Advanced Icephobic Coatings. J. Adhes. Sci. Technol. 2011, 25, 971–992. [Google Scholar] [CrossRef]

- Laforte, C.; Beisswenger, A. Icephobic Material Centrifuge Adhesion Test. In Proceedings of the International Workshop on Atmospheric Icing of Structures (IWAIS), Montreal, Canada, 12−16 June 2005. [Google Scholar]

- Susoff, M.; Siegmann, K.; Pfaffenroth, C.; Hirayama, M. Evaluation of icephobic coatings—Screening of different coatings and influence of roughness. Cold Reg. Sci. Technol. 2013, 282, 870–879. [Google Scholar] [CrossRef] [Green Version]

- Dotan, A.; Dodiuk, H.; Laforte, C.; Kenig, S. The Relationship between Water Wetting and Ice Adhesion. J. Adhes. Sci. Technol. 2009, 23, 1907–1915. [Google Scholar]

- Minsk, L.D. How are Ice phobic coatings. In Proceedings of the First International Workshop, Atmospheric Icing of Structures, Cold Regions Research & Engineering Laboratory, Hanover, NH, USA, 1−3 June 1982; pp. 93–95. [Google Scholar]

- Fortin, G. Considerations on the Use of Hydrophobic, Superhydrophobic or Icephobic Coatings as a Part of the Aircraft Ice Protection System; SAE Technical Paper 2013-01-2018: Warrendale, PA, USA, 2013. [Google Scholar]

- Papadakis, M.; Hung, K.E.; Vu, G.T.; Yeong, H.W.; Bidwell, C.S.; Breer, M.D.; Bencic, T.J. Experimental Investigation of Water Droplet Impingement on Airfoils, Finite Wings, and an S-Duct Engine Inlet; NASA/TM: Washington, DC, USA, 2002, 211700. [Google Scholar]

- Morita, K.; Gonzales, J.; Sakaue, H. Effect of PTFE Particle Size on Superhydrophobic Coating for Supercooled Water Prevention. Coatings 2018, 8, 426. [Google Scholar] [CrossRef] [Green Version]

- Federal Aviation Administration. Code of Federal Regulations; Federal Aviation Administration: Washington, DC, USA, 2014. [Google Scholar]

- Yokogawa Test & Measurement Corporation. WT1800 Precision Power Analyzer Getting Started Guide; Yokogawa Test & Measurement Corporation: Tokyo, Japan, 2011. [Google Scholar]

| Case | Base | High LWC |

|---|---|---|

| LWC [g/m3] | 0.6 | 0.4 |

| MVD [µm] | 16.0 | 21.4 |

| Temperature [°C] | −8.5~−8.0 | −10.0~−8.0 |

| A.O.A. [deg.] | 0 | 0 |

| Wind Speed [m/s] | 75 | 75 |

| Case | Base | High MVD | ||||

|---|---|---|---|---|---|---|

| Heating Area | HLE | H0510 | H1015 | HLE | H0510 | H1015 |

| Reference | 1.000 ± 0.007 | 0.551 ± 0.006 | 1.146 ± 0.009 | 1.000 ± 0.005 | 0.427 ± 0.005 | 1.006 ± 0.007 |

| ICE-WIPS | 0.180 ± 0.002 | 0.126 ± 0.005 | 0.232 ± 0.005 | 0.239 ± 0.002 | 0.168 ± 0.004 | 0.255 ± 0.005 |

| Case | Base | High MVD | High LWC |

|---|---|---|---|

| LWC [g/m3] | 0.6 | 0.5 | 1.3 |

| MVD [µm] | 15.0 | 21.3 | 21.0 |

| Temperature [°C] | −5.0 | −5.0 | −5.0 |

| A.O.A. [deg.] | 0 | 0 | 0 |

| Wind Speed [m/s] | 75 | 75 | 75 |

| Heating Area | HLE | H0510 | H1015 | |||

|---|---|---|---|---|---|---|

| Model | Reference | ICE-WIPS | Reference | ICE-WIPS | Reference | ICE-WIPS |

| Base | 1.000 ± 0.007 | 0.180 ± 0.002 | 0.551 ± 0.006 | 0.126 ± 0.005 | 1.146 ± 0.009 | 0.232 ± 0.005 |

| High MVD | 1.000 ± 0.005 | 0.239 ± 0.002 | 0.427 ± 0.005 | 0.168 ± 0.006 | 1.006 ± 0.007 | 0.255 ± 0.005 |

| High LWC | 1.000 ± 0.005 | 0.880 ± 0.004 | 0.912 ± 0.005 | 0.583 ± 0.004 | 1.148 ± 0.006 | 0.653 ± 0.004 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Morita, K.; Kimura, S.; Sakaue, H. Hybrid System Combining Ice-Phobic Coating and Electrothermal Heating for Wing Ice Protection. Aerospace 2020, 7, 102. https://doi.org/10.3390/aerospace7080102

Morita K, Kimura S, Sakaue H. Hybrid System Combining Ice-Phobic Coating and Electrothermal Heating for Wing Ice Protection. Aerospace. 2020; 7(8):102. https://doi.org/10.3390/aerospace7080102

Chicago/Turabian StyleMorita, Katsuaki, Shigeo Kimura, and Hirotaka Sakaue. 2020. "Hybrid System Combining Ice-Phobic Coating and Electrothermal Heating for Wing Ice Protection" Aerospace 7, no. 8: 102. https://doi.org/10.3390/aerospace7080102