Ammonia Sensor Based on Co2+/SCN− Modified Core-Shell MCM-41 for Rapid Naked-Eye Colorimetric Detection

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of SiO2 and Core-Shell MCM-41@SiO2 Nanoparticles

2.3. Functionalization of MCM-41@SiO2

2.4. NH3 Detection Tube Sensor Fabrication and Performance Characterization

2.5. Humidity Test and Long-Term Stability Test

2.6. Selectivity and Reusability Tests

3. Results and Discussion

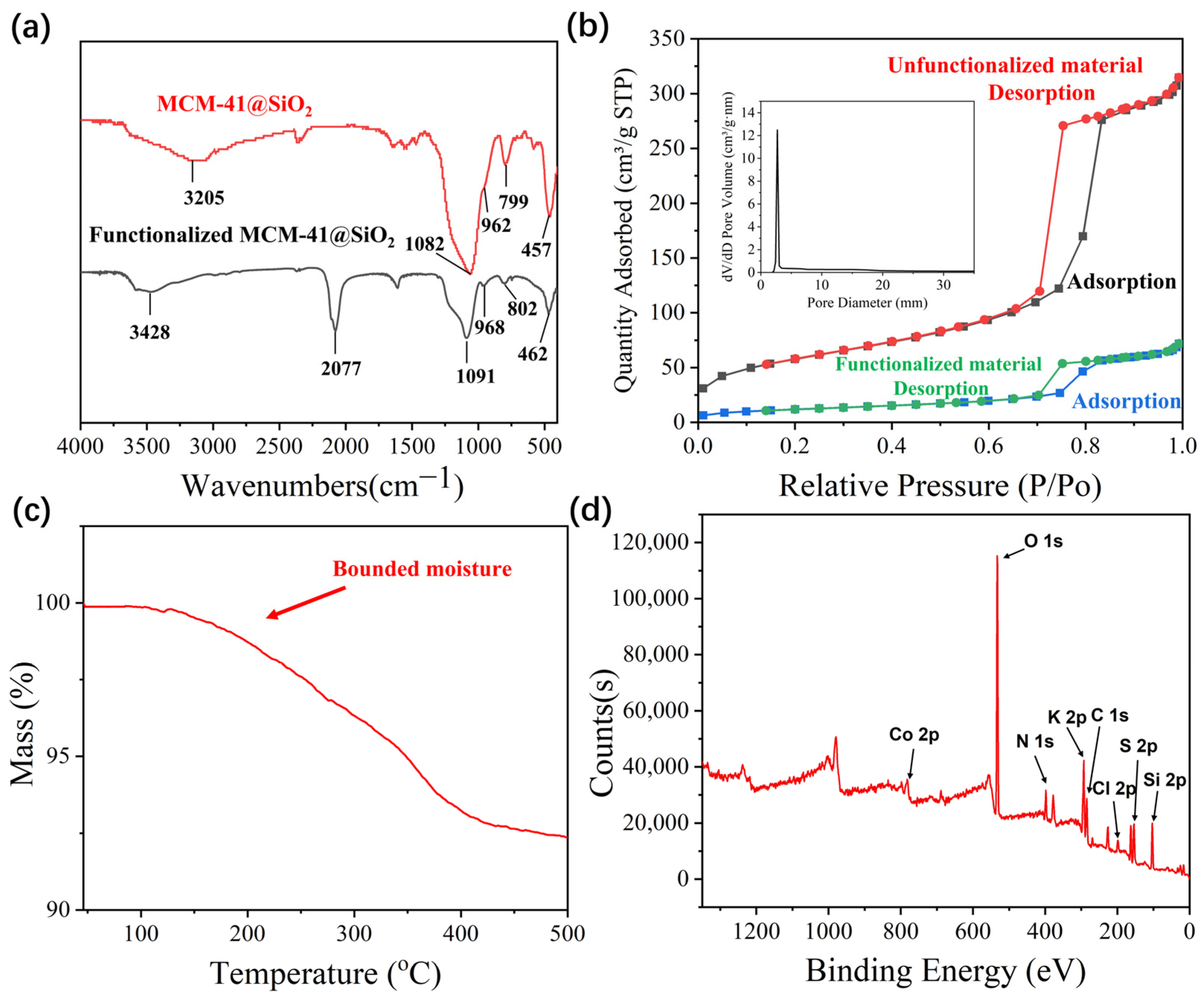

3.1. Characterizations of SiO2 and Core-Shell MCM-41@SiO2 Nanoparticles

3.2. Functionalization of the Core-Shell MCM-41@SiO2 Mesoporous Material

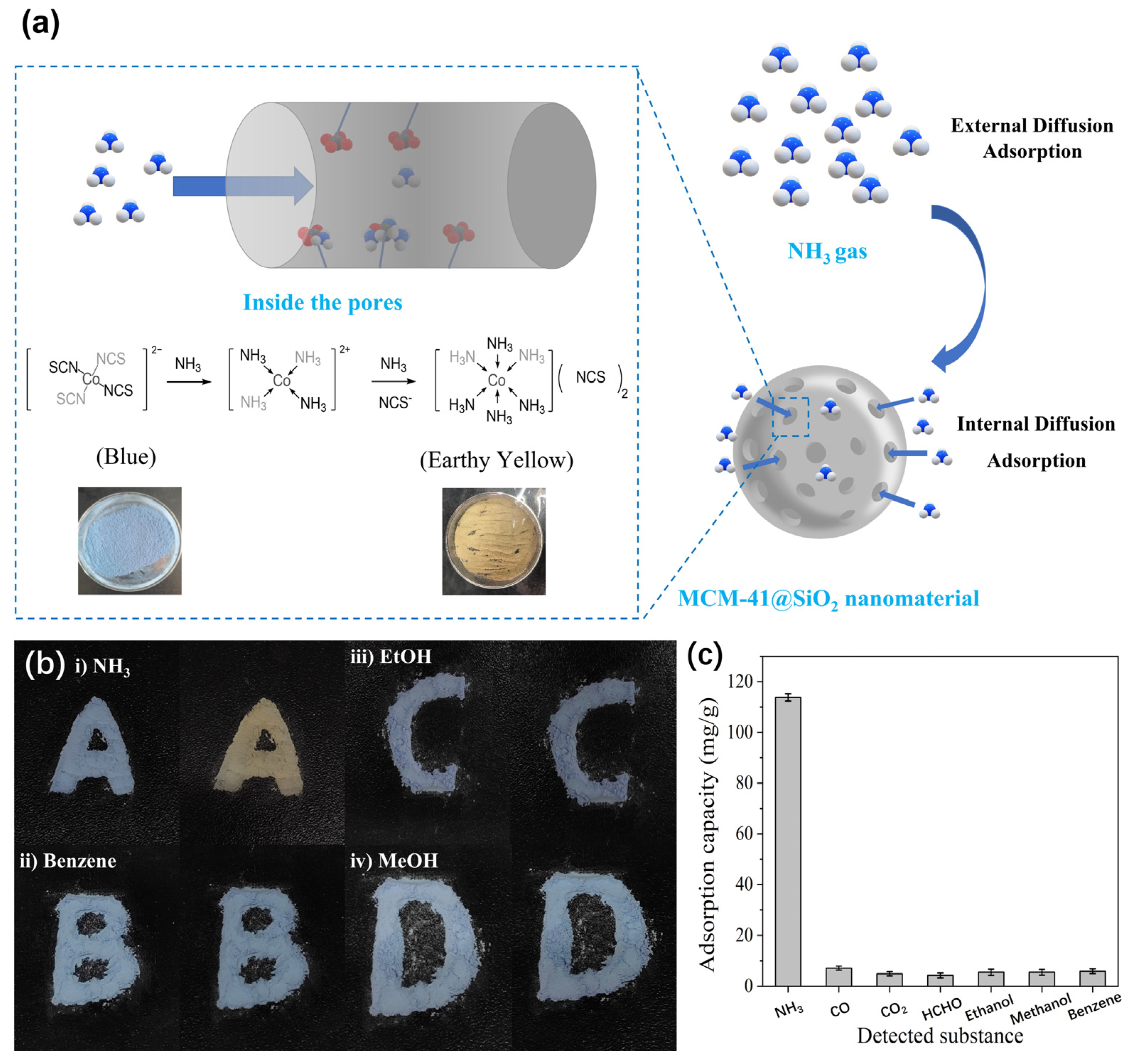

3.3. The Fabrication of Colorimetric Detection Tube and Its Detection Performance

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, X.; Gu, B.; van Grinsven, H.; Lam, S.K.; Liang, X.; Bai, M.; Chen, D. Societal benefits of halving agricultural ammonia emissions in China far exceed the abatement costs. Nat. Commun. 2020, 11, 4357. [Google Scholar] [CrossRef] [PubMed]

- Sienkiewicz, A.; Rusinek, I.; Siatecka, A.; Losada-Barreiro, S. Flower Color Change Demonstration as a Visualization of Potential Harmful Effects Associated with Ammonia Gas on Living Organisms. J. Chem. Educ. 2019, 96, 1982. [Google Scholar] [CrossRef]

- Ma, R.; Li, K.; Guo, Y.; Zhang, B.; Zhao, X.; Linder, S.; Guan, C.; Chen, G.; Gan, Y.; Meng, J. Mitigation potential of global ammonia emissions and related health impacts in the trade network. Nat. Commun. 2021, 12, 6308. [Google Scholar] [CrossRef]

- Claeys, W.; Van Hoecke, L.; Geerts, A.; Van Vlierberghe, H.; Lefere, S.; Van Imschoot, G.; Van Wonterghem, E.; Ghesquiere, B.; Vandenbroucke, R.E.; Van Steenkiste, C. A mouse model of hepatic encephalopathy: Bile duct ligation induces brain ammonia overload, glial cell activation and neuroinflammation. Sci. Rep. 2022, 12, 17558. [Google Scholar] [CrossRef] [PubMed]

- Zhao, H.; Liu, L.; Lin, X.; Dai, J.; Liu, S.; Fei, T.; Zhang, T. Proton-Conductive Gas Sensor: A New Way to Realize Highly Selective Ammonia Detection for Analysis of Exhaled Human Breath. ACS Sens. 2020, 5, 346. [Google Scholar] [CrossRef]

- Zheivot, V.I.; Nikoro, T.A.; Krivoruchko, V.N.; Panina, L.I.; Pinaeva, L.G.; Isupova, L.A. Potentials of gas chromatography in the determination of reaction products in the catalytic oxidation of ammonia to nitrogen(II) oxide. J. Anal. Chem. 2007, 62, 1170. [Google Scholar] [CrossRef]

- Trubyanov, M.M.; Mochalov, G.M.; Suvorov, S.S.; Puzanov, E.S.; Petukhov, A.N.; Vorotyntsev, I.V.; Vorotyntsev, V.M. Towards the interaction between calcium carbide and water during gas-chromatographic determination of trace moisture in ultra-high purity ammonia. J. Chromatogr. A 2018, 1560, 71. [Google Scholar] [CrossRef] [PubMed]

- Zaffaroni, R.; Ripepi, D.; Middelkoop, J.; Mulder, F.M. Gas Chromatographic Method for In Situ Ammonia Quantification at Parts per Billion Levels. ACS Energy Lett. 2020, 5, 3773. [Google Scholar] [CrossRef]

- Brunnemann, K.D.; Hoffmann, D. Chemical studies on tobacco smoke. XXXIV. Gas chromatographic determination of ammonia in cigarette and cigar smoke. J. Chromatogr. Sci. 1975, 13, 159. [Google Scholar] [CrossRef]

- Chakraborthy, A.; Nuthalapati, S.; Nag, A.; Afsarimanesh, N.; Alahi, M.E.E.; Altinsoy, M.E. A Critical Review of the Use of Graphene-Based Gas Sensors. Chemosensors 2022, 10, 355. [Google Scholar] [CrossRef]

- Ren, Z.; Shi, Y.; Song, T.; Wang, T.; Tang, B.; Niu, H.; Yu, X. Flexible Low-Temperature Ammonia Gas Sensor Based on Reduced Graphene Oxide and Molybdenum Disulfide. Chemosensors 2021, 9, 345. [Google Scholar] [CrossRef]

- Patial, P.; Deshwal, M. Selectivity and Sensitivity Property of Metal Oxide Semiconductor Based Gas Sensor with Dopants Variation: A Review. Trans. Electr. Electron. Mater. 2021, 23, 6. [Google Scholar] [CrossRef]

- Song, X.; Hu, R.; Xu, S.; Liu, Z.; Wang, J.; Shi, Y.; Xu, J.; Chen, K.; Yu, L. Highly Sensitive Ammonia Gas Detection at Room Temperature by Integratable Silicon Nanowire Field-Effect Sensors. ACS Appl. Mater. Interfaces 2021, 13, 14377. [Google Scholar] [CrossRef] [PubMed]

- Wang, P.; Wang, T.; Li, F.; Li, D.; Yang, Y.; Yu, H.; Dong, X. Enhanced sensing response of the first polyoxometalate electron acceptor modified MoS2 for NO2 gas detection at room temperature. Sens. Actuators B Chem. 2023, 382, 133495. [Google Scholar] [CrossRef]

- Wang, P.; Wang, T.; Pei, W.; Li, F.; Yang, Y.; Yu, H.; Dong, X. Bi-function of photocatalytic Cr(VI) removal and monitoring acetone gas by one-dimensional hierarchical TiO2 @polyoxometalates@MoS2 tandem heterojunctions. Sens. Actuators B Chem. 2023, 387, 133743. [Google Scholar] [CrossRef]

- Kanaparthi, S.; Singh, S.G. Solvent-free fabrication of a room temperature ammonia gas sensor by frictional deposition of a conducting polymer on paper. Org. Electron. 2019, 68, 108. [Google Scholar] [CrossRef]

- Ratan, S.; Kumar, C.; Kumar, A.; Jarwal, D.K.; Mishra, A.K.; Upadhyay, R.K.; Singh, A.P.; Jit, S. Room temperature high hydrogen gas response in Pd/TiO2/Si/Al capacitive sensor. Micro Nano Lett. 2020, 15, 632. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, S.; Zhang, D.; Yang, Y.; Zhao, J.; Yu, H.; Wang, T.; Wang, T.; Dong, X. Conductometric room temperature NOx sensor based on metal-organic framework-derived Fe2O3/Co3O4 nanocomposite. Sens. Actuators B Chem. 2023, 390, 133894. [Google Scholar] [CrossRef]

- Panes-Ruiz, L.A.; Shaygan, M.; Fu, Y.; Liu, Y.; Khavrus, V.; Oswald, S.; Gemming, T.; Baraban, L.; Bezugly, V.; Cuniberti, G. Toward Highly Sensitive and Energy Efficient Ammonia Gas Detection with Modified Single-Walled Carbon Nanotubes at Room Temperature. ACS Sens. 2018, 3, 79. [Google Scholar] [CrossRef] [Green Version]

- Tu, Y.; Kyle, C.; Luo, H.; Zhang, D.W.; Das, A.; Briscoe, J.; Dunn, S.; Titirici, M.M.; Krause, S. Ammonia Gas Sensor Response of a Vertical Zinc Oxide Nanorod-Gold Junction Diode at Room Temperature. ACS Sens. 2020, 5, 3568. [Google Scholar] [CrossRef]

- Bang, J.H.; Lim, S.H.; Park, E.; Suslick, K.S. Chemically responsive nanoporous pigments: Colorimetric sensor arrays and the identification of aliphatic amines. Langmuir 2008, 24, 13168. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, Z. Nanoporous Silica-Dye Microspheres for Enhanced Colorimetric Detection of Cyclohexanone. Chemosensors 2018, 6, 34. [Google Scholar] [CrossRef] [Green Version]

- Jaikang, P.; Paengnakorn, P.; Grudpan, K. Simple colorimetric ammonium assay employing well microplate with gas pervaporation and diffusion for natural indicator immobilized paper sensor via smartphone detection. Microchem. J. 2020, 152, 104283. [Google Scholar] [CrossRef]

- Hoang, A.T.; Cho, Y.B.; Kim, Y.S. A strip array of colorimetric sensors for visualizing a concentration level of gaseous analytes with basicity. Sens. Actuators B Chem. 2017, 251, 1089. [Google Scholar] [CrossRef]

- Kim, D.H.; Cha, J.H.; Lim, J.Y.; Bae, J.; Lee, W.; Yoon, K.R.; Kim, C.; Jang, J.S.; Hwang, W.; Kim, I.D. Colorimetric Dye-Loaded Nanofiber Yarn: Eye-Readable and Weavable Gas Sensing Platform. ACS Nano 2020, 14, 16907. [Google Scholar] [CrossRef] [PubMed]

- Al-Qahtani, S.D.; Habeebullah, T.M.; Alsoliemy, A.; Alzahrani, H.K.; Shah, R.; Alfi, A.A.; El-Metwaly, N.M. Preparation of polyvinyl alcohol reinforced with microcrystalline cellulose to function as test strips immobilized with a hydrazone chromophore for colorimetric identification of toxic ammonia. Mater. Chem. Phys. 2022, 275, 125218. [Google Scholar] [CrossRef]

- Esmaeili, S.; Zanjanchi, M.A.; Golmojdeh, H.; Shariati, S. Modification of MCM-410-Based Core-Shell for Construction of a Colorimetric Gas Sensor. IEEE Sens. J. 2021, 21, 17665. [Google Scholar] [CrossRef]

- Kruk, M.; Jaroniec, M.; Ko, C.H.; Ryoo, R. Characterization of the Porous Structure of SBA-15. Chem. Mater. 2000, 12, 1961. [Google Scholar] [CrossRef]

- Kishor, R.; Ghoshal, A.K. Amine-Modified Mesoporous Silica for CO2 Adsorption: The Role of Structural Parameters. Ind. Eng. Chem. Res. 2017, 56, 6078. [Google Scholar] [CrossRef]

- Li, C.; Wang, X.; Yang, A.; Chen, P.; Zhao, T.; Liu, F. Polyethyleneimine-Modified Amorphous Silica for the Selective Adsorption of CO(2)/N(2) at High Temperatures. ACS Omega 2021, 6, 35389. [Google Scholar] [CrossRef]

- He, S.; Han, C.; Wang, H.; Zhu, W.; He, S.; He, D.; Luo, Y. Uptake of Arsenic(V) Using Alumina Functionalized Highly Ordered Mesoporous SBA-15 (Alx-SBA-15) as an Effective Adsorbent. J. Chem. Eng. Data 2015, 60, 1300. [Google Scholar] [CrossRef]

- Pan, Q.; Ramanathan, A.; Snavely, W.K.; Chaudhari, R.V.; Subramaniam, B. Synthesis and Dehydration Activity of Novel Lewis Acidic Ordered Mesoporous Silicate: Zr-KIT-6. Ind. Eng. Chem. Res. 2013, 52, 15481. [Google Scholar] [CrossRef]

- Guillet-Nicolas, R.; Bérubé, F.; Thommes, M.; Janicke, M.T.; Kleitz, F. Selectively Tuned Pore Condensation and Hysteresis Behavior in Mesoporous SBA-15 Silica: Correlating Material Synthesis to Advanced Gas Adsorption Analysis. J. Phys. Chem. C 2017, 121, 24505. [Google Scholar] [CrossRef]

- Kishor, R.; Ghoshal, A.K. Polyethylenimine Functionalized As-Synthesized KIT-6 Adsorbent for Highly CO2/N2 Selective Separation. Energy Fuels 2016, 30, 9635. [Google Scholar] [CrossRef]

- Safaei Ghomi, J.; Akbarzadeh, Z.; Bakhtiari, A. Organic–inorganic hybrid material, dichloro N,N′-(1,2-phenylene)bis(2-aminobenzamide) cobalt(II)@Al-SBA-15: An environment friendly catalyst for the synthesis of 3-benzoxazol-2-yl-chromen-2-ones. J. Coord. Chem. 2019, 72, 826. [Google Scholar] [CrossRef]

- Meléndez-Ortiz, H.I.; Puente-Urbina, B.; Mercado-Silva, J.A.; García-Uriostegui, L. Adsorption performance of mesoporous silicas towards a cationic dye. Influence of mesostructure on adsorption capacity. Int. J. Appl. Ceram. Technol. 2019, 16, 1533. [Google Scholar] [CrossRef]

- Tillman, L.; Voskanyan, A.; Navrotsky, A. Synthesis of mesoporous silica using a mineral silica source. J. Am. Ceram. Soc. 2022, 106, 1993. [Google Scholar] [CrossRef]

- Ming, W.; Ma, J.; Wang, Y.; Li, R. Preparation and characterisation of MCM-41 materials with intra-wall cross-mesopores. Micro Nano Lett. 2015, 10, 363. [Google Scholar] [CrossRef]

- Zhao, X.S.; Ma, Q.; Lu, G.Q. VOC Removal: Comparison of MCM-41 with Hydrophobic Zeolites and Activated Carbon. Energy Fuels 1998, 12, 1051. [Google Scholar] [CrossRef]

- Yue, M.B.; Sun, L.B.; Cao, Y.; Wang, Y.; Wang, Z.J.; Zhu, J.H. Efficient CO2 capturer derived from as-synthesized MCM-41 modified with amine. Chemistry 2008, 14, 3442. [Google Scholar] [CrossRef]

- Zhao, X.S.; Lu, G.Q. Modification of MCM-41 by Surface Silylation with Trimethylchlorosilane and Adsorption Study. J. Phys. Chem. B 1998, 102, 1556. [Google Scholar] [CrossRef]

- Nguyen, H.T.T.; Habu, T.; Ohtani, M.; Kobiro, K. One-Step Direct Synthesis of SiO2–TiO2 Composite Nanoparticle Assemblies with Hollow Spherical Morphology. Eur. J. Inorg. Chem. 2017, 2017, 3017. [Google Scholar] [CrossRef]

- Potapov, V.V.; Cerdan, A.A.; Gorev, D.S. Silicic Acid Polymerization and SiO2 Nanoparticle Growth in Hydrothermal Solution. Polymers 2022, 14, 4044. [Google Scholar] [CrossRef] [PubMed]

| Entry | Stirring Speed (r/min) | Temperature (°C) | Aqua Ammonia:TEOS (v/v) | Diameter of SiO2 Nanoparticles (nm) | PDI | Diameter of MCM-41@SiO2 |

|---|---|---|---|---|---|---|

| 1 | 100 | 20 | 2:1 | 750 | 0.103 | 1200 |

| 2 | 200 | 20 | 2:1 | 680 | 0.082 | 1150 |

| 3 | 300 | 20 | 2:1 | 510 | 0.071 | 900 |

| 4 | 400 | 20 | 2:1 | 425 | 0.174 | 630 |

| 5 | 300 | 0 | 2:1 | 705 | 0.113 | - |

| 6 | 300 | 30 | 2:1 | 490 | 0.089 | - |

| 7 | 300 | 50 | 2:1 | 440 | 0.095 | - |

| 8 | 300 | 20 | 1:1 | 500 | 0.072 | - |

| 9 | 300 | 20 | 3:1 | 495 | 0.091 | - |

| 10 | 300 | 20 | 4:1 | 510 | 0.057 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, S.; Wei, K.; Cheng, F.; Li, Y.; Xue, M. Ammonia Sensor Based on Co2+/SCN− Modified Core-Shell MCM-41 for Rapid Naked-Eye Colorimetric Detection. Chemosensors 2023, 11, 336. https://doi.org/10.3390/chemosensors11060336

Liu S, Wei K, Cheng F, Li Y, Xue M. Ammonia Sensor Based on Co2+/SCN− Modified Core-Shell MCM-41 for Rapid Naked-Eye Colorimetric Detection. Chemosensors. 2023; 11(6):336. https://doi.org/10.3390/chemosensors11060336

Chicago/Turabian StyleLiu, Songtao, Kaixin Wei, Fuqiang Cheng, Yongsheng Li, and Min Xue. 2023. "Ammonia Sensor Based on Co2+/SCN− Modified Core-Shell MCM-41 for Rapid Naked-Eye Colorimetric Detection" Chemosensors 11, no. 6: 336. https://doi.org/10.3390/chemosensors11060336