The Bi-Level Optimization Model Research for Energy-Intensive Load and Energy Storage System Considering Congested Wind Power Consumption

Abstract

:1. Introduction

2. Uncertainty Analysis of Wind Power

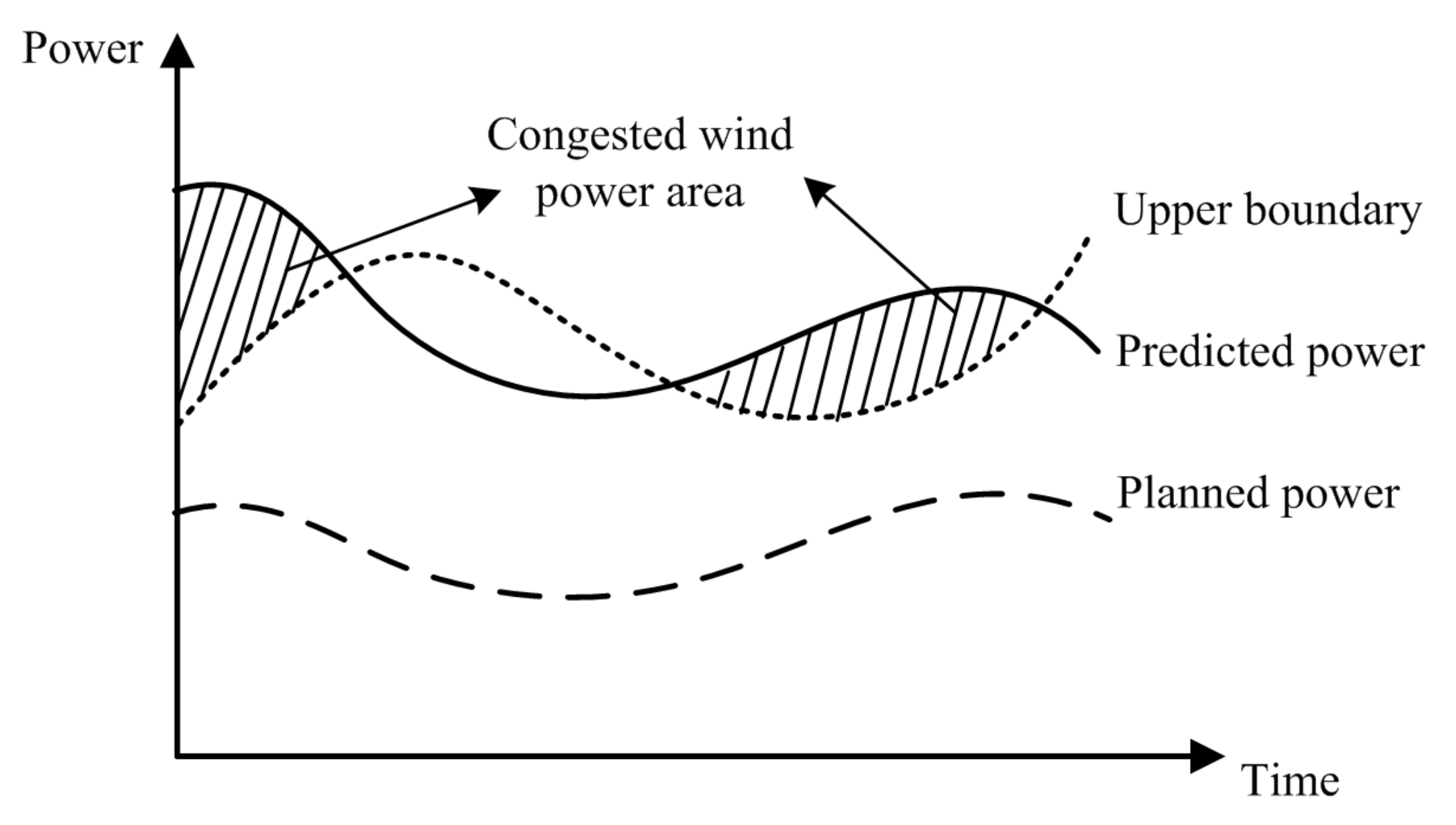

2.1. The Admissible Region of Wind Power

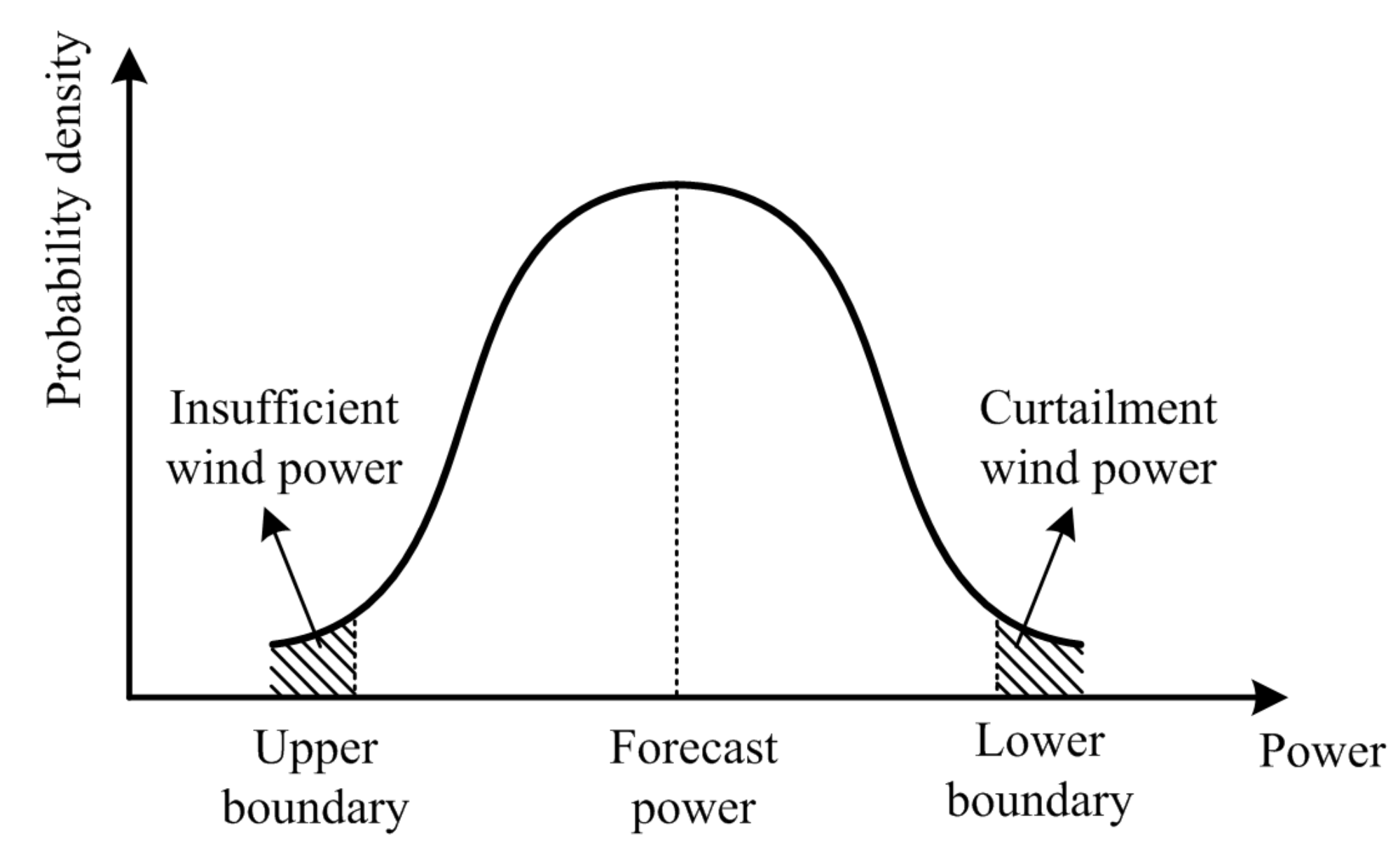

2.2. Distribution of Wind Power Output

2.3. Risk Analysis of Wind Curtailment

3. Model of Energy-Intensive Load Dispatching

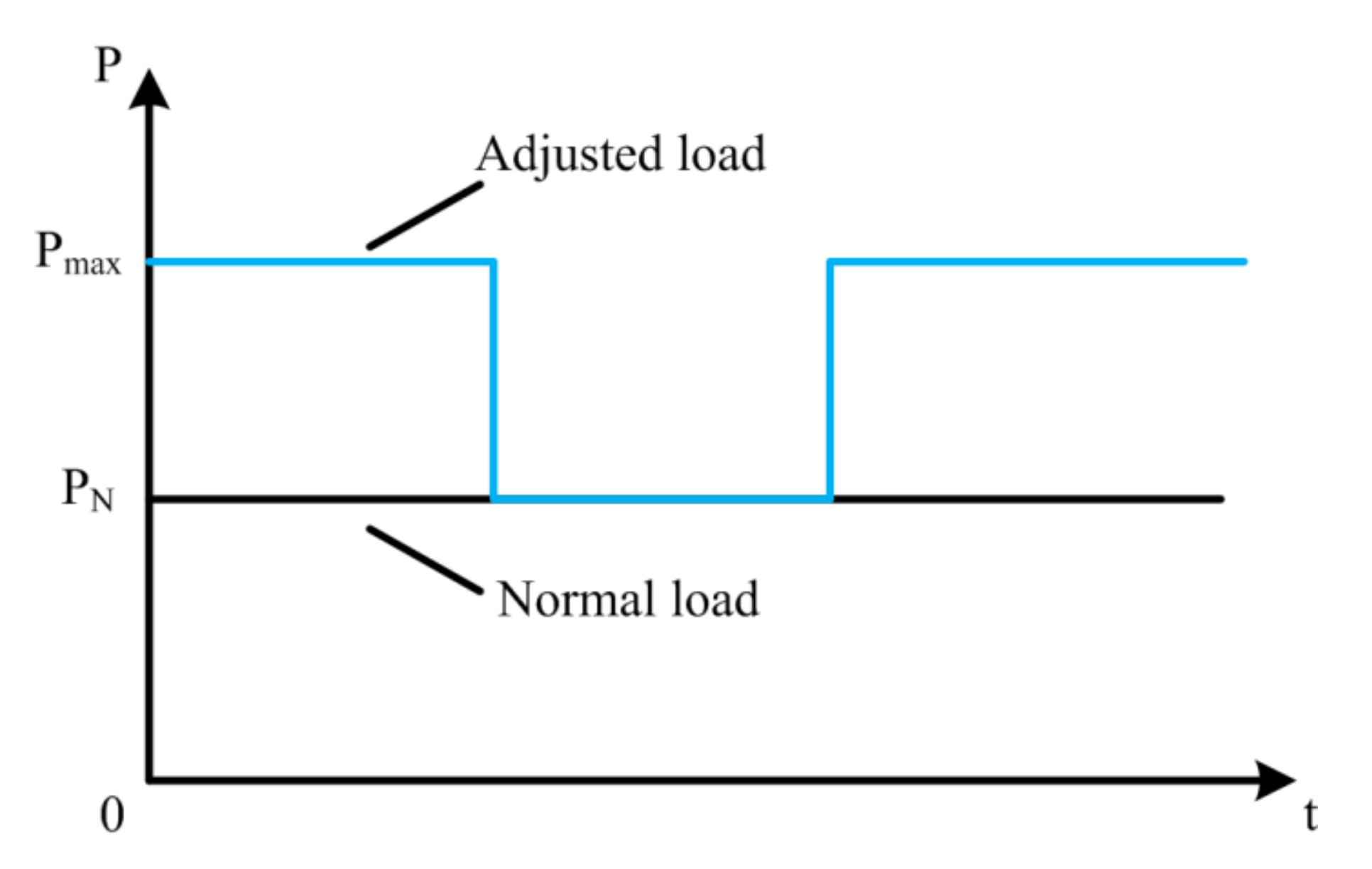

3.1. Regulation Characteristics of Energy-Intensive Load

- (1)

- Electrolytic aluminum production load

- (2)

- Titanium alloy production load

3.2. Model of Energy-Intensive Load Dispatching

3.3. Risk Constraints of Energy-Intensive Load

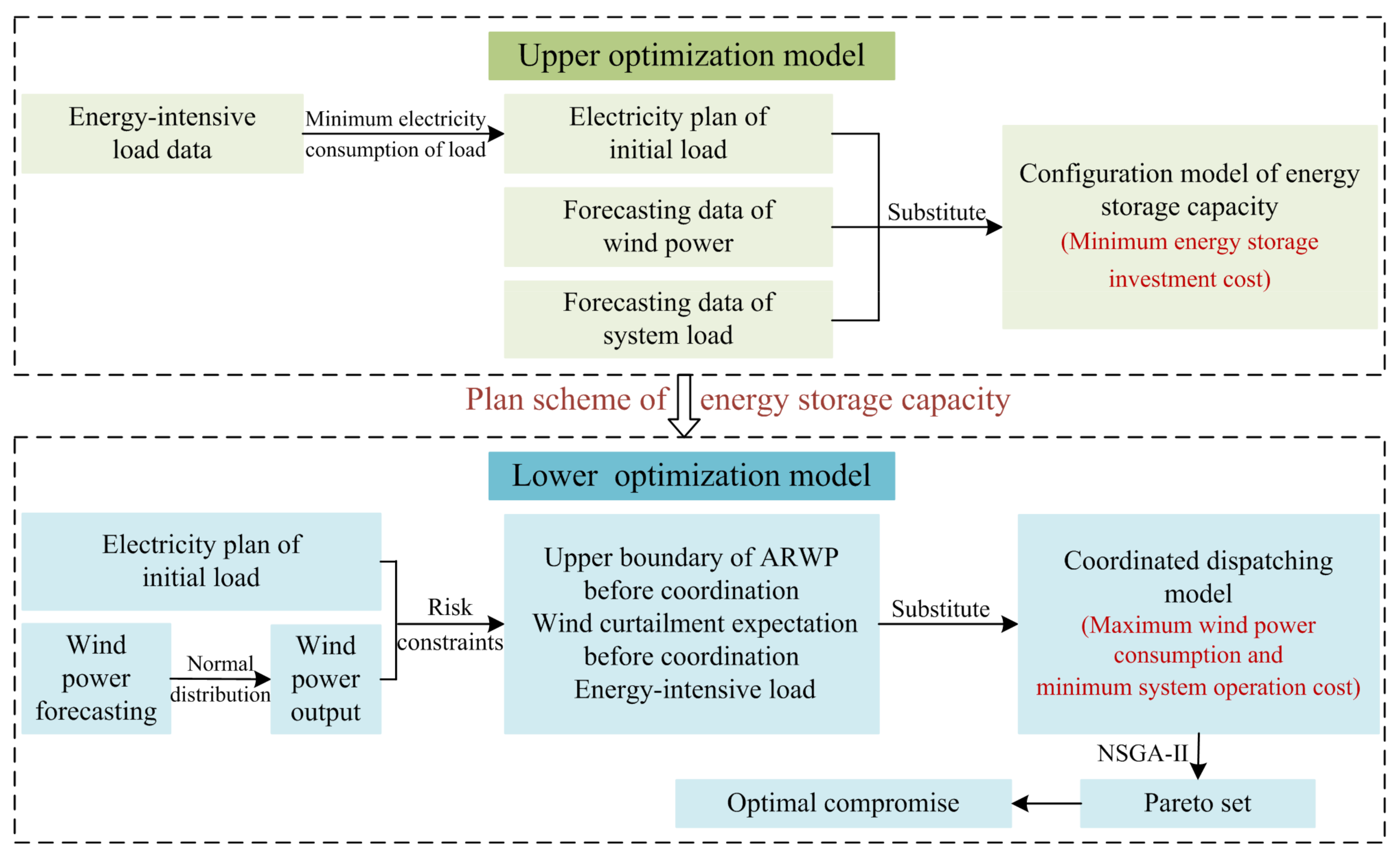

4. Bi-Level Optimization Model Considering Congested Wind Power Consumption

- (1)

- Upper optimization model. According to the energy-intensive load data, the energy-intensive load model is self-dispatch with the goal of minimizing power consumption, and the initial energy-intensive load’s electricity plan is obtained. At the same time, according to the wind power prediction data, system load prediction data, combined with the initial energy-intensive load’s electricity plan, the configuration of energy storage capacity is optimized to minimize the investment cost of energy storage system.

- (2)

- Lower optimization model. The uncertainty of wind power output follows the normal distribution, combined with the initial electricity plan of energy-intensive load, the upper boundary of ARWP before coordination, the expectation of wind curtailment before coordination and the increment of energy-intensive load are obtained by the risk constraint of energy-intensive load. Bring the above results into the coordinated dispatching model, aiming at the maximum wind power consumption and the lowest comprehensive operating cost of the system, using NSGA-II; to solve the problem, and finally the pareto solution set is obtained.

4.1. Model of Energy Storage Capacity Configuration

4.1.1. Objective Function

4.1.2. Constraints

4.2. Coordinated Dispatching Model of Energy-Intensive Load and Energy Storage System

4.2.1. Objective Function

- (3)

- The operating cost of conventional unitswhere N is the number of thermal power units; , and are the cost coefficient of thermal power units; is the output of the k-th thermal power unit at time t; is the start-up cost of the thermal power unit; is a 0–1 variable, which is used to indicate the current on/off state of the unit; is a 0–1 variable, which is used to indicate the starting state.

- (4)

- The charge and discharge management cost of energy storage systemwhere is the discharging cost coefficient of the energy storage system; is the charging cost coefficient of the energy storage system; is the discharge power of the energy storage system at time t; is the charging power of the energy storage system at time t.

- (5)

- The dispatching cost of energy-intensive loadwhere is the number of power changes of energy-intensive load; π is the corresponding equipment loss cost in case of single power change; is the raw material cost coefficient per unit energy consumption; is the equipment loss cost coefficient of unit regulated power; is the expected curtailment of wind during the dispatching period; is the increased labor cost of participating in the consumption of congested wind power during the control period; is shown in Formula (15).

- (6)

- The penalty cost of curtailment wind

4.2.2. Constraints

- (1)

- Conventional unit constraints

- (7)

- System power balance constraintswhere and represent the discharge and charging power of the battery at time t, respectively; represents the conventional load power at time t; represents the active power of the energy-intensive load j at time t.

- (8)

- Energy storage system charging and discharging constraints are as follows:

- (9)

- Constraints of energy-intensive load are shown in Formulas (5) and (6).

5. Case Analysis

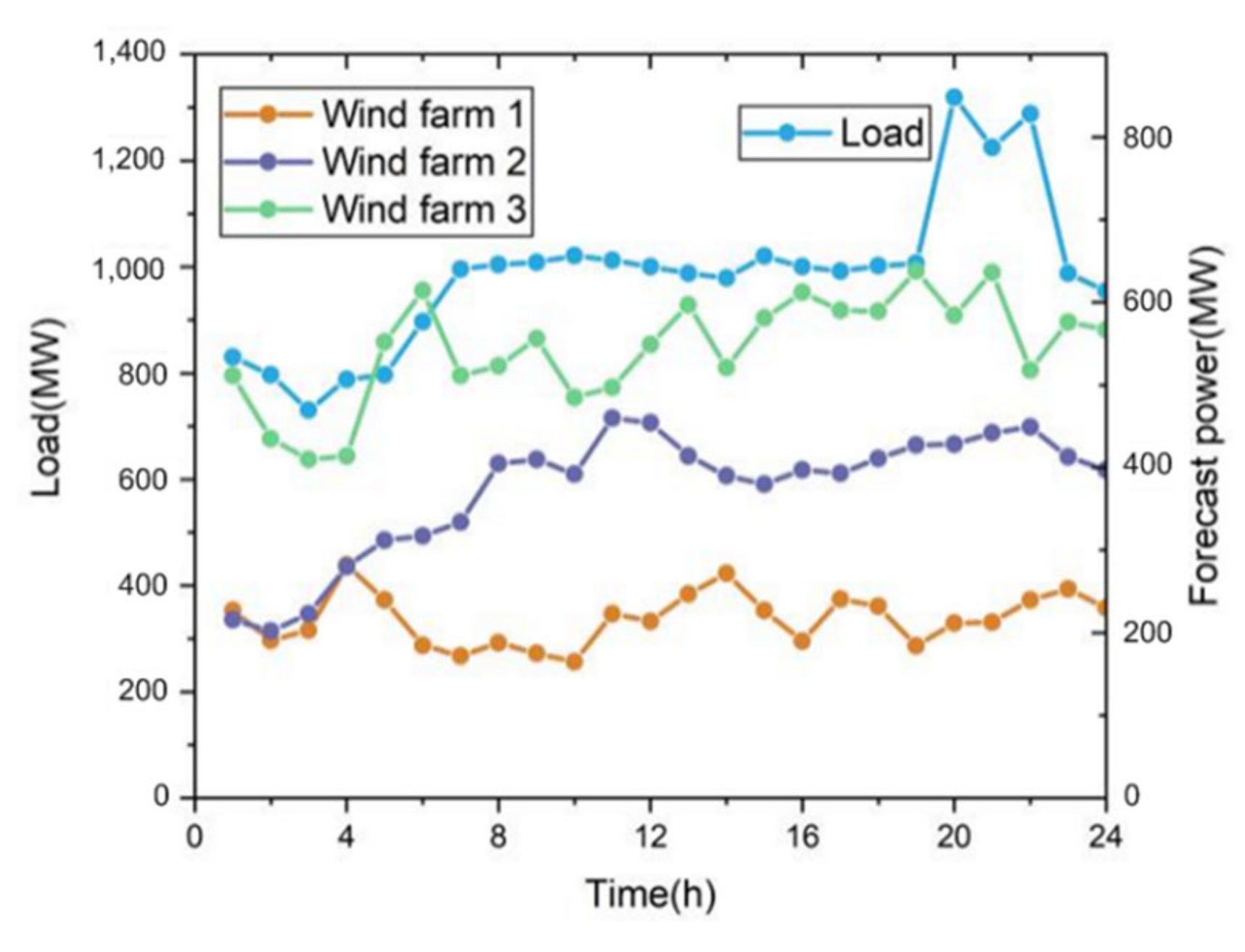

5.1. Basic Data and Scene Settings

- Case 1: Without considering the uncertainty of wind power, only energy-intensive load participates in regulation.

- Case 2: Considering the uncertainty of wind power, only energy-intensive load participates in the regulation.

- Case 3: Without considering the uncertainty of wind power, energy-intensive load and energy storage system work together.

- Case 4: Considering the uncertainty of wind power, energy-intensive load and energy storage system work together.

5.2. Result Analysis

5.2.1. Analysis of Storage Capacity Configuration Results

5.2.2. Analysis of Coordinated Dispatching Results

- (1)

- Operation result analysis of case 1

- (10)

- Operation result analysis of case 2

- (11)

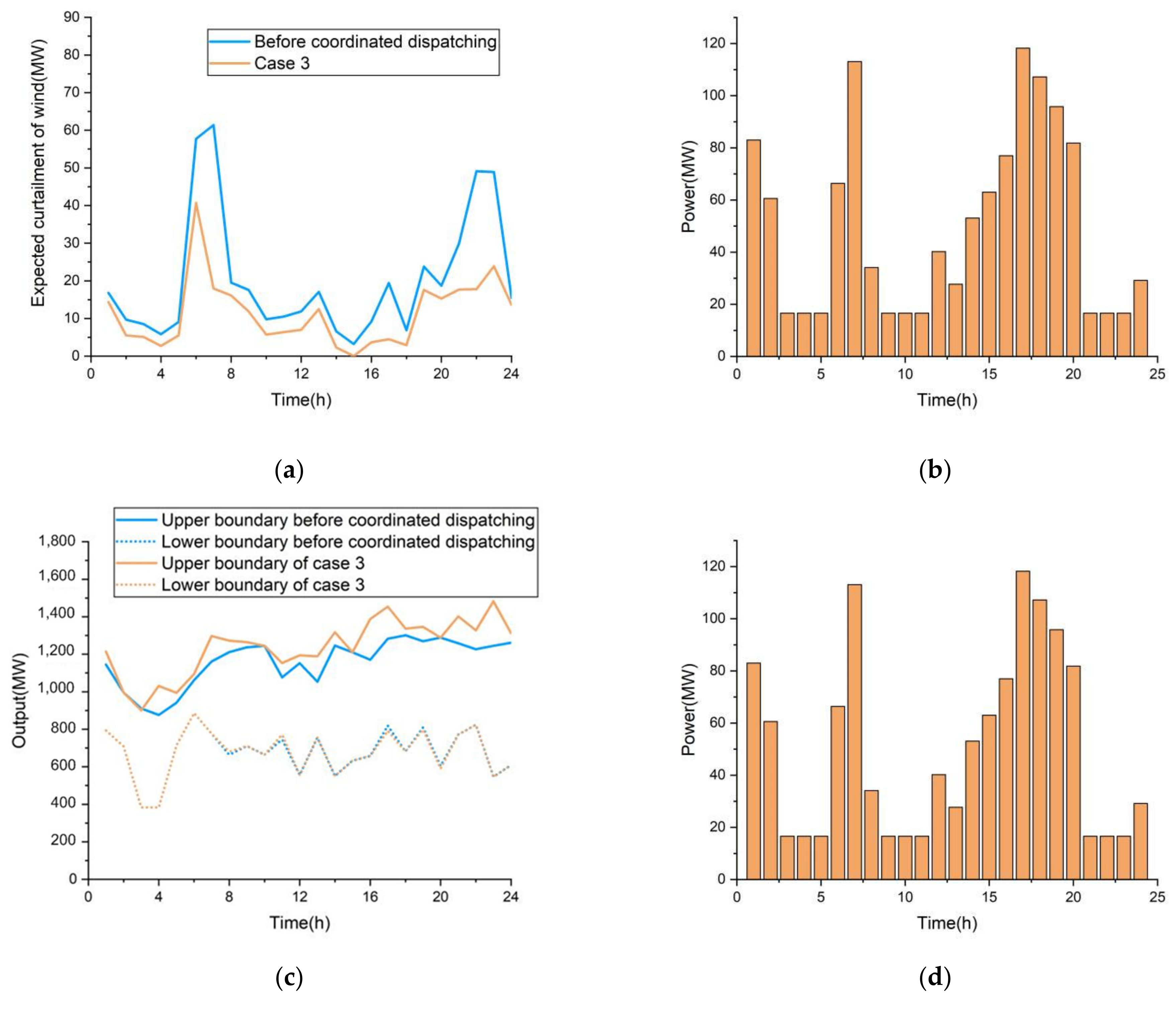

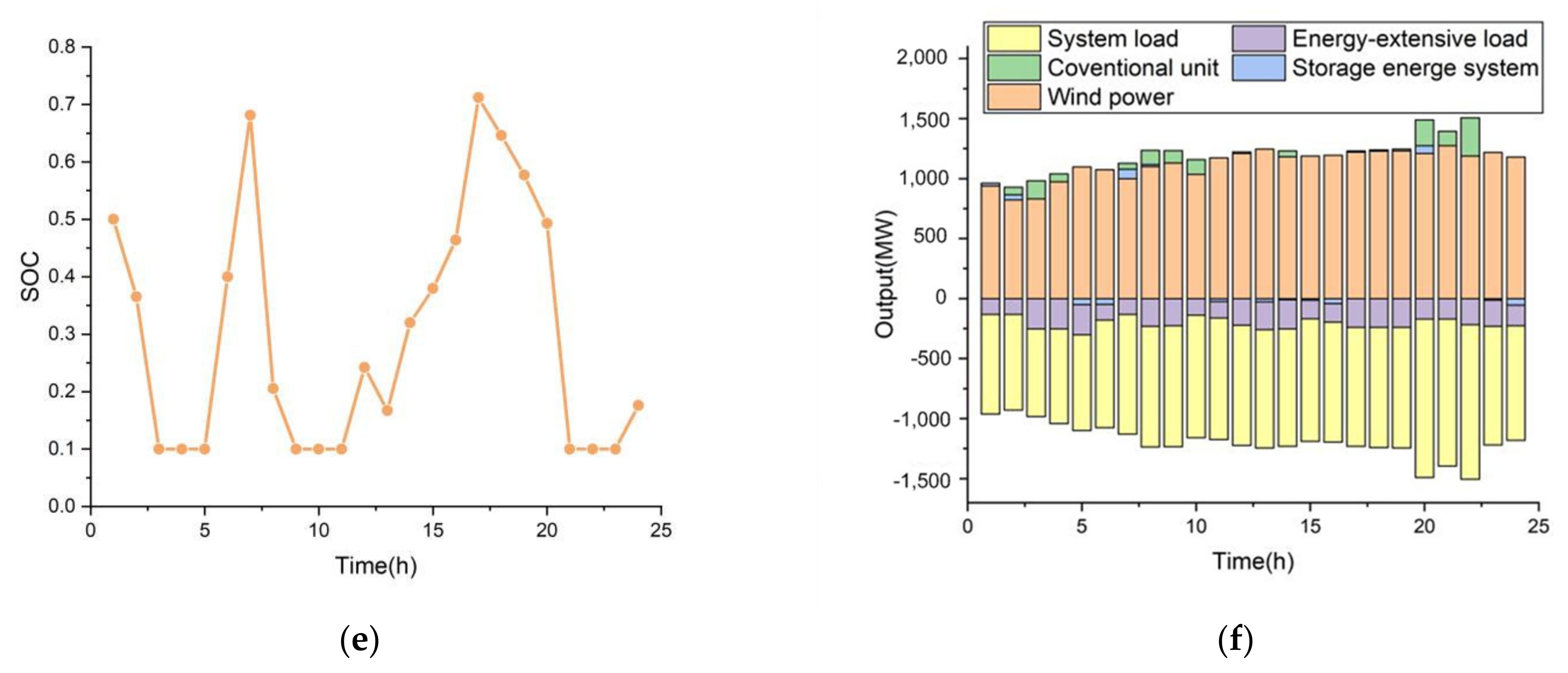

- Operation result analysis of case 3

- (12)

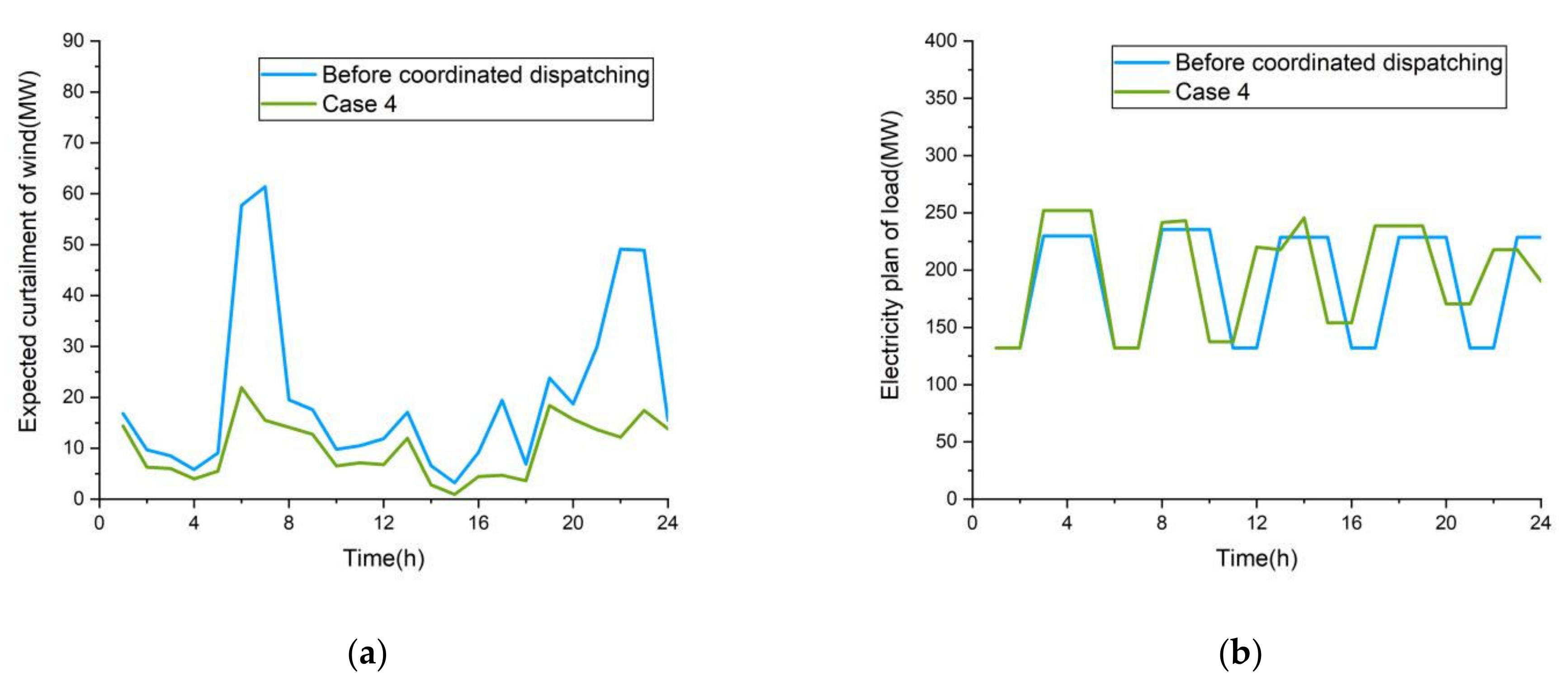

- Operation result analysis of case 4

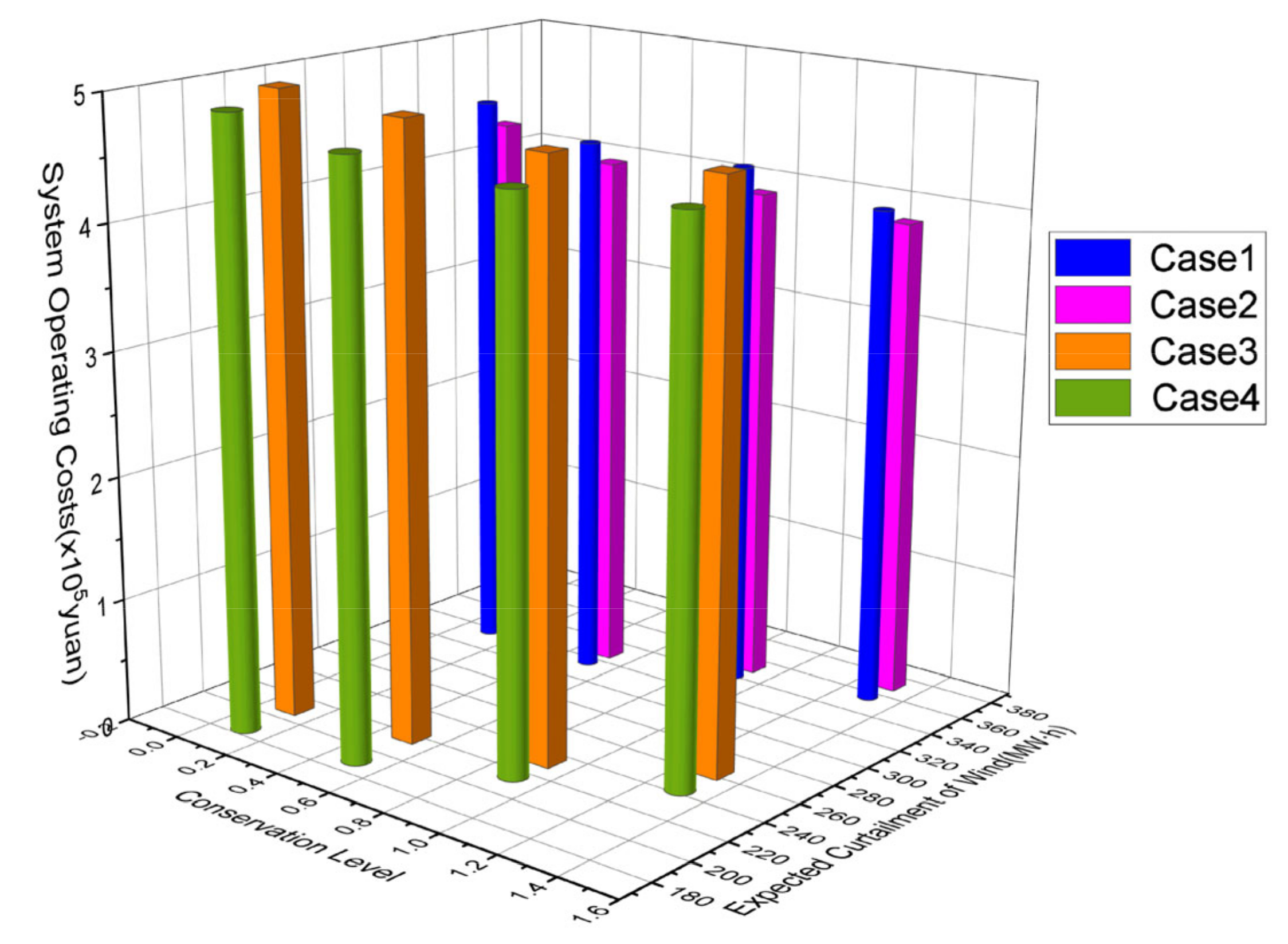

5.2.3. Influence of Conservative Degree Change of Energy-Intensive Load on Consuming Results

6. Conclusions

- (1)

- On the basis of analysis of a wind power uncertainty and energy-intensive load dispatching model, this paper establishes the risk constraints of energy-intensive load, which not only fully excavates the regulation potential of energy-intensive load but also solves the problem of mismatch between the regulation increment of energy-intensive load and wind power output.

- (2)

- In order to maximize the consumption of congested wind power, a bi-level optimization model considering congested wind power consumption is established in this paper. The optimal configuration model of the energy storage capacity is established with the goal of minimizing the investment cost of the energy storage system, and the coordinated dispatching model of the energy-intensive load and energy storage system is established with the goal of maximizing the consumption of wind power and minimizing the comprehensive operation cost of the system (so as to achieve the purpose of maximizing the consumption of congested wind power by using an energy-intensive load and energy storage system).

- (3)

- According to the example results, the minimum wind curtailment expectation of the proposed method is 204.3 MW·h, which is 65% lower than that before the coordinated dispatch, and the total admissible range of wind power increased by 572.5 MW·h, which effectively improve the ability of the power grid to integrate wind power and increased the overall level of consumption of congested wind power.

- (4)

- This paper establishes a model of the conservative degree of energy-intensive load participating in the consumption of wind power such that the load side can adjust the load in a targeted manner to avoid the risk of excessive wind power uncertainty. It also analyzes the impact of different conservative values on the consumption of wind power. The results show that under the conditions of a certain wind curtailment expectation, the lower the conservative level of the load, the greater the load increment. energy-intensive load enterprises can choose the risks they can bear according to their own characteristics to ensure corporate benefits.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ARWP | Admissible region of wind power |

| W | the number of wind farms |

| E | the number of energy-intensive load |

| N | the number of thermal power units |

| planned output | |

| wind power output fluctuation | |

| actual output | |

| the upper boundary before coordinated dispatching | |

| the lower boundary before coordinated dispatching | |

| the predicted output of wind farm | |

| the initial standard deviation of wind farm i load forecasting | |

| the standard deviation increment of wind farm i load forecasting process with time scale | |

| the penalty for wind curtailment | |

| the upper limit of output of wind farm i at time t | |

| the total active power | |

| continuous regulation | |

| state variable | |

| start flag of smelting furnace | |

| the oven power | |

| normal production power | |

| maximum down-regulated power of smelting furnace | |

| maximum up-regulated power of smelting furnace | |

| the maximum smelting time of smelting furnace | |

| the maximum oven time of smelting furnace | |

| the degree of conservation | |

| the electricity consumption plan before the adjustment | |

| the electricity consumption plan after the adjustment | |

| the adjusted upper boundary of ARWP | |

| the equal-year system coefficient | |

| the annual interest rate | |

| the service life of the energy storage system | |

| the investment and construction cost of the energy storage system | |

| the operation and maintenance cost of the energy storage system | |

| the unit power cost of the energy storage system | |

| the unit capacity cost of the energy storage system | |

| the operation and maintenance cost rate of the energy storage system | |

| the investment power of the energy storage system | |

| the investment capacity of the energy storage system | |

| the upper limits of the investment capacity of the energy storage system | |

| the lower limits of the investment capacity of the energy storage system | |

| the upper limits of the investment power of the energy storage system | |

| the lower limits of the investment power of the energy storage system | |

| the operating cost of conventional units | |

| the charge and discharge management cost of energy storage system | |

| the dispatching cost of energy-intensive load | |

| the penalty cost of curtailment wind | |

| the cost coefficient of thermal power units | |

| the cost coefficient of thermal power units | |

| the cost coefficient of thermal power units | |

| the output of thermal power unit | |

| the start-up cost of the thermal power unit | |

| 0–1 variable | |

| 0–1 variable | |

| the discharging cost coefficient of the energy storage system | |

| the charging cost coefficient of the energy storage system | |

| the discharge power of the energy storage system | |

| the charging power of the energy storage system | |

| the corresponding equipment loss cost | |

| the raw material cost coefficient per unit energy consumption | |

| the equipment loss cost coefficient of unit regulated power | |

| the increased labor cost of participating in the consumption of congested wind power during the control period | |

| the upper limits of the output of the conventional unit | |

| the lower limits of the output of the conventional unit | |

| the maximum descent rate of active power output of the conventional unit | |

| the maximum ascent rate of active power output of the conventional unit | |

| the continuous start-up time of the conventional unit | |

| the minimum start-up time of the conventional unit | |

| the continuous shutdown time of the conventional unit | |

| the minimum shutdown time of the conventional unit | |

| the discharge power of the battery | |

| the charging power of the battery | |

| the conventional load power | |

| the upper limit of the charge power of the energy storage device | |

| the upper limit of the discharge power of the energy storage device | |

| the charging efficiency of the energy storage system | |

| the discharging efficiency of the energy storage system | |

| the state of charge |

References

- Shahriari, M.; Cervone, G.; Clemente-Harding, L.; Delle Monache, L. Using the analog ensemble method as a proxy measurement for wind power predictability. Renew. Energy 2020, 146, 789–801. [Google Scholar] [CrossRef]

- Spokesperson of the National Energy Administration. Transcript of the online press conference of the National Energy Administration in the first quarter of 2021. China Electr. Power 2021, 02, 26–29. [Google Scholar]

- Simla, T.; Stanek, W. Reducing the impact of wind farms on the electric power system by the use of energy storage. Renew. Energy 2020, 145, 772–782. [Google Scholar] [CrossRef]

- Madaeni, S.H.; Sioshansi, R. Using Demand Response to Improve the Emission Benefits of Wind. IEEE Trans. Power Syst. 2013, 28, 1385–1394. [Google Scholar] [CrossRef]

- Lamsal, D.; Sreeram, V.; Mishra, Y.; Kumar, D. Output power smoothing control approaches for wind and photovoltaic generation systems: A review. Renew. Sustain. Energy Rev. 2019, 113, 1–22. [Google Scholar] [CrossRef]

- Tang, R.M. Promote the integration of power source network and load storage and multi-energy complementation—Policy interpretation of the “Guiding Opinions of the National Development and Reform Commission and the National Energy Administration on Promoting the Development of Power Source, Network, Load and Storage Integration and Multi-energy Complementation”. China Econ. Trade Her. 2021, 8, 10–11. [Google Scholar]

- Drovtar, I.; Uuemaa, P.; Rosin, A.; Kilter, J.; Valtin, J. Using demand side management in energy-intensive industries for providing balancing power—The Estonian case study. In Proceedings of the Power & Energy Society General Meeting, Vancouver, BC, Canada, 21–25 July 2013. [Google Scholar]

- Paulus, M.; Borggrefe, F. The potential of demand-side management in energy-intensive industries for electricity markets in Germany. Appl. Energy 2011, 88, 432–441. [Google Scholar] [CrossRef]

- Zhang, N.; Hu, Z.G.; Shen, B.; He, G.; Zheng, Y.N. An integrated source-grid-load planning model at the macro level: Case study for China’s power sector. Energy 2017, 126, 231–246. [Google Scholar] [CrossRef]

- Jonghe, C.D. Optimal Generation Mix with Short-Term Demand Response and Wind Penetration. IEEE Trans. Power Syst. 2012, 27, 830–839. [Google Scholar] [CrossRef]

- Kiran, B.; Kumari, M.S. Demand response and pumped hydro storage scheduling for balancing wind power uncertainties: A probabilistic unit commitment approach. Int. J. Electr. Power Energy Syst. 2016, 81, 114–122. [Google Scholar] [CrossRef]

- Daneshvar, M.; Mohammadi-Ivatloo, B.; Zare, K. Two-stage optimal robust scheduling of hybrid energy system considering the demand response programs. J. Clean. Prod. 2020, 248, 119267.1–119267.3. [Google Scholar] [CrossRef]

- Yang, H.; Yu, Q.; Liu, J.P.; Jia, Y.W.; Yang, G.Y.; Ackom, E.; Dong, Z.Y. Optimal Wind-Solar Capacity Allocation with Coordination of Dynamic Regulation of Hydropower and Energy Intensive Controllable Load. IEEE Access 2020, 8, 110129–110139. [Google Scholar] [CrossRef]

- Koohi-Fayegh, S.; Rosen, M.A. A review of energy storage types, applications and recent developments. J. Energy Storage 2020, 27, 101047. [Google Scholar] [CrossRef]

- Li, X.; Cao, X.; Li, C.; Yang, B.; Cong, M.; Chen, D.W. A Coordinated Peak Shaving Strategy Using Neural Network for Discretely Adjustable Energy-Intensive Load and Battery Energy Storage. IEEE Access 2019, 8, 5331–5338. [Google Scholar] [CrossRef]

- Khosravi, M.; Afsharnia, S.; Farhangi, S. Optimal sizing and technology selection of hybrid energy storage system with novel dispatching power for wind power integration. Int. J. Electr. Power Energy Syst. 2021, 127, 106660. [Google Scholar] [CrossRef]

- Sulaeman, S.; Tian, Y.; Benidris, M.; Mitra, J. Quantification of Storage Necessary to Firm Up Wind Generation. IEEE Trans. Ind. Appl. 2017, 53, 3228–3236. [Google Scholar] [CrossRef]

- Khalid, M.; Almuhaini, M.; Aguilera, R.P.; Savkin, A.V. Method for planning a wind–solar–battery hybrid power plant with optimal generation-demand matching. IET Renew. Power Gener. 2018, 12, 1800–1806. [Google Scholar] [CrossRef] [Green Version]

- Dicorato, M.; Forte, G.; Pisani, M.; Trovato, M. Planning and Operating Combined Wind-Storage System in Electricity Market. IEEE Trans. Sustain. Energy 2012, 3, 209–217. [Google Scholar] [CrossRef]

- He, H.; Peng, F.; Gao, Z.; Liu, X.; HU, S.; Zhou, W.; Sun, H. A Multi-Objective Risk Scheduling Model of an Electrical Power System-Containing Wind Power Station with Wind and Energy Storage Integration. Energies 2019, 12, 2153. [Google Scholar] [CrossRef] [Green Version]

- Sun, R.F.; Zhang, T.; Liang, J. Evaluation and application of wind power integration capacity in power grid. Autom. Electr. Power Syst. 2011, 35, 70–76. [Google Scholar]

- Li, P.; Yu, D.; Yang, M.; Wang, J. Flexible look-ahead dispatch realized by robust optimization considering cvar of wind power. IEEE Trans. Power Syst. 2018, 33, 5330–5340. [Google Scholar] [CrossRef]

- Dvorkin, Y.; Lubin, M.; Backhaus, S.; Chertkov, M. Uncertainty Sets for Wind Power Generation. IEEE Trans. Power Syst. 2016, 31, 3326–3327. [Google Scholar] [CrossRef] [Green Version]

- Ding, Y.; Shao, C.; Yan, J.; Song, Y.; Zhang, C.; Guo, C. Economical flexibility options for integrating fluctuating wind energy in power systems: The case of China. Appl. Energy 2018, 228, 426–436. [Google Scholar] [CrossRef]

- Ge, S.; Yu, K.; Chen, X.Y.; Liao, Y.C.; Huang, X.S.; Zhao, J. Research on power loss reduction method based on continuous regulating features of energy-intensive industrial loads. In Proceedings of the 2016 IEEE International Conference on Power System Technology, Wollongong, NSW, Australia, 28 September–1 October 2016. [Google Scholar]

- Ramlal, C.J.; Singh, A.; Rocke, S. Repetitive learning frequency control for energy intensive corporate microgrids subject to Cyclic Batch Loads. In Proceedings of the 2020 IEEE PES Innovative Smart Grid Technologies Europe (ISGT-Europe)—IEEE, Hague, The Netherlands, 26–28 October 2020. [Google Scholar]

- Tovarovskii, I.G.; Merkulov, A.E. Features of Temperature and Concentration Fields During Pig and Cast Iron Smelting in a Blast Furnace Workspace. Metallurgist 2016, 60, 589–593. [Google Scholar] [CrossRef]

- Psarros, G.N.; Dratsas, P.A.; Papathanassiou, S.A. A comparison between central- and self-dispatch storage management principles in island systems. Appl. Energy 2021, 298, 117181. [Google Scholar] [CrossRef]

- Mahapatra, S.; Badi, M.; Raj, S. Implementation of PSO, it’s variants and Hybrid GWO-PSO for improving Reactive Power Planning. In Proceedings of the 2019 Global Conference for Advancement in Technology (GCAT), Bangalore, India, 18–20 October 2019; pp. 1–6. [Google Scholar]

| Load Type | Typical Load | Power Stability Duration/h | Continuous Regulation |

|---|---|---|---|

| discretely adjustable load | Electrolytic aluminum | ≥2 | No |

| continuously adjustable load | Titanium alloy | 0 | Yes |

| Parameter | |||||

| Value | 0.8 | 450 yuan/MW·h | 120 yuan/MW·h | 120 yuan/MW·h | 300 yuan/time |

| Parameter | |||||||

| Value | 0.02 | 20 | 100,000 yuan/MVA | 150,000 yuan/MW·h | 0.04 | 6 yuan/MW | 4 yuan/MW |

| Parameter Unit | 1 | 2 | 3 |

|---|---|---|---|

| 200 | 300 | 380 | |

| 50 | 80 | 100 | |

| 130 | 140 | 150 | |

| 130 | 140 | 150 | |

| 0.0039 | 0.0030 | 0.0027 | |

| 17.33 | 16.23 | 14.12 | |

| 300 | 500 | 700 | |

| Minimum startup time/h | 2 | 3 | 4 |

| Minimum downtime/h | 2 | 3 | 4 |

| Start-up cost/yuan | 1000 | 1250 | 1500 |

| Case | Configuration Parameter | Investment Cost/(Yuan·d−1) | |

|---|---|---|---|

| Energy Storage Capacity/MW·H | Energy Storage Power/MW | ||

| 3 | 166 | 118 | 7437 |

| 4 | 192 | 137 | 9366 |

| Goals | Minimum Expected Curtailment of Wind | Minimum Operation Cost | Optimal Compromise | |

|---|---|---|---|---|

| Case1 | Expected curtailment of wind/MW·h | 203.5 | 418.4 | 325.8 |

| Operation cost/yuan | 502,843 | 353,492 | 429,543 | |

| Case2 | Expected curtailment of wind/MW·h | 236.9 | 441.5 | 337.4 |

| Operation cost/yuan | 499,201 | 349,363 | 405,563 | |

| Case3 | Expected curtailment of wind/MW·h | 162.5 | 284.7 | 223.9 |

| Operation cost/yuan | 534,292 | 428,394 | 478,134 | |

| Case4 | Expected curtailment of wind/MW·h | 180.4 | 237.6 | 204.3 |

| Operation cost/yuan | 509,278 | 409,021 | 459,272 | |

| Case | 1 | 2 | 3 | 4 |

|---|---|---|---|---|

| System operating cost/yuan | 429,543 | 405,563 | 478,134 | 459,272 |

| energy-intensive load cost/yuan | 281,219 | 255,923 | 253,842 | 246,438 |

| Energy storage cost/yuan | 0 | 0 | 128,165 | 122,695 |

| Conventional unit cost/yuan | 50,584 | 48,420 | 28,957 | 28,849 |

| Expected curtailment of wind/MW·h | 325.8 | 337.4 | 223.9 | 204.3 |

| Load increment/MW·h | 489.61 | 445.23 | 441.58 | 428.59 |

| Case | Conservation Level | System Operating Costs/Yuan | Expected Curtailment of Wind/MW·h |

|---|---|---|---|

| 1 | 1.3 | 401,638 | 355.68 |

| 0.9 | 425,890 | 340.95 | |

| 0.5 | 439,105 | 316.03 | |

| 0.1 | 458,264 | 317.08 | |

| 2 | 1.3 | 386,633 | 370.56 |

| 0.9 | 401,640 | 351.63 | |

| 0.5 | 419,271 | 328.19 | |

| 0.1 | 437,434 | 327.21 | |

| 3 | 1.3 | 462,743 | 262.29 |

| 0.9 | 472,974 | 232.62 | |

| 0.5 | 489,671 | 218.01 | |

| 0.1 | 501,224 | 209.93 | |

| 4 | 1.3 | 442,729 | 243.19 |

| 0.9 | 451,964 | 215.05 | |

| 0.5 | 470,691 | 190.12 | |

| 0.1 | 489,830 | 185.44 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Zhang, K.; Zhang, G.; Xie, T.; Wen, J.; Feng, C.; Ben, W. The Bi-Level Optimization Model Research for Energy-Intensive Load and Energy Storage System Considering Congested Wind Power Consumption. Processes 2022, 10, 51. https://doi.org/10.3390/pr10010051

Zhang S, Zhang K, Zhang G, Xie T, Wen J, Feng C, Ben W. The Bi-Level Optimization Model Research for Energy-Intensive Load and Energy Storage System Considering Congested Wind Power Consumption. Processes. 2022; 10(1):51. https://doi.org/10.3390/pr10010051

Chicago/Turabian StyleZhang, Shuyan, Kaoshe Zhang, Gang Zhang, Tuo Xie, Jiaxing Wen, Chao Feng, and Weihong Ben. 2022. "The Bi-Level Optimization Model Research for Energy-Intensive Load and Energy Storage System Considering Congested Wind Power Consumption" Processes 10, no. 1: 51. https://doi.org/10.3390/pr10010051