Experimental Investigation on the Machinability of PCBN Chamfered Tool in Dry Turning of Gray Cast Iron

Abstract

:1. Introduction

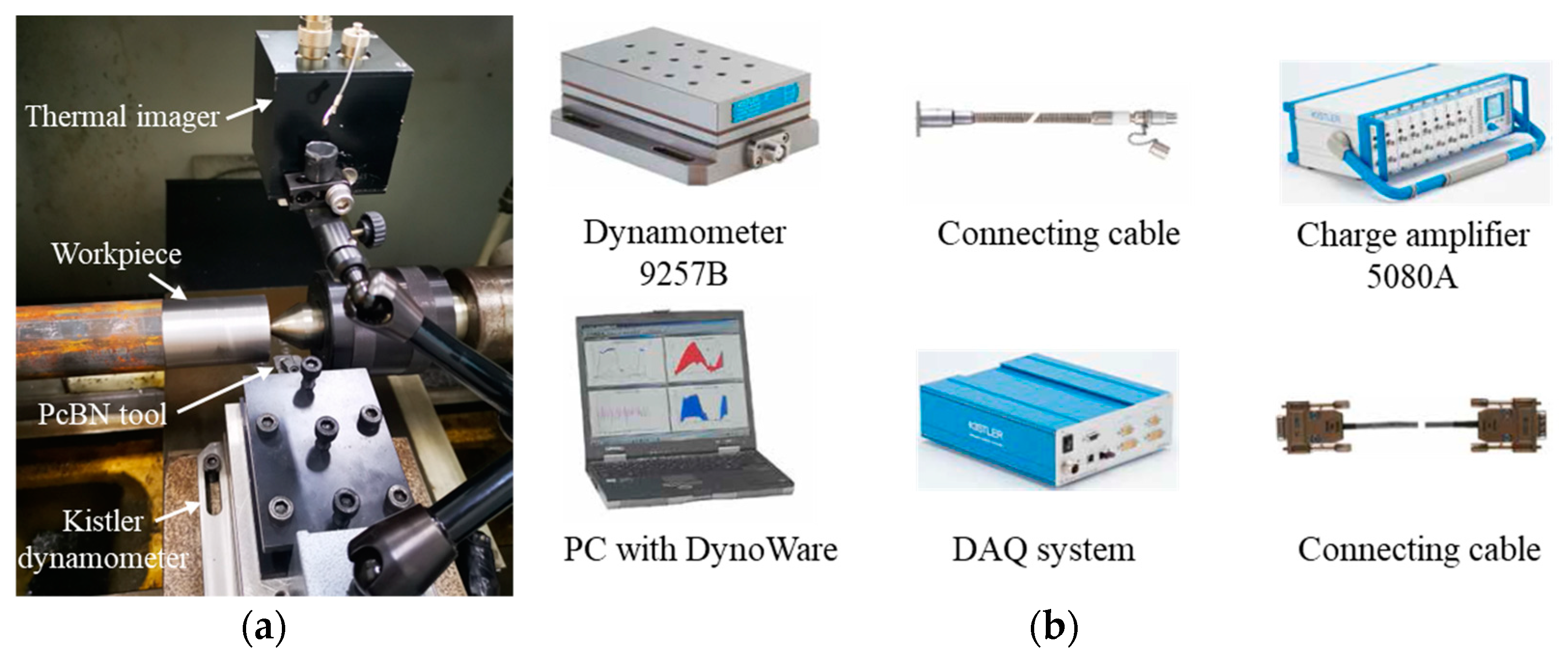

2. Experimental Procedure

3. Results and Discussions

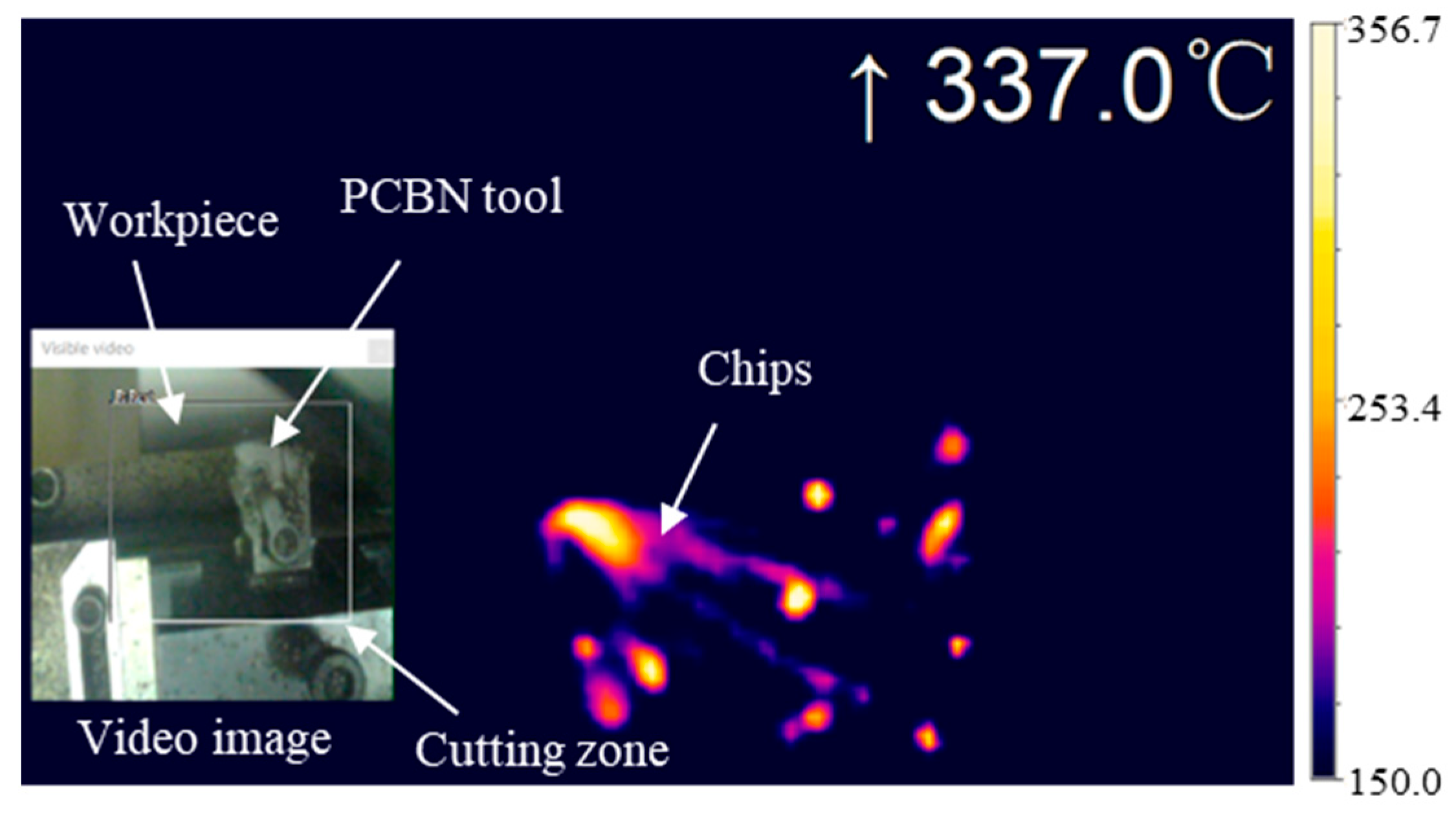

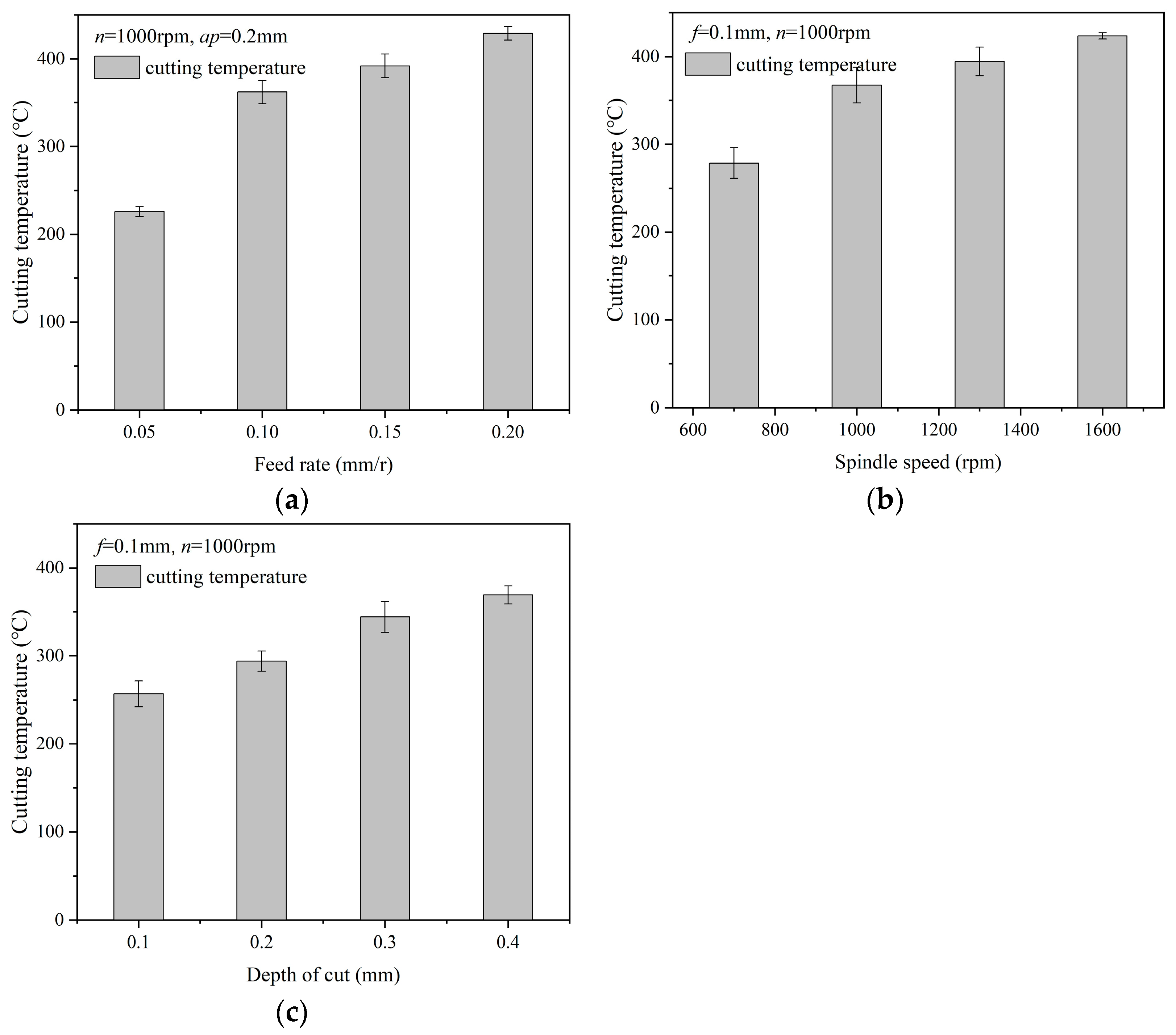

3.1. The Cutting Temperature

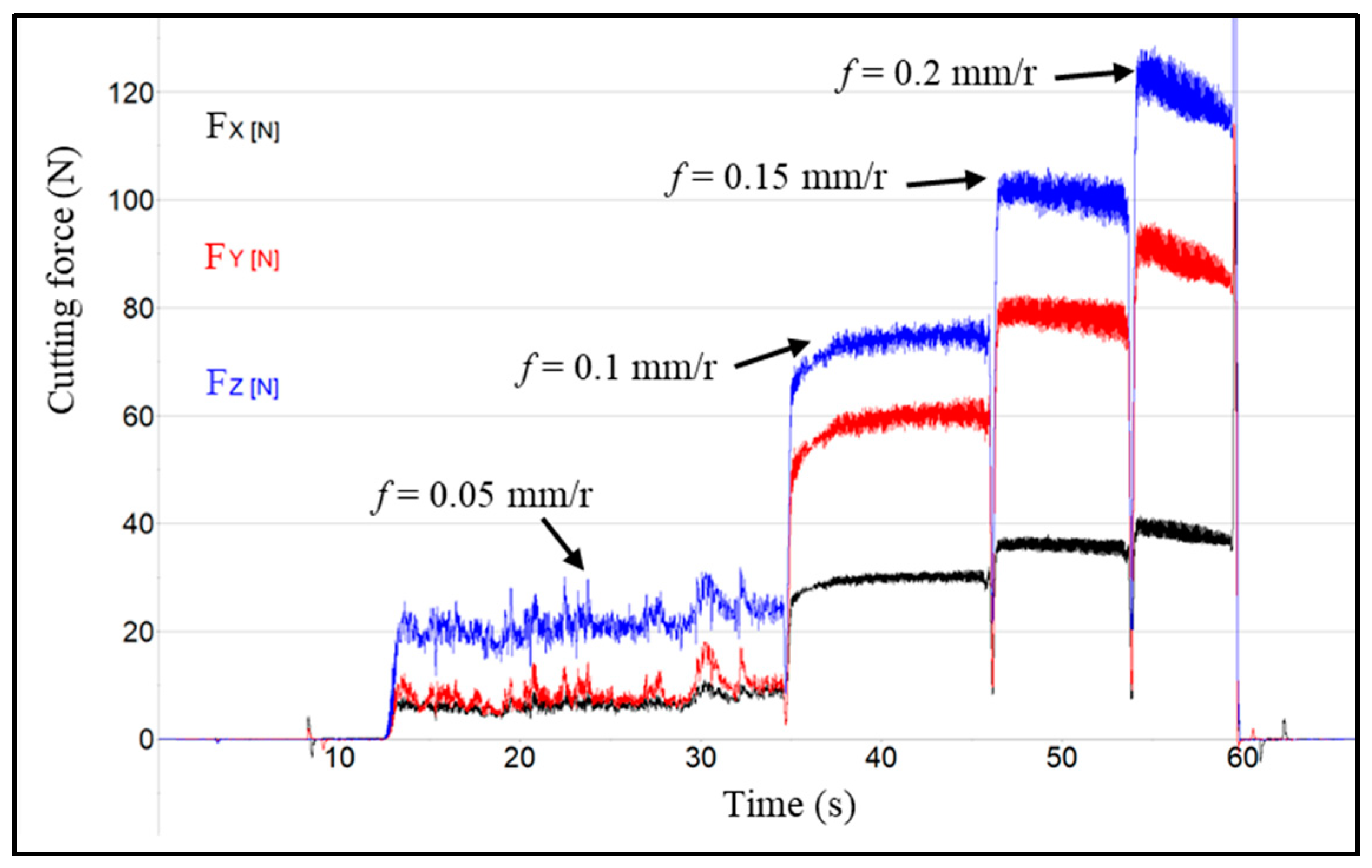

3.2. The Cutting Force

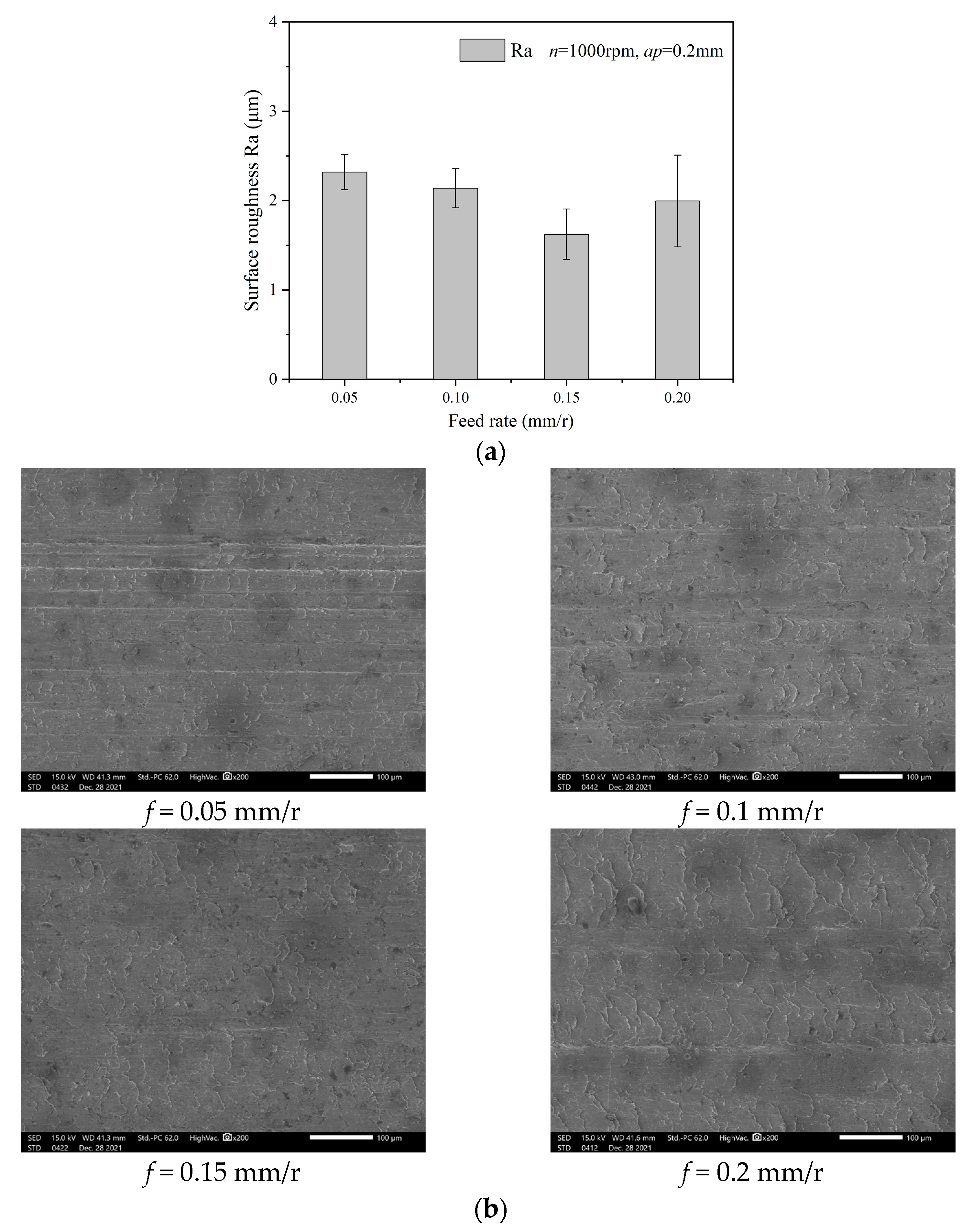

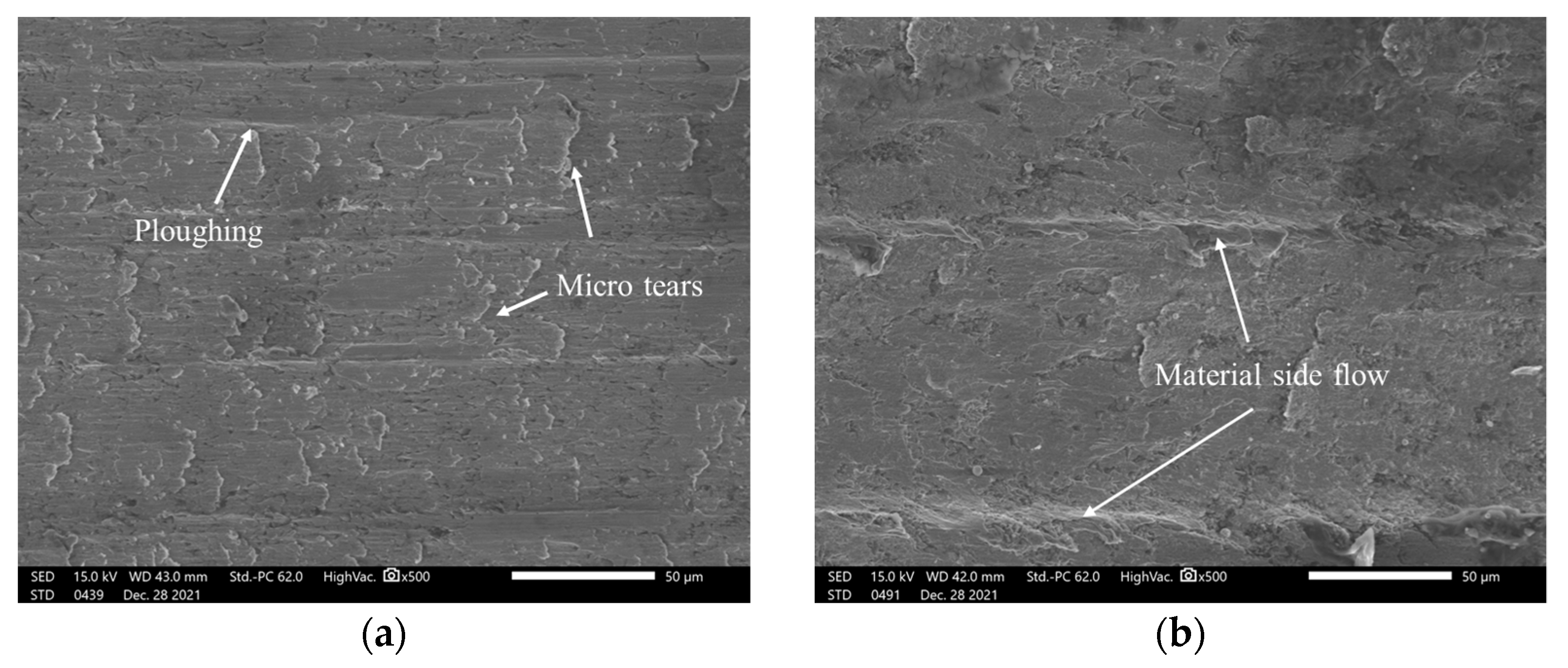

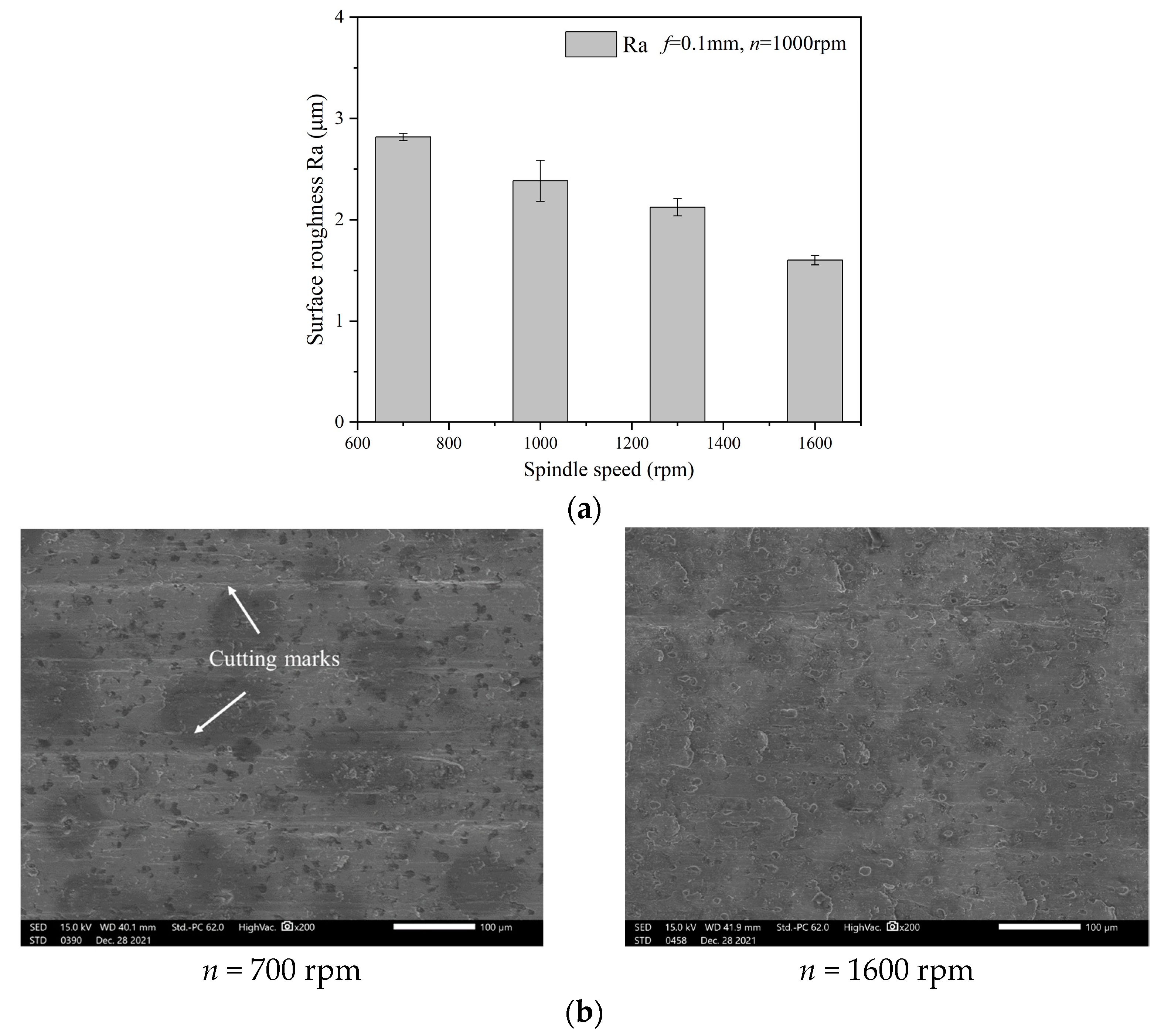

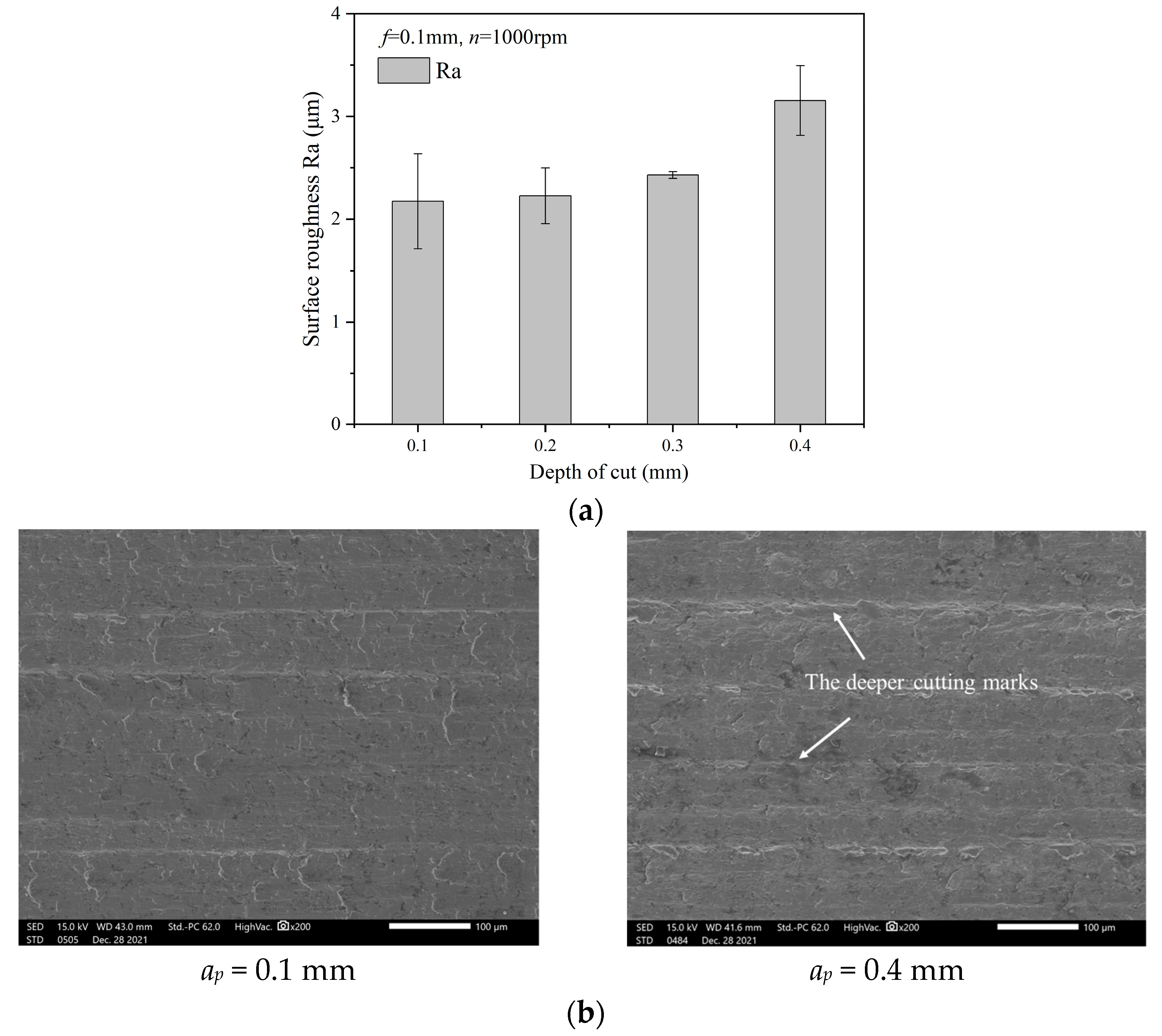

3.3. The Surface Quality

3.4. The Tool Wear

4. Conclusions

- Both the cutting temperature and the cutting force increased with the increase in feed rate and depth of cut. Although the cutting temperature increased with an increase in cutting speed, the built-up edge during the cutting process induced the cutting force to gradually increase with a larger cutting speed.

- The surface roughness values were found to decrease at first, and then increase with an increase in feed rate; the minimum surface roughness value was obtained with a feed rate of 0.15 mm/r. The feed rate should be selected to exceed the tool chamfer width to obtain a good surface quality. The surface roughness gradually decreased with the increase in cutting speed, but increased with the increase in depth of cut. The equivalent tool cutting edge angle decreased at a low depth of cut, which was helpful to obtain a smooth surface and achieve a relatively low surface roughness.

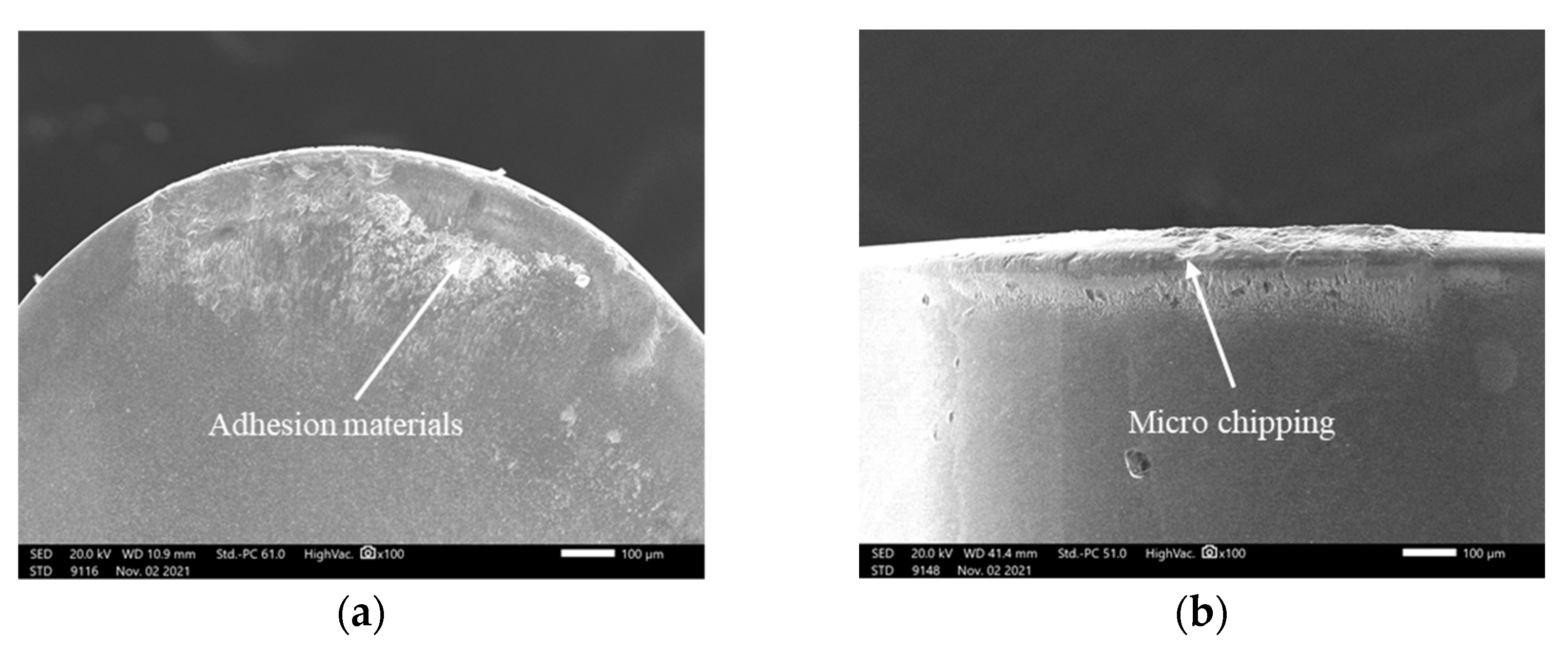

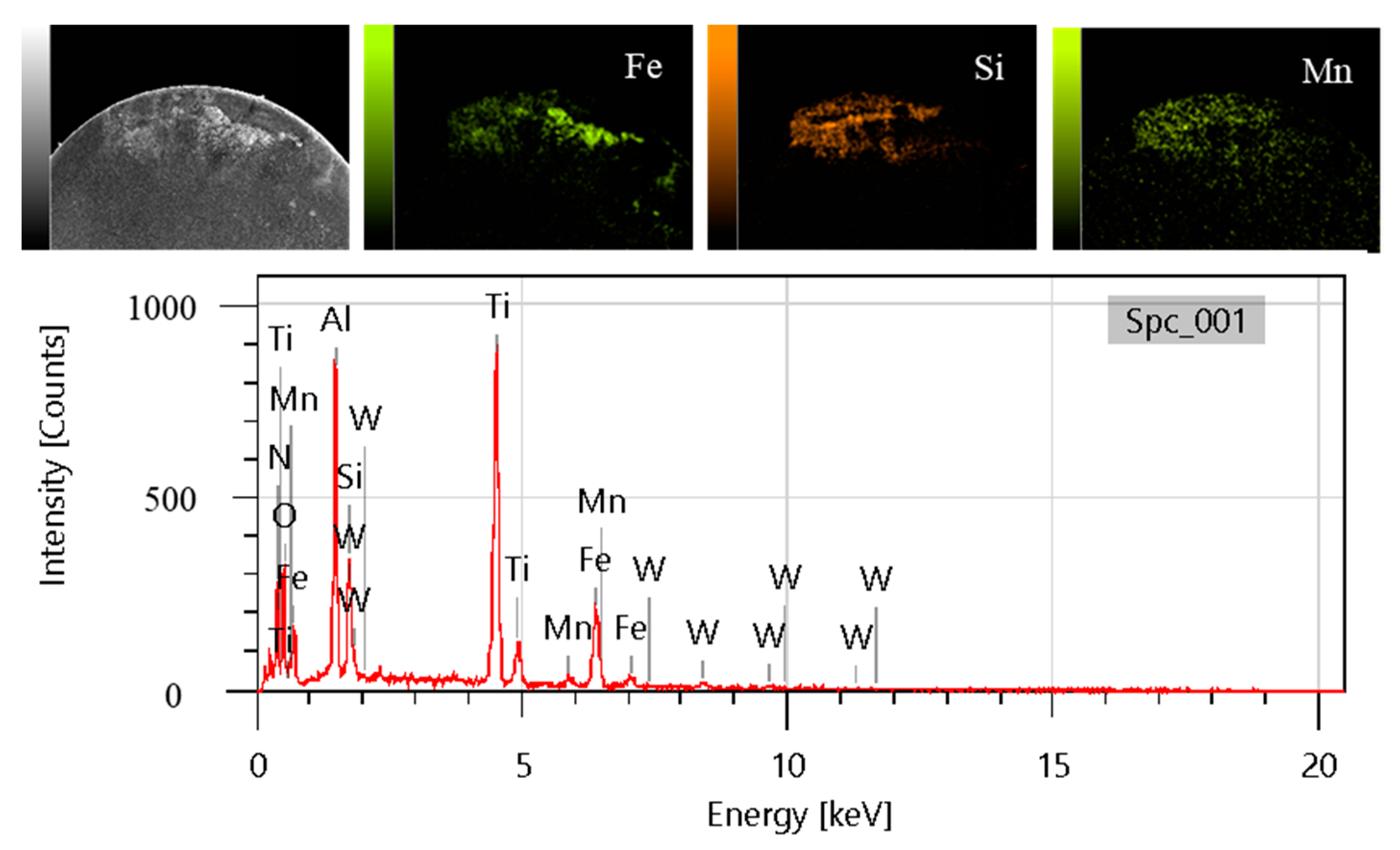

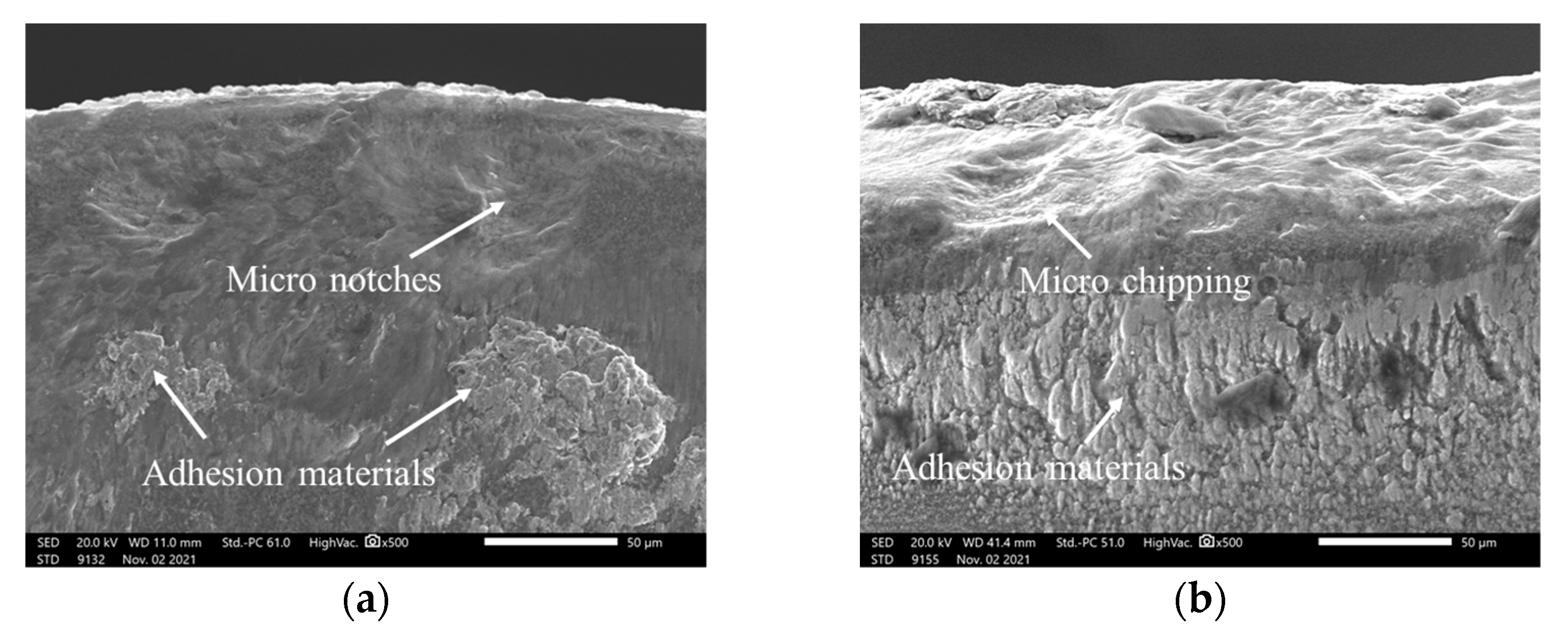

- The PCBN tool wear mode mainly involved micro notches on the rake face and micro chipping on the tool chamfer. During the cutting process, the workpiece material could easily adhere to and embed onto the tool surface, while the fall off of adhesion materials induced some tool material spalling on the tool surface. Micro chipping and adhesion wear were the main wear mechanism for the PCBN tool due to the negative rake angle on the tool chamfer.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ren, F.Z.; Li, F.J.; Liu, W.M.; Ma, Z.H.; Tian, B.H. Effect of inoculating addition on machinability of gray cast iron. J. Rare Earths 2009, 27, 294–299. [Google Scholar] [CrossRef]

- Genga, R.M.; Cornish, L.A.; Woydt, M.; Vuuren, A.J.; Polese, C. Microstructure, mechanical and machining properties of LPS and SPS NbC cemented carbides for face-milling of grey cast iron. Int. J. Refract. Met. Hard Mater. 2018, 73, 111–120. [Google Scholar] [CrossRef]

- Martinho, R.P.; Silva, F.J.G.; Baptista, A.P.M. Wear behaviour of uncoated and diamond coated Si3N4 tools under severe turning conditions. Wear 2007, 263, 1417–1422. [Google Scholar] [CrossRef] [Green Version]

- Martinho, R.P.; Silva, F.J.G.; Baptista, A.P.M. Cutting forces and wear analysis of Si3N4 diamond coated tools in high speed machining. Vacuum 2008, 82, 1415–1420. [Google Scholar] [CrossRef] [Green Version]

- Heck, M.; Ortner, H.M.; Flege, S.; Reuter, U.; Ensinger, W. Analytical investigations concerning the wear behavior of cutting tools used for the machining of compacted graphite iron and grey cast iron. Int. J. Refract. Met. Hard Mater. 2008, 26, 197–206. [Google Scholar] [CrossRef]

- Grzesik, W.; Kiszka, P.; Kowalczyk, D.; Rech, J.; Claudin, C. Machining of nodular cast iron (PF-NCI) using CBN tools. Procedia CIRP 2012, 1, 483–487. [Google Scholar] [CrossRef] [Green Version]

- Chen, L.; Zhou, J.; Bushlya, V.; Stahl, E.J. Influences of Micro Mechanical Property and Microstructure on Performance of Machining High Chromium White Cast Iron with cBN Tools. Procedia CIRP 2015, 31, 172–178. [Google Scholar] [CrossRef] [Green Version]

- Volodymyr, B.; Filip, L.; Axel, B.; Hisham, A.; Mattias, T.; Stahla, J.E.; Rachid, M. Tool wear mechanisms of PcBN in machining Inconel 718, Analysis across multiple length scale. CIRP Ann. 2021, 70, 73–78. [Google Scholar]

- Saketi, S.; Sveen, S.; Gunnarsson, S.; Saoubi, R.M.; Olsson, M. Wear of a high cBN content PCBN cutting tool during hard milling of powder metallurgy cold work tool steels. Wear 2015, 332–333, 752–761. [Google Scholar] [CrossRef]

- Larissa, J.S.; Denis, B.; Rolf, B.S. Evaluation of layer adhered on PCBN tools during turning of AISI D2 steel. Int. J. Refract. Met. Hard Mater. 2019, 84, 104977. [Google Scholar]

- Zhang, T.; Jiang, F.; Huang, H.; Lu, J.; Wu, Y.Q.; Jiang, Z.Y.; Xu, X.P. Towards understanding the brittle–ductile transition in the extreme manufacturing. Int. J. Extrem. Manuf. 2021, 3, 022001. [Google Scholar] [CrossRef]

- Vallabh, D.P.; Anish, H.G. Analysis and modeling of surface roughness based on cutting parameters and tool nose radius in turning of AISI D2 steel using CBN tool. Measurement 2019, 138, 34–38. [Google Scholar]

- Tatsuya, S.; Haruki, T.; Toshiyuki, E. Development of Novel CBN Cutting Tool for High Speed Machining of Inconel 718 Focusing on Coolant Behaviors. Procedia Manuf. 2017, 10, 436–442. [Google Scholar]

- Yun, H.; Zou, B.; Wang, J.; Huang, C.; Xing, H.; Shi, Z.; Xue, K. Design and fabrication of graded cBN tool materials through high temperature high pressure method. J. Alloys Compd. 2020, 832, 154937. [Google Scholar] [CrossRef]

- Mo, P.C.; Chen, J.; Zhang, Z.; Chen, C.; Pan, X.; Xiao, L.; Lin, F. The effect of cBN volume fraction on the performance of PCBN composite. Int. J. Refract. Met. Hard Mater. 2021, 100, 105643. [Google Scholar]

- Tamang, S.; Aravindan, S. Brazing of cBN to WC-Co by Ag-Cu-In-Ti alloy through microwave hybrid heating for cutting tool application. Mater. Lett. 2019, 254, 145–148. [Google Scholar] [CrossRef]

- Fei, H.; Wu, H.; Yang, X.; Xiong, J.; Zhang, L.; Chen, Z.; Jiang, K.; Liu, J. Pulsed magnetic field treatment of cBN tools for improved cutting performances. J. Manuf. Processes 2021, 69, 21–32. [Google Scholar] [CrossRef]

- Manoj, N.; Rakesh, S.; Rajender, K. Investigating machinability of AISI D6 tool steel using CBN tools during hard turning. Mater. Today Proc. 2021, 47, 3960–3965. [Google Scholar]

- Gutnichenko, O.; Nilsson, M.; Lindvall, R.; Bushlya, V.; Andersson, M. Improvement of tool utilization when hard turning with cBN tools at varying process parameters. Wear 2021, 477, 203900. [Google Scholar] [CrossRef]

- Schultheiss, F.; Bushlya, V.; Lenrick, F.; Johansson, D.; Kristiansson, S.; Ståhl, J.-E. Tool Wear Mechanisms of pCBN tooling during High-Speed Machining of Gray Cast Iron. Procedia CIRP 2018, 77, 606–609. [Google Scholar] [CrossRef]

- Henrik, P.; Filip, L.; Luiz, F.; Stahla, J.E.; Volodymyr, B. Wear mechanisms of PcBN tools when machining AISI 316L. Ceram. Int. 2021, 47, 31894–31906. [Google Scholar]

- Zeng, K.; Wu, X.; Jiang, F.; Zhang, J.; Kong, J.; Shen, J.; Wu, H. Experimental research on micro hole drilling of polycrystalline Nd:YAG. Ceram. Int. 2022, 48, 9658–9666. [Google Scholar] [CrossRef]

- Kumar, P.; Chauhan, S.R.; Aggarwal, A. Effects of cutting conditions, tool geometry and material hardness on machinability of AISI H13 using CBN tool. Mater. Today Proc. 2021, 46, 9217–9222. [Google Scholar] [CrossRef]

- Gao, H.; Liu, X.; Chen, Z. Cutting Performance and Wear/Damage Characteristics of PCBN Tool in Hard Milling. Appl. Sci. 2019, 9, 772. [Google Scholar] [CrossRef] [Green Version]

- Li, S.Y.; Chen, T.; Qiu, C.Z.; Wang, D.Y.; Liu, X.L. Experimental investigation of high-speed hard turning by PCBN tooling with strengthened edge. Int. J. Adv. Manuf. Technol. 2017, 92, 3785–3793. [Google Scholar] [CrossRef]

- Grzesik, W.; Zak, K. Friction quantification in the oblique cutting with CBN chamfered tools. Wear 2013, 304, 36–42. [Google Scholar] [CrossRef]

- Tang, X.; Nakamoto, K.; Obata, K.; Takeuchi, Y. Ultraprecision micromachining of hard material with tool wear suppression by using diamond tool with special chamfer. CIRP Ann. 2013, 62, 51–54. [Google Scholar] [CrossRef]

- Souza, D.J.A.; Weingaertner, W.L.; Schroeter, R.B.; Teixeira, C.R. Influence of the cutting edge micro-geometry of PCBN tools on the flank wear in orthogonal quenched and tempered turning M2 steel. J. Braz. Soc. Mech. Sci. Eng. 2014, 36, 763–774. [Google Scholar] [CrossRef]

- Ventura, C.E.H.; Koehler, J.; Denkena, B. Influence of cutting edge geometry on tool wear performance in interrupted hard turning. J. Manuf. Process 2015, 19, 129–134. [Google Scholar] [CrossRef]

- Chen, L.; Stahl, J.E.; Zhao, W.; Zhou, J. Assessment on abrasiveness of high chromium cast iron material on the wear performance of PCBN cutting tools in dry machining. J. Mater. Processing Technol. 2018, 255, 110–120. [Google Scholar] [CrossRef]

- Zhao, G.; Xin, L.; Li, L.; Zhang, Y.; He, N.; Jansen, H.N. Cutting force model and damage formation mechanism in milling of 70wt% Si/Al composite. Chin. J. Aeronaut. 2022. [Google Scholar] [CrossRef]

- Salim, C.; Mohamed, A.; Salim, B.; Ahmed, B.; Khaoula, S.; Abdelkrim, H. Coated CBN cutting tool performance in green turning of gray cast iron EN-GJL-250, modeling and optimization. Int. J. Adv. Manuf. Technol. 2021, 113, 3643–3665. [Google Scholar]

- Wu, X.; Shen, J.; Jiang, F.; Wu, H.; Li, L. Study on the oxidation of WC-Co cemented carbide under different conditions. Int. J. Refract. Met. Hard Mater. 2021, 94, 105381. [Google Scholar] [CrossRef]

- Samad, N.B.O.; Yigit, K. Investigating the influence of built-up edge on forces and surface roughness in micro scale orthogonal machining of titanium alloyTi6Al4V. J. Mater. Processing Technol. 2016, 235, 28–40. [Google Scholar]

- Wu, X.; Li, L.; Zhao, M.; He, N. Experimental investigation of specific cutting energy and surface quality based on negative effective rake angle in micro turning. Int. J. Adv. Manuf. Technol. 2016, 82, 1941–1947. [Google Scholar] [CrossRef]

| Properties | Value |

|---|---|

| Density (g/mm3) | 7.2 |

| Hardness (HB) | 193 |

| Tensile strength (MPa) | 320 |

| Elasticity modulus (GPa) | 135 |

| Poisson ratio | 0.3 |

| Parameters | Value |

|---|---|

| Spindle speed n (rpm) | 700, 1000, 1300, 1600 |

| Depth of cut ap (mm) | 0.1, 0.2, 0.3, 0.4 |

| Feed rate f (mm/r) | 0.05, 0.1, 0.15, 0.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, G.; Shen, J.; Wu, Z.; Wu, X.; Jiang, F. Experimental Investigation on the Machinability of PCBN Chamfered Tool in Dry Turning of Gray Cast Iron. Processes 2022, 10, 1547. https://doi.org/10.3390/pr10081547

Yin G, Shen J, Wu Z, Wu X, Jiang F. Experimental Investigation on the Machinability of PCBN Chamfered Tool in Dry Turning of Gray Cast Iron. Processes. 2022; 10(8):1547. https://doi.org/10.3390/pr10081547

Chicago/Turabian StyleYin, Ganggang, Jianyun Shen, Ze Wu, Xian Wu, and Feng Jiang. 2022. "Experimental Investigation on the Machinability of PCBN Chamfered Tool in Dry Turning of Gray Cast Iron" Processes 10, no. 8: 1547. https://doi.org/10.3390/pr10081547