Characterization of Sludge Resulting from Chemical Coagulation and Electrocoagulation of Pumping Water from Fishmeal Factories

Abstract

:1. Introduction

2. Materials and Methods

2.1. Electrocoagulation Pilot System

2.2. Obtaining and Preparing Samples

2.3. Physicochemical Tests

3. Results and Discussion

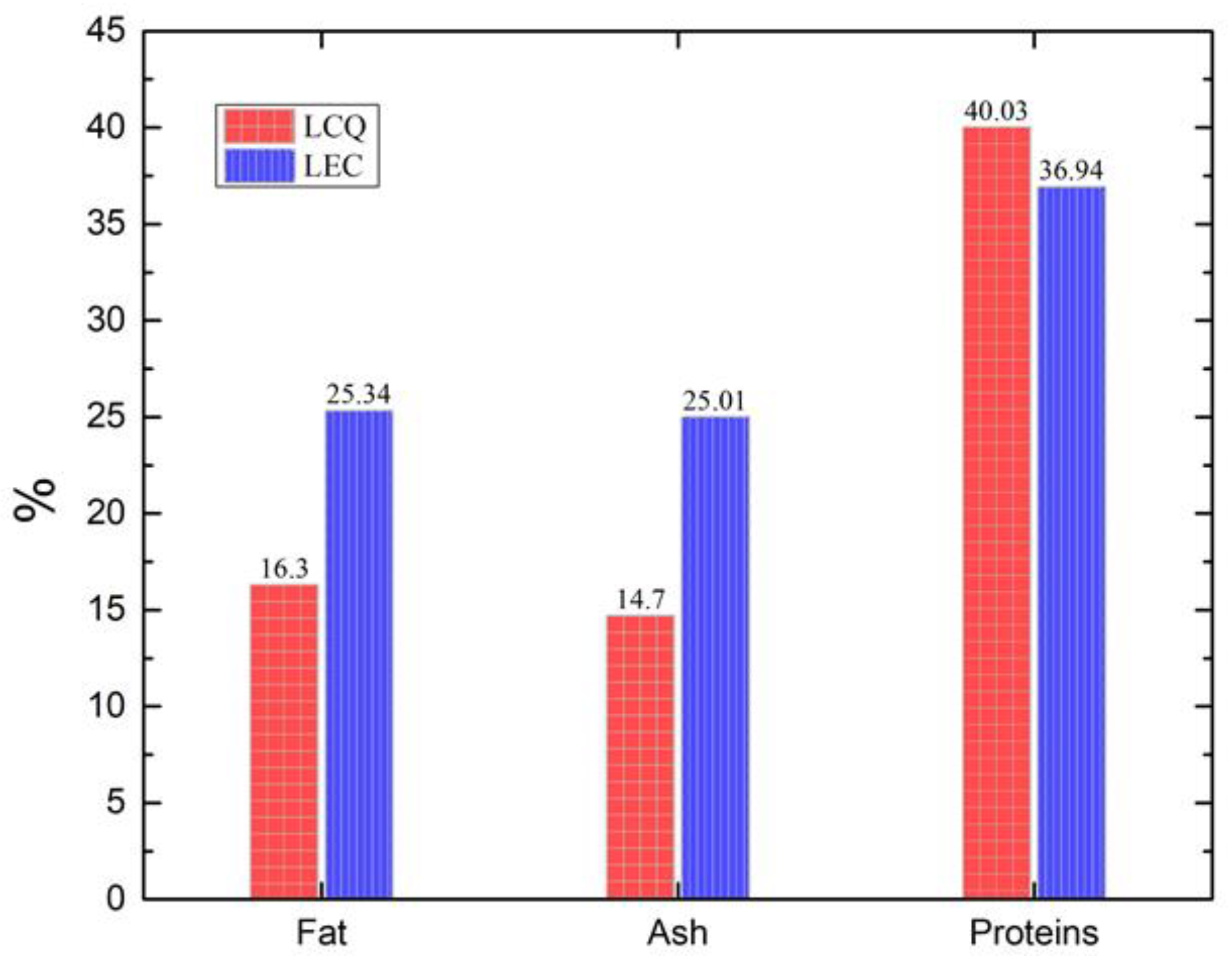

3.1. Proximate Composition of Sludge

3.2. Iron and Aluminum Content in Sludge

3.3. Fatty Acid Profile in the Fat Extracted from the Sludge

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Indexmundi, S.F. Producción de Harina de Pescado Por País en Miles de Toneladas. R. Available online: https://www.indexmundi.com/agriculture/?producto=harina-de-pescado&variable=produccion&l=es (accessed on 14 July 2022).

- Martí, C.; Roeckel, M.; Aspe, E.; Kanda, H. Recovery of proteins from fishmeal factory wastewaters. Process Biochem. 1994, 29, 39–46. [Google Scholar] [CrossRef]

- Figueroa, J.G.; Jung, H.Y.; Jeong, G.T.; Kim, J.K. The high reutilization value potential of high-salinity anchovy fishmeal wastewater through microbial degradation. World J. Microbiol. Biotechnol. 2015, 31, 1575–1586. [Google Scholar] [CrossRef]

- Centurión, R.I.; Ganoza, R.E.; Torres, R.M. Propuesta de Mejora en EL Control de Efluentes de Una Planta Pesquera; Universidad Peruana de Ciencias Aplicadas (UPC): Lima, Perú, 2007. [Google Scholar] [CrossRef]

- Aguilar, E.M.; Yupanqui, J.A. Optimización de la Dosis de Coagulante Y Floculante en El Tratamiento Químico Del Agua de Bombeo en Una Empresa Pesquera de Chimbote; Universidad Nacional de Trujillo: Trujillo, Perú, 2018; Available online: https://www.unitru.edu.pe/bitstream/handle/UNITRU/AguilarCruz (accessed on 12 July 2022).

- Espinoza, V.M.I. Propuesta de Adición de Lodos Recuperados Del Agua de Bombeo Para Mejorar El Rendimiento de Harina de Pescado en Una Empresa Pesquera; Universidad Nacional de Trujillo: Trujillo, Perú, 2016; Available online: https://www.dspace.unitru.edu.pe/bitstream/handle/UNITRU/7853 (accessed on 10 July 2022).

- Ministerio de la Producción. Anuario Estadístico Pesquero y Acuícola 2020. Lima 27, Perú. Available online: https://ogeiee.produce.gob.pe/index.php/en/shortcode/oee-documentos-publicaciones/publicaciones-anuales/item/1001-anuario-estadisticoo-pesquero-y-acuicola-2020 (accessed on 20 June 2022).

- Tay, J.H.; Show, K.Y.; Hung, Y.T. Seafood Processing Wastewater Treatment. ChemInform 37, 29–65. Available online: https://www.taylorfrancis.com/chapters/edit/10.1201/9780203026519-20/seafood-processing-wastewater-treatment-joo-hwa-tay-kuan-yeow-show-yung-tse-hung (accessed on 12 June 2022).

- Ministerio del Ambiente. Decreto Supremo N° 010-2018-MINAM. Lima, Perú. 2018. Available online: https://sinia.minam.gob.pe/dowload/file/fid/63554 (accessed on 12 March 2022).

- Brandt, M.J.; Johnson, K.M.; Elphinston, A.J.; Ratnayaka, D.D. Storage, clarification and chemical treatment. In Twort’s Water Supply; Elsevier: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Jarvis, P.; Banks, J.; Molinder, R.; Stephenson, T.; Parsons, S.A.; Jefferson, B. Processes for enhanced NOM removal: Beyond Fe and Al coagulation. Water Sci. Technol. Water Supply 2008, 8, 709–716. [Google Scholar] [CrossRef]

- Mollah, M.Y.; Morkovsky, P.; Gomes, J.A.; Kesmez, M.; Parga, J.; Cocke, D.L. Fundamentals, present and future perspectives of electrocoagulation. J. Hazard. Mater. 2004, 114, 199–210. [Google Scholar] [CrossRef] [PubMed]

- Hutcherson, J.R. A Comparison of Electrocoagulation and Chemical Coagulation Treatment Effectiveness on Frac Flowback and Produced Water. Ph.D. Thesis, Colorado State University, Fort Collins, CO, USA, 2015. [Google Scholar]

- Piña, M.; Martín, A.; González, C.; Prieto, F.; Guevara, A.; García, J. Revisión de variables de diseño y condiciones de operación en la electrocoagulación. Rev. Mex. De Ing. Química 2011, 10, 257–271. Available online: http://www.scielo.org.mx/scielo.php?script=sci_arttext&pid=S1665–27382011000200010 (accessed on 15 April 2022).

- Restrepo, A.; Arango, A.; Garcés, L. La Electrocoagulación: Retos y oportunidades en el tratamiento de aguas. Prod. Limpia 2006, 1, 58–77. [Google Scholar]

- Bensadok, K.; Belkacem, M.; Nezzal, G. Treatment of cutting oil/water emulsion by coupling coagulation and dissolved air flotation. Desalination 2007, 206, 440–448. [Google Scholar] [CrossRef]

- Mella, B.; Glanert, A.C.C.; Gutterres, M. Removal of chromium from tanning wastewater by chemical precipitation and electrocoagulation. In Proceedings of the XXXII Congress of the IULTCS, Istanbul, Türkiye, 29–31 May 2013. [Google Scholar]

- Apshankar, K.R.; Goel, S. Review and analysis of defluoridation of drinking water by electrocoagulation. J. Water Supply Res. Technol.—AQUA 2018, 67, 97–316. [Google Scholar] [CrossRef]

- Pranjal, P.D.; Mukesh, S.; Mihir, K.P. Recent progress on electrocoagulation process for wastewater treatment: A review. Sep. Purif. Technol. 2022, 292, 121058. [Google Scholar] [CrossRef]

- Kabdaşlı, I.; Arslan-Alaton, I.; Ölmez-Hancı, T.; Tünay, O. Electrocoagulation applications for industrial wastewaters: A Critical review. Environ. Technol. Rev. 2012, 1, 2–45. [Google Scholar] [CrossRef]

- Aguilar-Ascón, E.; Neyra-Ascón, W.; Albrecht-Ruiz, M.; Ibarra-Basurto, A. Optimizing the Reduction of Total Suspended Solids in Pump Water from Fish Factories Through Electrocoagulation using Response Surface Methodology. J. Ecol. Eng. 2021, 22, 269–277. [Google Scholar] [CrossRef]

- Rajaniemi, K.; Tuomikoski, S.; Lassi, U. Electrocoagulation Sludge Valorization—A Review. Resources 2021, 10, 127. [Google Scholar] [CrossRef]

- Ahmad, T.; Ahmad, K.; Ahad, A.; Alam, M. Characterization of water treatment sludge and its reuse as coagulant. J. Environ. Manag. 2016, 182, 606–611. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, T.; Ahmad, K.; Alam, M. Characterization of water treatment plant’s sludge and its safe disposal options. Procedia Environ. Sci. 2016, 35, 950–955. [Google Scholar] [CrossRef]

- Sharma, P.; Joshi, H. Utilization of electrocoagulation-treated spent wash sludge in making building blocks. Int. J. Environ. Sci. Technol. 2016, 13, 349–358. [Google Scholar] [CrossRef]

- Golder, A.K.; Samanta, A.N.; Ray, S. Anionic reactive dye removal from aqueous solution using a new adsorbent: Sludge generated in removal of heavy metal by electrocoagulation. Chem. Eng. J. 2002, 122, 107–115. [Google Scholar] [CrossRef]

- Santana, J.J.; Mena, V.F.; Betancor-Abreu, A.; Rodriguez-Raposo, R.; Izquierdo, J.; Souto, R.M. Use of alumina sludge arising from an electrocoagulation process as functional mesoporous microcapsules for active corrosion protection of aluminum. Prog. Org. Coat. 2021, 151, 106044. [Google Scholar] [CrossRef]

- FAO. Food and Nutrition Paper 14/7. Manuals of Food Quality Control. 7 Food Analisys: General Techniques, Additives, Contaminants and Composition; Food and Agriculture Organization of the United Nations: Rome, Italy, 1986. [Google Scholar]

- Horwitz, W. Official Methods of Analysis of AOAC International. Volume I, Agricultural Chemicals, Contaminants, Drugs/Edited by William Horwitz, 2010; AOAC International: Gaithersburg, MD, USA, 1997. [Google Scholar]

- Williams, T.R. Analytical Methods for Atomic Absorption Spectrophotometry; Perkin-Elmer Corp: Nolwalk, CT, USA, 1972. [Google Scholar]

- Sündermann, A.; Eggers, L.F.; Schwudke, D. Liquid Extraction: Bligh and Dyer. In Encyclopedia of Lipidomics; Wenk, M., Ed.; Springer: Dordrecht, The Netherlands, 2016. [Google Scholar] [CrossRef]

- Haan, T.Y.; Fen, C.S.; Radzi, M.F.; Ganasen, U. Comparative study for lake water remediation: Chemical coagulation and electrocoagulation. J. Kejuruter. SI 2018, 1, 81–87. [Google Scholar]

- Tchamango, S.R.; Kamdoum, O.; Donfack, D.; Babale, D. Comparison of electrocoagulation and chemical coagulation processes in the treatment of an effluent of a textile factory. J. Appl. Sci. Environ. Manag. 2017, 21, 1317–1322. [Google Scholar] [CrossRef]

- Tlaiaa, Y.S.; Naser, Z.A.R.; Ali, A.H. Comparison between coagulation and electrocoagulation processes for the removal of reactive black dye RB-5 and COD reduction. Desalin. Water Treat. 2020, 195, 154–161. [Google Scholar] [CrossRef]

- Holt, P.K.; Barton, G.W.; Wark, M.; Mitchell, C.A. A quantitative comparison between chemical dosing and electrocoagulation. Colloids Surf. A Physicochem. Eng. Asp. 2002, 211, 233–248. [Google Scholar] [CrossRef]

- Hardisson, A.; Revert, C.; Gonzales-Weler, D.; Rubio, C. Aluminium exposure through the diet. Food Sci. 2017, 3, 19. [Google Scholar] [CrossRef]

- Salas-Maldonado, A.; Ayala-Galdós, M.E.; Albrecht-Ruiz, M. Contenido de EPA y DHA en aceite crudo de pescado producido en el perú durante el periodo 1996–2000. CYTA-J. Food 2002, 3, 283–287. [Google Scholar] [CrossRef]

- Albrecht-Ruiz, M.; Salas-Maldonado, A. Chemical composition of light and dark muscle of Peruvian anchovy (Engraulis ringens) and its seasonal variation. J. Aquat. Food Prod. Technol. 2015, 24, 191–196. [Google Scholar] [CrossRef]

| Batch | % Fat | % Ash | % Proteins | |

|---|---|---|---|---|

| 1 | 13.75 ± 0.40 a | 14.14 ± 0.04 a | 41.26 ± 1.44 a,b | |

| Chemical coagulation sludge (LCQ) | 2 | 10.23 ± 0.33 b | 16.94 ± 0.08 b | 38.72 ± 0.96 b,c |

| 3 | 21.46 ± 0.44 c | 13.95 ± 0.09 c | 44.17 ± 2.21 a | |

| 4 | 19.76 ± 0.71 d | 13.76 ± 0.03 c | 35.98 ± 0.96 c | |

| 1 | 24.71 ± 0.54 a | 22.89 ± 0.31 b | 35.43 ± 0.52 b,c | |

| Electrocoagulation sludge (LEC) | 2 | 25.07 ± 2.21 a | 22.85 ± 0.36 b | 34.89 ± 0.61 c |

| 3 | 26.19 ± 0.60 a | 27.11 ± 0.14 a | 39.84 ± 0.70 a | |

| 4 | 25.41 ± 0.67 a | 27.19 ± 0.24 a | 37.59 ± 1.66 a,b |

| Batch | Fe % | Al % | |

|---|---|---|---|

| Chemical coagulation sludge (LCQ) | 1 | 4.60 ± 0.08 b | 0.01 |

| 2 | 4.64 ± 0.06 b | 0.01 | |

| 3 | 5.31 ± 0.03 a | 0.01 | |

| 4 | 4.69 ± 0.13 b | 0.01 | |

| Electrocoagulation sludge (LEC) | 1 | 0.03 | 4.12 ± 0.11 |

| 2 | 0.03 | 4.31 ± 0.17 | |

| 3 | 0.03 | 4.36 ± 0.10 | |

| 4 | 0.03 | 4.02 ± 0.02 |

| Chemical Coagulation Sludge (LCQ) | Electrocoagulation Sludge (LEC) | |||||||

|---|---|---|---|---|---|---|---|---|

| Ac. Fatty/Batch | 1 | 2 | 3 | 4 | 1 | 2 | 3 | 4 |

| C 14:0 (Myristic) | 10.65 | 9.73 | 10.89 | 10.44 | 10.72 | 10.62 | 10.63 | 10.63 |

| C 16:0 (Palmitic) | 24.88 | 23.69 | 25.8 | 25.03 | 29.85 | 30.11 | 30.29 | 31.1 |

| C 16:1 (Palmitoleic) | 10.93 | 8.96 | 11.24 | 11.01 | 9.37 | 9 | 9.13 | 9.01 |

| C 18:0 (Stearic) | 5.19 | 5.04 | 5.37 | 5.26 | 7.28 | 7.37 | 7.46 | 7.62 |

| C 18:1 w-9 (Oleic) | 10.11 | 11.67 | 10.28 | 10.07 | 9.87 | 9.28 | 9.34 | 9.58 |

| C 18:1 w-7 (Vaccenic) | 3.72 | 3.33 | 4.11 | 4.08 | 4.4 | 4.28 | 4.34 | 4.49 |

| C 18:2 w-6 (Linoleic) | 1.24 | 1.04 | 1.24 | 1.28 | 1.05 | 0.96 | 1.03 | 1.05 |

| C 20:5 w-3 (EPA) | 9.69 | 11.12 | 9 | 10.11 | 4.5 | 4.4 | 4.35 | 4.28 |

| C 22:5 w-3 (Cupladonic) | 1.06 | 1.43 | 1.02 | 1.13 | 1.61 | 1.63 | 1.73 | 1.78 |

| C 22:6 w-3 (DHA) | 8.59 | 1.43 | 7.64 | 8.66 | 8.08 | 8.41 | 8.21 | 7.62 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aguilar-Ascón, E.; Solari-Godiño, A.; Cueva-Martínez, M.; Neyra-Ascón, W.; Albrecht-Ruíz, M. Characterization of Sludge Resulting from Chemical Coagulation and Electrocoagulation of Pumping Water from Fishmeal Factories. Processes 2023, 11, 567. https://doi.org/10.3390/pr11020567

Aguilar-Ascón E, Solari-Godiño A, Cueva-Martínez M, Neyra-Ascón W, Albrecht-Ruíz M. Characterization of Sludge Resulting from Chemical Coagulation and Electrocoagulation of Pumping Water from Fishmeal Factories. Processes. 2023; 11(2):567. https://doi.org/10.3390/pr11020567

Chicago/Turabian StyleAguilar-Ascón, Edwar, Armando Solari-Godiño, Miguel Cueva-Martínez, Walter Neyra-Ascón, and Miguel Albrecht-Ruíz. 2023. "Characterization of Sludge Resulting from Chemical Coagulation and Electrocoagulation of Pumping Water from Fishmeal Factories" Processes 11, no. 2: 567. https://doi.org/10.3390/pr11020567

APA StyleAguilar-Ascón, E., Solari-Godiño, A., Cueva-Martínez, M., Neyra-Ascón, W., & Albrecht-Ruíz, M. (2023). Characterization of Sludge Resulting from Chemical Coagulation and Electrocoagulation of Pumping Water from Fishmeal Factories. Processes, 11(2), 567. https://doi.org/10.3390/pr11020567