Study on Mechanism and Verification of Columnar Penetration Grouting of Time-Varying Newtonian Fluids

Abstract

:1. Introduction

2. Rheological Equation of Time-Varying Newtonian Fluid

3. Study on Columnar Penetration Grouting Mechanism of Time-Varying Viscosity Newtonian Fluid

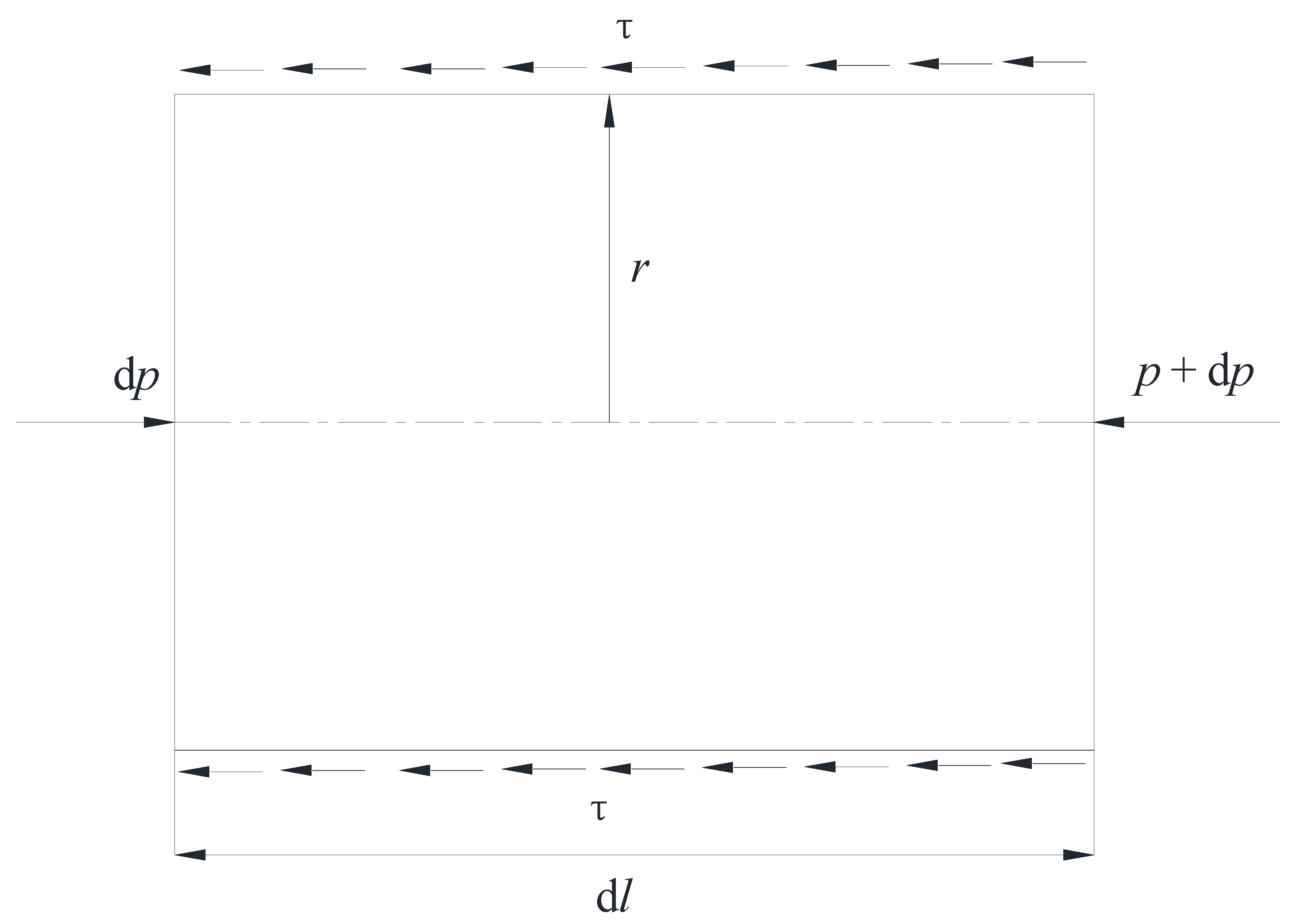

3.1. Time-Varying Newtonian Fluid Penetration Equation of Motion

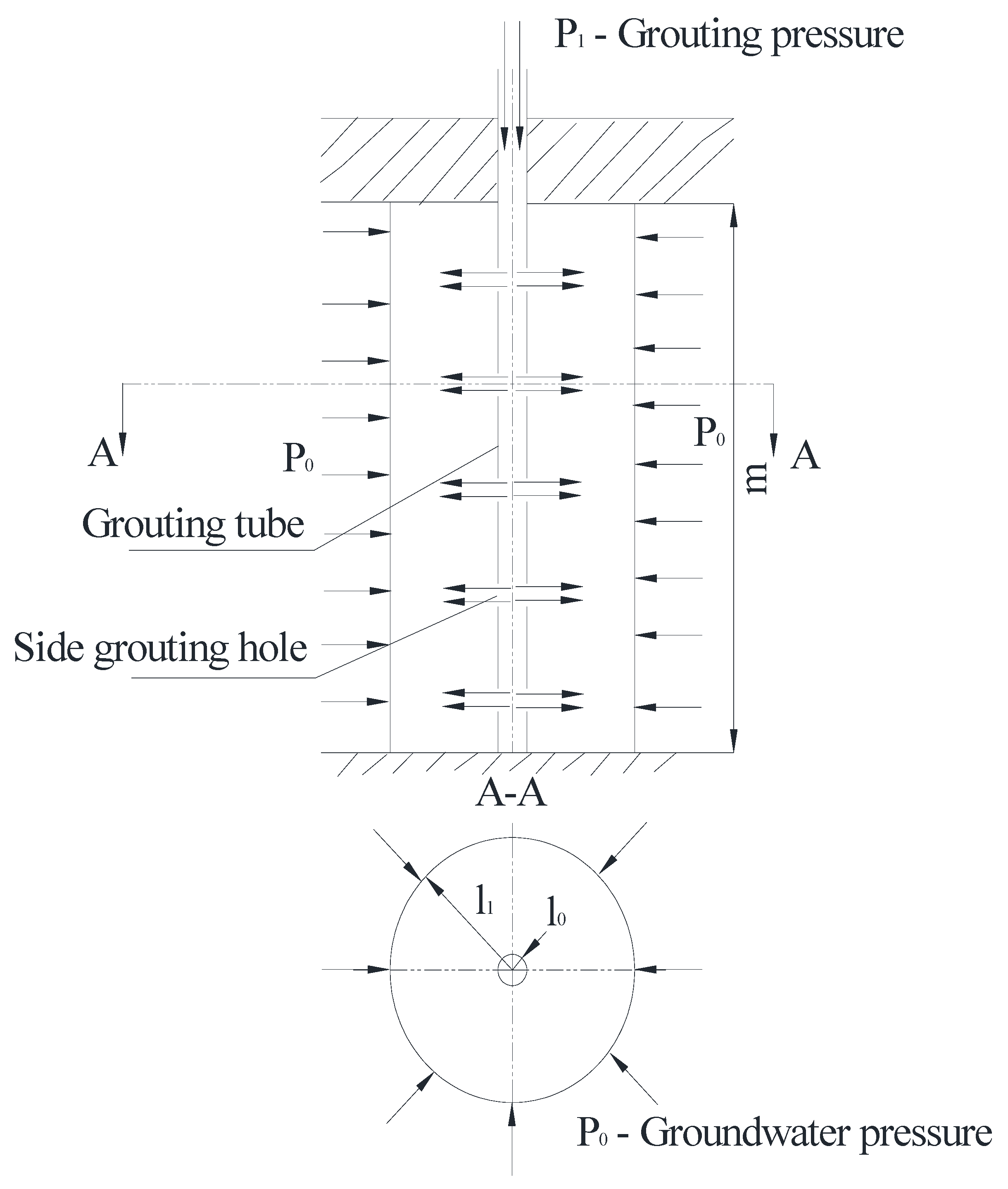

3.2. Columnar Penetration Grouting Mechanism of Time-Varying Viscosity Newtonian Fluid

- (1)

- The medium or material being injected satisfies isotropy and homogeneity;

- (2)

- The fluid is incompressible and the flow pattern remains unchanged during the grouting process;

- (3)

- The dynamic viscosity of Newtonian fluids is time-varying (increasing with time), and it changes exponentially with time;

- (4)

- The grouting is carried out by the filling pressure method, and the slurry is injected into the injected medium from the side hole of the grouting pipe and diffuses in a columnar surface;

- (5)

- The gravity effect of the fluid is neglected in the grouting process, and the influence of the diffusion path of the slurry in the injected medium is not considered;

- (6)

- The flow velocity is small, and the slurry is laminar, except for the turbulent flow state in the local area around the grouting hole.

4. The Applicable Scope and Parameter Determination of the Equation

4.1. Application Scope of Equation

4.2. Determining the Parameters in the Equation

- (1)

- (2)

- Measurement tests of Newtonian fluid viscosity are carried out using rotary or capillary viscometers and are obtained by analysis and calculation.

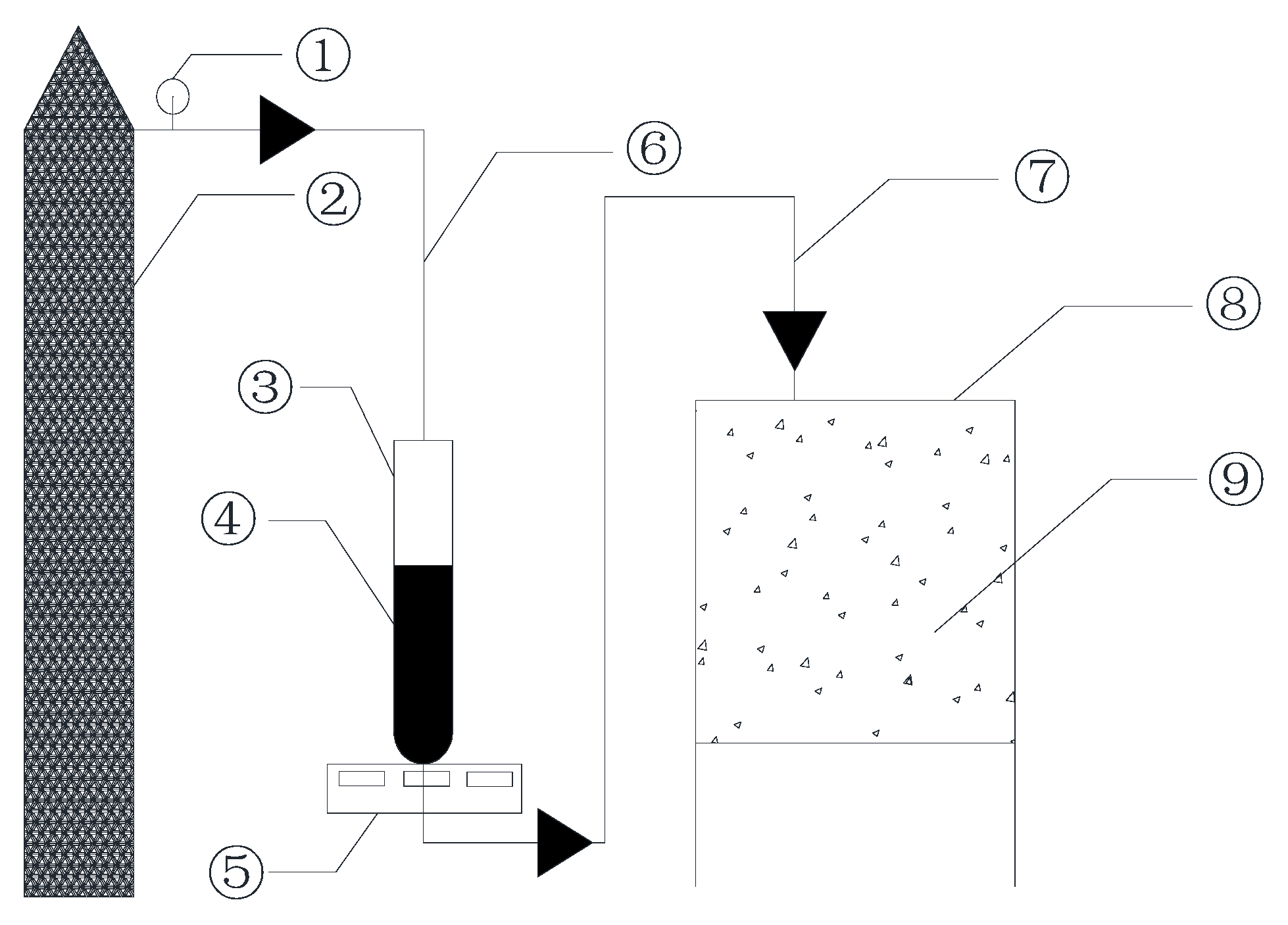

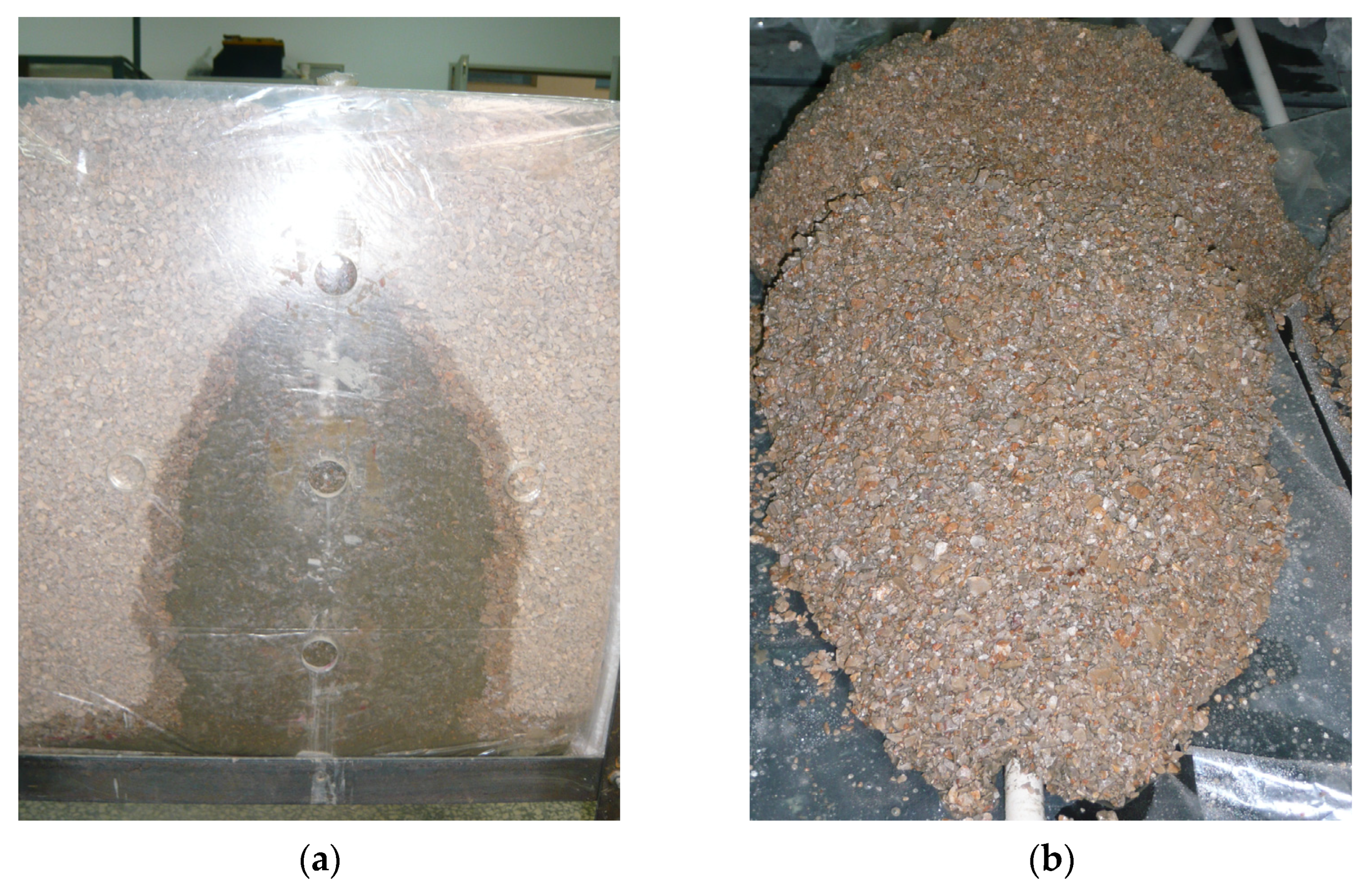

5. Grouting Verification Test

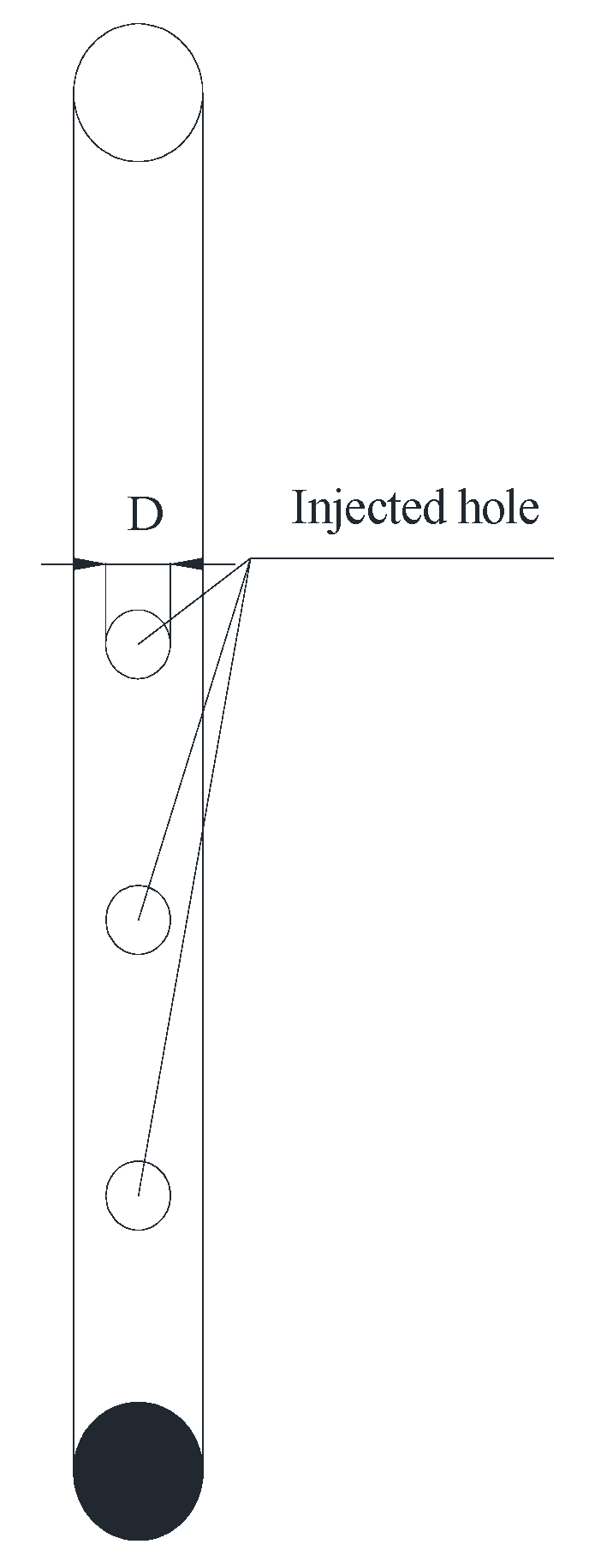

5.1. Experimental Device and Grouting Material

5.2. Grouting Verification Test

5.2.1. Experimental Design

5.2.2. Determination of Grouting Diffusion Radius

5.2.3. Analysis of Results

- (1)

- In this paper, sand gravel is selected as the injection medium. Although their particle size distribution is uniform and they are washed three times before the test to meet the isotropy and homogeneity conditions as much as possible, they are still different from the isotropy and homogeneity assumptions made in theoretical research.

- (2)

- Many factors affect the permeability and diffusion effect of viscosity time-varying Newtonian fluids in the injected medium. For example, when the cement slurry is configured, it is an unstable slurry, due to the excessive water separation rate, and it is assumed to be a stable slurry when the columnar permeability and diffusion mechanism equation of a viscosity time-varying Newtonian fluid is used to calculate the theoretical value. For example, problems such as precipitation and blockage may occur when cement slurry diffuses in the injected medium.

- (3)

- At present, although some research results have been obtained on the time-varying characteristics of viscosity of Newtonian fluid, they cannot fully reflect the time-varying law. In the future, we should further strengthen the research on the time-varying characteristics and laws of Newtonian fluids.

- (4)

- The diffusion path of Newtonian fluids in the injected medium, and the influence of gravity on the grouting effect, is not considered, which is the most important reason.

6. Conclusions

- (1)

- Based on the basic rheological equation of Newtonian fluids and its dynamic viscosity time-varying law, the penetration motion equation of a viscosity time-varying Newtonian fluid is studied.

- (2)

- Based on the penetration motion equation of a viscosity time-varying Newtonian fluid, the TVNCPGDM equation is derived, the application scope of the equation is analyzed, and the specific acquisition method of the parameters is determined.

- (3)

- A grouting experiment was designed, to verify the derived TVNCPGDM equation. The results show that the theoretical value of the grouting diffusion radius calculated by the TVNCPGDM equation is closer to the experimental value than the theoretical value of the diffusion radius obtained by the columnar penetration grouting equation without considering the time-varying viscosity of the Newtonian fluid. This shows that the TVNCPGDM equation derived in this paper can better reflect the diffusion law and diffusion morphology of columnar penetration grouting of Newtonian fluids in the injected medium with time, and the obtained diffusion radius of penetration grouting is more in line with the actual grouting engineering needs, so it can provide theoretical support and guidance for actual grouting construction.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Guo, X.-J.; Li, Y.; Cui, P.; Yan, H.; Zhuang, J.-Q. Intermittent viscous debris flow formation in Jiangjia Gully from the perspectives of hydrological processes and material supply. J. Hydrol. 2020, 589, 125184. [Google Scholar] [CrossRef]

- Tang, Y.-J.; Xu, Z.-M.; Yang, T.-Q.; Zhou, Z.-H.; Wang, K.; Ren, Z.; Yang, K.; Tian, L. Impacts of small woody debris on slurrying, persistence, and propagation in a low-gradient channel of the Dongyuege debris flow in Nu River, Southwest China. Landslides 2018, 15, 2279–2293. [Google Scholar] [CrossRef]

- Yang, Z.Q.; Zhao, X.G.; Chen, M.; Zhang, J.; Yang, Y.; Chen, W.T.; Bai, X.F.; Wang, M.M.; Wu, Q. Characteristics, dynamic analyses and hazard assessment of debris flows in Niumiangou Valley of Wenchuan County. Appl. Sci. 2023, 13, 1161. [Google Scholar] [CrossRef]

- Liu, Z.Q.; Yang, Z.Q.; Chen, M.; Xu, H.H.; Yang, Y.; Zhang, J.; Wu, Q.; Wang, M.M.; Song, Z.; Ding, F.S. Research Hotspots and Frontiers of Mountain Flood Disaster: Bibliometric and Visual Analysis. Water 2023, 15, 673. [Google Scholar] [CrossRef]

- Park, D.; Oh, J. Permeation grouting for remediation of dam cores. Eng. Geol. 2018, 233, 63–75. [Google Scholar] [CrossRef]

- Wang, G.-J. Grouting Technology Theory and Practice; China University of Mining and Technology Press: Beijing, China, 2000. [Google Scholar]

- Kuang, J.-Z. Geotechnical Grouting Theory and Engineering Examples; Science Press: Beijing, China, 1993. [Google Scholar]

- Yang, Z.-Q.; Wei, L.; Liu, Y.-Q.; He, N.; Zhang, J.; Xu, H.-H. Discussion on the Relationship between Debris Flow Provenance Particle Characteristics, Gully Slope, and Debris Flow Types along the Karakoram Highway. Sustainability 2023, 15, 5998. [Google Scholar] [CrossRef]

- Wang, A.-H.; Ding, X.-M.; Zhang, D.-Y. Grouting reinforcement technology for soft ground differential settlement disease of in-service highway. J. Se. U. 2017, 47, 397–403. [Google Scholar]

- Qi, W.-R.; Gao, Y.-T. Study on Comprehensive Construction and Monitoring Technology of Highway Tunnel Crossing Weak and Fractured Surrounding Rock. J. Highw. Transp. Res. Dev. 2021, 38, 88–96+105. [Google Scholar]

- Zeng, G.-X.; Zhao, S.-P.; Yao, A.-L.; Shi, X.-S.; Wang, Q.-Y.; Xu, S.-S. Finite Element Analysis of Small Duct Grouting Effect on Surrounding Rock Stability at Small Interval Highway Tunnel. Adv. Eng. Sci. 2008, 52, 1–6. [Google Scholar]

- Zhang, X.-J. Research on the Grouting Reinforcement Parameters of Tunnel Surrounding Rock in Saturated Soft Loess. J. Railw. Eng. Soc. 2021, 38, 60–65. [Google Scholar]

- Zeng, D.-Y.; Bai, D.-F. Research on the Measures of Metro Mine Method Tunnel Construction Side-crossing Bridge Pile Foundation in Long Distance. J. Railw. Eng. Soc. 2021, 38, 68–73+80. [Google Scholar]

- Chen, J.-X.; Chen, L.-J.; Luo, Y.-J.; Wang, C.-W.; Liu, W.-W. Mechanism and control method of large deformation for large-span chlorite schist tunnel. J. Traffic Transp. Eng. 2021, 21, 93–106. [Google Scholar]

- Hou, C.-J.; Wang, X.-Y.; Bai, J.-B.; Meng, N.-K.; Wu, W.-D. Basic theory and technology study of stability control for surrounding rock in deep roadway. J. Chin. Univ. Min. Technol. 2021, 50, 1–12. [Google Scholar]

- Kotha, G.; Kumari, M.A.; Rao, M.V.S.; Chamkha, A.J. Oldroyd-B Nanoliquid Flow Through a Triple Stratified Medium Submerged with Gyrotactic Bioconvection and Nonlinear Radiations. Arab. J. Sci. Eng. 2022, 47, 8863–8875. [Google Scholar]

- Kotha, G.; Kolipaula, V.R.; Rao, M.V.S.; Penki, S.; Chamkha, A.J. Internal heat generation on bioconvection of an MHD nanofluid flow due to gyrotactic microorganisms. Eur. Phys. J. Plus 2020, 135, 600. [Google Scholar] [CrossRef]

- Zou, J.-F.; Li, L.; Yang, X.-L. Penetration radius and pressure attenuation law in fracturing grouting. J. Hydraul. Eng. 2006, 37, 314–319. [Google Scholar]

- Baker, C. Comments on Paper ‘Rock Stabilization in Rock Mechanics; Muler Springer-Verlag NY: New York, NY, USA, 1974. [Google Scholar]

- Liu, J.-C. Study on crack grouting diffusion radius. In Collection Papers of China Institute of Water Resources and Hydropower Research (No.8); Water Resources and Electric Power Press: Beijing, China, 1982; pp. 186–195. [Google Scholar]

- Jiang, C.-W.; Ni, W.-Y. Theoretical analysis and the control technology of drilling and grouting. Saf. Coal Mines 1999, 14–15. [Google Scholar] [CrossRef]

- Nong, W.-L. Theories and Practice of Grouting; Northeast University Press: Shenyang, China, 1991. [Google Scholar]

- Yang, Z.-Q.; Hou, K.-P.; Ling, W.; Cheng, Y.; Yang, B.-J. Study of diffusion parameters of Newtonian fluid based on column-hemispherical penetration grouting. Rock Soil Mech. 2014, 35, 17–24. [Google Scholar]

- Liu, Q.-S.; Lu, C.-B.; Liu, B.; Lu, X.-L. Research on Rheological Behavior for Cement Grout Considering Temperature and Hydration Time Effects. Chin. J. Rock Mech. Eng. 2014, 33, 3730–3740. [Google Scholar]

- Wang, C.-J.; Diao, Y.-L.; Guo, C.-C.; Li, P.; Du, X.-M.; Pan, Y.-H. Two-stage column–hemispherical penetration diffusion model considering porosity tortuosity and time-dependent viscosity behavior. Acta Geotech. 2022, 1–20. [Google Scholar] [CrossRef]

- Fu, Y.-B.; Wang, X.-L.; Zhang, S.-Z.; Yang, Y. Modelling of Permeation Grouting considering Grout Self-Gravity Effect: Theoretical and Experimental Study. Adv. Mater. Sci. Eng. 2019, 2019, 7968240. [Google Scholar] [CrossRef] [Green Version]

- Ruan, W.-J. Research on Diffusion of Grouting and Basic Properties of Grouts. Chin. J. Geotech. Eng. 2005, 27, 69–73. [Google Scholar]

- Kong, Y.-X. Higher Percolation Mechanics; Press of University of Science and Technology of China: Beijing, China, 1999. [Google Scholar]

- Lu, Q.; Yang, Z.-C.; Yang, Z.-Q.; Yu, R.-X.; Zhu, Y.-Y.; Yang, Y.; Zhang, B.-H.; Wang, R.-C.; Fang, Y.-C.; Yu, D.-L.; et al. Penetration grouting mechanism of Binham fluid considering diffusion paths. Rock Soil Mech. 2022, 43, 385–394. [Google Scholar]

- Shen, C.-T.; Liu, H.-N. Non-Newtonian Fluid Mechanics and Its Application; Higher Education Press: Beijing, China, 1989. [Google Scholar]

- Gao, D.-R. Engineering Fluid Mechanics; Mechanical Industry Press: Beijing, China, 1999. [Google Scholar]

- Zenit, R.; Koch, D.L.; Sangani, A.S. Measurement of the average properties of a suspension of bubbles rising in a vertical channel. J. Fluid Mech. 2001, 429, 2–3. [Google Scholar] [CrossRef] [Green Version]

- Zhang, W.; Chen, W.-Y. Fluid Mechanics, 2nd ed.; Tianjin University Press: Tianjin, China, 2009. [Google Scholar]

- Zeng, X.-X. Mud Rheology and Viscosity Measurement; The Geological Society of Hunan: Hunan, China, 1981; pp. 161–170. [Google Scholar]

- Ruan, W.-J. Basic Properties of Grouts and Spreading of Grouts in Rock Mass Fissures; Jilin University: Jilin, China, 2013. [Google Scholar]

- Yang, Z.-Q.; Hou, K.-P.; Guo, T.-T. Research on time-varying behavior of cement grouts of different water-cement ratios. Appl. Mech. Mater. 2011, 73, 4398–4401. [Google Scholar] [CrossRef]

- Ministry of water resources and electric power. Standard for Test Methods of Earthworks; Beijing China Planning Publishing House: Beijing, China, 1989. [Google Scholar]

- Guo, T.-T.; Zhang, Z.-W.; Yang, Z.-Q.; Zhu, Y.-Y.; Yang, Y.; Guo, Y.-H.; Wang, R.-C.; Zhang, B.-H.; Fang, Y.-C.; Yu, D.-L.; et al. Penetration Grouting Mechanism of Time-Dependent Power-Law Fluid for Reinforcing Loose Gravel Soil. Minerals 2021, 11, 1391. [Google Scholar] [CrossRef]

- Yang, Z.-Q.; Ding, Y.; Yang, Y.; Zhu, Y.-Y.; Zhang, J.; Guo, Y.-F.; Chen, X.-G. Hydration-time-dependent rheological behaviors of Newtonian cement grouts with different water cement ratios. Trans. Chin. Soc. Agr. Eng. 2020, 36, 161–167. [Google Scholar]

- Yang, Z.-Q.; Niu, X.-D.; Hou, K.-P.; Zhou, Z.-H.; Liang, W.; Guo, Y.-H.; Lu, Y.-F.; Yang, B.-J.; Cheng, Y. Columnar diffusion of cement grout with time dependent rheological parameters. Chin. J. Rock Mech. Eng. 2015, 34, 1415–1425. [Google Scholar]

| According to the Equation of this Paper, the Calculated Value of Grouting Diffusion Radius Theory /mm | According to the Calculated Value of the Columnar Penetration Grouting Equation without Considering the Time-Varying Viscosity of Newtonian Fluid in Reference [7] /mm | Grouting Diffusion Radius Actual Measured Value /mm |

|---|---|---|

| 245.3 | 261.6 | 126.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, X.; Yang, Z.; Meng, X.; Wang, S.; Li, R.; Xu, H.; Wang, X.; Ye, C.; Xiang, T.; Xu, W.; et al. Study on Mechanism and Verification of Columnar Penetration Grouting of Time-Varying Newtonian Fluids. Processes 2023, 11, 1151. https://doi.org/10.3390/pr11041151

Zhao X, Yang Z, Meng X, Wang S, Li R, Xu H, Wang X, Ye C, Xiang T, Xu W, et al. Study on Mechanism and Verification of Columnar Penetration Grouting of Time-Varying Newtonian Fluids. Processes. 2023; 11(4):1151. https://doi.org/10.3390/pr11041151

Chicago/Turabian StyleZhao, Xuguang, Zhiquan Yang, Xiangrui Meng, Shaobin Wang, Rui Li, Hanhua Xu, Xiangpeng Wang, Changwen Ye, Tianbing Xiang, Wanzhong Xu, and et al. 2023. "Study on Mechanism and Verification of Columnar Penetration Grouting of Time-Varying Newtonian Fluids" Processes 11, no. 4: 1151. https://doi.org/10.3390/pr11041151