Research and Optimization of Operating Parameters of a Rotor Classifier for Calcined Petroleum Coke

Abstract

:1. Introduction

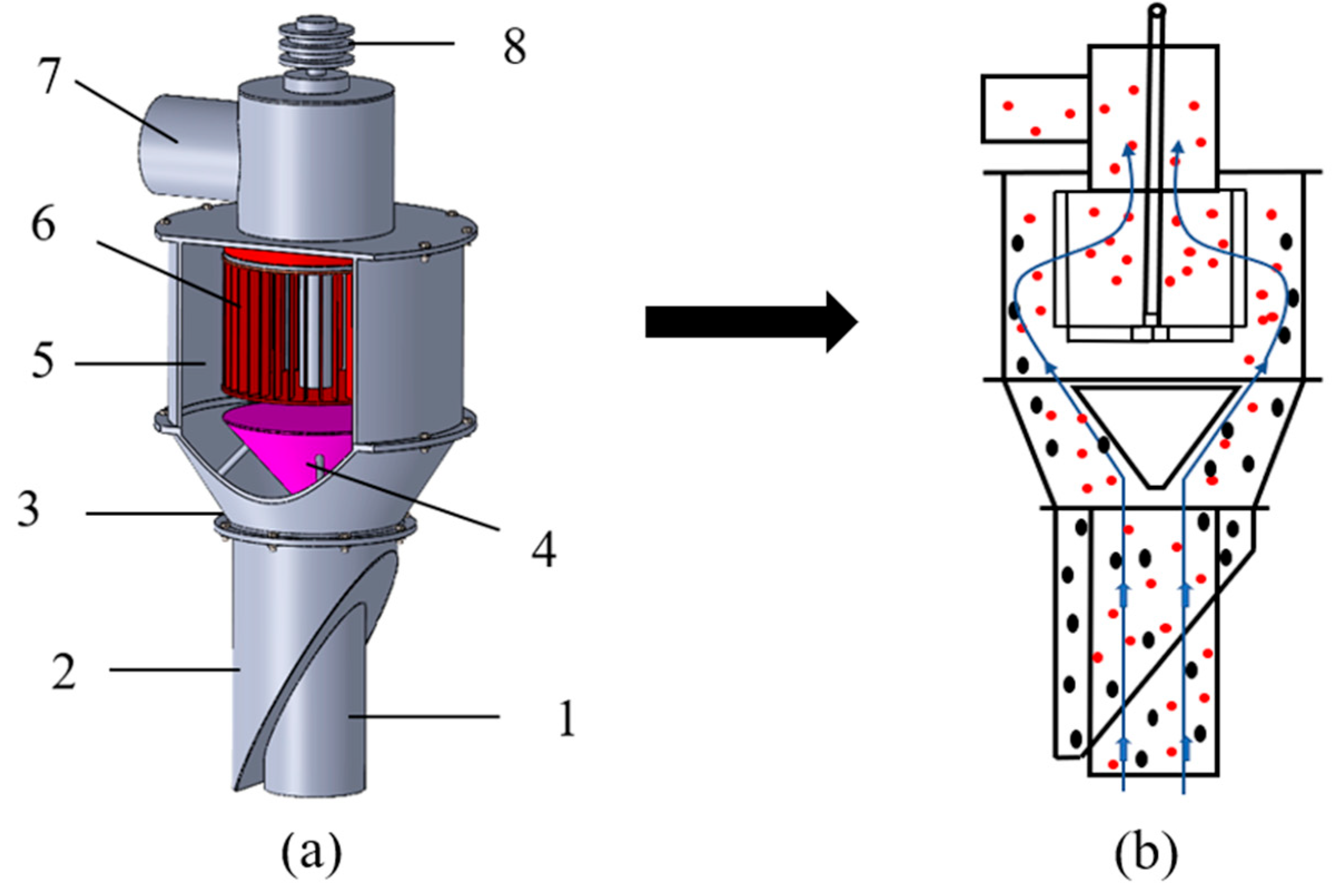

2. Structure and Working Principle

3. Experiment

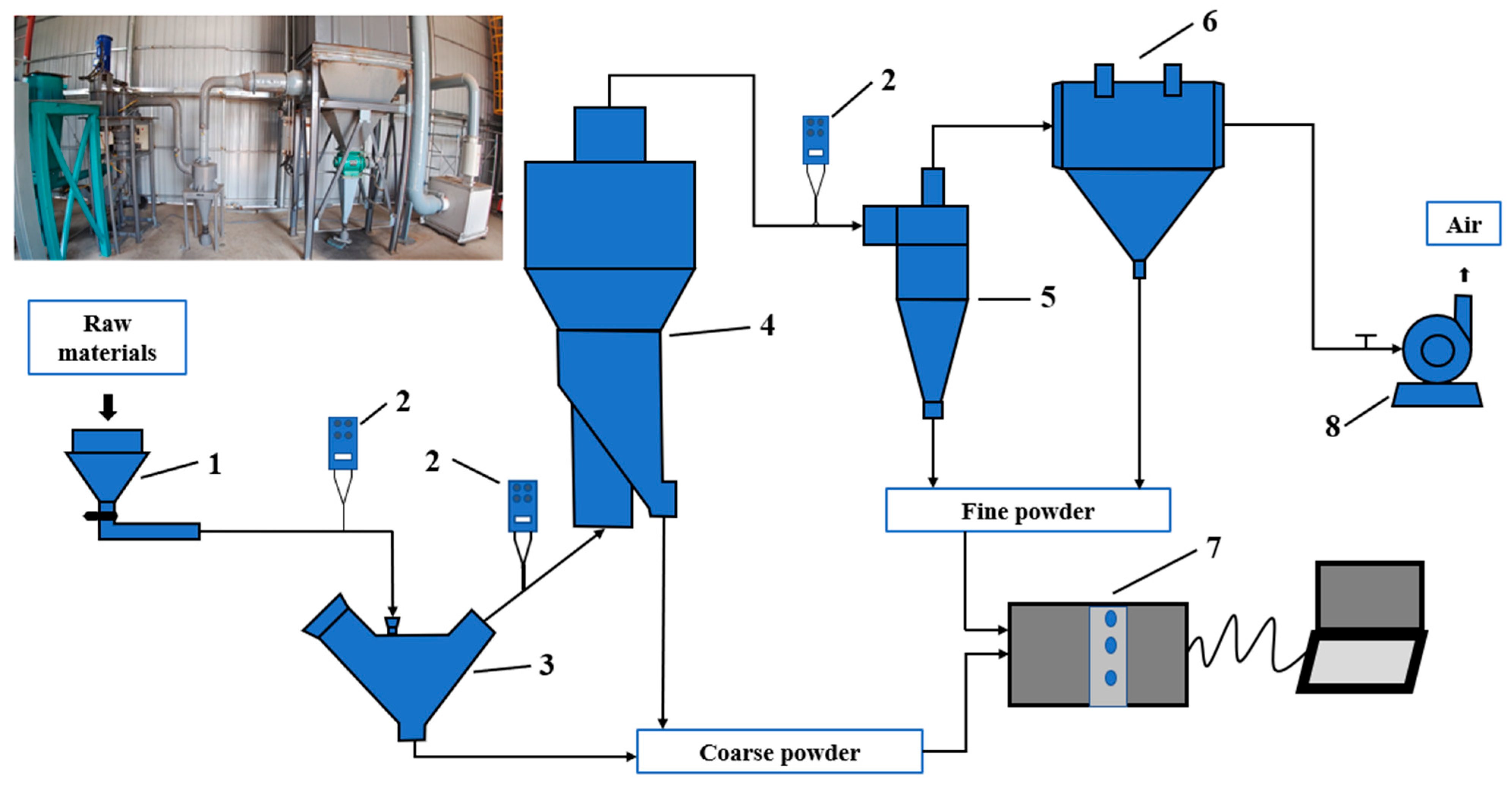

3.1. Raw Material and Experimental Setup

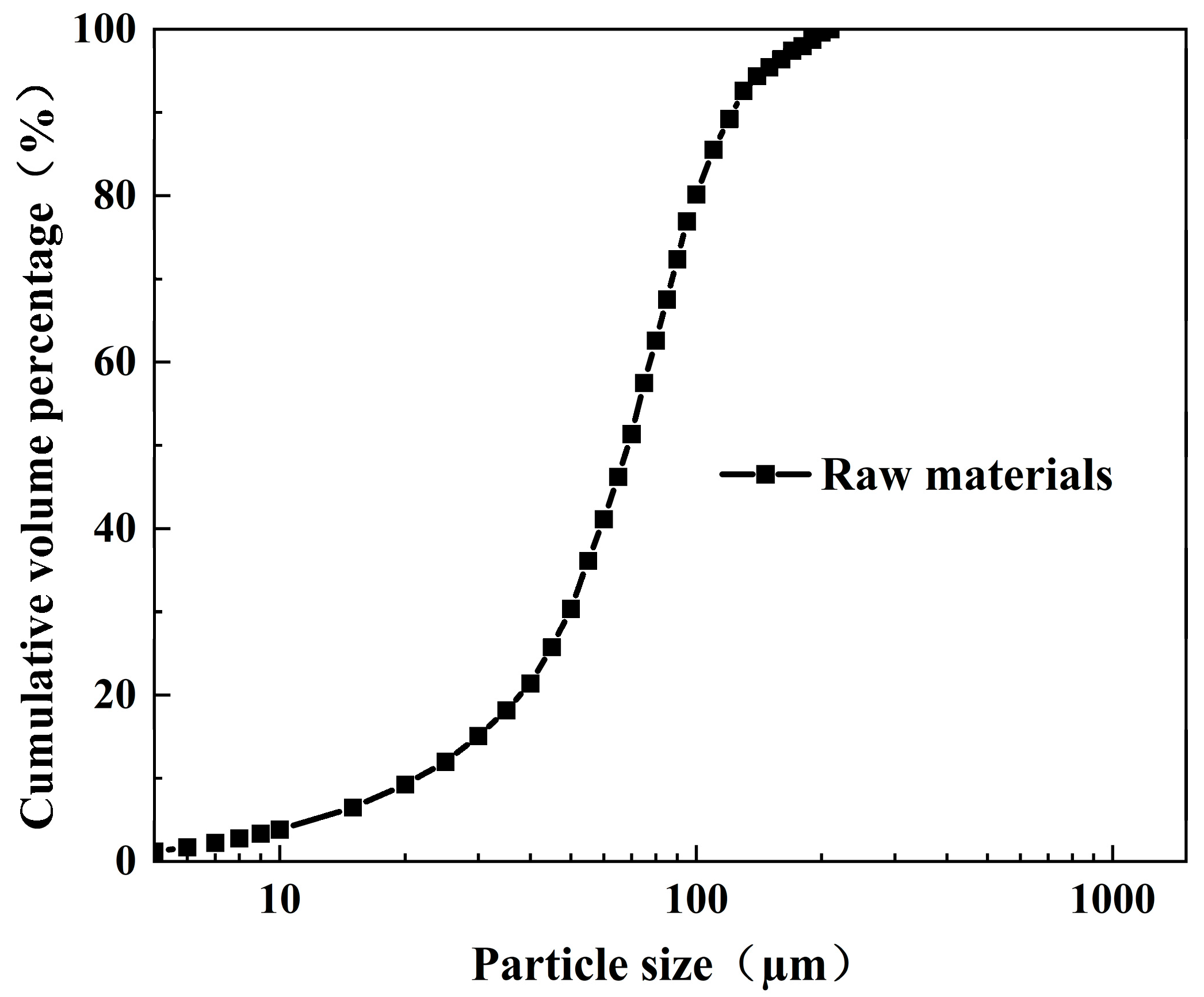

3.1.1. Raw Material

3.1.2. Experimental Device

3.2. The Classification Performance Index

3.2.1. Newton’s Classification Efficiency (ηN)

3.2.2. Cut Size (dc)

3.2.3. Classification Accuracy (K)

4. Experimental Results and Analysis

4.1. Effect of the Operating Parameters on the Classification Performance

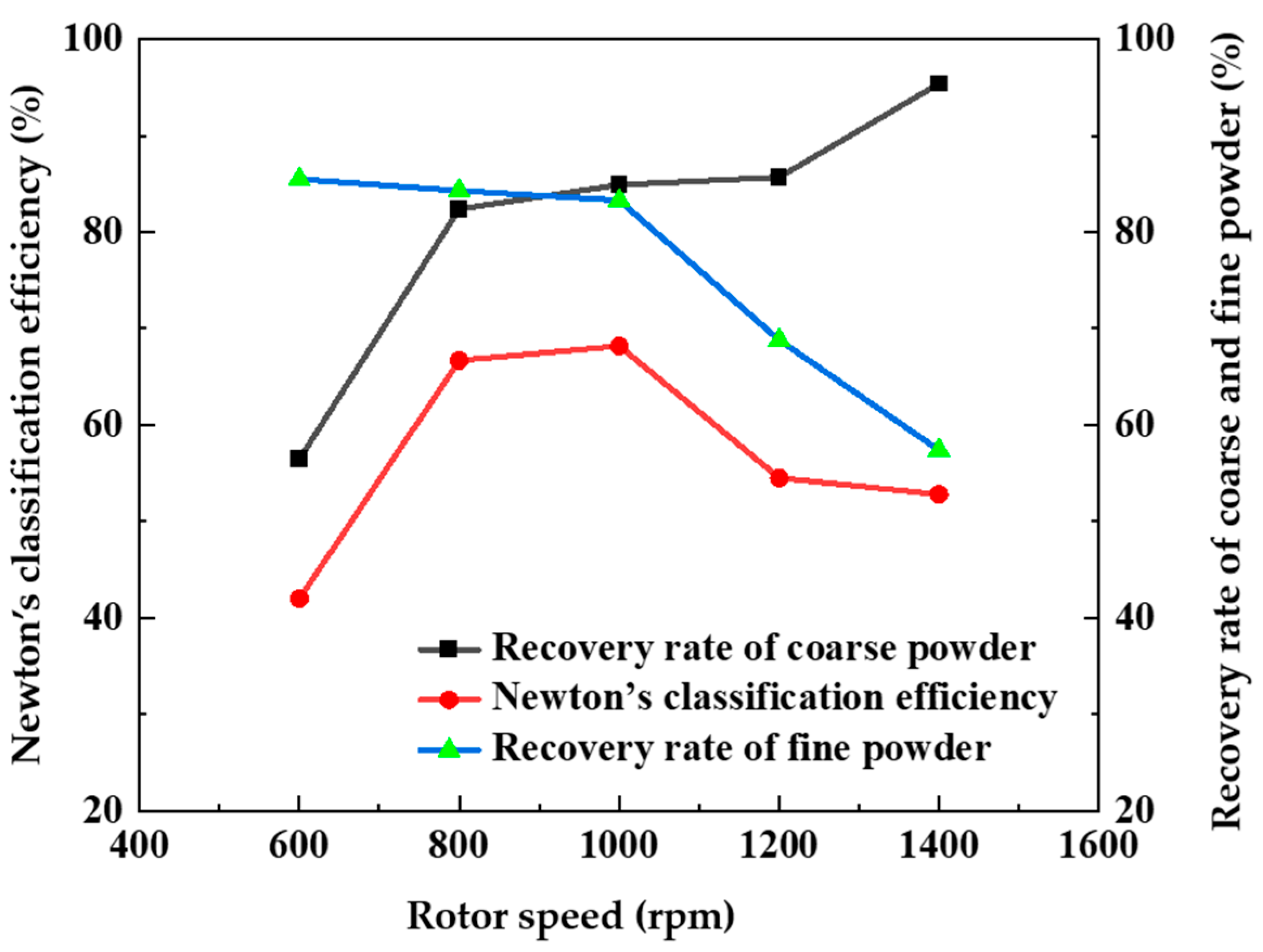

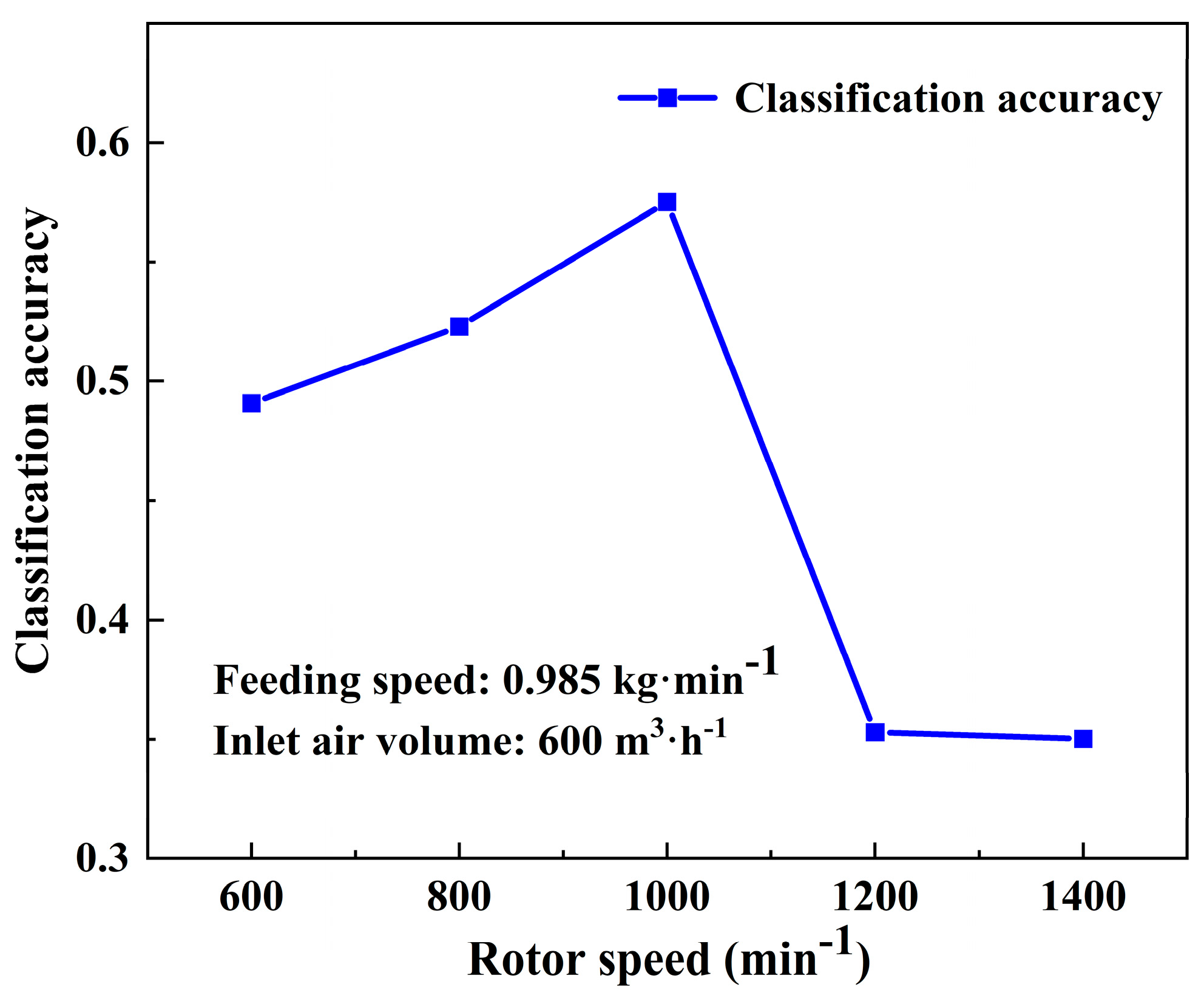

4.1.1. Effect of the Rotor Speed

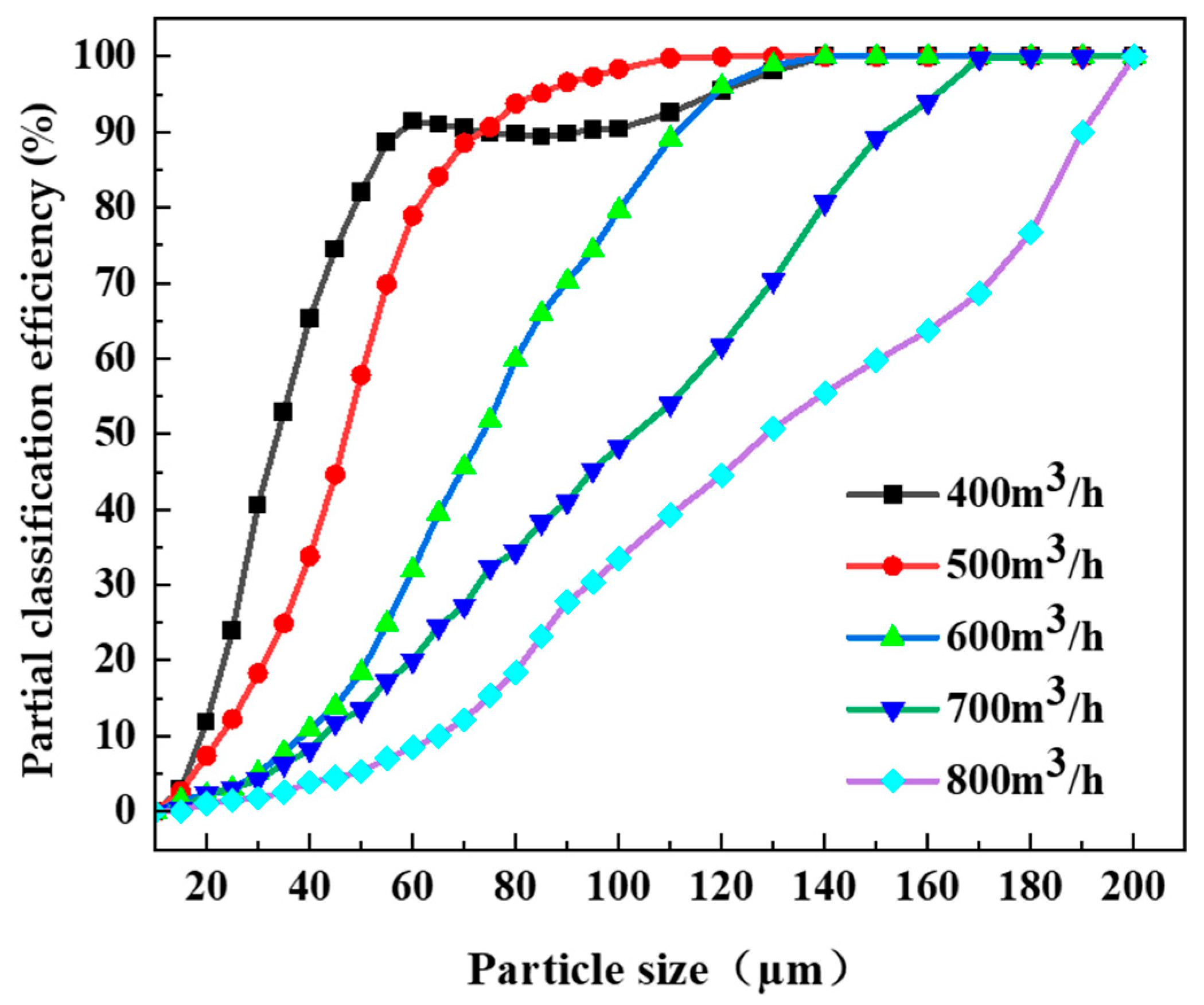

4.1.2. Effect of the Inlet Air Volume

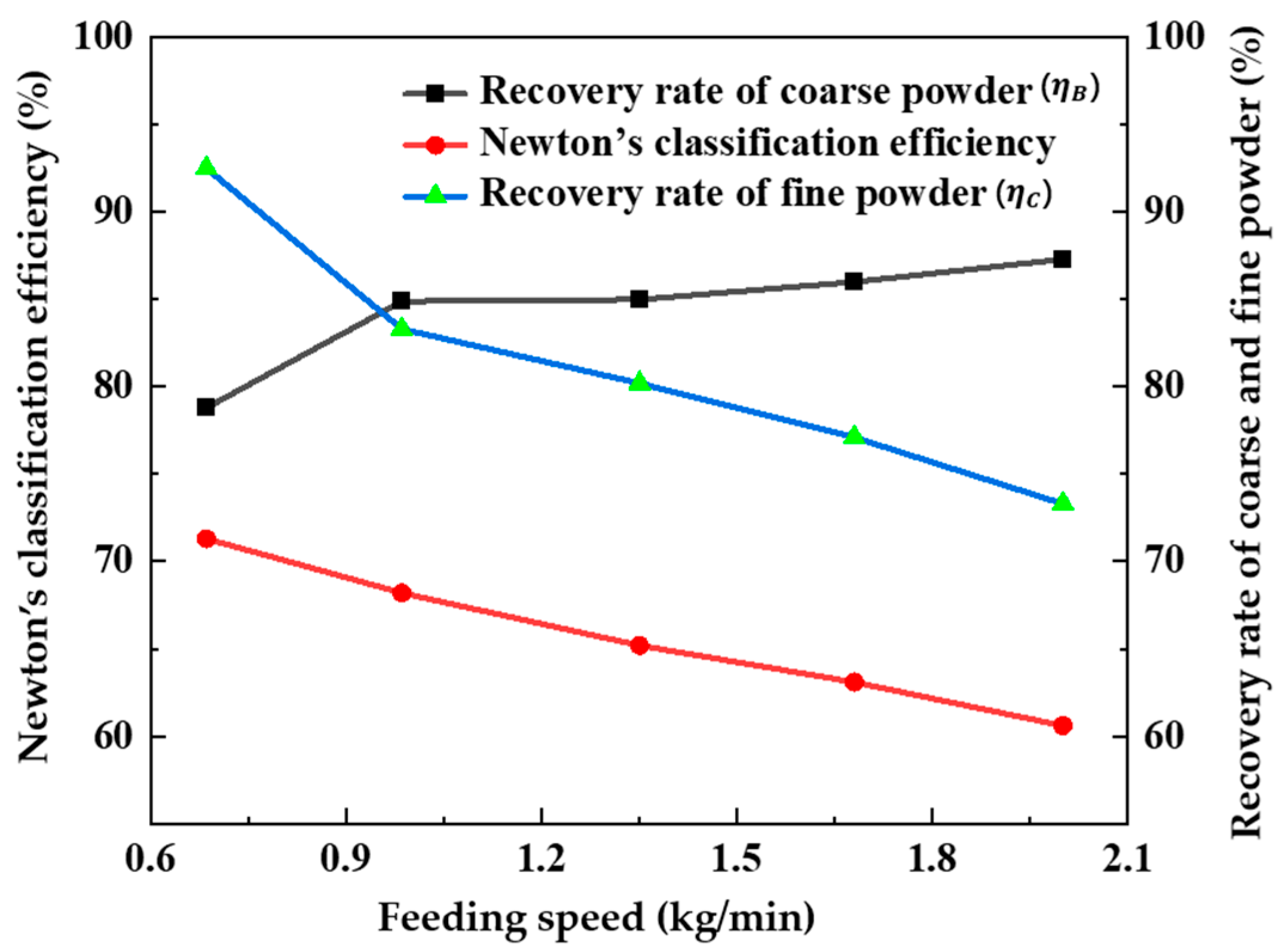

4.1.3. Effect of the Feed Rate

4.2. Orthogonal Experiment

4.2.1. Orthogonal Experimental Range Analysis

4.2.2. Estimation and Validation of Indicators for Orthogonal Experimental Results

5. Conclusions

- When the inlet air volume and feeding speed are determined, a too high rotor speed can cause a rapid decline in the classification performance due to uneven flow field distribution. The best classification results are achieved at a rotor speed of 1000 rpm.

- The classification performance is negatively affected by an excessively high or low inlet air volume at a determined rotor and feeding speed, while the maximum Newton’s classification efficiency is achieved at an inlet air volume of 500 m3·h−1.

- With the increase in the feeding speed, the classification performance decreased gradually. It is not feasible to simply increase the feeding speed to pursue yield in actual production and application, but a reasonable combination of operating parameters should be considered.

- Given an operating parameter (rotor speed or inlet air volume), there is always a corresponding rotor speed or inlet air volume that makes for the best classification of the calcined petroleum coke in a rotor classifier. Hence, the particle classification process is not only influenced by the strength of the flow field inside the classifier but also by the stability of the flow field and other comprehensive factors.

- The optimum operating parameters combination of calcined petroleum coke classification was obtained by considering the Newton’s classification efficiency and classification accuracy comprehensively, namely, rotor speed is 1000 rpm, inlet air volume is 500 m3·h−1, and feeding speed is 0.685 kg·min−1. In the meantime, the maximum Newton’s classification efficiency (ηN = 83.5%) and the highest classification accuracy (K = 0.626) are obtained.

- The secondary air, as one of the operating parameters, has not been investigated in this paper, and a later study could be devoted to the effect of the secondary air on the classification flow field and classification performance.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Edwards, L. The History and Future Challenges of Calcined Petroleum Coke Production and Use in Aluminum Smelting. Jom 2015, 67, 308–321. [Google Scholar] [CrossRef]

- Qu, Z.; Liu, Y. Market analysis and prediction of calcined coke. Light Met. 2015, 1–3. [Google Scholar] [CrossRef]

- Altun, O. Air classification performances of the components within the varied feed blends. Powder Technol. 2022, 399, 117092. [Google Scholar] [CrossRef]

- Chen, J.T.; Zhou, H.H.; Chang, W.B.; Ci, Y.X. Effect of particle size on lithium intercalation performance of graphite anode. Acta Phys.-Chim. Sin. 2003, 19, 278–282. [Google Scholar]

- Eswaraiah, C.; Angadi, S.I.; Mishra, B.K. Mechanism of particle separation and analysis of fish-hook phenomenon in a circulating air classifier. Powder Technol. 2012, 218, 57–63. [Google Scholar] [CrossRef]

- Karunakumari, L.; Eswaraiah, C.; Jayanti, S.; Narayanan, S.S. Experimental and numerical study of a rotating wheel air classifier. Aiche J. 2005, 51, 776–790. [Google Scholar] [CrossRef]

- Shapiro, M.; Galperin, V. Air classification of solid particles: A review. Chem. Eng. Process.-Process Intensif. 2005, 44, 279–285. [Google Scholar] [CrossRef]

- Xie, R.; Wang, X.; Xie, J.; Sun, X. Application status and development trend of ultra-micro pulverization technology. China Powder Technol. 2009, 15, 64–67. [Google Scholar]

- Guizani, R.; Mhiri, H.; Bournot, P. Effects of the geometry of fine powder outlet on pressure drop and separation performances for dynamic separators. Powder Technol. 2017, 314, 599–607. [Google Scholar] [CrossRef]

- Liu, R.; Liu, J.; Yu, Y. Effects of axial inclined guide vanes on a turbo air classifier. Powder Technol. 2015, 280, 1–9. [Google Scholar] [CrossRef]

- Yu, Y.; Kong, X.; Ren, C.; Liu, J. Effect of the rotor cage chassis on inner flow field of a turbo air classifierEinfluss des Kafiglaufergehauses auf das innere Stromungsfeld von einem Turbowindsichter. Mater. Werkst. 2021, 52, 772–780. [Google Scholar] [CrossRef]

- Betz, M.; Gleiss, M.; Nirschl, H. Effects of Flow Baffles on Flow Profile, Pressure Drop and Classification Performance in Classifiers. Processes 2021, 9, 1213. [Google Scholar] [CrossRef]

- Ren, W.; Liu, J.; Yu, Y. Design of a rotor cage with non-radial arc blades for turbo air classifiers. Powder Technol. 2016, 292, 46–53. [Google Scholar] [CrossRef]

- Dang, D.; Wang, K. Effect of classifying wheel speed on particle size distribution. China Powder Technol. 2016, 22, 82–85. [Google Scholar]

- Gao, L.; Yu, Y.; Liu, J. Influence of the rotating speed of the vortex air classifier on its classification accuracy. J. Chem. Eng. 2012, 63, 1056–1062. [Google Scholar]

- Feng, Y.; Liu, J.; Liu, S. Effects of operating parameters on flow field in a turbo air classifier. Miner. Eng. 2008, 21, 598–604. [Google Scholar] [CrossRef]

- Guo, L.; Liu, J.; Liu, S. Flow Field Characteristics of the Rotor Cage in Turbo Air Classifiers. Chin. J. Mech. Eng. 2009, 22, 426–432. [Google Scholar] [CrossRef]

- Liu, R.; Liu, J.; Yu, Y. Study of matching inlet air velocity and rotating cage speed in vortex air classifier. Chem. Eng. 2015, 43, 41–45. [Google Scholar]

- Zeng, Y.; Zhang, S.; Zhou, Y.; Li, M. Numerical Simulation of a Flow Field in a Turbo Air Classifier and Optimization of the Process Parameters. Processes 2020, 8, 237. [Google Scholar] [CrossRef]

- Denmud, N.; Baite, K.; Plookphol, T.; Janudom, S. Effects of Operating Parameters on the Cut Size of Turbo Air Classifier for Particle Size Classification of SAC305 Lead-Free Solder Powder. Processes 2019, 7, 427. [Google Scholar] [CrossRef]

- Yu, Y.; Ren, W.; Gao, L.; Liu, J. Analysis and optimization of process parameters affecting classification performances indices of the turbo air classifier. Mater. Werkst. 2015, 46, 970–977. [Google Scholar] [CrossRef]

- Kundu, T.; Das, S.K.; Tripathy, S.K.; Angadi, S.I. Performance evaluation of the VSK separator for treating mineral fines. Miner. Eng. 2021, 167, 106883. [Google Scholar] [CrossRef]

- Sun, Z.; Liang, L.; Liu, C.; Zhu, Y.; Zhang, L.; Yang, G. CFD simulation and performance optimization of a new horizontal turbo air classifier. Adv. Powder Technol. 2021, 32, 977–986. [Google Scholar] [CrossRef]

- Zeng, C.; Liu, C.; Chen, H. Effect of secondary air volume on the classification performance of LNJ-36A airflow classifier. Chem. Prog. 2015, 34, 3859–3863. [Google Scholar]

- Jia, F.; Mou, X.; Fang, Y.; Chen, C. A New Rotor-Type Dynamic Classifier: Structural Optimization and Industrial Applications. Processes 2021, 9, 1033. [Google Scholar] [CrossRef]

- Mou, X.; Jia, F.; Fang, Y.; Chen, C. CFD-Based Structural Optimization of Rotor Cage for High-Efficiency Rotor Classifier. Processes 2021, 9, 1148. [Google Scholar] [CrossRef]

- Li, Q.; Mou, X.; Fang, Y. Effects of a Guide Cone on the Flow Field and Performance of a New Dynamic Air Classifier. Processes 2022, 10, 874. [Google Scholar] [CrossRef]

- Yang, L.; Sun, Z.; Yang, X.; Sun, G.; Zhou, Y. Study on the classification performance of a horizontal wheel type FCC catalyst classifier. J. Pet. (Pet. Process.) 2019, 35, 66–72. [Google Scholar]

- Fang, Y.; Li, Z.; Kong, W. tudy on the optimal working condition of high-efficiency rotor type powder separator. J. Beijing Univ. Technol. 2010, 30, 1488–1491. [Google Scholar]

| No. | Name of Equipment | Specification Type (Manufacturer, Location) | Technical Parameters | Note |

|---|---|---|---|---|

| 01 | Raw material silo | φ600 (Green Energy Co., Ltd., Hangzhou, China) | Effective volume 0.2 m3 | |

| 02 | Single tube screw feeder | LX-φ122*1200 (Green Energy Co., Ltd., Hangzhou, China) | Feed rate 10~200 kg·h−1 Reduction motor power 1.1 kW | Inverter speed control |

| 03 | Static disperser | FS-15 (Powder Research Institute Of Nanjing Tech University, Nanjing, China) | ||

| 04 | Rotor classifier | ZF-15 (Powder Research Institute Of Nanjing Tech University, Nanjing, China) | Treatment air volume 300~1200 m3·h−1 Rotor speed 200~1450 rpm Motor power 2.2 kW | Inverter speed control |

| 05 | Cyclone dust collector | φ300 (Powder Research Institute Of Nanjing Tech University, Nanjing, China) | ||

| 06 | Bag filter dust collector | HMC-32A (Zhejiang Lantian Dust Exclusion Equipment Co., Ltd., Haining, China) | Filter area 24 m2 | |

| 07 | Centrifugal fan | 9-19 (Huashide Shandong Fan Co., Ltd., Shandong, China) | Air volume 300~2200 m3·h−1 Full pressure 6870~5680 Pa Motor power 11 kW | Damper adjustment |

| Rotor Speed (rpm) | (μm) |

|---|---|

| 600 | 134.6 |

| 800 | 88.3 |

| 1000 | 73.6 |

| 1200 | 65.4 |

| 1400 | 44 |

| Inlet Air Volume (m3·h−1) | (%) | (%) | (%) |

|---|---|---|---|

| 400 | 79.4 | 90.9 | 70.3 |

| 500 | 87.9 | 89.9 | 76.8 |

| 600 | 83.3 | 84.9 | 68.2 |

| 700 | 90.0 | 62.5 | 52.5 |

| 800 | 94.3 | 51.4 | 45.7 |

| Feeding Speed (kg·min−1) | (μm) | K |

|---|---|---|

| 0.685 | 85.7 | 0.604 |

| 0.985 | 73.6 | 0.575 |

| 1.350 | 72.0 | 0.509 |

| 1.680 | 51.7 | 0.463 |

| 2.000 | 49.4 | 0.457 |

| Operating Parameters | Level 1 | Level 2 | Level 3 |

|---|---|---|---|

| A: n (rpm) | 800 | 1000 | 1200 |

| B: Q (m3·h−1) | 400 | 500 | 600 |

| C: f (kg·min−1) | 0.685 | 0.985 | 1.350 |

| No. | Process Parameters | Classification Performance Indices | ||||

|---|---|---|---|---|---|---|

| n (rpm) | Q (m3·h−1) | f (kg·min−1) | K | |||

| 1 | A1 | B1 | C1 | ) | 0.511 | 61.5 |

| 2 | A1 | B2 | C2 | ) | 0.554 | 74.9 |

| 3 | A1 | B3 | C3 | ) | 0.456 | 103 |

| 4 | A2 | B1 | C2 | ) | 0.562 | 33.8 |

| 5 | A2 | B2 | C3 | ) | 0.482 | 46.1 |

| 6 | A2 | B3 | C1 | ) | 0.604 | 85.7 |

| 7 | A3 | B1 | C3 | ) | 0.630 | 26.2 |

| 8 | A3 | B2 | C1 | ) | 0.309 | 35.7 |

| 9 | A3 | B3 | C2 | ) | 0.387 | 65.4 |

| A | B | C | |

|---|---|---|---|

| 3 | 3 | 3 | |

| max {} − min {} | max {} − min {} | max {} − min {} | |

| K | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| A | B | C | A | B | C | A | B | C | |

| 2.08 | 1.86 | 2.11 | 1.52 | 1.68 | 1.56 | 239.4 | 121.5 | 190.2 | |

| 2.15 | 2.17 | 1.98 | 1.65 | 1.49 | 1.47 | 165.6 | 164.0 | 174.1 | |

| 1.68 | 1.89 | 1.82 | 1.41 | 1.41 | 1.55 | 134.6 | 254.1 | 175.3 | |

| 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | |

| 0.693 | 0.620 | 0.703 | 0.507 | 0.560 | 0.520 | 79.800 | 40.500 | 63.400 | |

| 0.717 | 0.723 | 0.660 | 0.550 | 0.497 | 0.490 | 55.200 | 54.667 | 58.033 | |

| 0.560 | 0.630 | 0.607 | 0.470 | 0.470 | 0.517 | 44.867 | 84.700 | 58.433 | |

| 0.157 | 0.103 | 0.096 | 0.080 | 0.090 | 0.030 | 34.924 | 44.200 | 5.367 | |

| Particle Size Distribution | Product Standard (μm) | Fine Powder Product (μm) |

|---|---|---|

| 7.0 ± 2.0 | 8.314 | |

| 19.0 ± 1.0 | 18.686 | |

| 38.0 ± 3.0 | 39.043 | |

| ≤60 | 58.795 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, J.; Hui, C.; Zhao, Z.; Fang, Y. Research and Optimization of Operating Parameters of a Rotor Classifier for Calcined Petroleum Coke. Processes 2024, 12, 603. https://doi.org/10.3390/pr12030603

Peng J, Hui C, Zhao Z, Fang Y. Research and Optimization of Operating Parameters of a Rotor Classifier for Calcined Petroleum Coke. Processes. 2024; 12(3):603. https://doi.org/10.3390/pr12030603

Chicago/Turabian StylePeng, Jiaxiang, Chenxi Hui, Ziwei Zhao, and Ying Fang. 2024. "Research and Optimization of Operating Parameters of a Rotor Classifier for Calcined Petroleum Coke" Processes 12, no. 3: 603. https://doi.org/10.3390/pr12030603