Characteristic Analysis and Coating Application of the Innovative HVOF System Based on the Digital Model

Abstract

:1. Introduction

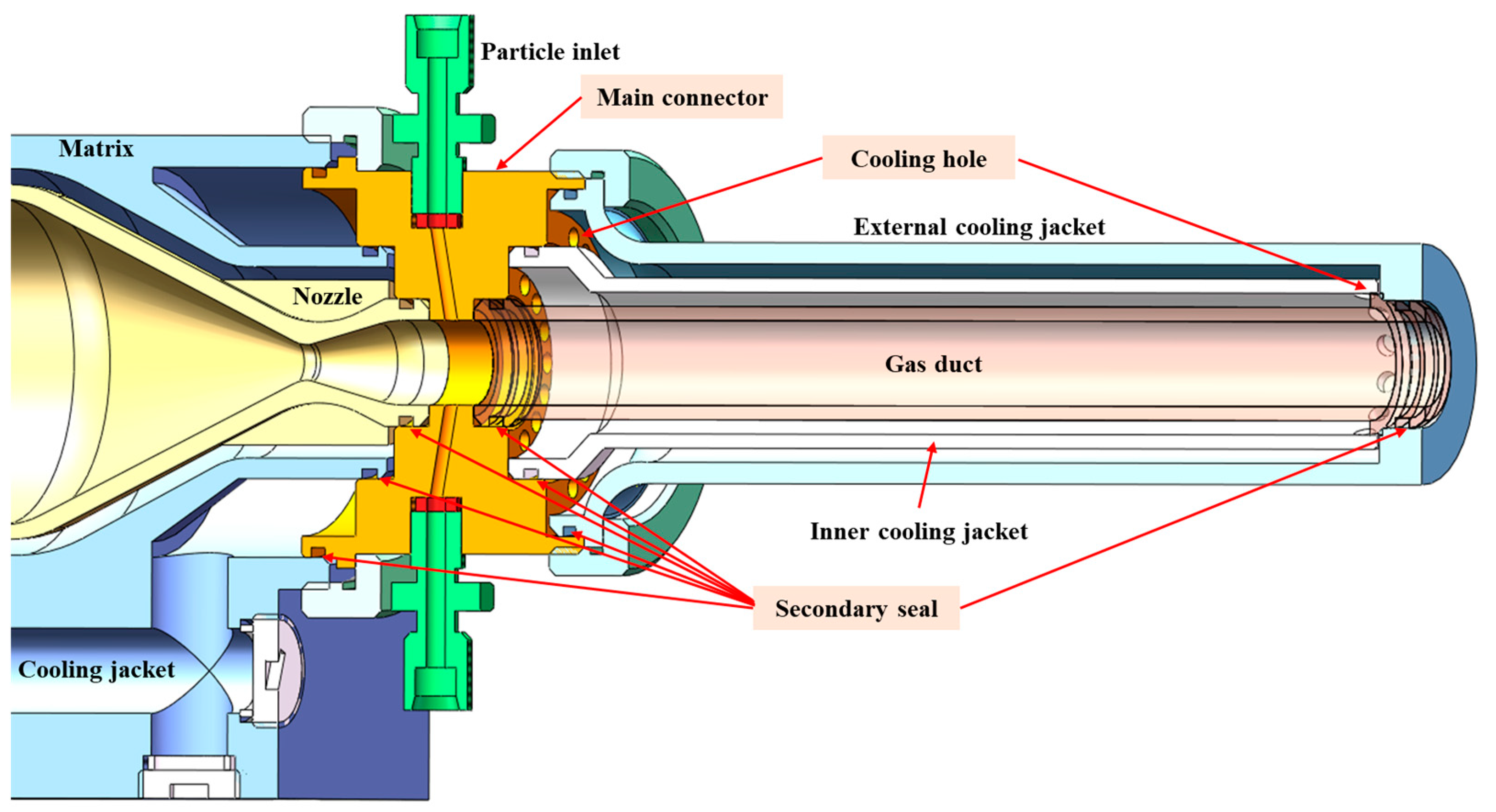

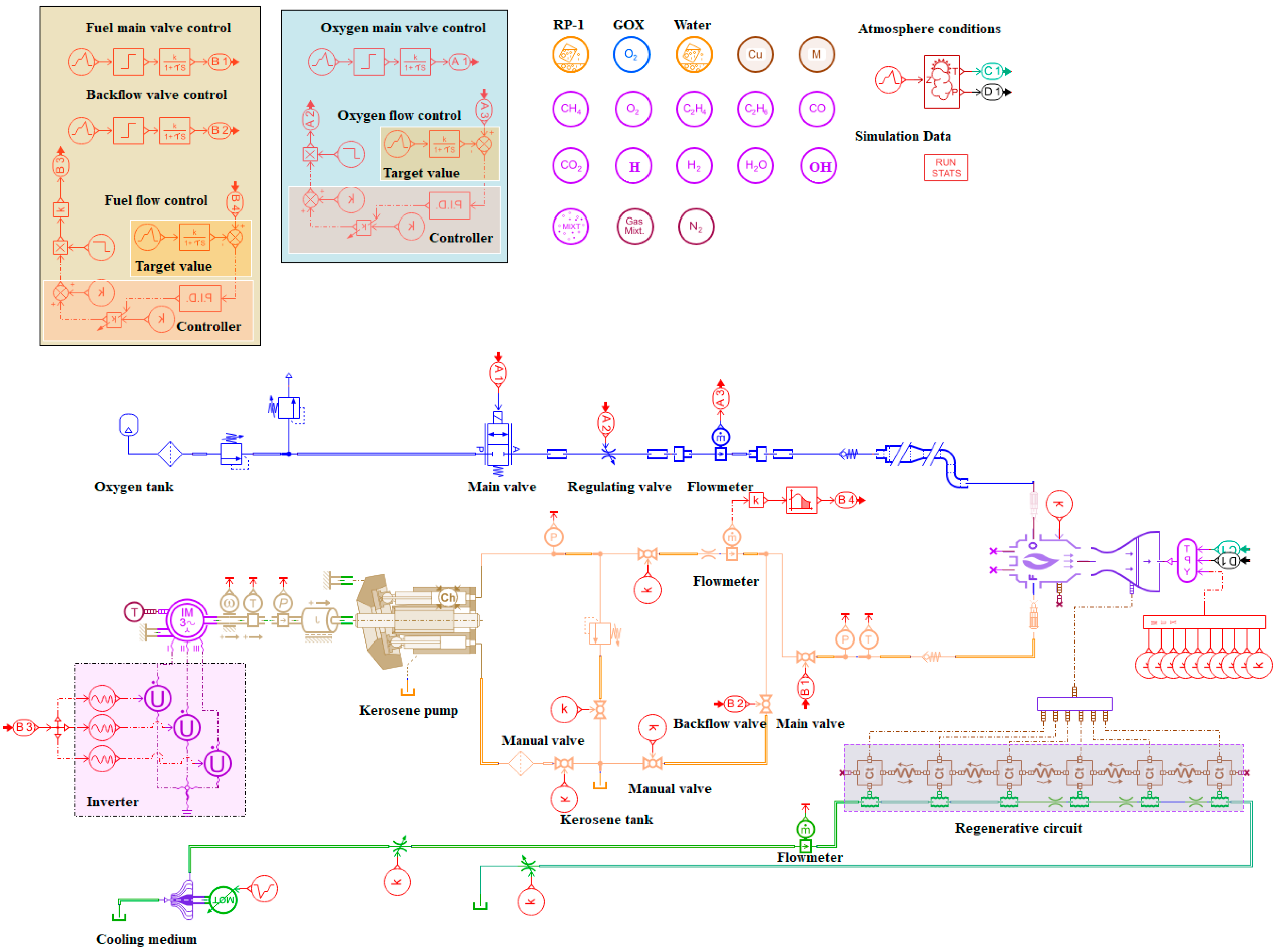

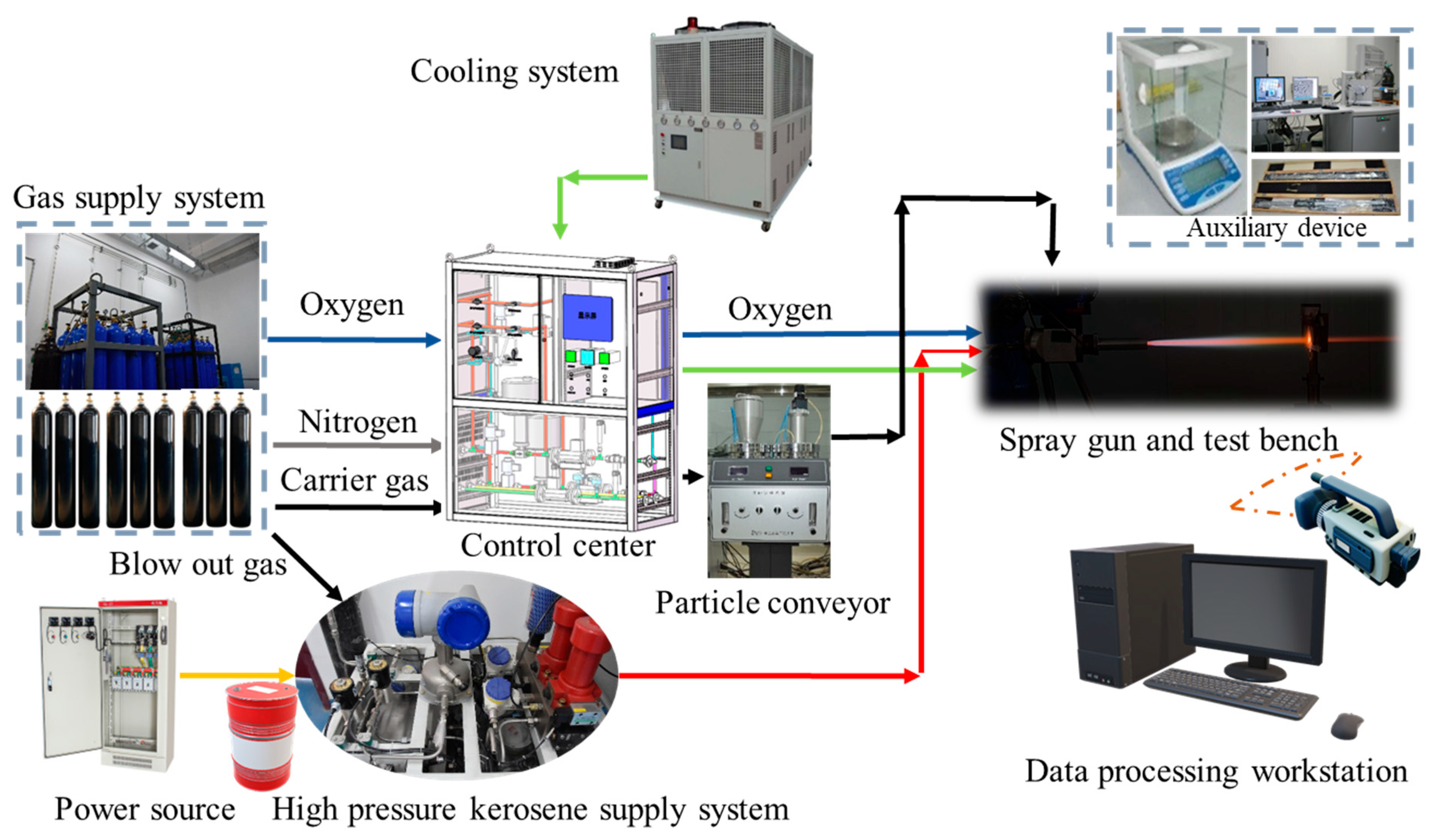

2. The HVOF Spray System

2.1. System Framework and Components

2.2. Working Process

2.3. Measurement and Control Methods

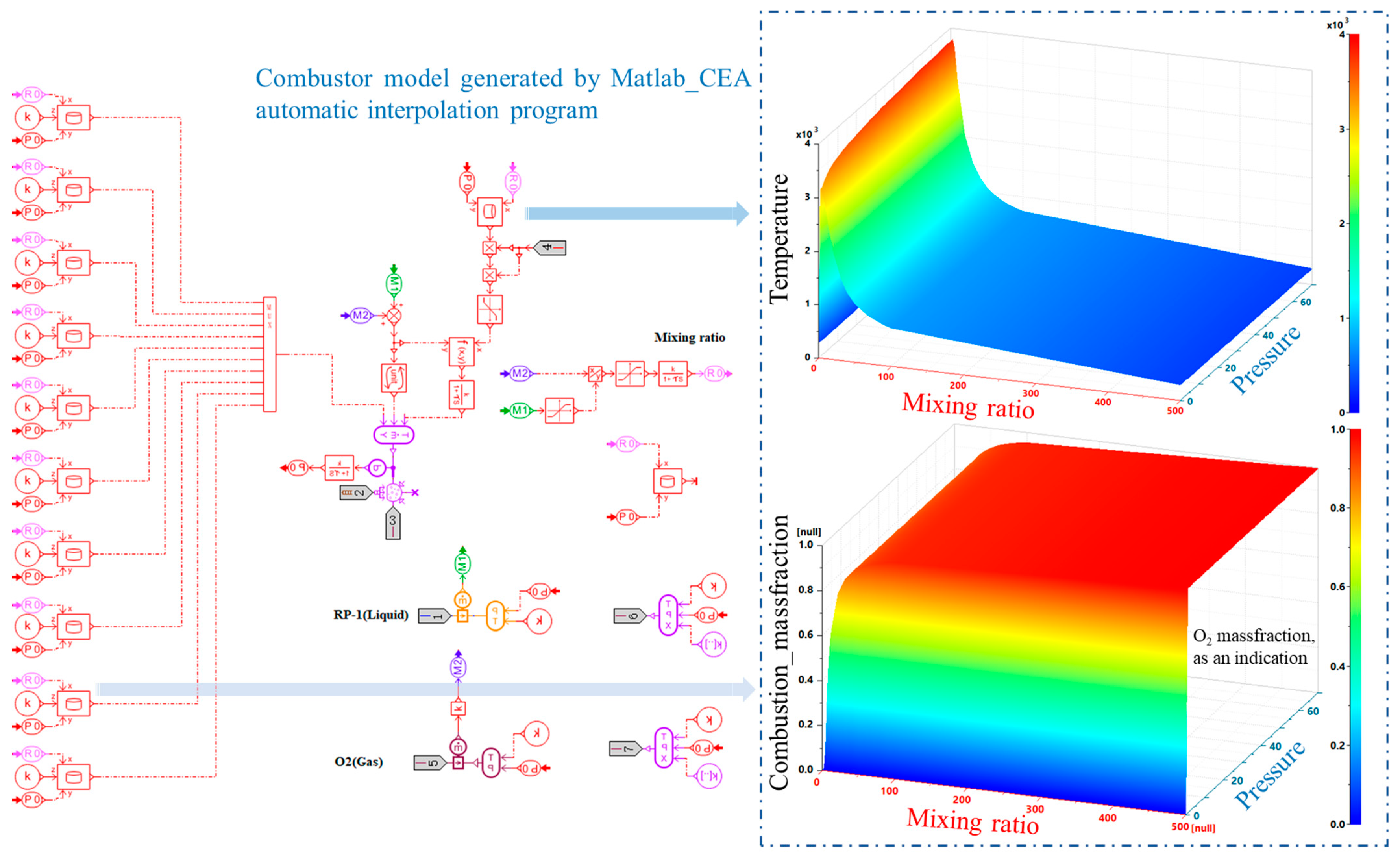

3. The Digital Model

3.1. Pipeline and Valve Model

3.2. High-Pressure Cylinder Model

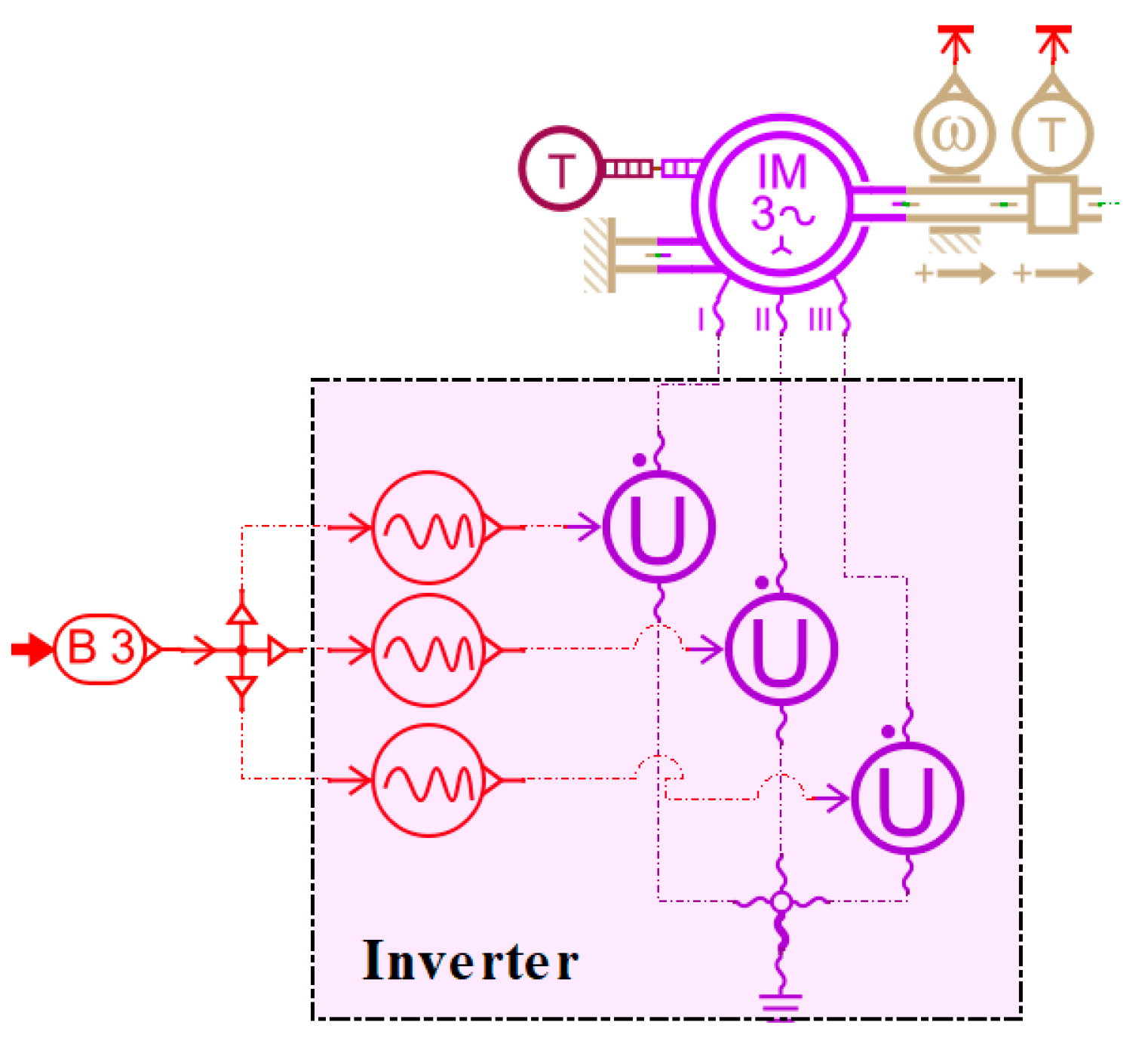

3.3. Pump Model

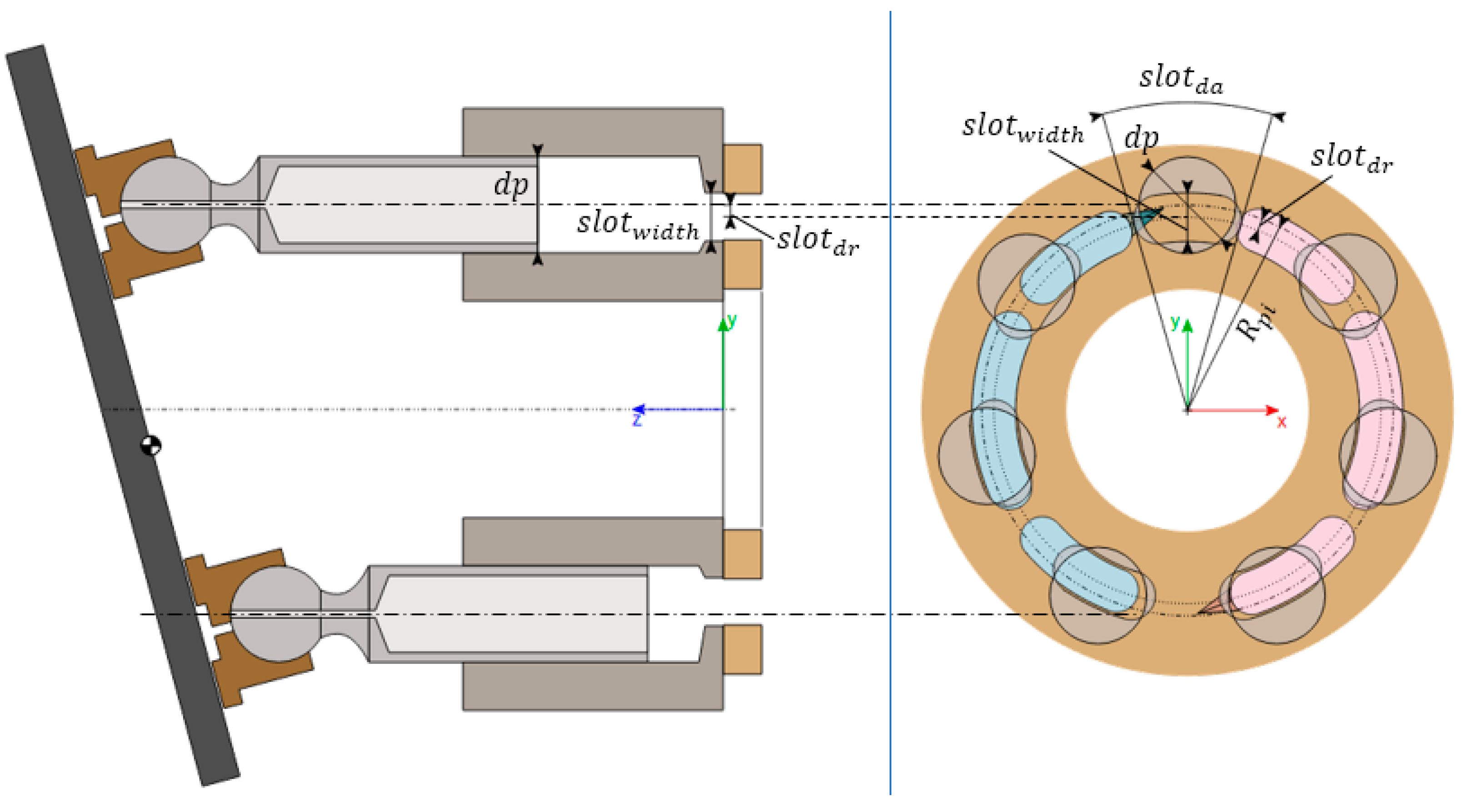

3.4. Spary Gun Model

3.5. Digital Model of the System

4. Experiment

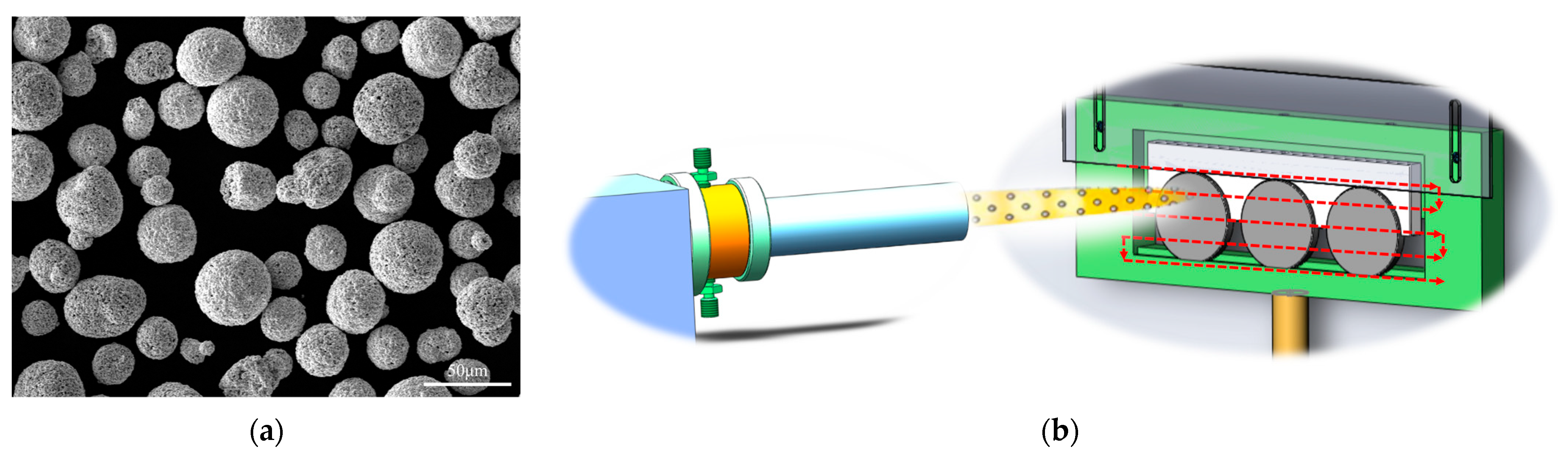

4.1. Material Preparation and Spray Process

4.2. Experiment Scheme Design Method

4.3. Characterization and Measurement

5. Results and Discussion

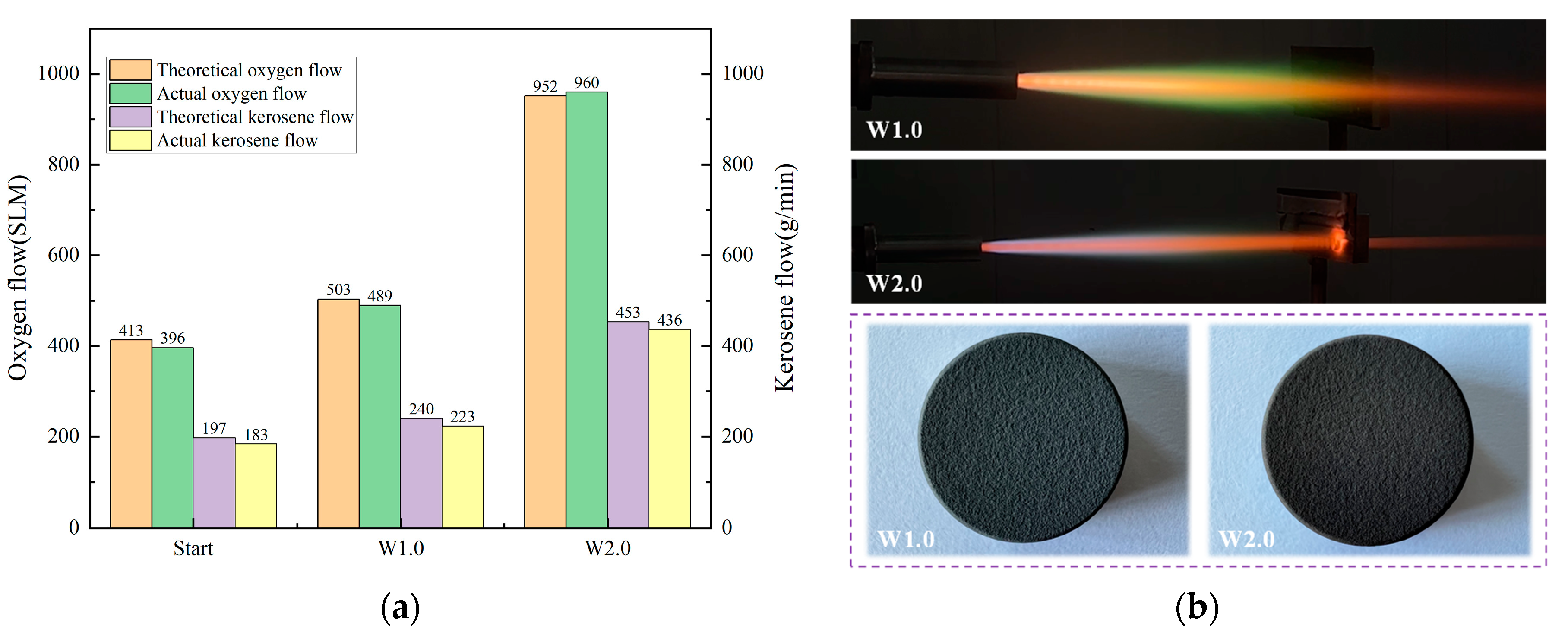

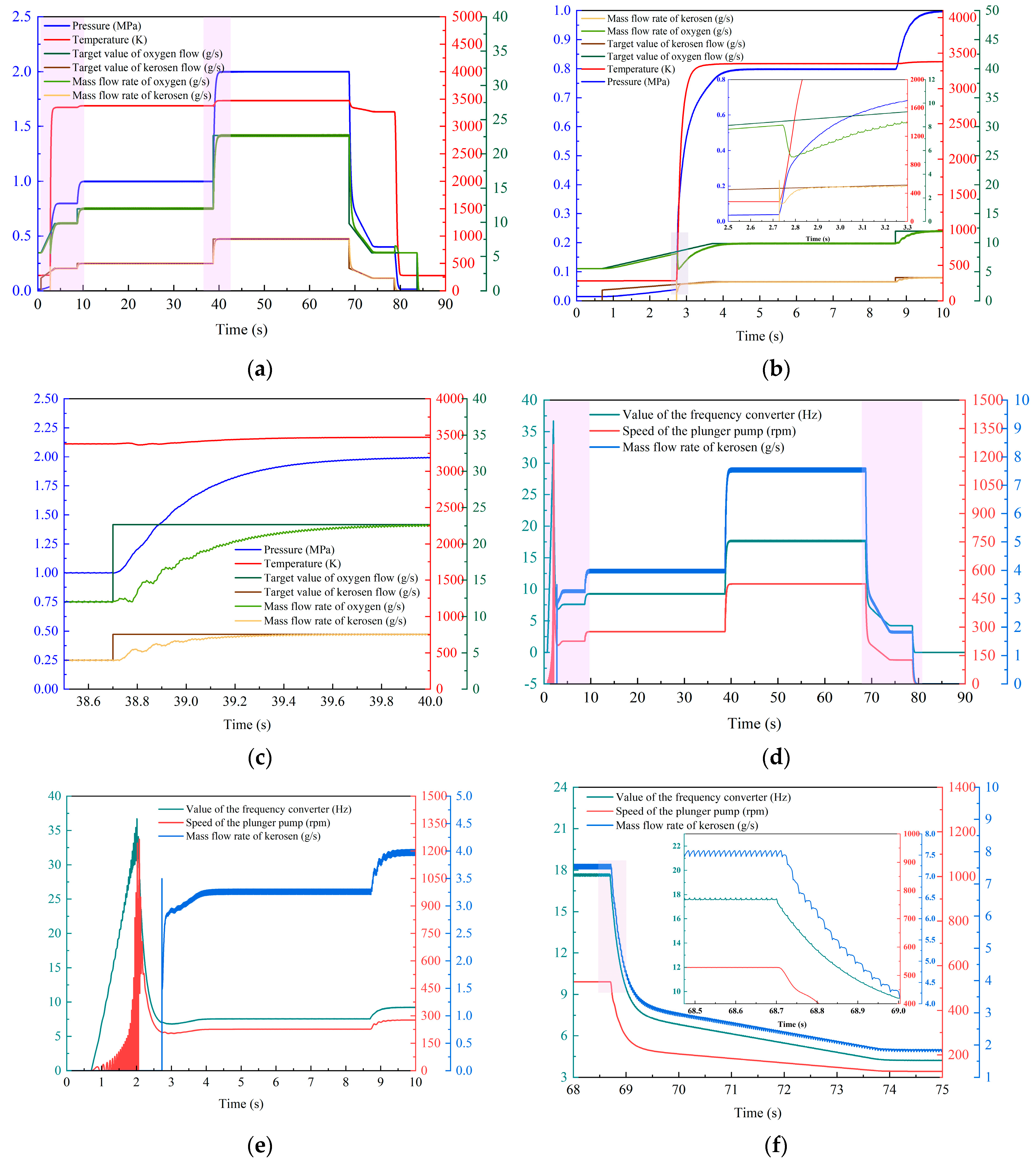

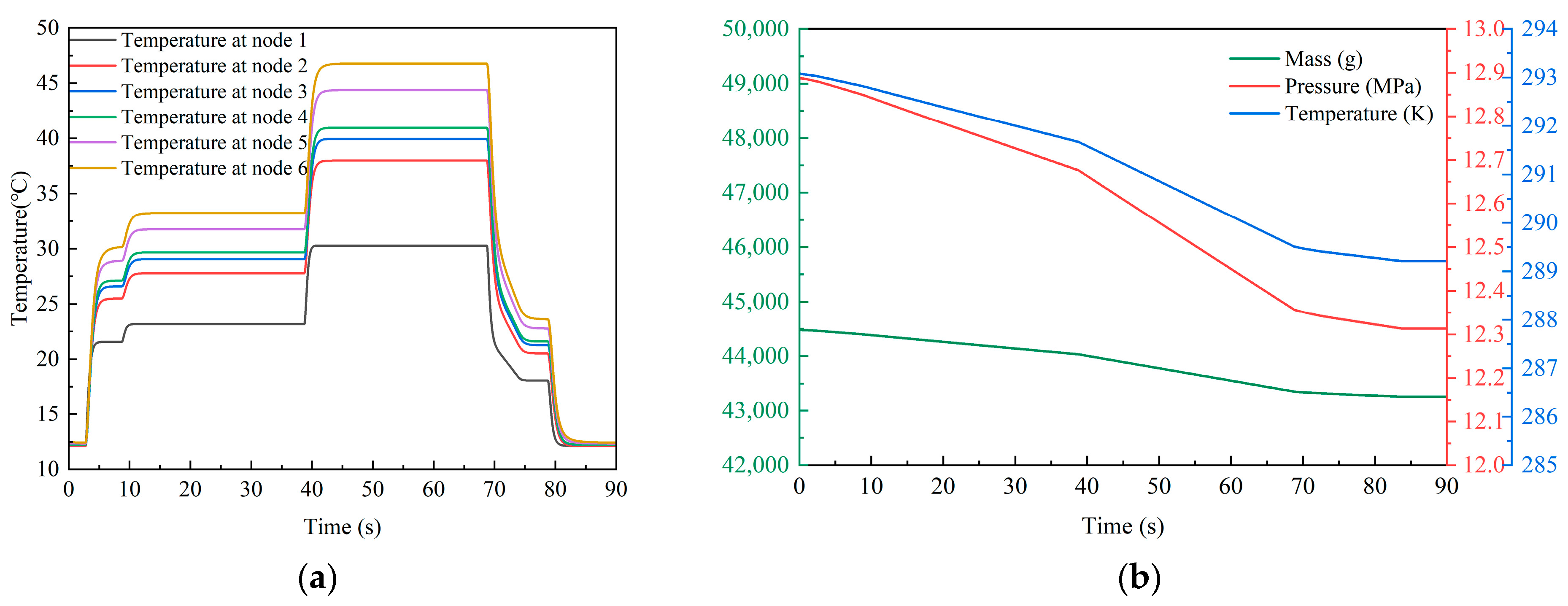

5.1. Typical Working Parameters of the Spray Process

5.2. The Adjustment Process of the System Working Conditions

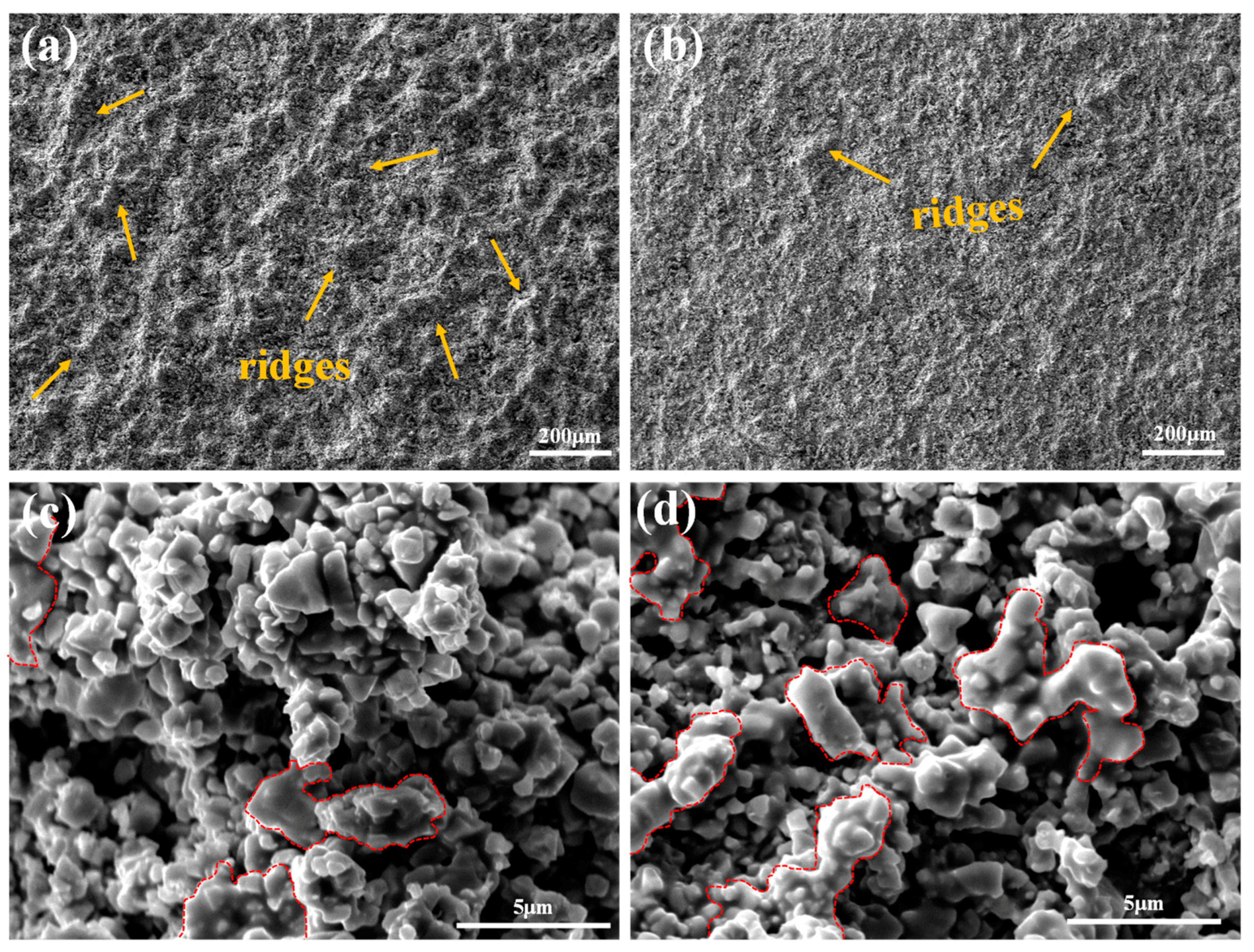

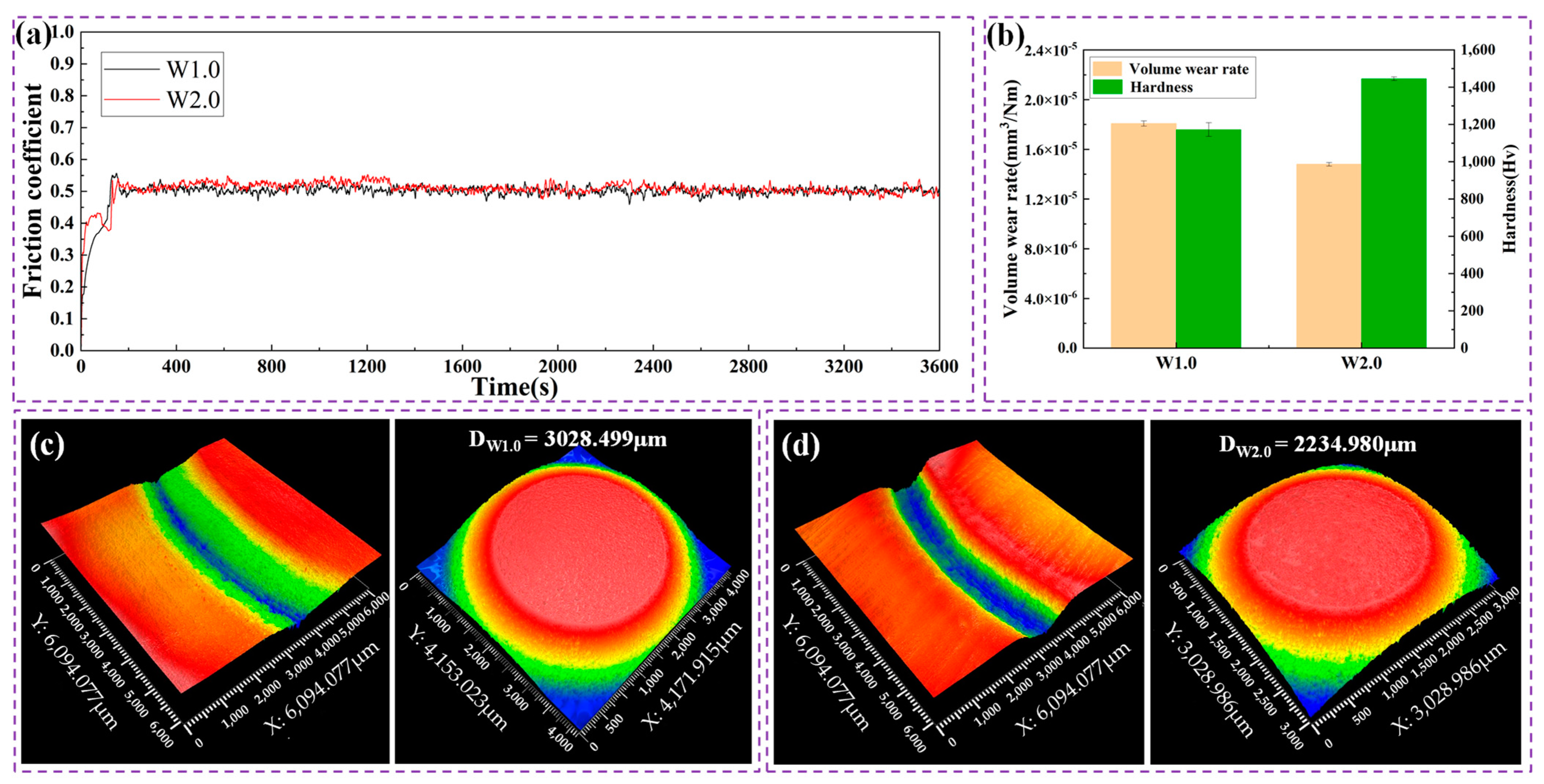

5.3. Characterization and Analysis of the Coatings

6. Conclusions

- (1)

- An efficient design method based on the digital model designed by the AMESim multidisciplinary simulation platform of oxygen/kerosene high-pressure HVOF spray system was proposed for the first time. The dynamic characteristics of key components such as a combustion chamber, a kerosene pump, a cooling jacket and an oxygen cylinder group were obtained by calculating the two process parameters under the pressures of 1.0 MPa and 2.0 MPa, respectively. The simulation results show that the dynamic response time of the system was less than 0.7 s although the duration was 1.3 s when the working medium changed from W1.0 to W2.0. Meanwhile, the error between the simulation and experiment results was generally less than 5%, which proves the accuracy of the digital model and the efficiency of the design method.

- (2)

- The microstructure and mechanical properties of WC-12Co coatings deposited at pressures of 1.0 MPa and 2.0 MPa demonstrate that the innovative high-pressure HVOF spray technology is extremely feasible and efficient in the preparation of denser cemented carbide coatings. The microhardness of the coatings deposited at the working condition of W2.0 is 1446 Hv, which is about 23% higher than at W1.0 (1173 Hv). The corresponding volume wear rate was reduced from 1.81 × 10−5 mm3/Nm to 1.48 × 10−5 mm3/Nm by about 18%. Therefore, it was demonstrated that the increase of the pressure of the combustion chamber in the spray gun is beneficial for enhancing the density and wear resistance of the coating so as to improve the actual performance of the coating.

- (3)

- The accuracy of the system model and the advantages of the innovative high-pressure HVOF spray technology based on the digital model were thoroughly verified by the actual experiments, which indicates that the design method has important theoretical value and application significance for exploring the spray process parameters and predicting the spraying effect under higher working conditions.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| chamber pressure (MPa) | total flow rate (m3/s) | ||

| T | ideal temperature (K) | inlet flow rate (m3/s) | |

| C* | characteristic velocity (m/s) | outlet flow rate (m3/s) | |

| expansion ratio | the piston-cylinder leakage flow rate (m3/s) | ||

| total flow rate (g/s) | the slipper-swash plate leakage flow rate (m3/s) | ||

| mixture ratio | the barrel-port plate leakage flow rate (m3/s) | ||

| gas oxygen flow rate (g/s) | theoretical displacement (m3/rad) | ||

| kerosene flow rate (g/s) | rotation speed of the plunger pump (rad/s) | ||

| throat diameter (mm) | voltage (V) | ||

| exit diameter (mm) | stator cyclic inductance (H) | ||

| chamber diameter (mm) | power of motor (W) | ||

| chamber length (mm) | dispersion coefficient | ||

| specific impulse (m/s) | modified rotor current (A) | ||

| ideal thrust (N) | pump head (m) | ||

| density (kg/m3) | reference head (m) | ||

| input mass flow rate (kg/s) | head function | ||

| input enthalpy flow rate (W) | adimensional variables | ||

| combined bulk modulus (Pa) | adimensional variables | ||

| effective volume (m3) | reference torque (Nm) | ||

| heat exchange (W) | head function | ||

| cross-sectional area () | fluid inertia () | ||

| inclination angle (°) | flow coefficient | ||

| coefficient of friction | flow function | ||

| attractive term | pressure loss coefficient | ||

| covolume | isentropic calorific factor | ||

| heat flow provided to or exiting from the control volume (W) | current pressure ratio | ||

| pressure difference (Pa) | critical pressure ratio | ||

| radial clearance (m) | time delay parameter (s) | ||

| outer diameter of the piston (m) | volume (m3) | ||

| contact length (m) | mass fraction of each component | ||

| average hydrodynamic viscosity (kg/m/s) | mixture ratio in digital model | ||

| eccentricity of the piston | temperature of the mixture | ||

| sleeve speed (m/s) | heat flux (W) | ||

| piston speed (m/s) | thermal conductance () | ||

| the sum of the constant volume and the variable volume of each chamber (m3) | heat exchange area () |

References

- Mittal, G.; Paul, S. Suspension and solution precursor plasma and HVOF spray: A review. J. Therm. Spray Technol. 2022, 31, 1443–1475. [Google Scholar] [CrossRef]

- Pawlowski, L. The Science and Engineering of Thermal Spray Coatings, 2nd ed.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2008. [Google Scholar]

- Matthews, S.; James, B. Review of thermal spray coating applications in steel industry: Part 1-hardware in steel making to the continuous annealing process. J. Therm. Spray Technol. 2010, 19, 1267–1276. [Google Scholar] [CrossRef]

- Aranke, O.; Algenaid, W.; Awe, S.; Joshi, S. Coatings for automotive gray cast iron brake discs: A review. Coatings 2019, 9, 552. [Google Scholar] [CrossRef]

- Varis, T.; Suhonen, T.; Jokipii, M.; Vuoristo, P. Influence of powder properties on residual stresses formed in high-pressure liquid fuel HVOF sprayed WC-CoCr coatings. Surf Coat Tech. 2020, 388, 125604. [Google Scholar] [CrossRef]

- Wang, H.; Qiu, Q.; Gee, M.; Hou, C.; Liu, X.; Song, X. Wear resistance enhancement of HVOF-sprayed WC-Co coating by complete densification of starting powder. Mater Design 2020, 191, 108586. [Google Scholar] [CrossRef]

- Gong, T.; Yao, P.; Zuo, X.; Zhang, Z.; Xiao, Y.; Zhao, L.; Zhou, H.; Deng, M.; Wang, Q.; Zhong, A. Influence of WC carbide particle size on the microstructure and abrasive wear behavior of WC–10Co–4Cr coatings for aircraft landing gear. Wear 2016, 362, 135–145. [Google Scholar] [CrossRef]

- Khuengpukheiw, R.; Saikaew, C.; Wisitsoraat, A. Wear resistance of HVOF sprayed NiSiCrFeB, WC-Co/NiSiCrFeB, WC-Co, and WC-Cr3C2-Ni rice harvesting blades. Mater. Test. 2021, 63, 62–72. [Google Scholar] [CrossRef]

- Zhang, F.; Tabecki, A.; Bennett, M.; Begg, H.; Lionetti, S.; Paul, S. Feasibility study of high-velocity oxy-fuel (HVOF) sprayed cermet and alloy coatings for geothermal applications. J. Therm Spray Techn. 2023, 32, 339–351. [Google Scholar] [CrossRef]

- Anusha, K.; Routara, B.; Guha, S. A review on high-velocity oxy-fuel (HVOF) coating technique. J. Inst. Eng. India Ser. D 2023, 104, 831–848. [Google Scholar] [CrossRef]

- Teles, D.; de Castro, V.; dos Reis Tagliari, M.; de Souza, A.; de Fraga Malfatti, C. Effect of HVOF spray coating on the tribological surface of onshore gate valves. Wear 2024, 546–547, 205322. [Google Scholar] [CrossRef]

- Liu, S.; Wu, H.; Xie, S.; Planche, M.; Rivolet, D.; Moliere, M.; Liao, H. Novel liquid fuel HVOF torches fueled with ethanol: Relationships between in-flight particle characteristics and properties of WC-10Co-4Cr coatings. Surf. Coat. Tech. 2021, 408, 126805. [Google Scholar] [CrossRef]

- Żórawski, W. The microstructure and tribological properties of liquid-fuel HVOF sprayed nanostructured WC–12Co coatings. Surf. Coat. Tech. 2013, 220, 276–281. [Google Scholar] [CrossRef]

- Li, C.; Yang, H.; Li, H. Effect of gas conditions on HVOF flame and properties of WC-Co coatings. Mater. Manuf. Process 1999, 14, 383–395. [Google Scholar] [CrossRef]

- Li, C.; Ohmori, A.; Harada, Y. Effect of powder structure on the structure of thermally sprayed WC-Co coatings. J. Mater. Sci. 1996, 31, 785–794. [Google Scholar] [CrossRef]

- Sun, B.; Fukanuma, H. Deposition of WC-Co coatings by a novel high pressure HVOF. J. Therm. Spray. Techn. 2013, 22, 263–271. [Google Scholar] [CrossRef]

- Gerner, D.; Azarmi, F.; McDonnell, M.; Okeke, U. Application of machine learning for optimization of HVOF process parameters. J. Therm Spray Techn. 2023, 1–11. [Google Scholar] [CrossRef]

- Kanno, A.; Takagi, K.; Arai, M. Influence of chemical composition, grain size, and spray condition on cavitation erosion resistance of high-velocity oxygen fuel thermal-sprayed WC cermet coatings. Sur. Coat. Tech. 2020, 394, 125881. [Google Scholar] [CrossRef]

- Wang, H.; Wu, Y.; Cheng, J.; Zhu, S.; Cao, M.; Hong, S. Effect of binder phases on the cavitation erosion behavior of HVOF sprayed WC-based coatings. Surf. Coat. Tech. 2023, 472, 129887. [Google Scholar] [CrossRef]

- Lu, Y.; Liu, C.; Kevin, I.; Huang, H.; Xu, X. Digital Twin-driven smart manufacturing: Connotation, reference model, applications and research issues. Robot. Comput.-Int. Manuf. 2020, 61, 101837. [Google Scholar] [CrossRef]

- Ren, J.; Zhou, T.; Rong, Y.; Ma, Y.; Ahmad, R. Feature-based modeling for industrial processes in the context of digital twins: A case study of HVOF process. Adv. Eng. Inform. 2022, 51, 101486. [Google Scholar] [CrossRef]

- Li, M.; Christofides, P. Multi-scale modeling and analysis of an industrial HVOF thermal spray process. Chem. Eng. Sci. 2005, 60, 3649–3669. [Google Scholar] [CrossRef]

- Zhao, X.; Li, C.; Li, S.; Jiang, H.; Han, X. Time-varying evolutionary mechanism analysis of the multiphase flow during high-velocity oxygen-fuel (HVOF) thermal spraying WC-12Co particle. Surf. Coat. Tech. 2023, 461, 129435. [Google Scholar] [CrossRef]

- Li, W.; Yin, S.; Wang, X. Numerical investigations of the effect of oblique impact on particle deformation in cold spraying by the SPH method. Appl. Surf. Sci. 2010, 256, 3725–3734. [Google Scholar] [CrossRef]

- Gnanasekaran, B.; Liu, G.; Fu, Y.; Wang, G.; Niu, W.; Lin, T. A Smoothed Particle Hydrodynamics (SPH) procedure for simulating cold spray process-A study using particles. Surf. Coat. Tech. 2019, 377, 124812–124853. [Google Scholar] [CrossRef]

- Yang, M.; Song, P.; Kong, D.; Huang, T.; Jin, Q. Wear and corrosion properties of HVOF sprayed WC-Cr3C2 composite coating for application in polysilicon cyclone separator. J. Mater. Res. Technol. 2024, 29, 78–89. [Google Scholar] [CrossRef]

- Cao, T. Rocket Engine Dynamics; National University of Defense Technology Press: Changsha, China, 2004. [Google Scholar]

- Meyer, C.; Maul, W. The application of neural networks to the SSME startup transient. In Proceedings of the 27th Joint Propulsion Conference, Sacramento, CA, USA, 24–26 June 1991; p. 2530. [Google Scholar] [CrossRef]

- Jimenez, M.; Pluchart, S.; Mouvand, S.; Broca, O. Rocket engine digital twin–modeling and simulation benefits. In AIAA Propulsion and Energy 2019 Forum; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2019; p. 4114. [Google Scholar] [CrossRef]

- Pan, H.; Zhang, L. Application of AMESim software in dynamic simulation of liquid rocket engine system. Rocket Propuls. 2011, 037, 6–11. [Google Scholar] [CrossRef]

- Chen, H.; Liu, H.; Chen, J. Forced start process of supplementary combustion cycle engine. J. Aerosp. Power 2015, 30, 3010–3016. [Google Scholar] [CrossRef]

- Zheng, D.; Wang, H.; Hu, J. Research on transient characteristics of high-thrust hydrogen-oxygen engine. Propuls. Technol. 2021, 42, 9. [Google Scholar] [CrossRef]

- Cui, P.; Song, J.; Li, Q.; Chen, L.; Liang, T.; Sun, J. Dynamics modeling and simulation analysis of electric pump-pressure liquid kerosene variable thrust rocket engine: PartⅠ-single-point condition analysis. Chin. J. Aeronaut. Astronaut. 2022, 43, 248–262. [Google Scholar] [CrossRef]

- Siemens. Simcenter AMESim 2304 Liquid Propulsion library User’s Guide; Siemens Industry Software NV: Leuven, Belgium, 2023. [Google Scholar]

- Su, Q.; Zha, B.; Wang, J.; Yan, M.; Gao, Y.; Sun, Z.; Huang, W. Simulation and application of a new multiphase flow ablation test system for thermal protection materials based on liquid rocket engine. Aerospace 2022, 9, 701. [Google Scholar] [CrossRef]

- Su, Q.; Wang, J.; Yan, M.; Sun, Z.; Huang, W.; Zha, B. Dynamic characteristics of lox/kerosene variable thrust liquid rocket engine test system based on general modular simulation method. Int. J. Aerospace Eng. 2022, 2022, 2171471. [Google Scholar] [CrossRef]

- Zhou, C.; Yu, N.; Wang, J.; Cai, G. Starting and regulating characteristics of electric pump feed system for LRE under different schemes. Appl. Sci. 2022, 12, 6441. [Google Scholar] [CrossRef]

- Li, J. A fast method for dynamic simulation of low temperature engine system. Missile Space Launch Technol. 2012, 1, 13–17. [Google Scholar] [CrossRef]

- Siemens. Simcenter AMESim 2304 Thermal Hydraulic Library User’s Guide; Siemens Industry Software NV: Leuven, Belgium, 2023. [Google Scholar]

- Siemens. Simcenter AMESim 2304 Pneumatic Library User’s Guide; Siemens Industry Software NV: Leuven, Belgium, 2023. [Google Scholar]

- McBride, B.J.; Zehe, M.J.; Gordon, S. NASA Glenn Coefficients for Calculating Thermodynamic Properties of Individual Species; NASA/TP-2002-211556; NASA: Washington, DC, USA, 2002. [Google Scholar]

- Siemens. Simcenter AMESim 2304 Thermal Hydraulic Component Design Library User’s Guide; Siemens Industry Software NV: Leuven, Belgium, 2023. [Google Scholar]

- Siemens. Simcenter AMESim 2304 Electric Motors and Drives Library User’s Guide; Siemens Industry Software NV: Leuven, Belgium, 2023. [Google Scholar]

- Siemens. Simcenter AMESim 2304 Signal, Control Library User’s Guide; Siemens Industry Software NV: Leuven, Belgium, 2023. [Google Scholar]

- Siemens. Simcenter AMESim 2304 Gas Mixture Library User’s Guide; Siemens Industry Software NV: Leuven, Belgium, 2023. [Google Scholar]

- Siemens. Integration Algorithms Used in Simcenter Amesim; Siemens Industry Software NV: Leuven, Belgium, 2023. [Google Scholar]

- Siemens. Simcenter AMESim 2304 Design Exploration User’s Guide; Siemens Industry Software NV: Leuven, Belgium, 2023. [Google Scholar]

- ASTM.G 99; Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus. Annual Book of ASTM Standards G-99-95a. ASTM International: West Conshohocken, PA, USA, 2000; Volume 5, pp. 1–5. [CrossRef]

| Parameters | Symbol | Unit | Value |

|---|---|---|---|

| Chamber pressure | MPa | 2 | |

| Ideal temperature | T | K | 3472 |

| Characteristic velocity | C* | m/s | 1749.4 |

| Expansion ratio | 4.59 | ||

| Total flow rate | g/s | 30.22 | |

| Mixture ratio | 3.0 | ||

| Gas oxygen flow rate | g/s | 22.66 | |

| Kerosene flow rate | g/s | 7.55 | |

| Throat diameter | mm | 5.6 | |

| Exit diameter | mm | 12 | |

| Chamber diameter | mm | 46 | |

| Chamber length | mm | 62 | |

| Specific impulse | m/s | 2561.7 | |

| Ideal thrust | N | 718.2 | |

| Parameters | Flow/(g/s) | Pressure/MPa | Accuracy |

|---|---|---|---|

| Kerosene | 20 | 5 | 1.5% |

| Gas oxygen | 47.63 (2000 SLM) | 5 | 1.5% |

| Carry gas | 2.08 (100 SLM) | 1 | 1% |

| Blow out gas | 41.67 (2000 SLM) | 5 | 1% |

| Coolant | 694.44 (2.5 m3/h) | 2 | 1% |

| No. | Pressure (MPa) | Temperature (K) | Actual Oxygen (SLM) | Actual Fuel (g/min) | Powder Feed Rate (g/min) | Spray Distance (mm) |

|---|---|---|---|---|---|---|

| Start | 0.8 | 3351 | 396 | 183 | -- | -- |

| W1.0 | 1.0 | 3380 | 489 | 223 | 40 | 380 |

| W2.0 | 2.0 | 3472 | 960 | 436 | 40 | 380 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, M.; Yuan, X.; Su, Q.; Sun, Z.; Zhao, G.; Zha, B. Characteristic Analysis and Coating Application of the Innovative HVOF System Based on the Digital Model. Processes 2024, 12, 657. https://doi.org/10.3390/pr12040657

Yan M, Yuan X, Su Q, Sun Z, Zhao G, Zha B. Characteristic Analysis and Coating Application of the Innovative HVOF System Based on the Digital Model. Processes. 2024; 12(4):657. https://doi.org/10.3390/pr12040657

Chicago/Turabian StyleYan, Mingxia, Xiaojing Yuan, Qingdong Su, Zhensheng Sun, Guan Zhao, and Bailin Zha. 2024. "Characteristic Analysis and Coating Application of the Innovative HVOF System Based on the Digital Model" Processes 12, no. 4: 657. https://doi.org/10.3390/pr12040657

APA StyleYan, M., Yuan, X., Su, Q., Sun, Z., Zhao, G., & Zha, B. (2024). Characteristic Analysis and Coating Application of the Innovative HVOF System Based on the Digital Model. Processes, 12(4), 657. https://doi.org/10.3390/pr12040657