1. Introduction

Powder mixing is a widely implemented unit operation in several particulate processing industries (e.g., food, pharmaceutical, chemical, etc.) for combining two or more raw materials in the required proportions into a final blend (mixture). Uniformity in the composition of the final blend is a key requirement and has a considerable influence on the quality of the final product. Since mixing dictates the uniformity in the composition of the blend, which is then sent for further downstream processing, the performance of this particular operation is critical to the operational efficiency of these industries [

1]. Various industrial blenders with different mixing mechanisms are available and can be chosen based on the processing requirements. For example, tumbling blenders are often implemented for mixing granular materials, and a bin blender is the most commonly-used variation of the tumbling blender in the pharmaceutical industries, due to a high level of safety and convenience [

2]. However, due to the presence of multiple zones, which demonstrate different mixing behavior in a tumbling blender, understanding the process dynamics in detail would be beneficial for optimal process design. These zones have variable blend uniformity (e.g., presence of super-potent and sub-potent zones). Moreover, as pharmaceutical industries often have to deal with fine powders, which have poor flowability or tend to segregate, mixing them efficiently may become quite challenging [

3]. In general, powder flow processes are erratic and have an inherent variability associated with them, due to which various flow analyzing methods (experimental or modeling) are required to obtain a good prediction of their behavior. Mathematical model frameworks developed from physical principles and calibrated with experimental data would aid in providing better process understanding and could prove to be a more resource- and time-saving alternative when compared to other experimental methods for the process design and optimization analysis. The various model-based tools that can be used for process development are predictive models, flexibility and feasibility analysis, steady state and dynamic optimization, sensitivity analysis and controller design [

4].

Tolerance in the variability of the blend composition depends on the application, which in the case of pharmaceutical industries is narrow as they need to comply with the stringent product quality norms specified by the regulatory authorities (e.g., United States Food and Drug Administration (USFDA)). A more robust and science-based process design methodology is being implemented in the pharmaceutical industries, to ensure the retention of the detailed process knowledge and re-assess the various product quality risks and uncertainties associated with these. Good product quality can be realized by designing robust manufacturing processes by incorporation thorough process knowledge. Managing and retaining an explicit process knowledge throughout the product life-cycle is an important aspect, as stated in the guidance developed by the International Conference on Harmonisation of Technical Requirements for Registration of Pharmaceuticals for Human Use (ICH): ICH-Q10 [

5].

A detailed mathematical model that is validated, well-tuned and calibrated can be used as an efficient tool for pharmaceutical manufacturing process development studies [

6], which will help to outline the design space. The design space is defined as “the multidimensional combination and interaction of input variables (e.g., material attributes) and process parameters that have been demonstrated to provide assurance of quality” (ICH: Q8 (R2)). A batch mixing operation involves a large parametric space, which consists of processing parameters (i.e., blender RPM, fill level, loading order), equipment design, material properties, etc. [

2,

7]. A process consists of several input parameters, but only some are highly sensitive and critical towards the optimal operational efficiency of the process. Therefore, identifying the critical process parameters (CPPs) and understanding their effect on the process efficiency is an important step in establishing the design space and evaluating how effectively the process can withstand any parametric variability without a negative impact on the product quality. The manufacturing steps implemented by the pharmaceutical industries must meet the good manufacturing practices (GMP) guidelines to achieve high process efficiency and good product quality as outlined by the USFDA. This will also allow the product quality to be built consistently in each and every step of the manufacturing process as per the QbD (quality by design) and PAT (process analytical technology) guidelines.

PAT has been defined as “a system for designing, analyzing, and controlling manufacturing through timely measurements of critical quality and performance attributes of raw and in-process materials and processes with the goal of ensuring final product quality” (ICH: Q8 (R2) [

6]). It recommends the implementation of measurement and control tools for the CPPs and material properties in the process so that the desired product quality can be obtained. The process variables and parameters must be maintained within the acceptable limits, and any deviation may lead to the production of inferior quality product and also result in process failure, which may have a hazardous impact on the environment, health, safety, etc. A mathematical model can also aid in the design and evaluation of an efficient control loop system based on the process understanding. In short, a process model can be used for virtual experimentation and can be a prerequisite for the design, analysis, control and optimization studies of a process.

Another important step in the design stage of a manufacturing process is process risk analysis. Risk has been defined as “the combination of the probability of occurrence of harm and the severity of that harm” (ICH: Q9). It is necessary to formulate an effective risk management process that is comprised of analyzing and assessing the risks associated with a process (i.e., environmental, health, safety, etc.). A robust risk management process includes several steps, which are risk assessment (risk identification, risk analysis, risk evaluation), risk control (risk reduction, risk acceptance), followed by reviewing the outputs of the risk management process [

8]. A good understanding of the potential risks will lead to a reduction in prediction uncertainties and increase the sustainability of the process. Model-based tools can be excellent aids for evaluating the process risks as they can be used to gain process knowledge, identify the CPPs and understand the inter-dependence of the CPPs. These models can then be applied to optimization studies and sensitivity analysis and designing efficient control systems.

1.1. Problem Statement

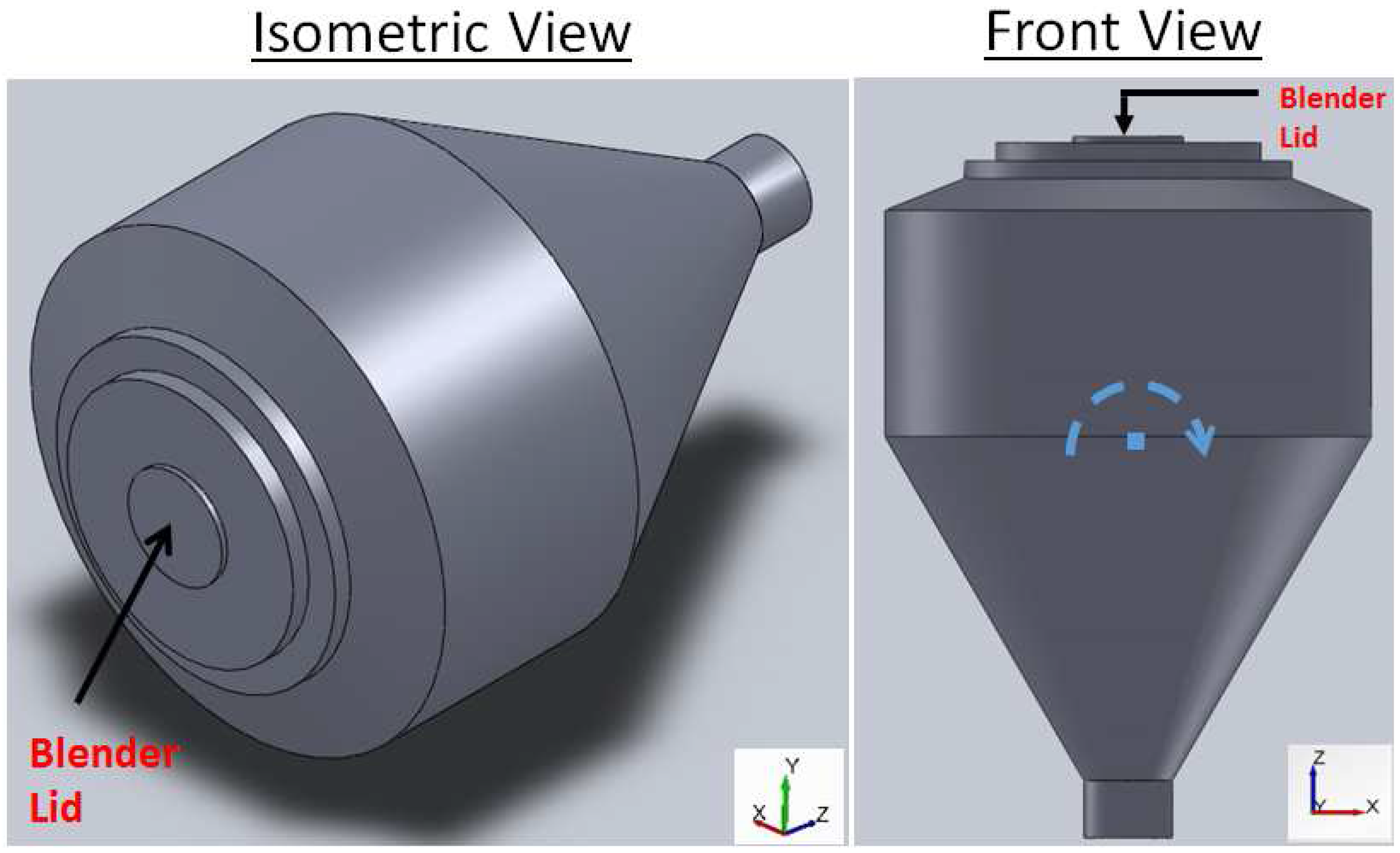

In the bin blender studied here, three different types of raw materials with different particle sizes and densities have been mixed, and it is hypothesized that multiple zones with different mixing dynamics may be present. At present, the blend composition in the industrial setup is obtained with the aid of a sensor, which is mounted on the lid of the blender. This sensor is able to detect the composition in the near-lid region only and performs a reading every time the bin is inverted. However, it is unknown if the data obtained at the lid are representative of the overall variability of the entire blend due to the scope of the sensor being limited to a tiny volume of the blender. Thief sampling interrupts the process and is invasive. It has also been shown to be unreliable [

9]. Since the scale of the blender is large (800 liters), obtaining data about the bulk would also be challenging. Hence, a DEM study has been conducted to test whether composition measurements made at the near-lid zone are able to represent the overall variability in the blend composition [

10].

1.2. Objectives

In this work, a discrete element model for an industrial batch bin blender has been presented, and the mixing dynamics have been studied in terms of the blend composition at different locations inside the blender. The blend composition information has been further translated into RSD and intensity of segregation and used to investigate the objectives specified below:

Determine if the composition measured near the blender lid can be utilized to estimate the variability in the bulk mixture

Identify the areas of segregation (i.e., super-potent and sub-potent regions)

Identify the key processing parameters and evaluate the mixing dynamics by varying them

Demonstrate how a model-based method could be used to recommend more optimal operational parameters and improve the operational efficiency of the mixing operation

2. Background

DEM is often used to simulate powder flow as it treats the particles as discrete entities and is able to track the flow-field of individual particles. The mathematical formulation of DEM is derived from first-principles. DEM calculates the total force acting on the particles due to particle-particle contacts and particle-boundary contacts (contact forces) and other body forces, for example the force of gravity. It then computes the acceleration or velocity using Newton’s second law and updates the particle position based on the velocity information. Two types of forces, normal pressure force and tangential frictional force, act on the particles due to contact. The contact forces are calculated from the various contact models that are available (i.e., Hertzian normal contact force model, Cundall and Stack normal force model, J-K-Rnormal and adhesive force model for cohesive particles, Mindlin–Deresiewicz/Coulomb friction tangential force model, etc.) [

11]. In this work, the Hertzian normal contact force model and Mindlin–Deresiewicz tangential force model have been used, as the present model simulates free-flowing non-cohesive powders. The Hertzian normal contact force model assumes a non-linear spring-dashpot model and is applicable within elastic limits for spherical and smooth particles with continuous surface and undergoing non-conforming contact. As detailed by Kruggel-Emden et al. [

12], particle-particle contact is detected between two spherical particles when the distance between their centers is less than the sum of their radii; and a particle-boundary contact is detected when the distance between the particle center and the boundary is less than the particle radius. However, a very small overlap (or deformation) may be allowed. As shown in Equation (

1), the total force (

) acting on the particles is the summation of the normal contact force (

), tangential/frictional contact force (

) and body force (

). In a bin blender model, the only body force acting may be due to gravity.

The acceleration of the particles is calculated from Newton’s law

, where

m is the particle mass and

is the acceleration vector. The position of the particles is updated from Euler’s equations of rotational motion as shown in Equation (3) [

13]. Here,

x,

y and

z are the spatial coordinates of the particle position;

I is the moment of inertia;

is the angular velocity vector; and

is the torque.

The normal or tangential contact forces are calculated as

. Here,

is the normal or tangential contact force;

is the normal or tangential overlap;

k is the stiffness coefficient factor;

is the rate of normal or tangential deformation; and

is the damping coefficient. The detailed expressions of these parameters have been given by Dubey et al. [

13]. The stiffness coefficient controls the particle stiffness and is a function of the particle size and other material properties (i.e., Poisson’s ratio and Young’s modulus). The stiffness of a body can be defined as its ability to resist deformation when a force is applied on it. Fine tuning of the values of Poisson’s ratio and Young’s modulus is important because it decides the stiffness of the particles, which on the other hand controls the particle deformation or overlap upon contact. It is suggested that the particle overlap be controlled so that the model stays within the elastic limit [

14].

DEM has been used to simulate various granular processes. DEM is considered as an explicit particle level model because it treats the particles as discrete entities and is able to capture the effect of equipment geometry, material properties and different particle-particle and particle-geometry interactions on the basis of the forces acting due to different contacts. It is an excellent tool to obtain fundamental particle level information, which is not possible based on other modeling techniques which have been used to model powder systems (i.e., population balance models (PBM) [

15], continuum models [

16], Markov chain models [

17], etc.). DEM can be effectively used for performing qualitative process analysis, process design and optimization, equipment design studies (e.g., determining if any dead zones are present based on the flow pattern), scale-up studies, troubleshooting practical processing issues, etc.

DEM has been used widely to study different kinds of batch and continuous blenders with different mixing mechanisms for both free-flowing and cohesive particles. For example, previous works present extensive studies on the mixing dynamics of the V-blender [

18], conical blender [

19], slant conical blender [

20], rotating drums [

21] and other continuous processing blenders [

15,

22]. Chaudhuri et al. studied the mixing of cohesive particles in a tumbling blender [

7]. Bin blenders, in particular, have been studied explicitly by other researchers using DEM. Segregation studies were conducted by Sudah et al. [

23] in bin blenders for different loading conditions and fill levels using mono-disperse spheres. Particle movement by convection in the radial direction was shown to be dominant over dispersion in the axial direction inside a bin blender with the help of a DEM model [

2]. Using a GPU-based DEM model, it was found that installing the blender at an inclined angle improved the mixing performance of a bin blender [

24]. Ren et al. [

25] also studied the effect of different numbers and lengths of baffles on the mixing dynamics inside a Gallay tote bin blender. Lemieux et al. compared the flow behaviors of a bin blender and a V-blender for different loading profiles [

26]. Detailed analysis of the mixing mechanism and the effect of processing conditions on the mixing dynamics have been investigated in these studies. The present work outlines the steps involved in the implementation of the discrete element methodology to create a model of an industrial-scale tumbling bin blender. The model has been used to investigate the effectiveness of sampling locations in determining the blend homogeneity inside the blender and also to study how the mixing performance inside the blender could be improved.

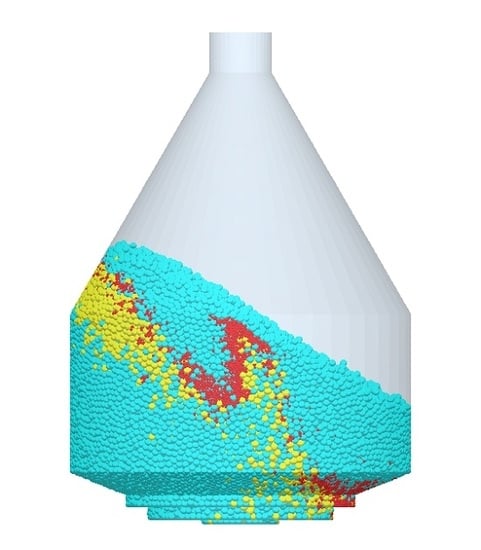

4. Results and Discussion

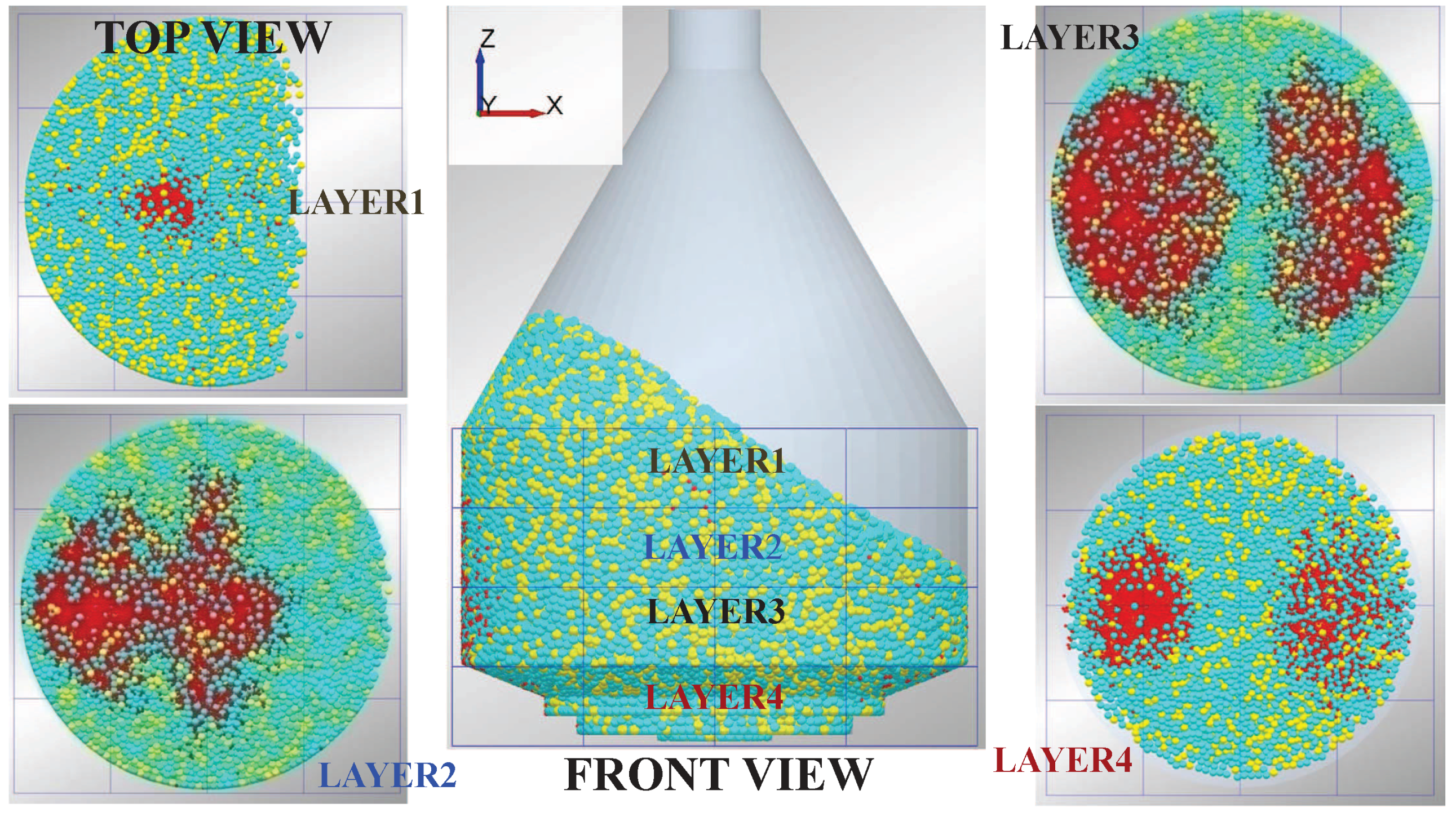

As mentioned earlier, it should be noted that the results reported in this section have been obtained from a model-based analysis, which qualitatively represents the scenario detailed in

Section 1.1 (problem statement). Investigating the mixing performance in different zones inside the blender will help to identify the sub-optimal mixing zones that may be present. In order to improve the mixing efficiency and enhance the blend quality, the processing conditions can be adjusted as required. Any unit operation is sensitive to certain critical process parameters (CPPs), and it has been shown in the previous studies [

2,

33] that the mixing efficiency changes significantly with the change in the conditions of these process parameters. A Cartesian coordinate system has been used for discretization of the blender into several zones. The geometry has been divided into four layers as seen in

Figure 3. Each layer has been further divided into 16 grid bins. Therefore, the geometry has been divided into a total of 64 grid bins (4 × 4 × 4 in the

x,

y and

z directions, respectively). It should be noted that a grid bin represents a zone or location inside the blender. When the model-based RSD of the blend composition is calculated, samples are collected from these zones for the RSD measurement. Therefore, changing the bin size will change the total number of zones inside the blender, which will in turn change the number of samples collected for the RSD measurement. In order to fix the bin size, the RSD has been calculated as a function of time by varying the bin size (which in turn changes the total number of bins), and the final bin size has been chosen in the range where the change in RSD between two bin sizes was not significant.

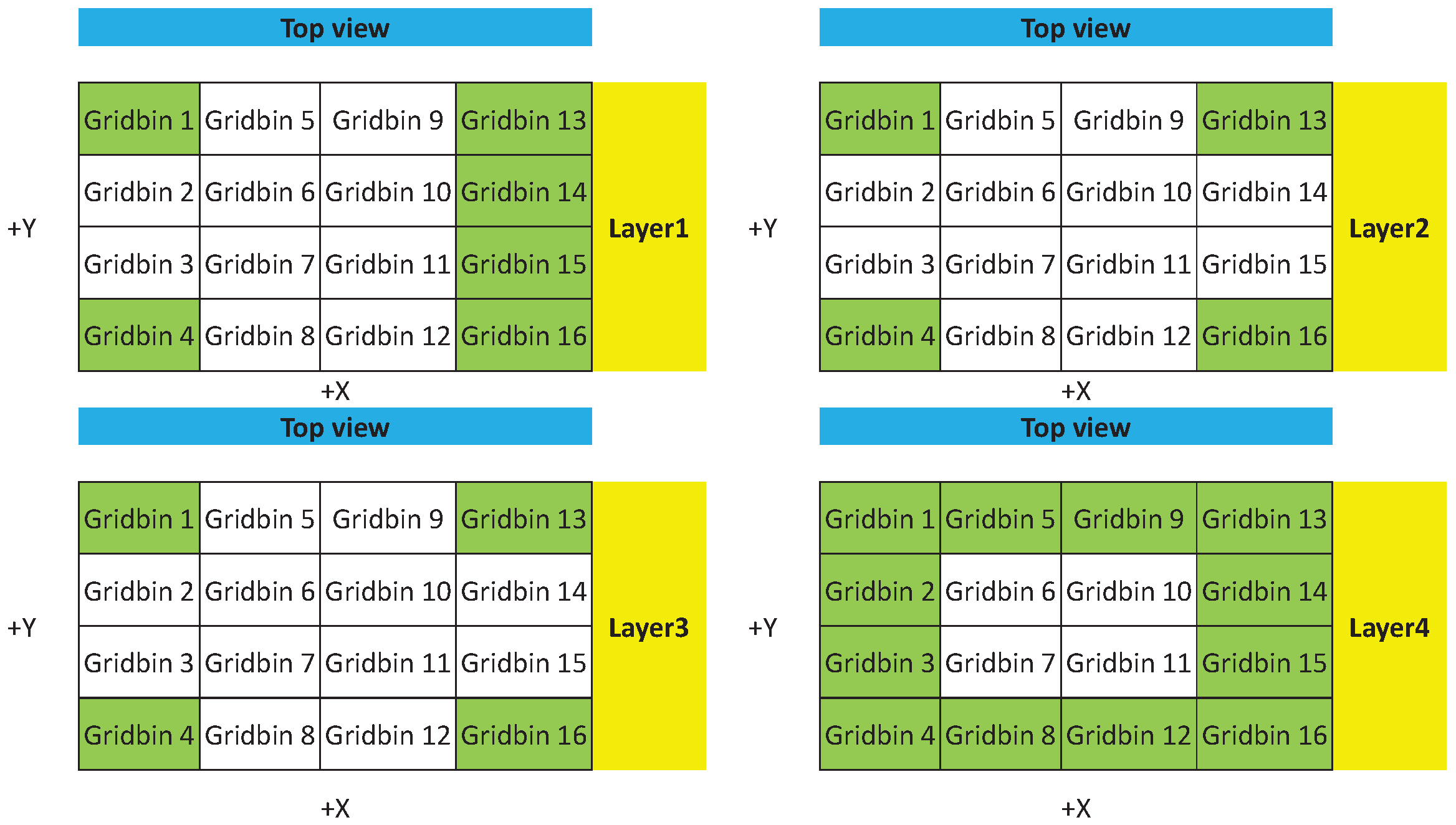

Figure 3 and

Figure 4 give a pictorial representation of the grid bins/zones inside the blender. It can be seen from

Figure 3 that there are almost no particles or very few particles present in some of the grid bins. This is because a Cartesian coordinate system has been considered in order to discretize the cylindrical vessel. Therefore, these bins have been excluded from the RSD calculation so that spurious results are not obtained.

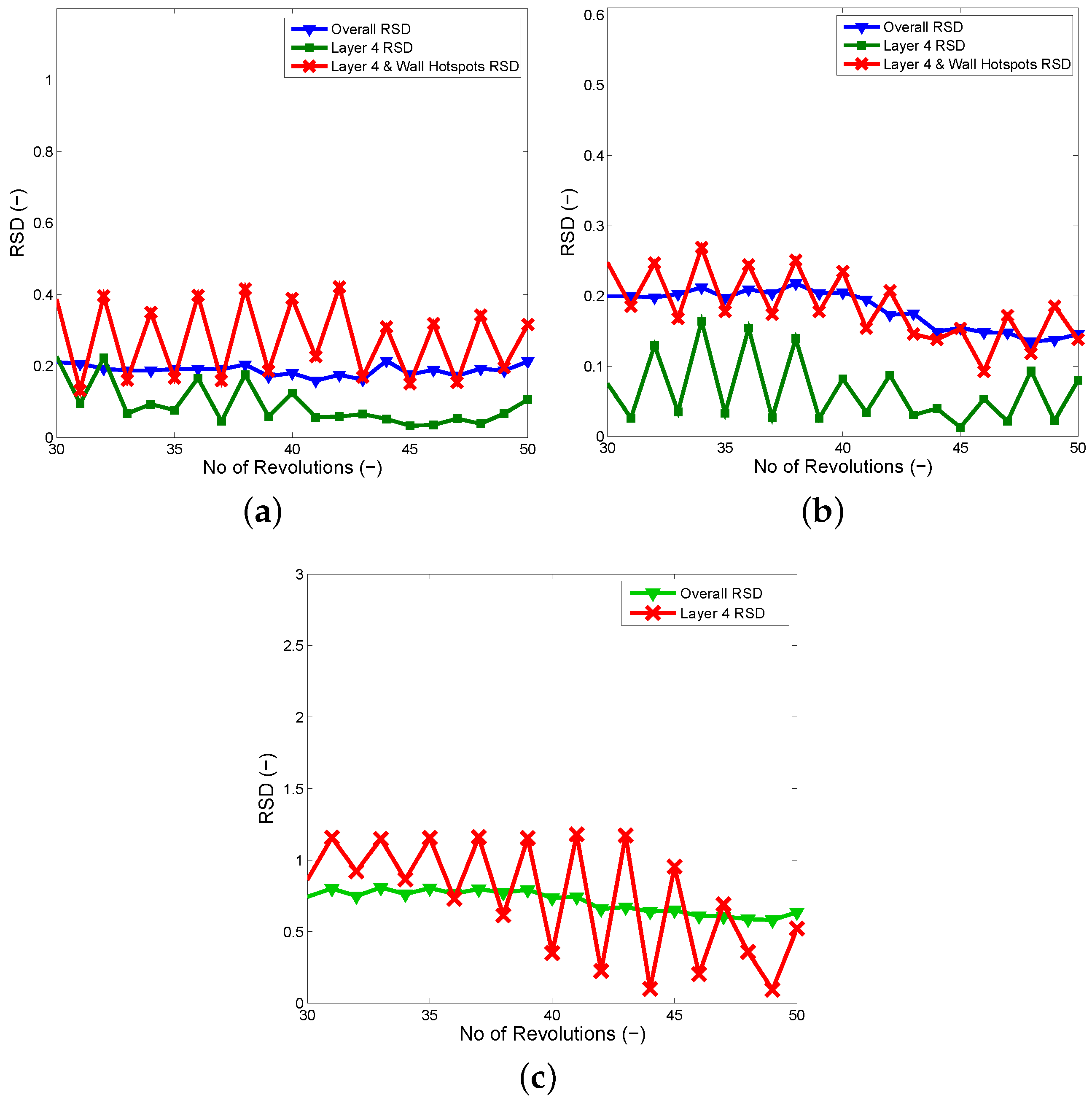

Figure 4 presents the Cartesian grid bin representation of the four layers from the top view. It shows the excluded grid bins, which have been marked in green. The Grid Bins 6, 7, 10 and 11 in Layer 4 are all closest to the blender lid. Hence, the compositions from these four bins have been used to calculate the RSD at the lid.

Figure 5 represents the comparison between the overall RSD with respect to each material type, as a function of the number of revolutions, to their RSD in Layer 4 only (i.e., the near-lid region). RSD (for the

i-th material type) has been determined based on Equation (

4) as shown below. The overall RSD has been calculated by considering all of the grid bins excluding the ones highlighted in green, as shown in

Figure 4. As explained above, samples collected from these grid bins have been used for RSD calculation. These RSDs represent instantaneous values as they are calculated from compositions in the grid bins at the end of a revolution.

As mentioned, the blender has been divided into several bins, and samples for measurements have been collected from each of these bins. Here,

is the overall average fractional composition;

is the fractional composition at the

i-th bin; and M is the total number of bins. In other words, M is the total number of samples collected from the model for performing the RSD calculations.

Figure 5a–c represents the comparison of RSDs obtained from the different locations (i.e., overall RSD, Layer 4 RSD and Layer 4 and wall hotspots RSD). The calculation of the overall RSD has been defined above. The Layer 4 RSD is the RSD at the blender lid. The meaning of ‘Layer 4 and wall hotspots RSD’ will be explained later in this section. The oscillations present are an inherent property of DEM simulation and have been observed previously in the literature [

15]. As the powder particles can interact with each other and the geometry wall and move around the space in several different ways, based on the interaction parameters, contact angle, etc., oscillations in the output variables are often observed. The oscillations present in the overall RSD are much smaller in magnitude because the RSD has been computed taking all particles into consideration. However, from

Figure 3, it can be seen that there is a mass of a few hundred particles present above Layer 1 when the blender is in the inverted position, which cannot be included in the calculation, as the discretization scheme does not allow it. Therefore, some particles are moving in and out of this mass (which changes the total number of particles considered for calculation) at every revolution. Therefore, the small oscillations are seen in the overall RSD. The oscillations present in the Layer 4 RSD are of higher magnitude because the RSD has been calculated for Layer 4 only, which is a small section inside the blender. A large number of particles can move in and out of this layer at every revolution, thus changing the total number of particles in Layer 4, which gives rise to the oscillations. It can be seen from

Figure 5a,b that the RSDs from the compositions from the near lid regions are under-estimating the overall variability of API 1 and API 2 in the mixture. However, the mean values of the near lid RSD for each revolution give closer estimates of the overall variability for the extra granular phase compared to the other two components, as seen from

Figure 5c. Overall, we can conclude that the measurements made near the lid are insufficient to capture the variability in composition of the blend.

It is important to note that the blend uniformity may improve when the ingredients are mixed for a longer period of time. The importance of mixing time has been discussed briefly in

Section 4. The lower the RSD, the lesser is the variability in composition of the ingredients. If the ingredients are well and uniformly mixed over all of the zones inside the blender, there is still a possibility that the near-lid RSD will be able to represent the overall blend variability towards the end of the mixing time. However, these readings are not sufficient to estimate the dynamic variability of the blend, especially during the initial stages of mixing when the overall variability of the blend is high (as seen from

Figure 5, as well). The information on dynamic variation is important (e.g., if a control loop needs to be designed in the future), which can be obtained easily from the model. For example, Godena et al. have highlighted the important steps involved in designing a batch process control system [

34].

In order to obtain a better approximation of the overall RSD in the case of API 1 and API 2, there is a scope for identifying other sampling locations. The data from the additional sampling locations along with the near-lid readings could give a better estimate of the overall mixture variability. The RSD plots with the legend ‘Layer 4 and wall hotspot RSD’ in

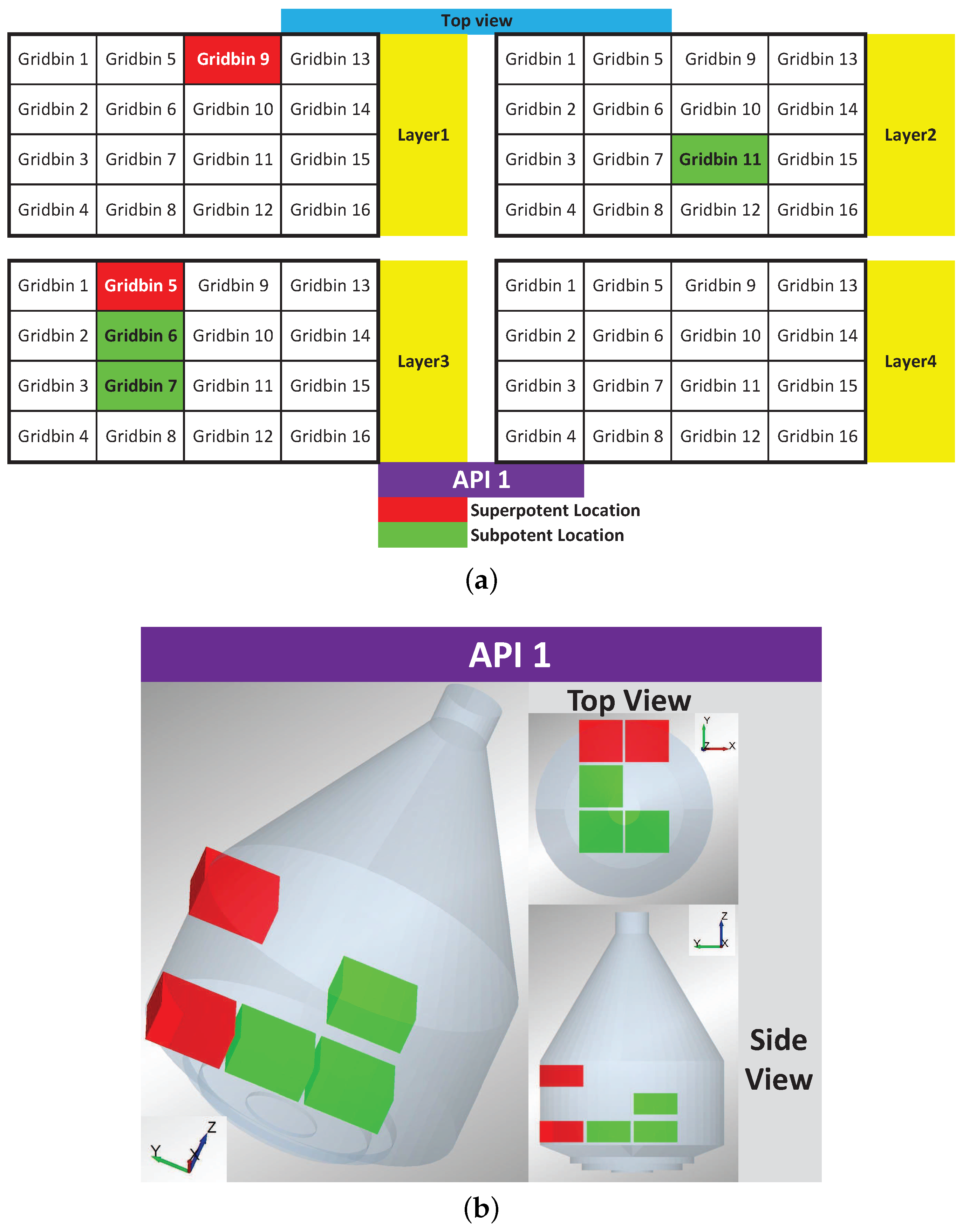

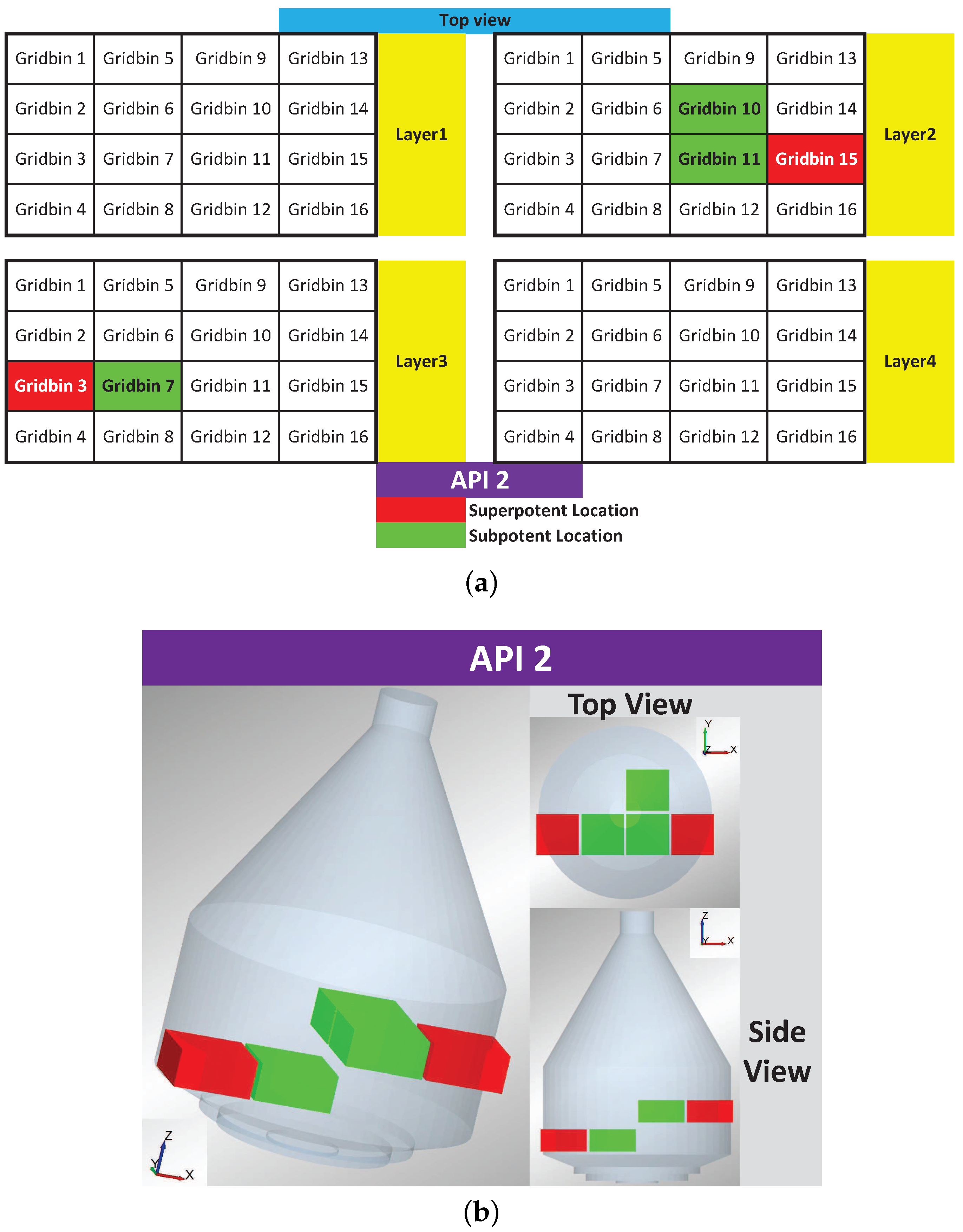

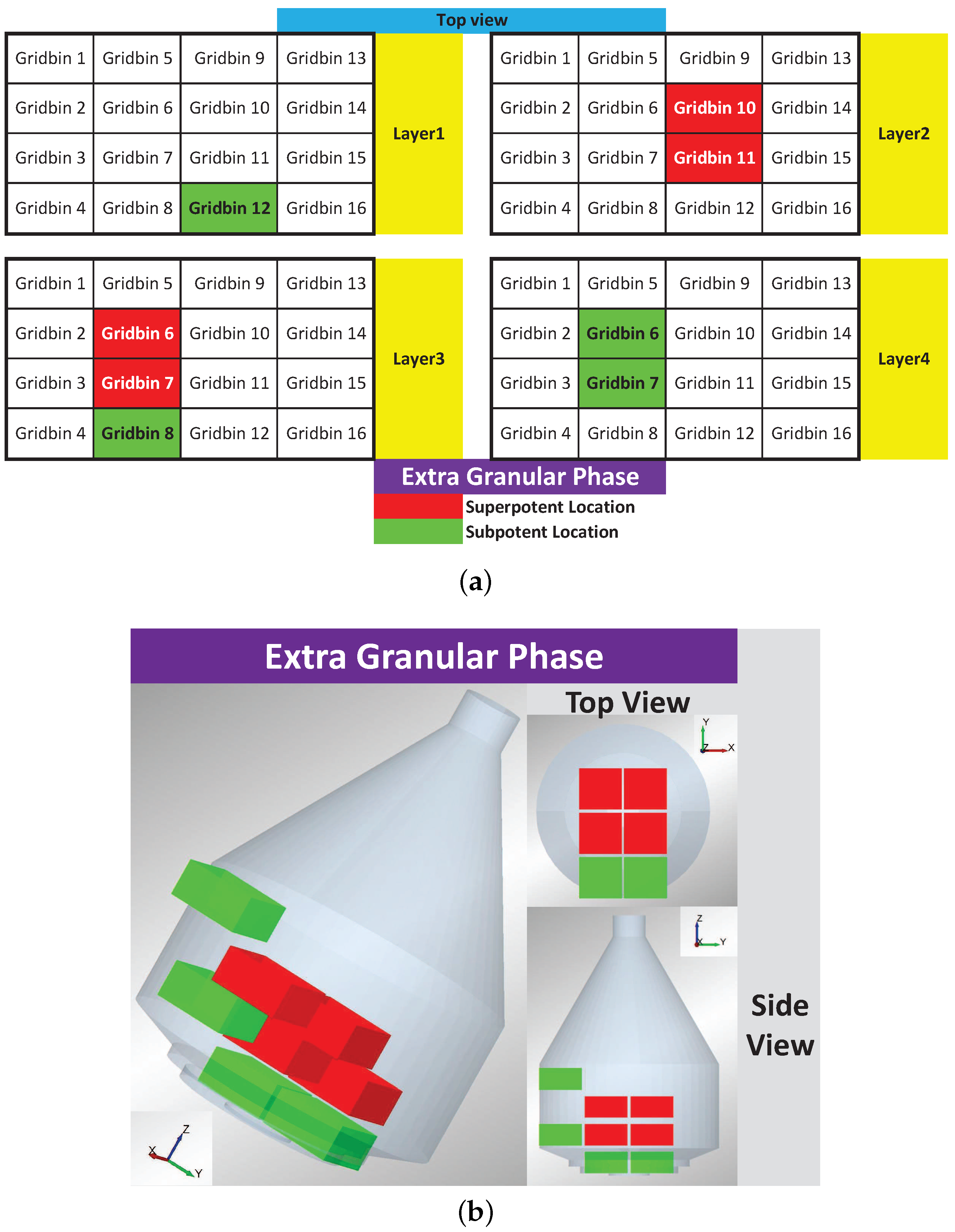

Figure 5a,b have been calculated after identifying the additional sampling locations, as has been detailed in this paragraph. In this study, the zones/bins with maximum and minimum fractional composition (with respect to the whole blender) have been identified at every revolution once the first 30 revolutions are complete (i.e., from 30th revolution to the 50th, a total of 21 revolution points). If a maximum or minimum composition has occurred in a particular bin more than three times (or at more than three revolution points), then that bin has been marked. The colors red and green stand for super-potent (maximum or more than the overall average composition) and sub-potent (minimum or less than the overall average composition) locations, respectively.

Figure 6a,b shows the bin locations for API 1 in the Cartesian system and 3D representation, respectively. It can be seen that the super-potent spots are occurring towards the wall, and the sub-potent spots are occurring towards the center most of the times. Similarly,

Figure 7a,b presents the bin locations for API 2 in the Cartesian system and 3D representation, respectively. A similar segregation pattern is observed in the case of API 2, as well. The zones identified in this study represent poorly-mixed regions. Thus, they can be potential sampling sites to enable better understanding of the blend composition. For each of these components, only the super-potent regions near the blender wall have been chosen as the additional sampling points due to the ease of data collection without interfering with the blend system. For example, one way to monitor the wall regions can be by drilling a hole on the equipment wall at the required location and installing a window and a sensor.

The additional sampling sites in the case of API 1 are Grid Bin 9 in Layer 1 and Grid Bin 5 in Layer 3. The additional sampling sites in case of API 2 are Grid Bin 15 in Layer 2 and Grid Bin 3 in Layer 3. The new RSD has been calculated by including the additional sampling data points along with the Layer 4 data and termed as ‘Layer 4 and wall hotspot RSD’. The new RSD has been compared in

Figure 5a,b with the overall RSD. It can be seen from the plots that there is a good approximation, and the new RSD is not under-estimated when compared to the overall mixture RSD.

Figure 8a,b gives the bin locations for the extra granular phase in the Cartesian system and 3D representation, respectively. In the case of the extra granular phase, the super-potent spots occur towards the center, and the sub-potent spots occur towards the wall. This implies that the extra granular phase is forming a slowly-mixing segregated layer towards the center, which is away from the wall of the blender. Alexander et al. reported that the segregation pattern changes with the change in the blender RPM. For example, at a low blender speed, they observed that the smaller-sized particles form a separated band at the center surrounded by an outer band of large-sized particles, and the pattern is reversed when the blender speed increases [

35]. In the present study, the blender RPM is low, and a similar observation of smaller particles segregated towards the center and larger particles towards the wall has been obtained. There is a possibility that similar observation can be made in the experimental setup, as well as in the beginning of the mixing operation; however, the segregated zones may go away with time when the mixing is complete.

The system is comprised of three types of materials, each consisting of particles with different sizes. As a result, the chances of observing segregation is high. Segregation effects are often seen in different powder handling operations as particles with different sizes and density often tend to form segregated layers, thus deteriorating mixing performance [

36]. In order to quantify the extent of segregation of the three material types, the intensity of segregation (I) has been determined based on the equation below (Equation (

5) [

37]).

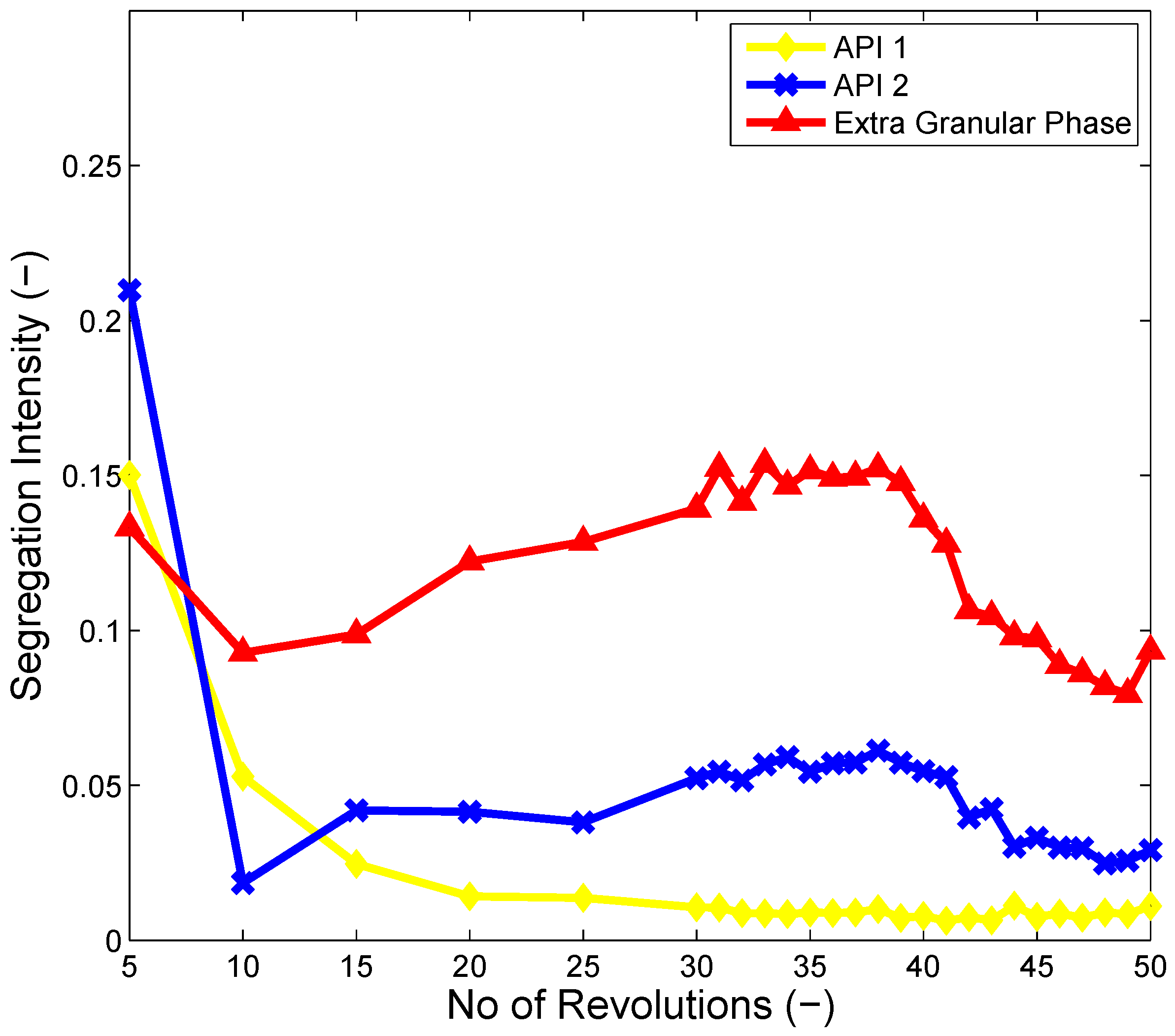

Figure 9 gives the intensity of segregation as a function of the number of revolutions. It can be seen that the segregation intensity of the extra granular phase is the highest. The API 1 and API 2 particle sizes used in the simulation are comparable (the size ratio between the two is 1:1.05), but the extra granular phase particles are much smaller (approximately 2.5-times) than the other two. As a result, the extra granular phase forms a segregated layer, which is mixing slower compared to the other two material types, since the segregation intensity of the extra granular phase is comparatively high. It is also seen that the extra granular phase is mainly concentrated towards the center and is mixing very slowly. Therefore, it has a high variability throughout the mixture. This may be the reason why the near-lid measurements are able to capture the overall RSD of composition for the extra granular phase. On the other hand, API 1 and API 2 have certain well-mixed and poorly-mixed zones due to which the measurements at the blender lid are not able to capture the overall RSD of these two entities. The segregation pattern is a strong function of the fill level, blender RPM and particle properties (i.e., size and shape). In the previous studies, it has been observed that the segregation pattern of differently-sized and -shaped particles varies with the change in the processing conditions [

38,

39].

Segregation of a component during mixing is not desired, hence the model has been used to evaluate the changes that need to be made in the processing conditions such that the segregation effect is lowered and a better quality blend is obtained in lesser operational time. Certain process parameters critical to mixing (e.g., fill level and RPM) have been varied, and their effect on the mixing dynamics has been studied. This will help determine how these CPPs can be tuned in order to reduce the segregation intensity and also enhance the mixing efficiency, which will allow the slowly-mixing center consisting of the extra granular phase to go away. Two more cases have been run where the fill level has been reduced to 40% (total number of particles simulated is 125,000) in one, and the blender RPM has been increased to 12 in another one, keeping all other simulation parameters the same as the base case.

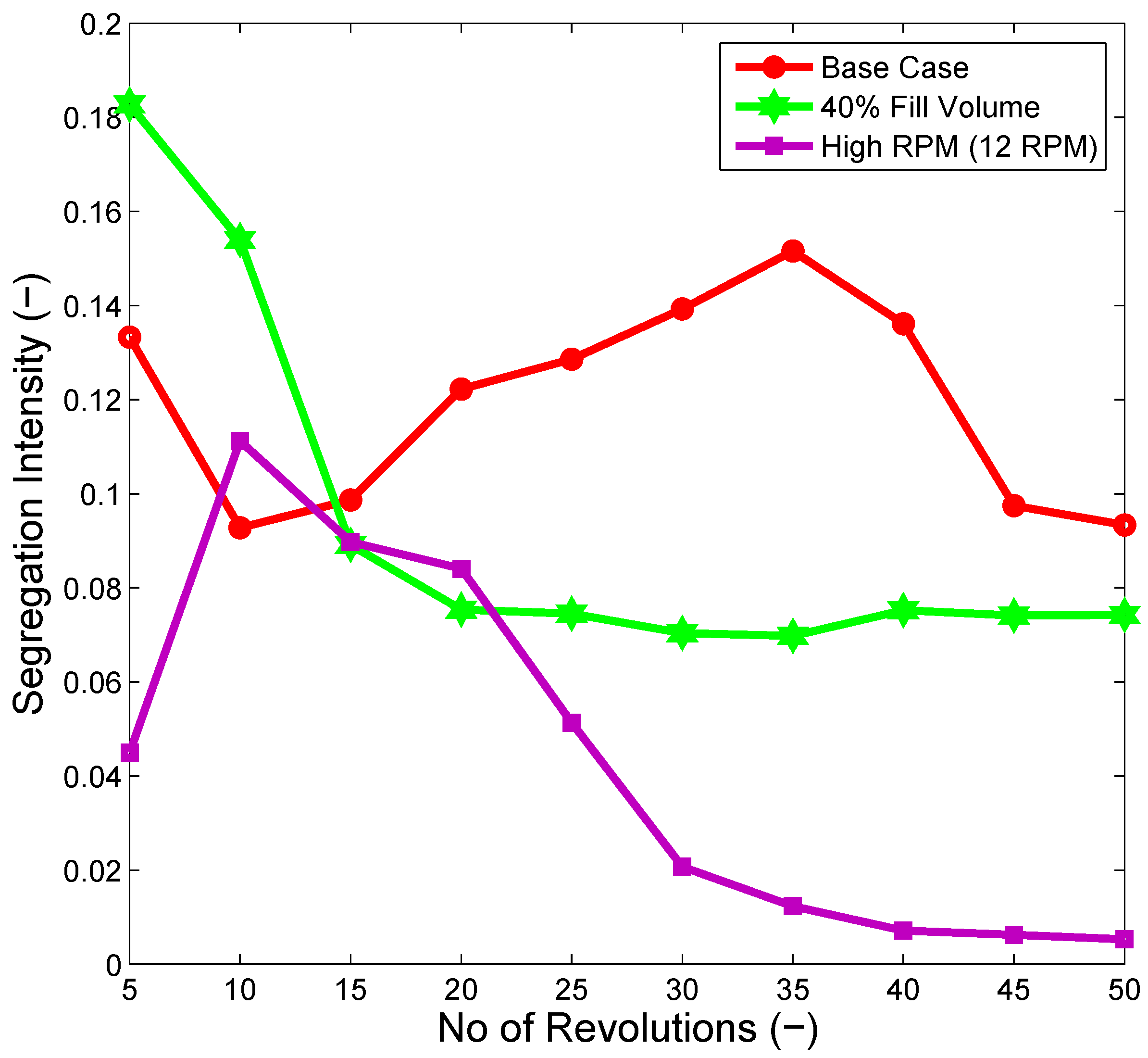

Figure 10 shows the change in intensity of the segregation of the extra granular phase with the variation in RPM and fill level. It can be seen from

Figure 10 that the segregation intensity reduces with the increase in RPM or the decrease in fill level. As the RPM increases, it increases the convective transport of the particles, thus resulting in a fast mixing, which enhances the mixing efficiency. With the decrease in fill level, the particles have enough space to travel from one location to another, which aids in particle transport. In the bin blender simulations, it has been noticed that the mixing of the materials takes place mainly near the free surface of the batch as the blender rotates. Therefore, at a higher fill level and low blender RPM, the segregated layer of the extra granular phase at the center is not getting enough space and energy to move around. However, as the fill level is reduced and the blender RPM increased, a better mixing of the extra granular phase is being achieved. As considerable effects of these process parameters have been observed on the mixing dynamics, therefore a separate study has been conducted to understand the influence of the various process parameters (as detailed in

Section 4). It is important to observe the effect of the different process parameters as this will help to arrive at an optimal processing condition.

The developed model has been compared with some of the experimental work done by other researchers on studying the segregation patterns in tumbling blenders. The results of the the model qualitatively match the observations made in these works. For example, Alexander et al. carried out an experimental study on the segregation patterns in a tumbling V-blender [

40]. They observed that the smaller particles occupy the interior, whereas the bigger particles tend to occupy the exterior space. The reason behind this observation as outlined by the authors is that the big and heavy particles tend to travel more rectilinearly than the smaller and lighter particles in a transverse forcing field. As a result, the smaller particles can follow trajectories with higher curvatures and tend to occupy the interior of a curved flow path-line when compared to the bigger particles. Similarly Alizadeh et al. [

41] used a radioactive tracking method in order to investigate the segregation pattern in tumbling blenders. They used differently-sized glass spheres in their experiment and observed that the smallest size of glass spheres (3 mm in diameter) forms a core along the material rotation axis, and they are surrounded by the larger spheres (5 mm and 6 mm diameter). Porion et al. [

42] used a nuclear magnetic resonance (NMR) imaging technique to study the mixing and segregation in a 3D batch blender (shaker-mixer) and observed a similar segregation pattern based on the particle size (i.e., the large coated beads segregated to the outer part of the cell in their experiment). The results obtained from this model also depict that the larger particles (API 1 and API 2) tend to occupy the outer volume of the blender, and the smaller particles (extra granular phase) form a slowly-mixing core. This shows that when compared to the other experimental observations available in the literature for different types of tumbling batch blenders, the present model shows a good qualitative agreement.

Effect of Process Parameters on Blend CQAs

As identified in the previous studies [

43], the main design and process variables that affect the mixing dynamics are geometry, the design of the blender and the mixing mechanism, blender size, fill level, rotation speed of the blender (RPM), material loading order and material properties of the raw materials. In the present study, the design parameters or equipment geometry and the material properties are fixed. Therefore, the process variables (i.e., the fill level, loading order and blender RPM) have been varied in order to determine their effect on the mixing performance of this particular system. This study will help to demonstrate how this model can be used for process design and to determine the sensitivity of the process parameters. The RSD has been calculated every five revolutions, based on the RSD of API 1, since this is the API of interest.

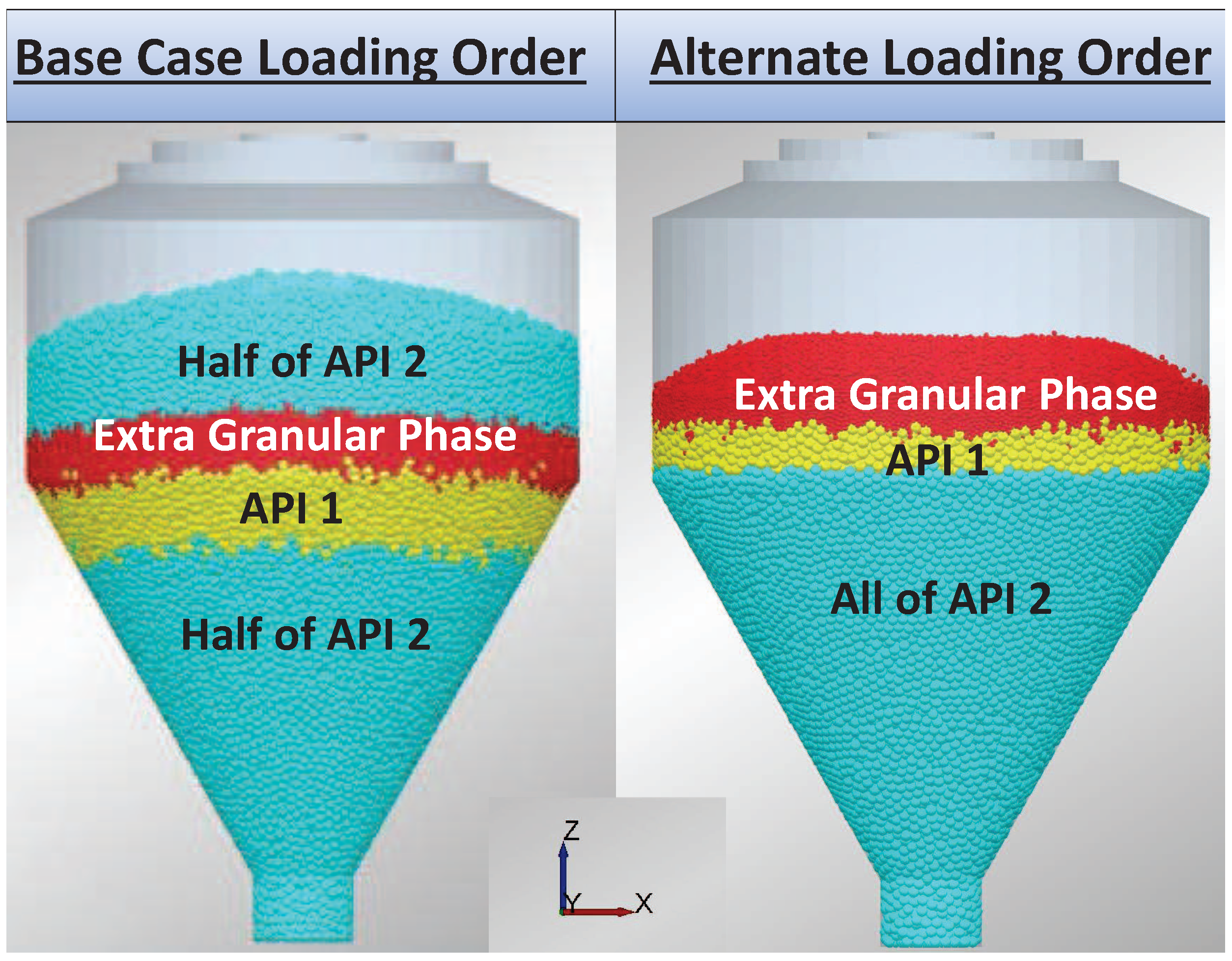

Figure 11 shows the two different loading orders (i.e., base case loading order and alternate loading order). In the alternate loading order, materials have been added as all API 2 followed by all API 1 followed by all of the extra granular phase.

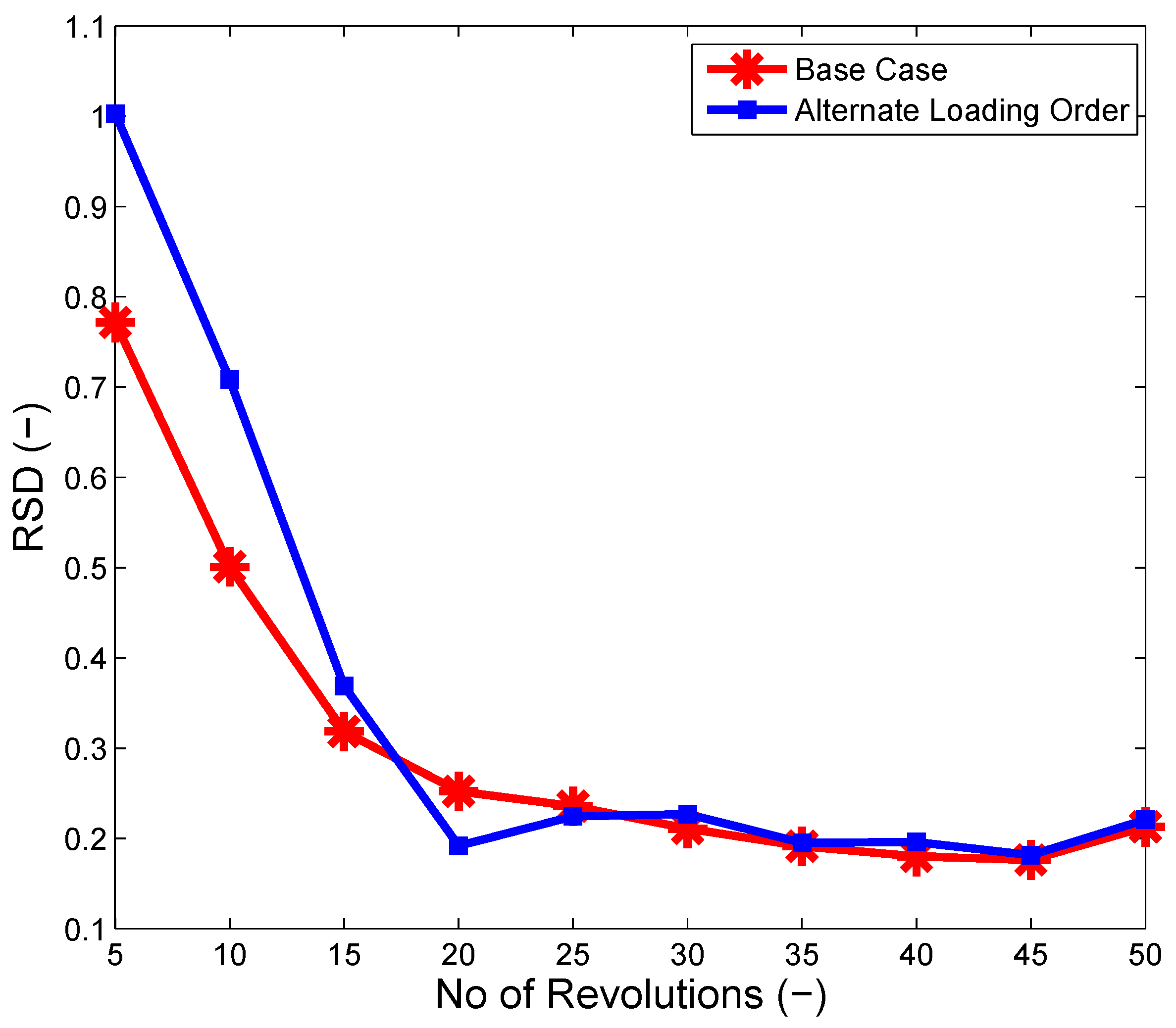

Figure 12 presents the plot of RSD with respect to API 1 with different loading orders. It has been seen that the effect of the loading order is the least in the present case as the average change in RSD with the alternate loading order is 0.5% only. Therefore, loading order has not been considered for further investigation, as it has been found to be the least sensitive process parameter for the present system.

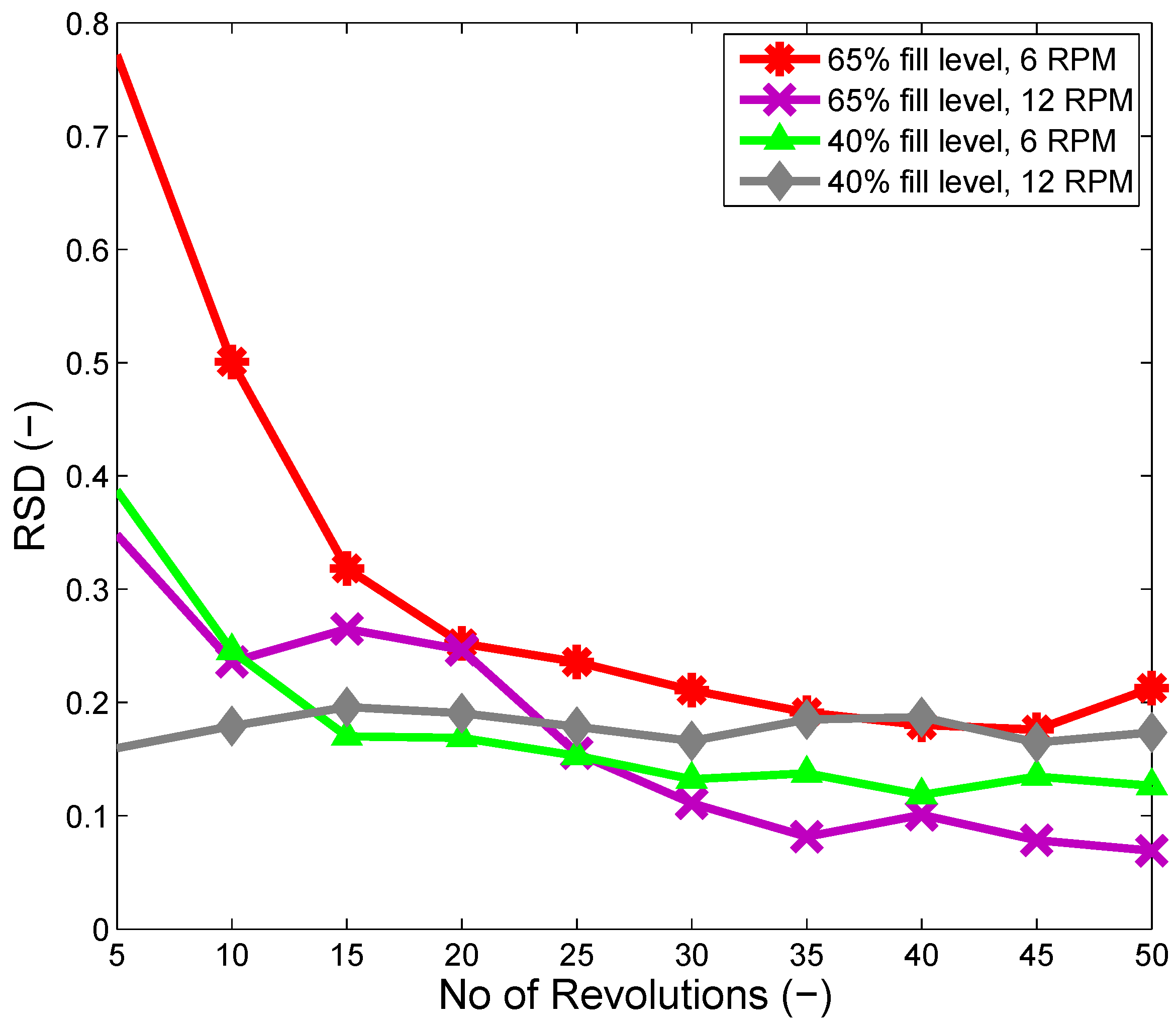

Two process parameters (fill level, blender RPM) have been studied and two levels of each have been considered. The two levels for the fill level are high 65% and low 40% and blender RPM are low 6 RPM and high 12 RPM. Following a factorial design,

simulation conditions were obtained. These conditions are as shown below (it should be noted that all other input parameters are the same as defined in

Section 3.3):

Case 1: Blender RPM = 6 and fill level = 65% (which is the base case)

Case 2: Blender RPM = 6 and fill level = 40%

Case 3: Blender RPM = 12 and fill level = 65%

Case 4: Blender RPM = 12 and fill level = 40%

Figure 13 illustrates the RSD of API 1 as a function of the number of revolutions for the four different conditions as listed above. The RSD decreases with the reduction in the fill level and the increase in the blender RPM. As highlighted previously, this occurs due to the increase in convective particle transport as the RPM increases. As the blender RPM increases, it imparts more energy to the particles, which in turn increases their kinetic energy. As a result, the particles are mixed better. The RSD increases with the increase in the fill level because with the increase in the fill level, lesser free space is available for particle movement, which hinders the particle transport. RSD decreases over the number of revolutions for Case 2 (blender RPM = 6 and fill level = 40%) and Case 3 (blender RPM = 12 and fill level = 65%) when compared to the base case. However, for Case 4 (blender RPM = 12 and fill level = 40%), the RSD is the least (among all four cases) until the 12th revolution, after which the RSD starts increasing and approaches the base case RSD at the 35th revolution. One explanation for this observation is that due to a high RPM and low fill volume (i.e., less amount of raw materials), the ingredients are mixed comparatively faster (i.e., by 12 revolutions), and mixing beyond 12 revolutions causes segregation. The particles could be undergoing a spatial re-arrangement due to the contact and body forces acting on them, which may lead to a segregation of the previously well-mixed blend. Therefore, mixing time is also an important factor to be considered in the case of a batch mixing operation. Mendez et al. illustrated the effect of mixing time on the homogeneity of the drug product in the mixture using a V-blender and observed that this parameter can be used to control the mixing operation on a large scale during batch production [

44]. While studying the optimum mixing time for a mixture of lactose and colloidal silicon dioxide, Sindel et al. also observed that the variability of the mixture reduces with time initially and reaches an optimum homogeneity, then starts increasing again [

45].

Mixing time is an important factor in deciding the blend quality [

46] in the case of the batch mode of operation. Optimal mixing time will change if the CPPs are varied. It can be adjusted to obtain the desired product quality. However, in this work, a study on the mixing time has not been conducted, as the present DEM model is computationally intensive. However, the same framework can be used to study the effect of mixing time. In order to run the model for a longer time period, it is suggested that a reduced order model (ROM) is developed from the DEM. An ROM is faster and will have the details of the DEM, as well [

47]. The other option is to use parallel computing tools to speed up the simulation.