Laboratory Investigation of Granite Permeability after High-Temperature Exposure

Abstract

:1. Introduction

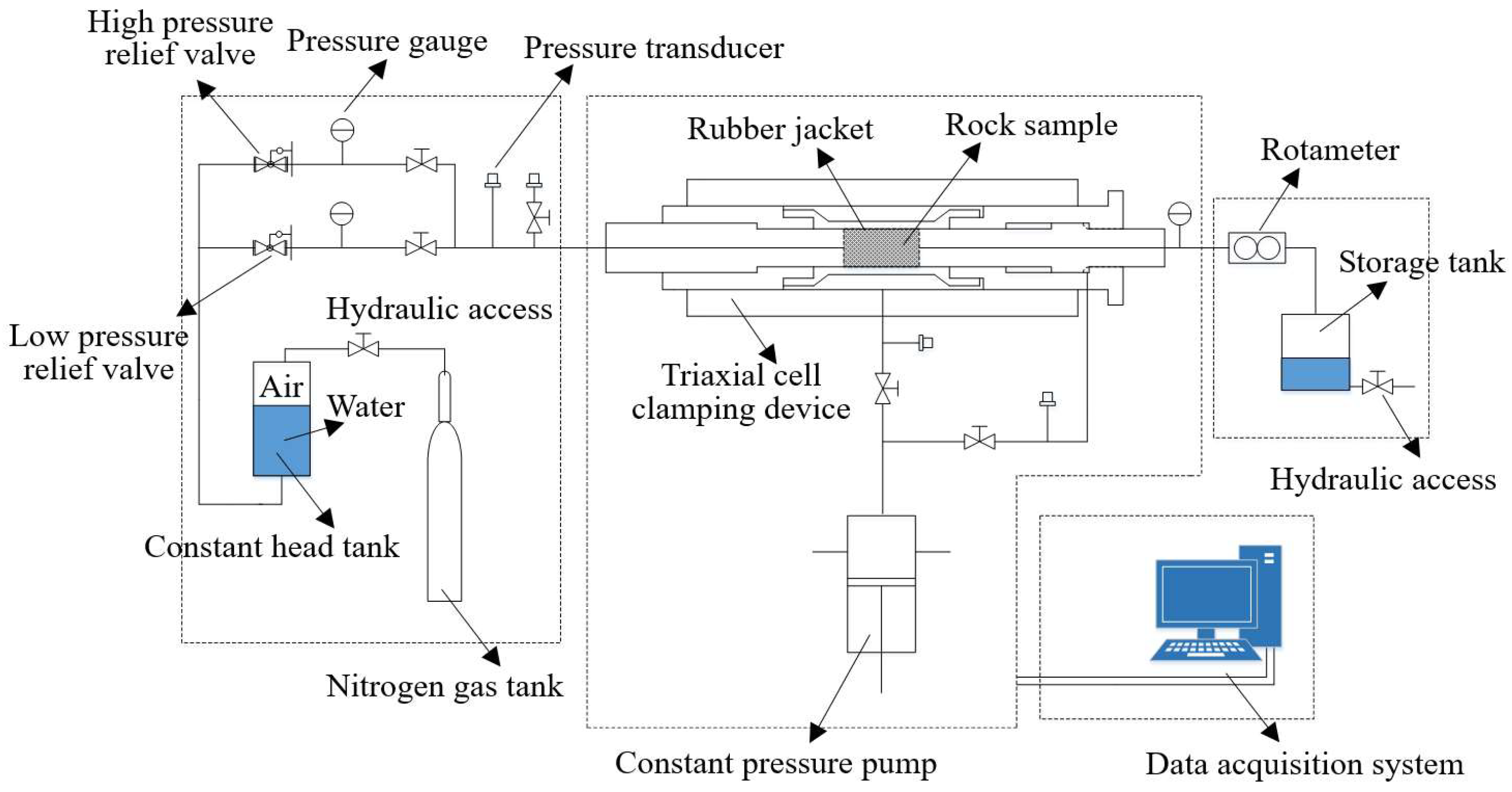

2. Experimental Methodology

2.1. Sample Preparation

2.2. Fluid Flow Test Procedure

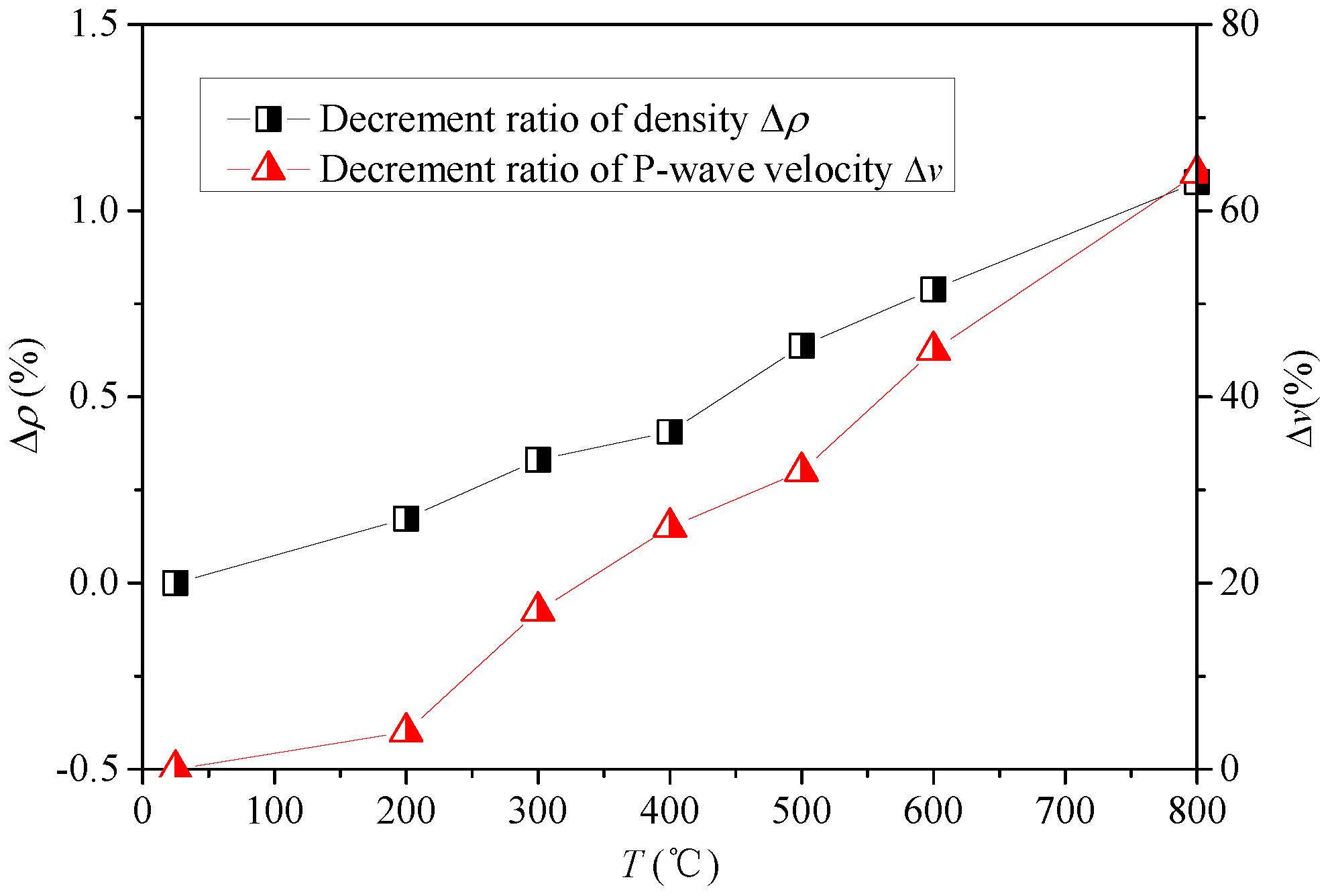

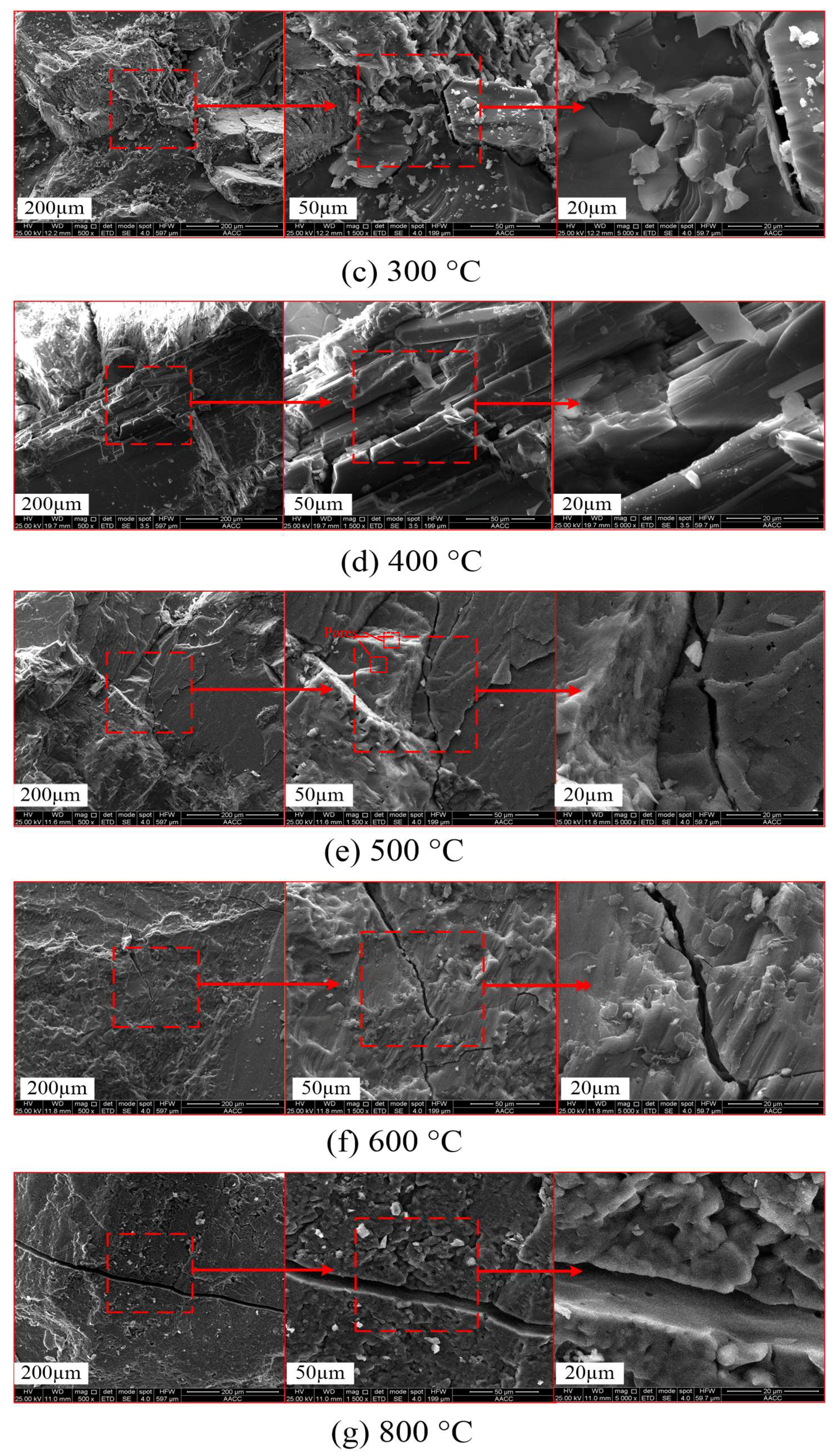

3. Physical Properties of Granites after High-Temperature Exposure

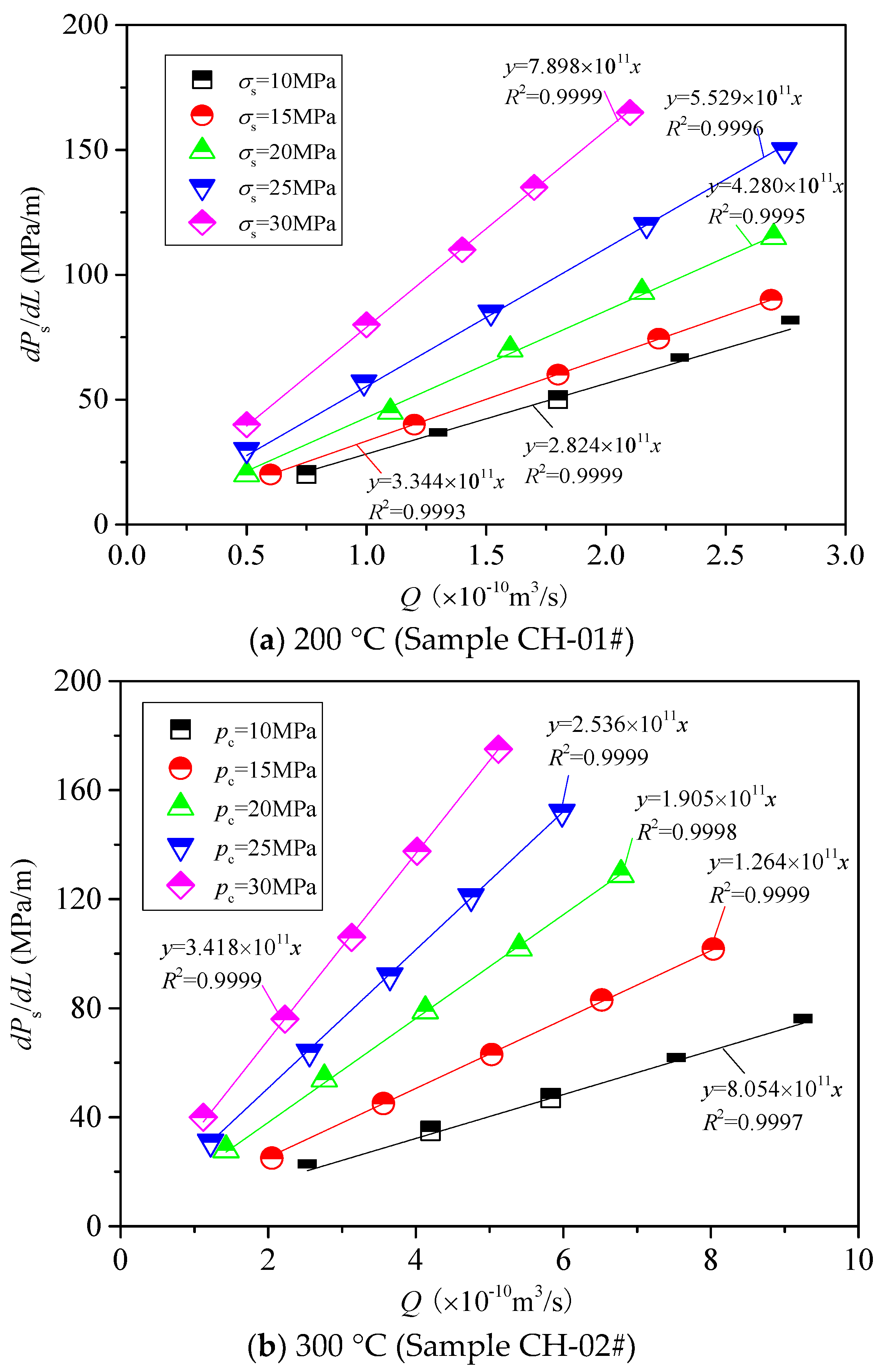

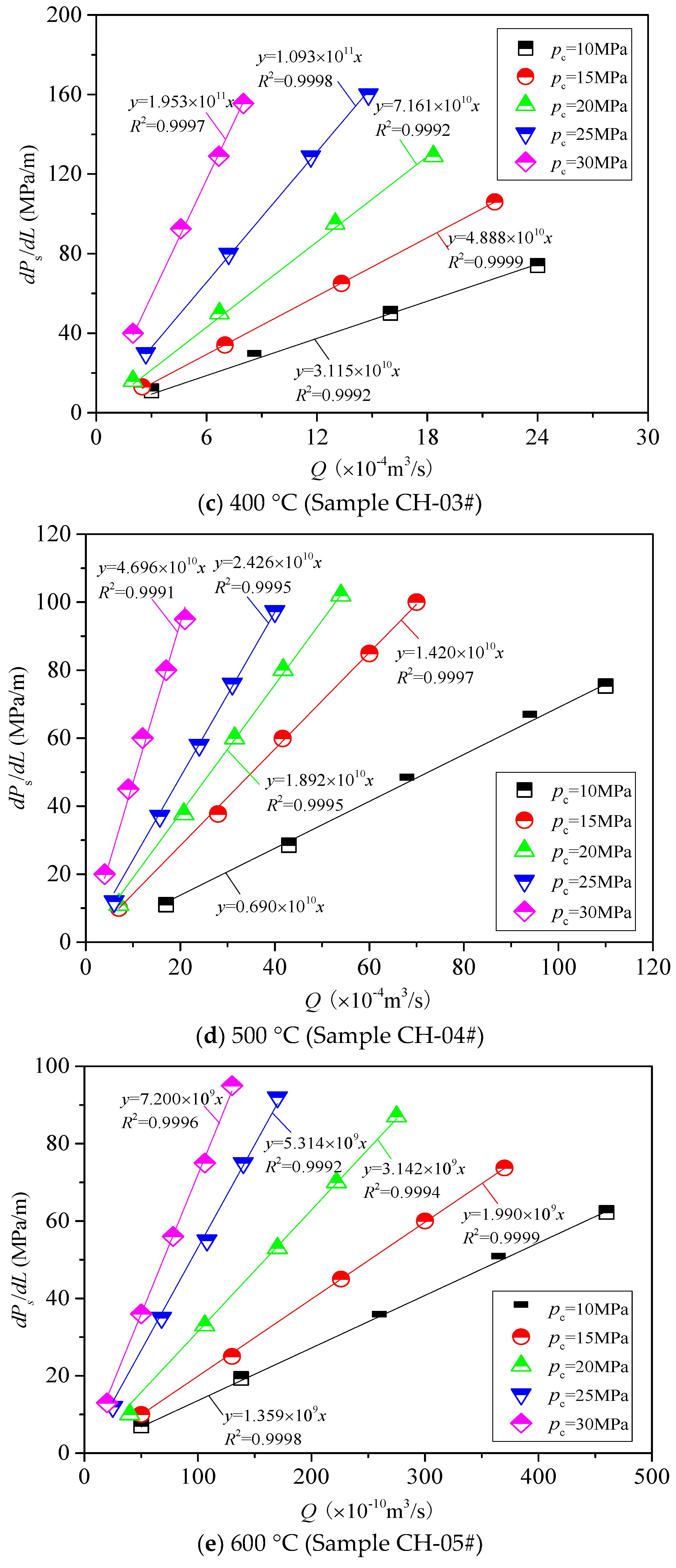

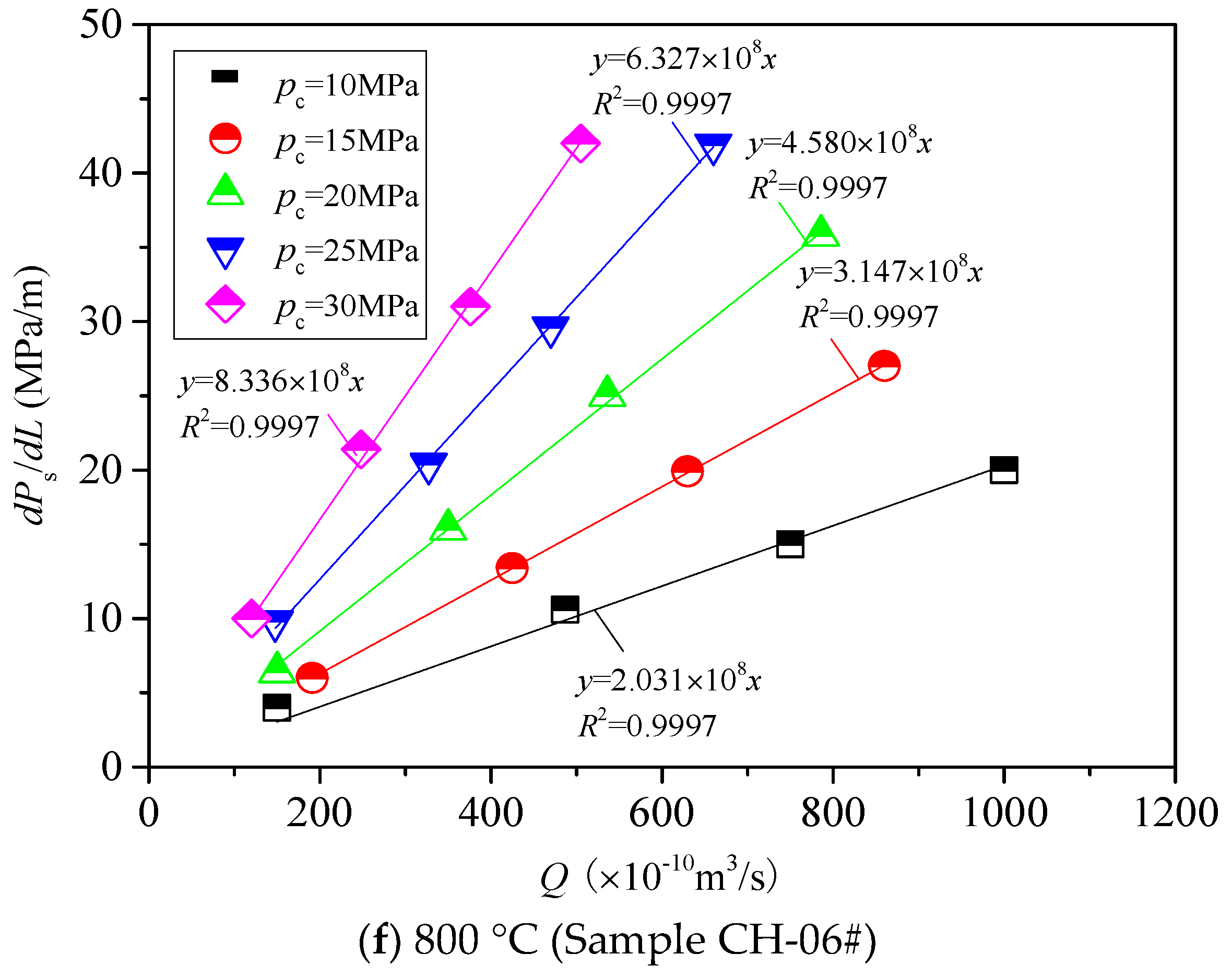

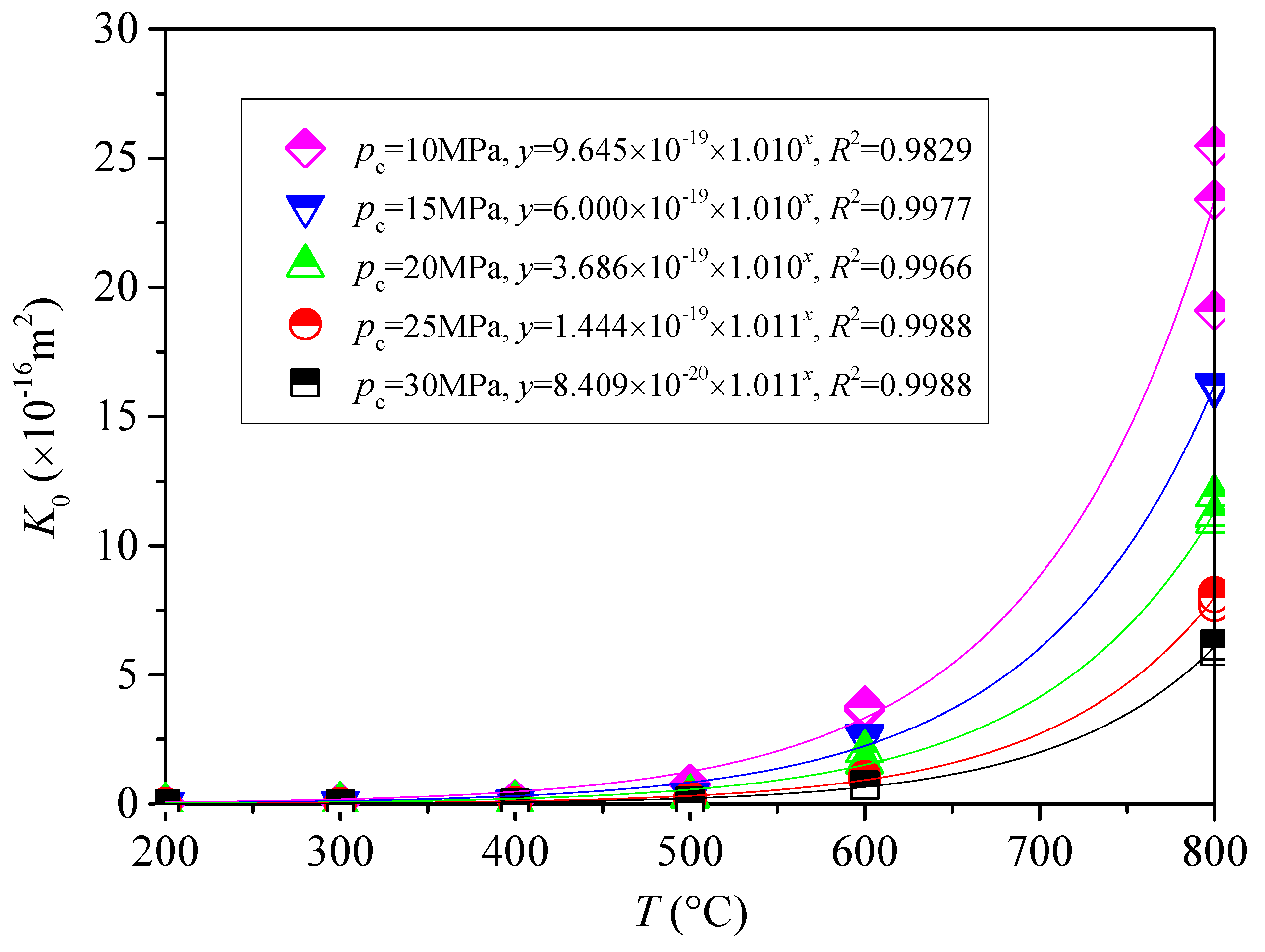

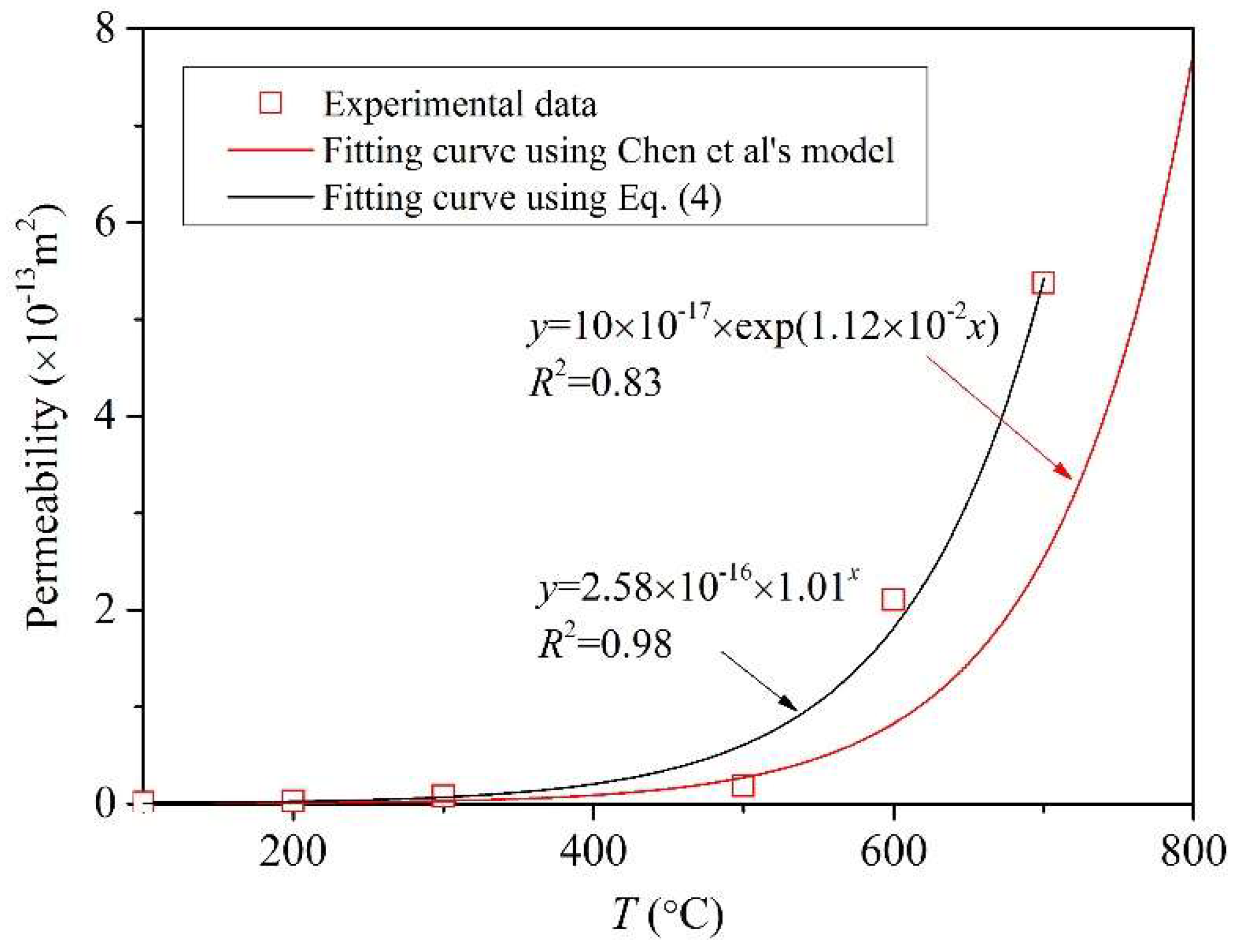

4. Fluid Flow Behaviours of Granites after High-Temperature Exposure

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Wang, J.S.Y.; Mangold, D.C.; Tsang, C.F. Thermal impact of waste emplacement and surface cooling associated with geologic disposal of high-level nuclear waste. Environ. Geol. Water Sci. 1988, 11, 183–239. [Google Scholar] [CrossRef]

- Nicholson, K. Environmental protection and the development of geothermal energy resources. Environ. Geochem. Health 1994, 16, 86–87. [Google Scholar] [CrossRef] [PubMed]

- Luo, J.A.; Wang, L.G.; Tang, F.R.; Zheng, L. Variation in the temperature field of rocks overlying a high-temperature cavity during underground coal gasification. Min. Sci. Technol. 2011, 21, 709–713. [Google Scholar] [CrossRef]

- Liu, R.; Li, B.; Jiang, Y.; Yu, L. A numerical approach for assessing effects of shear on equivalent permeability and nonlinear flow characteristics of 2-D fracture networks. Adv. Water Resour. 2018, 111, 289–300. [Google Scholar] [CrossRef]

- Zhao, Y.S.; Wan, Z.J.; Feng, Z.J.; Yang, D.; Zhang, Y.; Qu, F. Triaxial compression system for rock testing under high temperature and high pressure. Int. J. Rock Mech. Min. Sci. 2012, 52, 132–138. [Google Scholar] [CrossRef]

- Ozguven, A.; Ozcelik, Y. Effects of high temperature on physico-mechanical properties of Turkish natural building stones. Eng. Geol. 2014, 183, 127–136. [Google Scholar] [CrossRef]

- Shao, S.; Ranjith, P.G.; Wasantha, P.L.P.; Chen, B.K. Experimental and numerical studies on the mechanical behaviour of Australian Strathbogie granite at high temperatures: An application to geothermal energy. Geothermics 2015, 54, 96–108. [Google Scholar] [CrossRef]

- Sun, H.; Sun, Q.; Deng, W.; Zhang, W.; Lü, C. Temperature effect on microstructure and p-wave propagation in Linyi sandstone. Appl. Therm. Eng. 2017, 115, 913–922. [Google Scholar] [CrossRef]

- Yong, C.; Wang, C.Y. Thermally induced acoustic emission in Westerly granite. Geophys. Res. Lett. 1980, 7, 1089–1092. [Google Scholar] [CrossRef]

- Griffiths, L.; Lengliné, O.; Heap, M.J.; Baud, P.; Schmittbuhl, J. Thermal cracking in Westerly Granite monitored using direct wave velocity, coda wave interferometry and acoustic emissions. J. Geophys. Res. Solid Earth 2018. [Google Scholar] [CrossRef]

- Freire-Lista, D.M.; Fort, R.; Varas-Muriel, M.J. Thermal stress-induced microcracking in building granite. Eng. Geol. 2016, 206, 83–93. [Google Scholar] [CrossRef]

- Wang, H.F.; Bonner, B.P.; Carlson, S.R.; Kowallis, B.; Heard, H.C. Thermal stress cracking in granite. J. Geophys. Res. 1989, 94, 1745–1758. [Google Scholar] [CrossRef]

- Yin, T.B.; Li, X.B.; Cao, W.Z.; Xia, K.W. Effects of thermal treatment on tensile strength of Laurentian granite using Brazilian test. Rock Mech. Rock Eng. 2015, 48, 2213–2223. [Google Scholar] [CrossRef]

- Zhang, L.Y.; Mao, X.B.; Lu, A.H. Experimental study on the mechanical properties of rocks at high temperature. Sci. China 2009, 52, 641–646. [Google Scholar] [CrossRef]

- Chaki, S.; Takarli, M.; Agbodjan, W.P. Influence of thermal damage on physical properties of a granite rock: Porosity, permeability and ultrasonic wave evolutions. Constr. Build. Mater. 2008, 22, 1456–1464. [Google Scholar] [CrossRef]

- Zoback, M.D.; Byerlee, J.D. The effect of microcrack Dilatancy on the permeability of Westerly granite. J. Geophys. Res. 1975, 80, 752–755. [Google Scholar] [CrossRef]

- Ding, Q.L.; Ju, F.; Mao, X.B.; Ma, D.; Yu, B.Y. Experimental investigation of the mechanical behavior in unloading conditions of sandstone after high-temperature treatment. Rock Mech. Rock Eng. 2016, 49, 2641–2653. [Google Scholar] [CrossRef]

- Chen, S.W.; Yang, C.H.; Wang, G.B. Evolution of thermal damage and permeability of Beishan granite. Appl. Therm. Eng. 2017, 110, 1533–1542. [Google Scholar] [CrossRef]

- Verma, A.K.; Jha, M.K.; Maheshwar, S.; Singh, T.N.; Bajpai, R.K. Temperature-dependent thermophysical properties of Ganurgarh shales from Bhander group, India. Environ. Earth Sci. 2016, 75, 1–11. [Google Scholar] [CrossRef]

- Yin, Q.; Ma, G.W.; Jing, H.W. Experimental study on mechanical properties of sandstone specimens containing a single hole after high-temperature exposure. Géotech. Lett. 2015, 5, 43–48. [Google Scholar] [CrossRef]

- Hu, D.W.; Zhou, H.; Zhang, F.; Shao, J.F. Evolution of poroelastic properties and permeability in damaged sandstone. Int. J. Rock Mech. Min. Sci. 2010, 47, 962–973. [Google Scholar] [CrossRef]

- Kumari, W.G.P.; Ranjith, P.G.; Perera, M.S.A.; Chen, B.K.; Abdulagatov, I.M. Temperature-dependent mechanical behaviour of Australian Strathbogie granite with different cooling treatments. Eng. Geol. 2017, 229, 31–44. [Google Scholar] [CrossRef]

- Zhang, W. Study on the Microscopic Mechanism of Rock Thermal Damage and the Evolution Characteristics of Macroscopic Physical and Mechanical Properties; China University of Mining and Technology: Xuzhou, China, 2017. [Google Scholar]

- Zhang, W.; Sun, Q.; Hao, S.; Geng, J.; Lv, C. Experimental study on the variation of physical and mechanical properties of rock after high temperature treatment. Appl. Therm. Eng. 2016, 98, 1297–1304. [Google Scholar] [CrossRef]

- Pereira, A.H.A.; Miyaji, D.Y.; Cabrelon, M.D.; Medeiros, J.; Rodrigues, J.A. A study about the contribution of the α-β phase transition of quartz to thermal cycle damage of a refractory used in fluidized catalytic cracking units. Cerâmica 2014, 60, 449–456. [Google Scholar] [CrossRef]

- Géraud, Y. Variations of connected porosity and inferred permeability in a thermally cracked granite. Geophys. Res. Lett. 1994, 21, 979–982. [Google Scholar] [CrossRef]

- Xi, D.Y. Physical characteristics of mineral phase transition in the granite. Acta Mineral. Sin. 1994, 14, 223–227. [Google Scholar]

- Griffiths, L.; Heap, M.J.; Baud, P.; Schmittbuhl, J. Quantification of microcrack characteristics and implications for stiffness and strength of granite. Int. J. Rock Mech. Min. Sci. 2017, 100, 138–150. [Google Scholar] [CrossRef]

- David, C.; Menéndez, B.; Darot, M. Influence of stress-induced and thermal cracking on physical properties and microstructure of La Peyratte granite. Int. J. Rock Mech. Min. Sci. 1999, 36, 433–448. [Google Scholar] [CrossRef]

- Liu, R.; Jiang, Y.; Li, B.; Wang, X. A fractal model for characterizing fluid flow in fractured rock masses based on randomly distributed rock fracture networks. Comput. Geotech. 2015, 65, 45–55. [Google Scholar] [CrossRef]

- Liu, R.; Li, B.; Jiang, Y. A fractal model based on a new governing equation of fluid flow in fractures for characterizing hydraulic properties of rock fracture networks. Comput. Geotech. 2016, 75, 57–68. [Google Scholar] [CrossRef]

- Takada, M.; Fujii, Y.; Jun-lchi, K. Study on the effect of confining pressure on permeability of rock in triaxial compression failure process. J. MMIJ 2012, 127, 151–157. [Google Scholar] [CrossRef]

- Zhang, Z.; Nemcik, J. Fluid flow regimes and nonlinear flow characteristics in deformable rock fractures. J. Hydrol. 2013, 477, 139–151. [Google Scholar] [CrossRef]

- Li, B.; Liu, R.; Jiang, Y. Influences of hydraulic gradient, surface roughness, intersecting angle, and scale effect on nonlinear flow behavior at single fracture intersections. J. Hydrol. 2016, 538, 440–453. [Google Scholar] [CrossRef]

- Yin, Q.; Ma, G.W.; Jing, H.W.; Su, H.J.; Wang, Y.C.; Liu, R.C. Hydraulic properties of 3D rough-walled fractures during shearing: An experimental study. J. Hydrol. 2017, 555, 169–184. [Google Scholar] [CrossRef]

| Samples | T (°C) | ρ (g/cm3) | ρ′ (g/cm3) | Δρ (%) | v (km/s) | v′ (km/s) | Δv (%) |

|---|---|---|---|---|---|---|---|

| CH-01# | 200 | 2.68 | 2.67 | 0.17 | 4.70 | 4.50 | 4 |

| CH-02# | 300 | 2.68 | 2.67 | 0.33 | 4.94 | 4.10 | 17 |

| CH-03# | 400 | 2.67 | 2.66 | 0.41 | 4.97 | 3.70 | 26 |

| CH-04# | 500 | 2.68 | 2.66 | 0.64 | 4.54 | 3.08 | 32 |

| CH-05# | 600 | 2.67 | 2.65 | 0.79 | 4.70 | 2.60 | 45 |

| CH-06# | 800 | 2.67 | 2.64 | 1.08 | 4.70 | 1.70 | 64 |

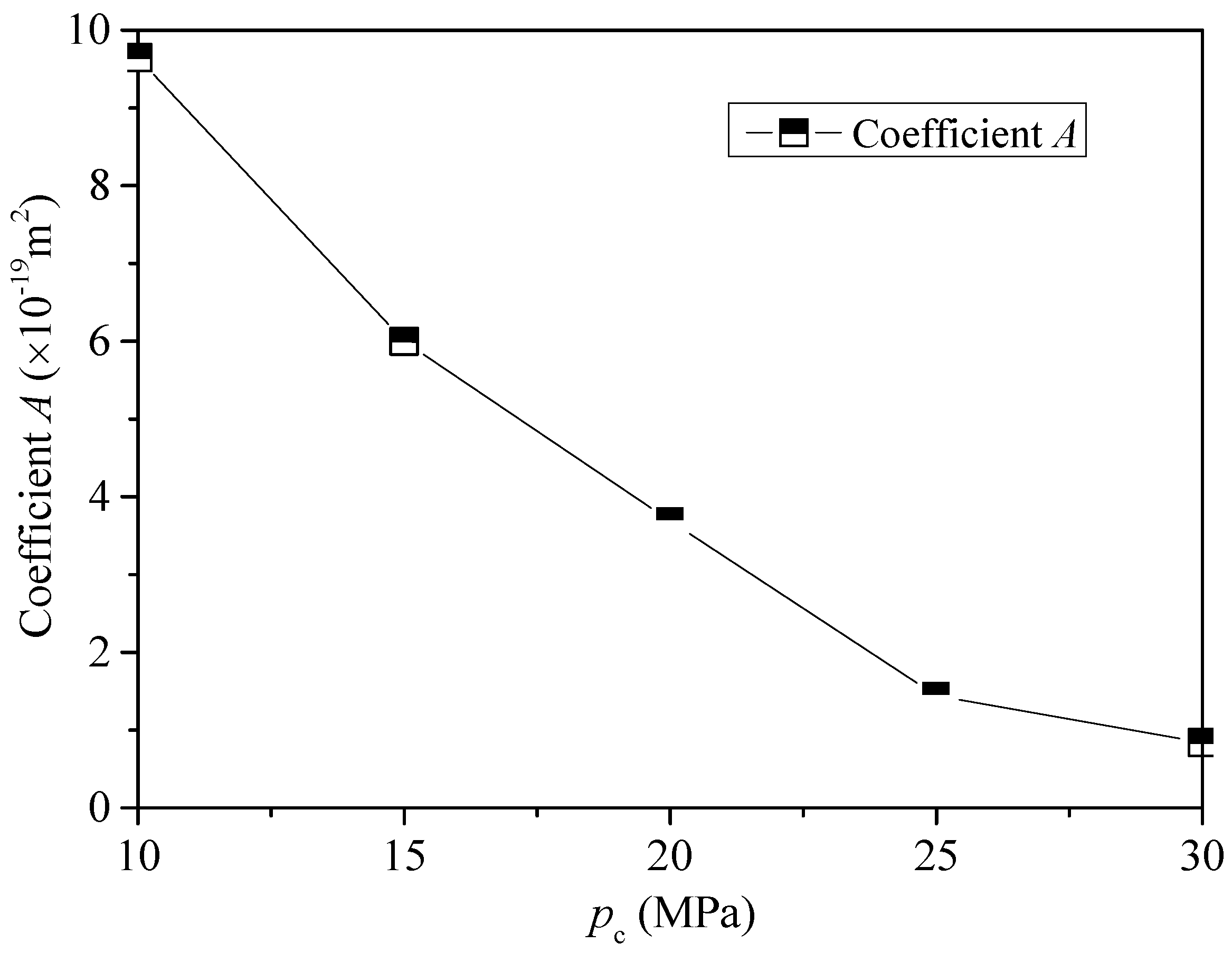

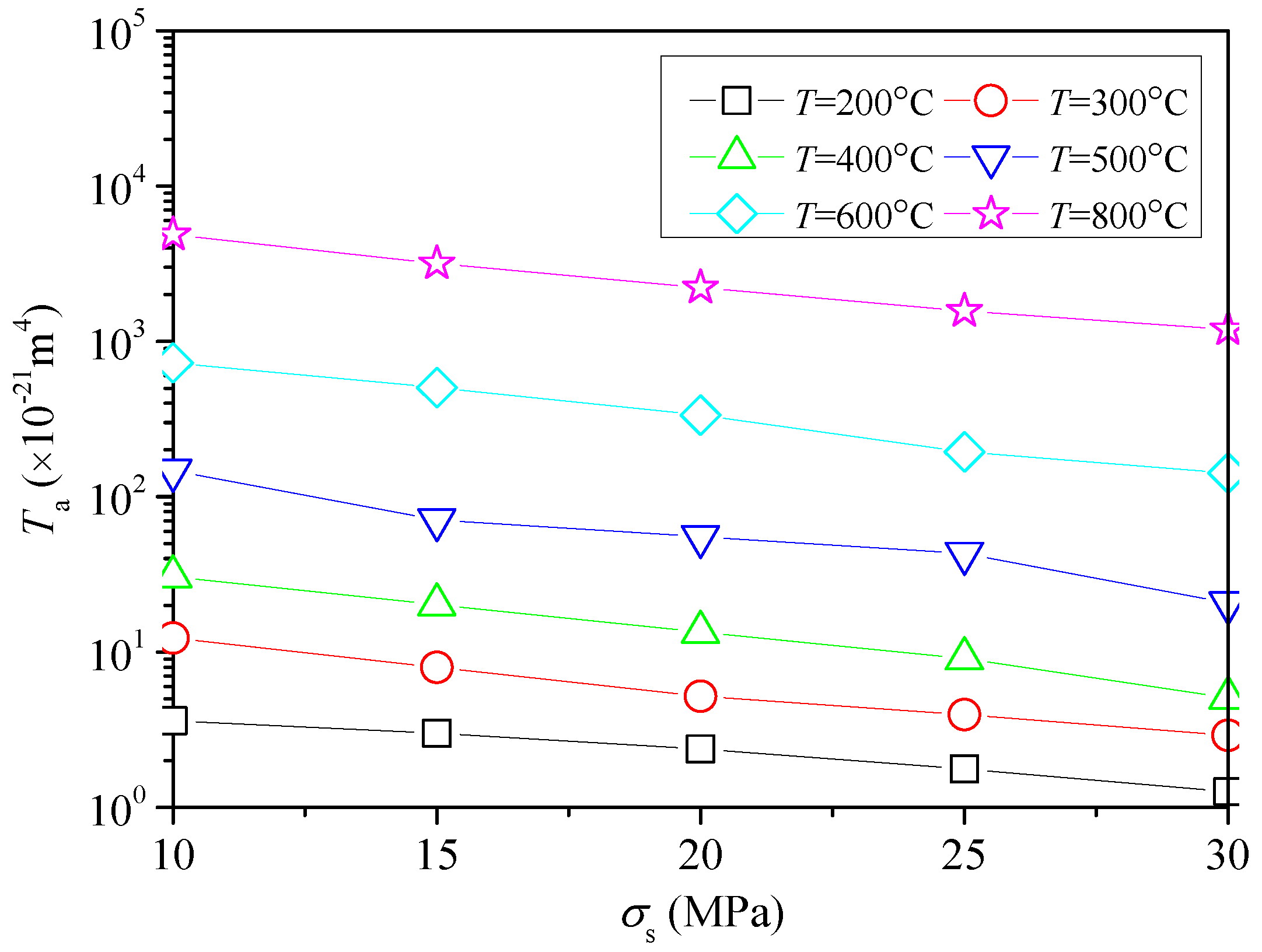

| Temperature (°C) | Average Equivalent Permeability (×10−18 m2) | ||||

|---|---|---|---|---|---|

| pc = 10 MPa | pc = 15 MPa | pc = 20 MPa | pc = 25 MPa | pc = 30 MPa | |

| 200 | 1.84 | 1.53 | 1.21 | 0.9 | 0.64 |

| 300 | 6.26 | 4.06 | 2.65 | 2.02 | 1.48 |

| 400 | 15.60 | 10.29 | 6.85 | 4.63 | 2.58 |

| 500 | 75.17 | 36.13 | 28.16 | 21.96 | 10.53 |

| 600 | 371.13 | 257.25 | 170.72 | 98.9 | 72.38 |

| 800 | 2336.46 | 1619.23 | 1130.04 | 799.18 | 608.17 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, L.; Yin, Q.; Jing, H. Laboratory Investigation of Granite Permeability after High-Temperature Exposure. Processes 2018, 6, 36. https://doi.org/10.3390/pr6040036

He L, Yin Q, Jing H. Laboratory Investigation of Granite Permeability after High-Temperature Exposure. Processes. 2018; 6(4):36. https://doi.org/10.3390/pr6040036

Chicago/Turabian StyleHe, Lixin, Qian Yin, and Hongwen Jing. 2018. "Laboratory Investigation of Granite Permeability after High-Temperature Exposure" Processes 6, no. 4: 36. https://doi.org/10.3390/pr6040036