Fabrication of New Liquid Crystal Device Using Layer-by-Layer Thin Film Process

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

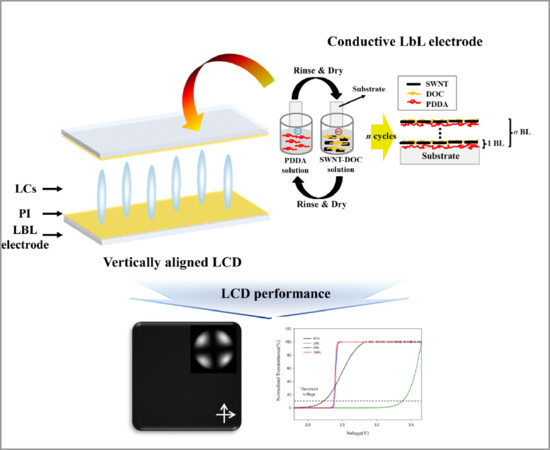

2.2. Fabrication of LCD Cells Using SWNT LBL Transparent Electrodes

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| BL | Bilayer |

| CNT | Carbon nanotube |

| CVD | Chemical vapor deposition |

| DI | Deionized, DOC: Sodium deoxycholate |

| E-O | Electro-optical |

| FE-SEM | Field emission scanning electron microscopy |

| FFS | Fringe-field switching |

| IPA | Isopropylalcohol |

| IPS | In-plane switching |

| ITO | Indium tin oxide |

| LBL | layer-by-layer |

| LCD | Liquid crystal display |

| PDDA | Poly(diallyldimethylammonium chloride) |

| PET | Poly(ethylene terephthalate) |

| PI | Polyimide |

| POM | Polarized optical microscope |

| QCM | Quartz crystal microbalance |

| SWNT | Single-walled carbon nanotube |

| TNI | Nematic-to-isotropic transition temperature |

| UV–Vis | UV–Visible spectroscopy |

| VA | Vertical alignment |

| V-T | Voltage-transmittance |

References

- Ohe, M.H.; Kondo, K.S. Electro-optical characteristics and switching behavior of the in-plane switching mode. Appl. Phys. Lett. 1995, 67, 3895–3897. [Google Scholar] [CrossRef]

- Lee, Y.J.; Kim, Y.K.; Jo, S.I.; Bae, K.S.; Choi, B.D.; Kim, J.H.; Yu, C.J. Fast vertical alignment mode with continuous multi-domains for a liquid crystal display. Opt. Express 2009, 17, 23417–23422. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.H.; Lee, S.L.; Kim, H.Y. Electro-optic characteristics and switching principle of a nematic liquid crystal cell controlled by fringe-field switching. Appl. Phys. 1998, 73, 2881–2883. [Google Scholar] [CrossRef]

- Igasaki, Y.; Saito, H. Substrate temperature dependence of electrical properties of ZnO:Al epitaxial films on sapphire. J. Appl. Phys. 1991, 69, 2190–2195. [Google Scholar] [CrossRef]

- Lan, Y.F.; Peng, W.C.; Lo, Y.H.; He, J.L. Indium tin oxide films deposited by thermionic-enhanced DC magnetron sputtering on unheated polyethylene terephthalate polymer substrate. Mater. Res. Bull. 2009, 44, 1760–1764. [Google Scholar] [CrossRef]

- Lin, Y.C.; Shi, W.Q.; Chen, Z.Z. Effect of deflection on the mechanical and optoelectronic properties of indium tin oxide films deposited on polyethylene terephthalate substrates by pulse magnetron sputtering. Thin Solid Films 2009, 517, 1701–1705. [Google Scholar] [CrossRef]

- Gu, G.; Shen, Z.; Burrows, P.E.; Forrest, S.R. Transparent flexible organic light-emitting devices. Adv. Mater. 1997, 9, 725–728. [Google Scholar] [CrossRef]

- Cairns, D.R.; Witte, R.P.; Sparacin, D.K.; Sachsman, S.M.; Paine, D.C.; Crawford, G.P.; Newton, R.P. Strain-dependent electrical resistance of tin-doped indium oxide on polymer substrates. Appl. Phys. Lett. 2000, 76, 1425–1427. [Google Scholar] [CrossRef]

- Tao, C.S.; Jiang, J.; Tao, M. Natural resource limitations to terawatt-scale solar cells. Sol. Energy Mater. Sol. Cells 2011, 95, 3176–3180. [Google Scholar] [CrossRef]

- Wu, Z.; Chen, Z.; Du, X.; Logan, J.M.; Sippel, J.; Nikolou, M.; Kamaras, K.; Reynolds, J.R.; Tanner, D.B.; Hebard, A.F.; et al. Transparent, conductive carbon nanotube films. Science 2004, 305, 1273–1276. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; Fang, S.; Zakhidov, A.A.; Lee, S.B.; Aliev, A.E.; Williams, C.D.; Atkinson, K.R.; Baughman, R.H. Strong, transparent, multifunctional, carbon nanotube sheets. Science 2005, 309, 1215–1219. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.Y.; Connor, S.T.; Cui, Y.; Peumans, P. Solution-Processed Metal Nanowire Mesh Transparent Electrodes. Nano Lett. 2008, 8, 689–692. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hsu, P.C.; Wang, S.; Wu, H.; Narasimhan, V.K.; Kong, D.; Lee, H.R.; Cui, Y. Performance enhancement of metal nanowire transparent conducting electrodes by mesoscale metal wires. Nat. Commun. 2013, 25, 2522–2528. [Google Scholar] [CrossRef] [PubMed]

- Meiss, J.; Riede, M.K.; Leo, K. Optimizing the morphology of metal multilayer films for indium tin oxide (ITO)-free inverted organic solar cells. Appl. Phys. Lett. 2009, 105, 063108-1–063108-5. [Google Scholar] [CrossRef]

- Tung, V.C.; Chen, L.M.; Allen, M.J.; Wassei, J.K.; Nelson, K.; Kaner, R.B.; Yang, Y. Low-temperature solution processing of graphene-carbon nanotube hybrid materials for high-performance transparent conductors. Nano Lett. 2009, 9, 1949–1955. [Google Scholar] [CrossRef] [PubMed]

- Mei, X.G.; Ouyang, J.Y. Ultrasonication-assisted ultrafast reduction of graphene oxide by zinc powder at room temperature. Carbon 2011, 49, 5389–5397. [Google Scholar] [CrossRef]

- Alemu, D.L.; Wei, H.Y.; Ho, K.C.; Chu, C.W. Highly conductive PEDOT:PSS electrode by simple film treatment with methanol for ITO-free polymer solar cells. Energy Environ. Sci. 2012, 5, 9662–9671. [Google Scholar] [CrossRef]

- Na, S.I.; Kim, S.S.; Jo, J.; Kim, D.Y. Efficient and Flexible ITO-Free Organic Solar Cells Using Highly Conductive Polymer Anodes. Adv. Mater. 2008, 21, 4061–4067. [Google Scholar] [CrossRef]

- Zhang, D.; Ryu, K.; Liu, X.; Polikarpov, E.; Ly, J.; Tompson, M.E.; Zhou, C. Transparent, conductive, and flexible carbon nanotube films and their application in organic light-emitting diodes. Nano Lett. 2006, 6, 1880–1886. [Google Scholar] [CrossRef] [PubMed]

- Ma, W.; Song, L.; Yang, R.; Zhang, T.; Zhao, Y.; Sun, L.; Zhang, Z. Directly synthesized strong, highly conducting, transparent single-walled carbon nanotube films. Nano Lett. 2007, 7, 2307–2311. [Google Scholar] [CrossRef] [PubMed]

- Green, A.A.; Hersam, M.C. Colored Semitransparent Conductive Coatings Consisting of Monodisperse Metallic Single-Walled Carbon Nanotubes. Nano Lett. 2008, 8, 1417–1422. [Google Scholar] [CrossRef] [PubMed]

- Dan, B.; Irvin, G.C.; Pasquali, M. Continuous and scalable fabrication of transparent conducting carbon nanotube films. ACS Nano 2009, 3, 835–843. [Google Scholar] [CrossRef] [PubMed]

- Park, Y.T.; Ham, A.Y.; Yang, Y.H.; Grunlan, J.C. Fully organic ITO replacement through acid doping of double-walled carbon nanotube thin film assemblies. RSC Adv. 2011, 1, 662–671. [Google Scholar] [CrossRef]

- Yu, X.; Rajamani, R.; Stelson, K.A.; Cui, T. Fabrication of carbon nanotube based transparent conductive thin films using layer-by-layer technology. Surf. Coat. Technol. 2008, 202, 2002–2007. [Google Scholar] [CrossRef]

- Decher, G.; Lvov, Y.; Schmitt, J. Proof of multilayer structural organization in self-assembled polycation-polyanion molecular films. Thin Solid Films 1994, 244, 772–777. [Google Scholar] [CrossRef]

- Hammond, P.T. Form and function in multilayer assembly: New applications at the nanoscale. Adv. Mater. 2004, 16, 1271–1293. [Google Scholar] [CrossRef]

- Park, Y.T.; Ham, A.Y.; Grunlan, J.C. High electrical conductivity and transparency in deoxycholate-stabilized carbon nanotube thin films. J. Phys. Chem. C 2010, 114, 6325–6333. [Google Scholar] [CrossRef]

- Park, Y.T.; Ham, A.Y.; Grunlan, J.C. Heating and acid doping thin film carbon nanotube assemblies for high transparency and low sheet resistance. J. Mater. Chem. 2011, 21, 363–368. [Google Scholar] [CrossRef]

- Park, J.J.; Hyun, W.J.; Mun, S.C.; Park, Y.T.; Park, O.O. Highly stretchable and wearable graphene strain sensors with controllable sensitivity for human motion monitoring. ACS Appl. Mater. Interfaces 2015, 7, 6317–6324. [Google Scholar] [CrossRef] [PubMed]

- Zhou, M.; Dong, S. Bioelectrochemical interface engineering: Toward the fabrication of electrochemical biosensors, biofuel cells, and self-powered logic biosensors. Accounts Chem. Res. 2011, 44, 1232–1243. [Google Scholar] [CrossRef] [PubMed]

- Chung, I.J.; Kim, W.; Jang, W.; Park, H.W.; Sohn, A.; Chung, K.B.; Kim, D.W.; Choi, D.; Park, Y.T. Layer-by-layer assembled graphene multilayers on multidimensional surfaces for highly durable, scalable, and wearable triboelectric nanogenerators. J. Mater. Chem. A 2018, 6, 3108–3115. [Google Scholar] [CrossRef]

- Wang, H.Y.; Wu, T.X.; Zhu, X.Y.; Wu, S.T. Correlations between liquid crystal director reorientation and optical response time of a homeotropic cell. J. Appl. Phys. 2004, 95, 5502–5508. [Google Scholar] [CrossRef]

- Seo, D.S.; Kim, J.H. Generation of pretilt angle in NLC and EO characteristics of transcription-aligned TNLCD fabricated by transcription alignment on polyimide surfaces. Liq. Cryst. 1999, 26, 397–400. [Google Scholar] [CrossRef]

- Kim, T.H.; Ju, C.H.; Kang, H. Vertical alignment of liquid crystal on tocopherol substituted polystyrene films. Liq. Cryst. 2018, 45, 801–810. [Google Scholar] [CrossRef]

- Oh, S.K.; Nakagawa, M.S.; Ichimura, K.H. Relationship between the ability to control liquid crystal alignment and wetting properties of calix[4]resorcinarene monolayers. J. Mater. Chem. 2001, 11, 1563–1569. [Google Scholar] [CrossRef]

| Electrodes | Resistance (kΩ) | Transparency (at 550 nm) |

|---|---|---|

| ITO | 0.02 | 84.14 |

| SWNT 2 BLs | 29 | 95.50 |

| SWNT 6 BLs | 1.3 | 82.22 |

| SWNT 10 BLs | 0.5 | 69.02 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moon, G.; Jang, W.; Son, I.; Cho, H.A.; Park, Y.T.; Lee, J.H. Fabrication of New Liquid Crystal Device Using Layer-by-Layer Thin Film Process. Processes 2018, 6, 108. https://doi.org/10.3390/pr6080108

Moon G, Jang W, Son I, Cho HA, Park YT, Lee JH. Fabrication of New Liquid Crystal Device Using Layer-by-Layer Thin Film Process. Processes. 2018; 6(8):108. https://doi.org/10.3390/pr6080108

Chicago/Turabian StyleMoon, Gitae, Wonjun Jang, Intae Son, Hyun A. Cho, Yong Tae Park, and Jun Hyup Lee. 2018. "Fabrication of New Liquid Crystal Device Using Layer-by-Layer Thin Film Process" Processes 6, no. 8: 108. https://doi.org/10.3390/pr6080108