3.2.2. D50

To estimate the effect of milling, quantification of size reduction needs to be done. For that reason, a single parameter must be studied rather than the whole particle size distribution. d50 is the most commonly used single parameter estimate for particle size. d50 has been used as an estimate for size reduction in a mill in previous studies, as well [

17]. d50 is defined as the particle size under which there are 50%, weight- or volume-based, of the milled granules. In the present study, d50 values are weight-based.

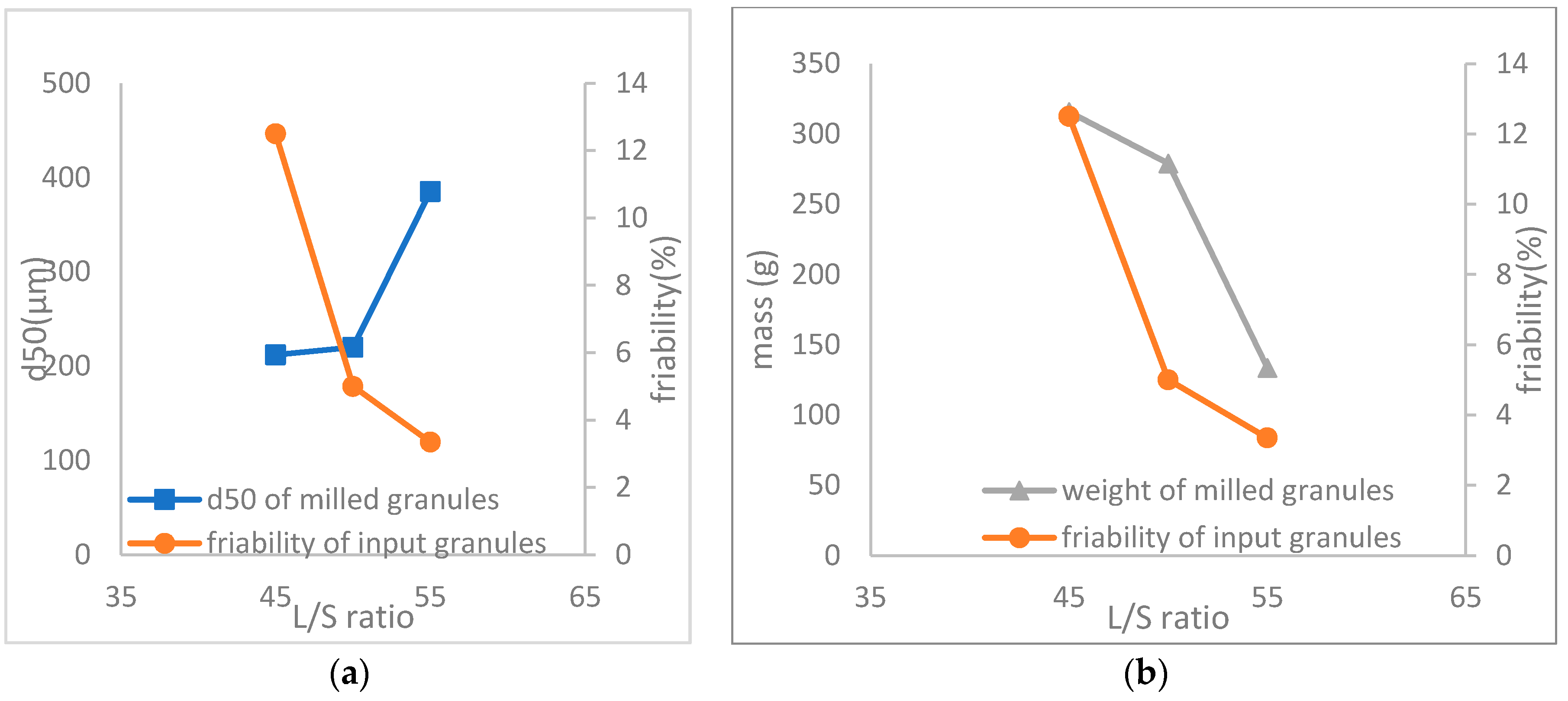

Similar to the case of %fines, the plot in

Figure 4a also does not show a clear trend of milled product d50 for all the levels of impeller speed or batch loading. To get a clear understanding of the effect of impeller speed and batch loading on milled product d50, individual graphs of milled product d50 vs. impeller speed for each level of batch loading are also shown (

Figure 4b–d).

Figure 4b–d shows that, for the same level of batch loading, the higher the total amount of material collected at end of milling cycle (throughput at 300 seconds), the lower is the milled product d50, i.e., the d50 of the milled product and the throughput of the mill are inversely correlated. Earlier it was observed that the throughput and %fines were directly correlated. Therefore, %fines and d50 of milled product are inversely correlated, i.e., the lower the d50 of the milled particles, the greater the number of fines generated during milling. This shows that a large degree of size reduction cannot be obtained without intense fines formation, and this is in agreement with the work done by Verheezen et al. [

10].

Therefore, the batch loading and the impeller speed affect the throughput of the mill. This can be seen as milling being governed by two different regimes in a Comil [

18].

Impact regime, in this regime mill throughput is dominated by exit of particles that are broken. Breakage occurs due to the collision between particle and impeller and particle and particle, and also because of shear between the impeller and the screen [

9,

10].

The other regime is called quasi static; in this regime, the mill throughput is dominated by the exit of the already existing smaller particles. This exit of smaller particles is a consequence of movement of particles within the mill [

18] due to the rotation of the impeller. Among the two regimes, impact regime is more size reduction oriented. These regimes generally coexist and dominate during different times during the milling cycle.

As the impeller speed increases, the particles’ residence time in the mill increases, despite the fact that the increase in impeller speed means faster movement of particles [

19,

20]. This is because of the recirculation induced by high impeller speeds. However, it is known that increase in impeller speed leads to more breakage, as the particles in the mill are subjected to more collision and shear between the screen and the impeller [

6,

9,

10]. This means that the quasi static regime, which is dominated by exit of particles out of the mill due to their movement, is prevalent at lower impeller speeds, whereas the impact regime which is related to breakage is prevalent at higher impeller speeds.

When the batch loading in the mill is large, there is a greater number of particles in the mill that are smaller than the screen size. For the same input granules to the mill, though the ratio of particles above the screen size and below the screen size is still same, a smaller batch loading will have fewer particles smaller than the screen size. Hence, a larger batch loading is favored by the quasi static regime over a smaller batch loading due to the presence of a greater number of particles smaller than the screen size.

At the same time, a smaller batch loading means that the particles in the mill have more possibility of achieving high velocities, at the same impeller speed, which would result in an increased number of high-velocity collisions. For a larger batch loading, the majority of the energy imparted by the impeller is depleted in moving the huge number of particles rather than resulting in high-speed collisions of particles (lack of space also prevents the particles from achieving high speed). Hence, a smaller batch loading is favored by impact regime over a large batch.

300 g batch loading at 3000 rpm is the batch most favored by impact regime batch because of its low batch loading and high impeller speed. Therefore, this batch results in the lowest d50 of 400 µm and the highest %fines of 14.1%. Similarly, 1000 g batch loading and 1500 rpm is the batch most favored by quasi static regime due to its large batch loading and low impeller speed and rightly the d50 of this batch is the highest at 565 µm and the %fines are lowest at 2.2%. The rest of the runs falls in between these two extremes.

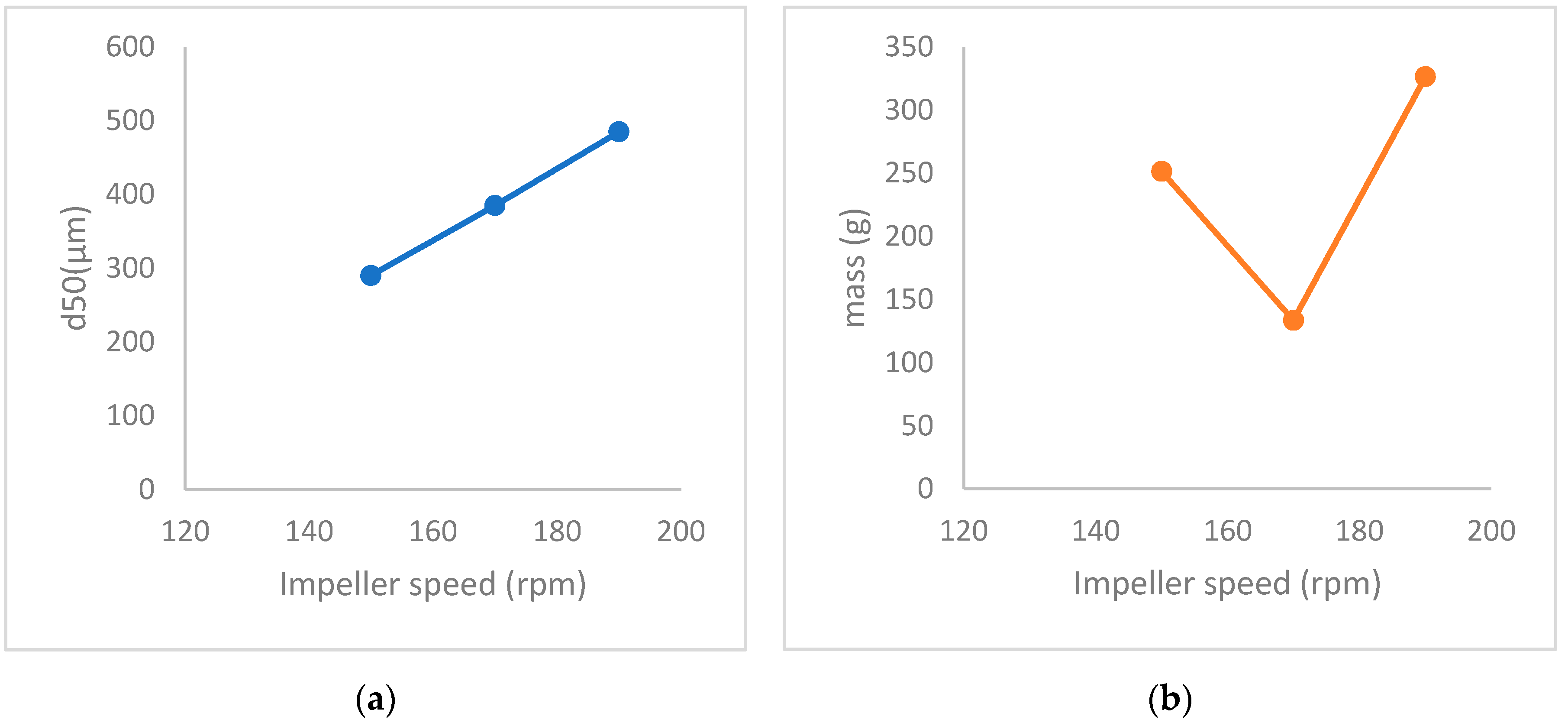

Table 4 and

Figure 5 represent the milling data of an experiment with batch loading of 600 g and an impeller speed of 3000 rpm. It was observed that after 30 s of milling the mass of granules collected was 251.4 g. The input batch had approximately 311 g of granules that were smaller than 1000 μm, which is approximately the size of the mill screen. In

Figure 5b it can be seen that, as the time taken for milling increased, the particle size distribution shifted towards the right and the d50 of the granules increased (

Table 4). This can be attributed to the fact that initially during the mill cycle, the particles which are already smaller than the screen size attempt to escape from the mill (simultaneously there is the occurrence of breakage but the majority of particles that escape are the already existing smaller particles). This also explains the huge exodus of particles initially, 251.4 g in 30 s, but by the end of 5 min cycle only 445.3 g (less than 200 g extra in an additional 270 s) was collected. This leads to the conclusion that the quasi static regime dominates the initial phase of milling and is later taken over by the impact regime.

Among the 300 g, 600 g and 1000 g batch loadings, the 300 g setting resulted in milled product with the lowest d50 (at each impeller speed setting),

Figure 6. Since milling is dominated by the impact regime at low fill level, there is more breakage at the lowest fill level. It can further be observed that the d50 of the milled product is inversely proportional to batch loading We see an exception for 3000 rpm, this is probably because of the different regimes in which a 600 g batch loading and a 1000 g batch loading operate (especially at this impeller speed). High batch loading might reach the impact regime at the end of the milling cycle, leading to excess breakage of particles towards the end (due to its virtue of greater mass, leads to an exit of a huge mass initially in the quasi static regime, thereby reaching the low fill level case towards the end of milling cycle). Whereas the medium batch loading combined with recirculation at high impeller speed might always operate in the cusp regime between quasi static and impact, where the breakage is not the dominant phenomena.

This also explains the anomalous pattern observed in

Figure 3c and

Figure 4c, because of this abnormal shift in breakage pattern, 2250 rpm induces more breakage than 3000 rpm leading to maximum throughput at 2250 rpm (for 600 g batch loading).

An analysis of variance (ANOVA) was performed on various milled granule properties to signify the effect of milling on these properties. From these analyses, it was found that milling had a significant effect on span, friability, porosity, bulk and tapped density of granules, as shown in

Table 5.

Since bulk density is an important property for further downstream processing and is necessary for the development of tablet press model, an attempt was made to develop a simple regressive predictive model for bulk density and tapped density, shown in Equations (9) and (10).

where m is batch loading (kg); d50 and d10 mentioned are that of the milled granules in mm. For the bulk density equation, R

2 was found to be 0.9534, adjusted R

2 was found to be equal to 0.8370, and significance, F, was equal to 0.1124. Similarly, for the tapped density equation, R

2 was found to be 0.995, adjusted R

2 was found to be equal to 0.983 and significance, F, was equal to 0.0119. Both these equations were validated using one of the experimental values and the error was found to be approximately 10% in both cases.