Development of High-Fibre and Low-FODMAP Crackers

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Methods

2.2.1. Determination of Moisture, Ash, Carbohydrates, Fats, Proteins, and Fibre Contents

2.2.2. Determination of the FODMAP Content

2.2.3. Development of Cracker Formulations

2.2.4. Preparation of Crackers

2.2.5. Sensory Analysis of Crackers

2.3. Statistical Analysis

3. Results and Discussion

3.1. Chemical Composition of Raw Materials and Fructan Content

3.2. Results of Sensory Analysis

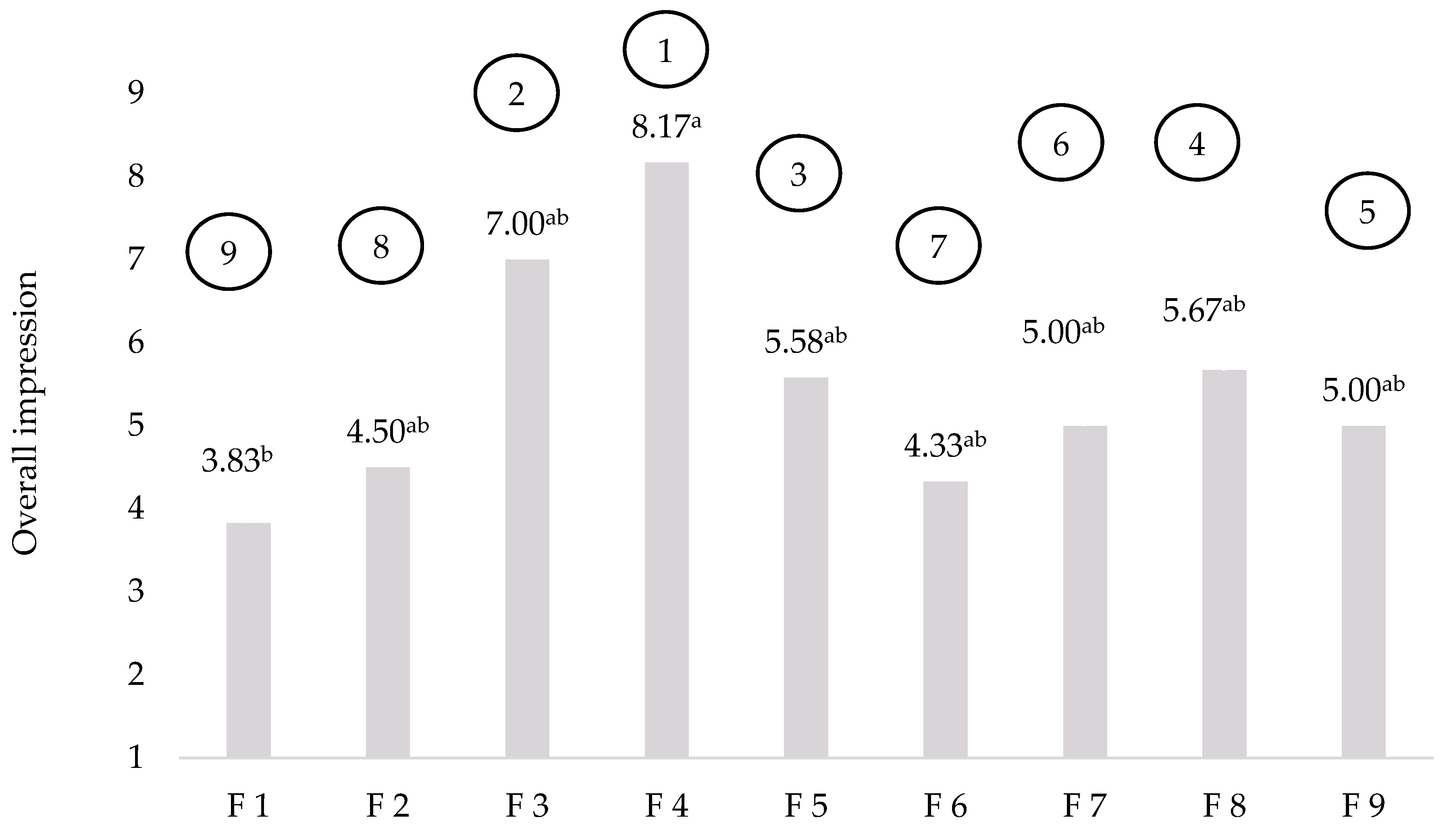

3.2.1. Acceptability and Preference of Nine Crackers

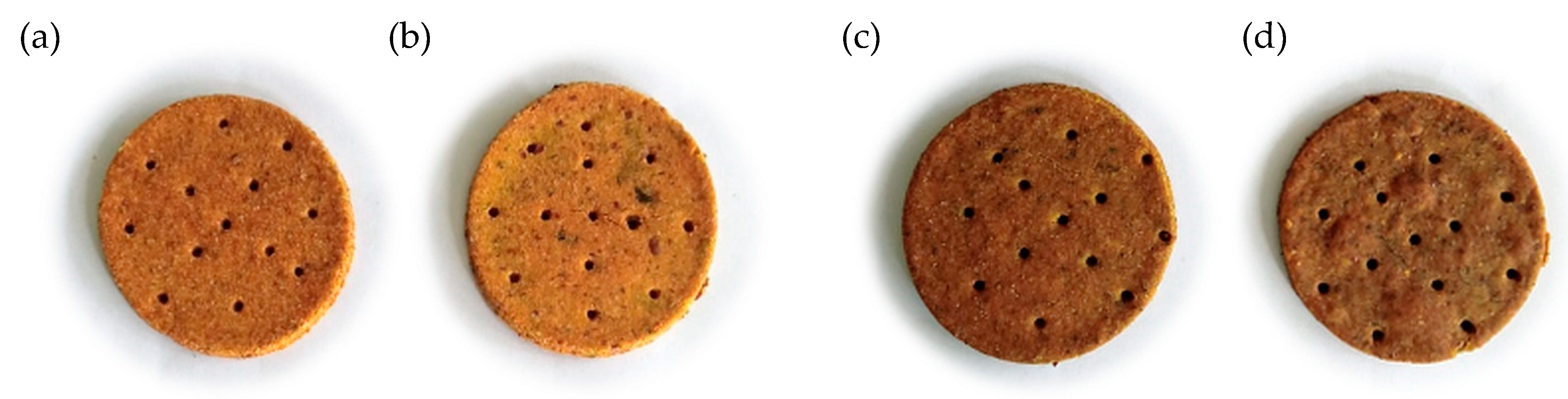

3.2.2. Sensory Profile of Four Best-Rated Crackers

3.3. Nutritive Value, Fructan Content, and Labelling of Crackers

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Biesiekierski, J.R.; Peters, S.L.; Newnham, E.D.; Rosella, O.; Muir, J.G.; Gibson, P.R. No effects of gluten in patients with self-reported non-celiac gluten sensitivity after dietary reduction of fermentable, poorly absorbed, short-chain carbohydrates. Gastroenterology 2013, 145, 320–328. [Google Scholar] [CrossRef] [PubMed]

- Brouns, F.; Delzenne, N.; Gibson, G. The dietary fibres—FODMAP controversy. Cereal Food World 2017, 62, 98–103. [Google Scholar] [CrossRef]

- Ispiryan, L.; Zannini, E.; Arendt, E.K. Characterization of the FODMAP-profile in cereal-product ingredients. J. Cereal Sci. 2020, 92, 102916. [Google Scholar] [CrossRef]

- Kahlon, T.S.; Avena-Bustillos, R.J.; Chiu, M.-C.M. Sensory evaluation of gluten-free quinoa whole grain snacks. Heliyon 2016, 2, e00213. [Google Scholar] [CrossRef] [PubMed]

- Bellini, M.; Tonarelli, S.; Barracca, F.; Rettura, F.; Pancetti, A.; Ceccarelli, L.; Ricchiuti, A.; Costa, F.; de Bortoli, N.; Marchi, S.; et al. Chronic constipation: Is a nutritional approach reasonable? Nutrients 2021, 13, 3386. [Google Scholar] [CrossRef]

- Čukelj, N.; Novotni, D.; Sarajlija, H.; Drakula, S.; Voučko, B.; Ćurić, D. Flaxseed and multigrain mixtures in the development of functional biscuits. LWT Food Sci. Technol. 2017, 86, 85–92. [Google Scholar] [CrossRef]

- Gao, D.; Helikh, A.; Duan, Z.; Liu, Y.; Shang, F. Development of pumpkin seed meal biscuits. East. Eur. J. Enterp. Technol. 2022, 2, 36–42. [Google Scholar] [CrossRef]

- Balbino, S.; Dorić, M.; Vidaković, S.; Kraljić, K.; Škevin, D.; Drakula, S.; Voučko, B.; Čukelj, N.; Obranović, M.; Ćurić, D. Application of cryogenic grinding pretreatment to enhance extractability of bioactive molecules from pumpkin seed cake. J. Food Process Eng. 2019, 42, 1–13. [Google Scholar] [CrossRef]

- Habuš, M.; Mykolenko, S.; Iveković, S.; Pastor, K.; Kojić, J.; Drakula, S.; Ćurić, D.; Novotni, D. Bioprocessing of wheat and amaranth bran for the reduction of fructan levels and application in 3D-printed snacks. Foods 2022, 11, 1649. [Google Scholar] [CrossRef]

- Loponen, J.; Gänzle, M. Use of sourdough in low-FODMAP baking. Foods 2018, 7, 96. [Google Scholar] [CrossRef]

- Siepmann, F.B.; Ripari, V.; Waszczynskyj, N.; Spier, M.R. Overview of sourdough technology: From production to marketing. Food Bioprocess Technol. 2018, 11, 242–270. [Google Scholar] [CrossRef]

- Świąder, K.; Florowska, A.; Konisiewicz, Z.; Chen, Y.-P. Functional tea-infused set yoghurt development by evaluation of sensory quality and textural properties. Foods 2020, 9, 1848. [Google Scholar] [CrossRef]

- Heiniö, R.L.; Noort, M.W.J.; Katina, K.; Alam, S.A.; Sozer, N.; de Kock, H.L.; Hersleth, M.; Poutanen, K. Sensory characteristics of wholegrain and bran-rich cereal foods—A review. Trends Food Sci. Technol. 2016, 47, 25–38. [Google Scholar] [CrossRef]

- AACC International. Approved Methods of Analysis, 11th ed.; Cereals & Grains Association: Saint Paul, MN, USA, 2010; ISBN 978-1-891127-68-2. [Google Scholar]

- Balbino, S.; Repajić, M.; Obranović, M.; Medved, A.M.; Tonković, P.; Dragović-Uzelac, V. Characterization of lipid fraction of Apiaceae family seed spices: Impact of species and extraction method. J. Appl. Res. Med. Aromat. Plants 2021, 25, 100326. [Google Scholar] [CrossRef]

- Gill, S.K.; Rossi, M.; Bajka, B.; Whelan, K. Dietary fibre in gastrointestinal health and disease. Nat. Rev. Gastroenterol. Hepatol. 2021, 18, 101–116. [Google Scholar] [CrossRef]

- ISO Standard No. 11035; Sensory Analysis—Identification and Selection of Descriptors for Establishing a Sensory Profile by a Multidimensional Approach. International Organization for Standardization: Geneva, Switzerland, 1994.

- ISO Standard No. 13299; Sensory Analysis—Methodology—General Guidance for Establishing a Sensory Profile. International Organization for Standardization: Geneva, Switzerland, 1994.

- ISO Standard No. 6658; Sensory Analysis—Methodology—General Guidance. International Organization for Standardization: Geneva, Switzerland, 1994.

- Knudsen, K.E.B.; Nørskov, N.P.; Bolvig, A.K.; Hedemann, M.S.; Laerke, H.N. Dietary fibres and associated phytochemicals in cereals. Mol. Nutr. Food Res. 2017, 61, 1–37. [Google Scholar]

- Varney, J. Getting Enough Fibre. Monash University. 2021. Available online: https://www.monashfodmap.com/blog/getting-enough-fibre/ (accessed on 14 August 2022).

- Varney, J.; Barrett, J.; Scarlata, K.; Catsos, P.; Gibson, P.R.; Muir, J.G. FODMAPs: Food composition, defining cutoff values and international application. J. Gastroenterol. Hepatol. 2017, 32, 53–61. [Google Scholar] [CrossRef]

- Currò, D. Current evidence on the therapeutic use of fiber in irritable bowel syndrome. Expert Rev. Gastroenterol. Hepatol. 2021, 16, 426–436. [Google Scholar] [CrossRef]

- Coskuner, Y.; Karababa, E. Some physical properties of flaxseed (Linum usitatissimum L.). J. Food Eng. 2007, 78, 1067–1073. [Google Scholar] [CrossRef]

- Commission Regulation (EU) No 1047/2012 of 8 November 2012 Amending Regulation (EC) No 1924/2006 with Regard to the List of Nutrition Claims Text with EEA Relevance OJ L 310, 9.11.2012, p. 36–37. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32012R1047 (accessed on 14 August 2022).

- Ullah, R.; Nadeem, M.; Khalique, A.; Imran, M.; Mehmood, S.; Javid, A.; Hussain, J. Nutritional and therapeutic perspectives of Chia (Salvia hispanica L.): A review. J. Food Sci. Technol. 2016, 53, 1750–1758. [Google Scholar] [CrossRef]

- Selimović, A.; Miličević, D.; Selimović, A.; Žuljević, S.O.; Jašića, A.; Vranac, A. Properties of crackers with buckwheat sourdough. Acta Chim. Slov. 2017, 10, 152–158. [Google Scholar] [CrossRef]

- Pham, V.T.; Fehlbaum, S.; Seifert, N.; Richard, N.; Bruins, M.J.; Sybesma, W.; Rehman, A.; Steinert, R.E. Effects of colon-targeted vitamins on the composition and metabolic activity of the human gut microbiome—A pilot study. Gut Microbes 2021, 13, 1875774. [Google Scholar] [CrossRef] [PubMed]

- Roth, B.; Larsson, E.; Ohlsson, B. Poor intake of vitamins and minerals is associated with symptoms among patients with irritable bowel syndrome. J. Gastroen. Hepatol. 2022, 37, 1253–1262. [Google Scholar] [CrossRef] [PubMed]

- Severini, C.; Derossi, A.; Ricci, I.; Caporizzi, R.; Fiore, A. Printing a blend of fruit and vegetables. New advances on critical variables and shelf life of 3D edible objects. J. Food Eng. 2018, 220, 89–100. [Google Scholar] [CrossRef]

- Sedej, I.; Sakač, M.; Mandic, A.; Misan, A.; Pestoric, M.; Šimurina, O. Quality assessment of gluten-free crackers based on buckwheat flour. LWT Food Sci. Technol. 2011, 44, 694–699. [Google Scholar] [CrossRef]

- Colla, K.; Costanzo, A.; Gamlath, S. Fat replacers in baked food products. Foods 2018, 7, 192. [Google Scholar] [CrossRef]

- Khouryieh, H.; Aramouni, F. Physical and sensory characteristics of cookies prepared with flaxseed flour. J. Sci. Food Agric. 2012, 92, 2366–2372. [Google Scholar] [CrossRef] [PubMed]

- Šimurina, O.; Sedej, I.; Sakač, M.; Hadnađev, M.; Filipčev, B.; Pestorić, M.; Pribiš, V. Buckweat in the wholegrain cracker production. Prog. Theor. Exp. Phys. 2009, 13, 153–156. [Google Scholar]

- Majchrzak, K.K.; Sumara, A.; Fornal, E.; Montowska, M. Oilseed proteins—Properties and application as a food ingredient. Trends Food Sci. Technol. 2020, 106, 160–170. [Google Scholar] [CrossRef]

- Moayyedi, P.; Andrews, C.N.; MacQueen, G.; Korownyk, C.; Marsiglio, M.; Graff, L.; Kvern, B.; Lazarescu, A.; Liu, L.; Paterson, W.G.; et al. Canadian association of gastroenterology clinical practice guideline for the management of irritable bowel syndrome (IBS). J. Can. Assoc. Gastroenterol. 2019, 2, 6–29. [Google Scholar] [CrossRef]

| Chia Seeds | Pumpkin Seed Meal | Flax Seeds | White Maize Flour | Millet Flour | Buckwheat Flour | Rice Protein | Sweet Potato Puree | |

|---|---|---|---|---|---|---|---|---|

| Proteins | 20.0 | 59.4 | 23.8 | 6.3 | 10.0 | 10.8 | 83.0 | 1.0 |

| Fats | 31.0 | 15.8 | 26.6 | 0.9 | 3.3 | 2.9 | 4.5 | 1.9 |

| Carbohydrates | 6.3 | nd | 9.0 | 78.0 | 73.0 | 70.1 | 2.9 | 7.6 |

| Salt | 0.05 | na | 0.1 | 0.3 | 0.2 | 0.1 | <0.05 | 0.03 |

| F1 | F2 | F3 | F4 | F5 | F6 | F7 | F8 | F9 | ||

|---|---|---|---|---|---|---|---|---|---|---|

|

Main flours (% of total flour) | Maize | 70 | 70 | 70 | 70 | 22 | / | / | / | / |

| Proso millet | 30 | 30 | 30 | 30 | 45 | 50 | 20 | / | 85 | |

| Buckwheat | / | / | / | / | 33 | 50 | 80 | 100 | 15 | |

|

Additional ingredients (% of flour weight) | Water | 100 | 100 | 73 | 73 | 100 | 80 | 80 | 100 | 75 |

| Fat spread | 20 | 24 | 60 | 60 | 42 | 17 | 17 | / | 15 | |

| Olive oil | / | / | / | / | / | / | / | 25 | / | |

| Rice protein | 30 | 30 | 36 | 36 | 20 | 30 | 30 | 30 | 10 | |

| Flax seeds | / | / | / | 18 | 12 | 15 | 5 | |||

| Chia seeds | 10 | 10 | 18 | / | 14 | / | 10 | / | ||

| Pumpkin seed meal | / | / | / | / | 20 | / | 40 | |||

| Sweet potato puree | / | / | 35 | 35 | / | 20 | 15 | 30 | 30 | |

| Salt | 1.25 | 2 | 2.4 | 2.4 | 1.4 | 0.8 | 1 | 1 | 1 | |

| Spices | / | / | Med. mix 1.2 | Chives 2.4 | Pepper; wild garlic 0.7; 0.7 | Med. mix 0.8 | Wild garlic; shallot 0.5; 0.5 | Tumeric; dill 0.5; 2 | / | |

| Yeast | / | 2 | / | / | / | / | / | |||

|

Soudough (% of dough weight) | 20 | - | 20 | 20 | 20 | 20 | 20 | 20 | 20 | |

| Sensory Attribute | Description | |

|---|---|---|

| Appearance | Colour | Degree of brownness, ranging from light brown to dark brown |

| Uniformity of surface | Uniform–non-uniform, smooth–rough | |

| Odour | Overall | Overall intensity of odour |

| Taste and flavour | Bitter taste | Basic taste produced by caffeine |

| Bitter aftertaste | Bitterness after chewing | |

| Overall | Overall intensity of taste and flavour | |

| Texture in mouth | Hardness | Force applied by the molar teeth to compress the cracker |

| Chewiness | Number of chews necessary for food to be swallowed | |

| Granularity | Sense of particle size and shape (larger particles–higher granularity) | |

| Dryness | Amount of saliva absorbed by sample crumbs during mastication | |

| Solubility | Chewing required until the biscuit disintegrates (more chewing–less solubility) | |

| Teeth adhesiveness | Ability of food to adhere to the teeth when chewed | |

| Raw Material | Fructan and Galactooligosaccharides | Total Dietary Fibre | Soluble Fibre | Insoluble Fibre | Minerals (As ash) |

|---|---|---|---|---|---|

| Buckwheat flour | nd | 6.12 ± 0.53 | 1.55 ± 0.03 | 4.57 ± 0.12 | 3.01 ± 0.00 |

| Millet flour | 0.29 ± 0.01 | 14.90 ± 0.35 | 8.01 ± 0.14 | 6.89 ± 0.11 | 1.26 ± 0.02 |

| White maize flour | 0.03 ± 0.06 | 2.34 ± 0.15 | 1.09 ± 0.03 | 1.25 ± 0.03 | 0.97 ± 0.09 |

| Rice protein | 0.14 ± 0.00 | 3.78 ± 0.69 | 2.21 ± 0.48 | 1.57 ± 0.21 | 1.19 ± 0.07 |

| Chia seeds | 0.36 ± 0.00 | 37.90 ± 0.04 | 7.26 ± 0.00 | 30.64 ± 0.00 | 4.76 ± 0.00 |

| Flax seeds | 0.64 ± 0.22 | 27.88 ± 0.00 | 7.24 ± 0.00 | 20.64 ± 0.21 | 3.85 ± 0.01 |

| Pumpkin seed meal | 0.83 ± 0.03 | 14.80 ± 0.01 | 6.86 ± 0.02 | 7.94 ± 0.09 | 7.49 ± 0.06 |

| Cracker F3 | Cracker F4 | Cracker F5 | Cracker F8 | |

|---|---|---|---|---|

| Energy (kJ/kcal) | 1883/450 | 1866/446 | 1820/435 | 1871/447 |

| Water content | 4.86 ± 0.04 c | 5.48 ± 0.05 b | 4.31 ± 0.04 d | 8.02 ± 0.05 a |

| Minerals (as ash) | 2.81 ± 0.01 c | 2.91 ± 0.01 c | 5.59 ± 0.00 b | 6.33 ± 0.00 a |

| Fats | 17.72 ± 0.12 a,b | 17.11 ± 0.62 b,c | 14.98 ± 0.00 c | 19.60 ± 0.10 a |

| of which saturated | 1.37 ± 0.00 | 1.54 ± 0.00 | 1.66 ± 0.00 | 2.71 ± 0.00 |

| Proteins | 24.94 ± 0.14 b,c | 25.97 ± 0.04 a | 26.08 ± 0.04a b | 24.02 ± 0.03 c |

| Carbohydrates | 44.00 ± 0.28 b | 43.51 ± 0.69 b | 44.41 ± 2.67 b | 38.83 ± 2.80 a |

| Dietary fibre | 7.49 ± 0.21 c | 7.12 ± 0.18 d | 8.92 ± 0.58 b | 9.53 ± 0.78 a |

| of which soluble | 1.25 ± 0.13 d | 1.65 ± 0.08 c | 2.06 ± 0.78 b | 2.34 ± 0.51 a |

| Fructan | 0.10 ± 0.00 a | 0.12 ± 0.00 a | 0.12 ± 0.00 a | 0.11 ± 0.00 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Radoš, K.; Čukelj Mustač, N.; Varga, K.; Drakula, S.; Voučko, B.; Ćurić, D.; Novotni, D. Development of High-Fibre and Low-FODMAP Crackers. Foods 2022, 11, 2577. https://doi.org/10.3390/foods11172577

Radoš K, Čukelj Mustač N, Varga K, Drakula S, Voučko B, Ćurić D, Novotni D. Development of High-Fibre and Low-FODMAP Crackers. Foods. 2022; 11(17):2577. https://doi.org/10.3390/foods11172577

Chicago/Turabian StyleRadoš, Kristina, Nikolina Čukelj Mustač, Katarina Varga, Saša Drakula, Bojana Voučko, Duška Ćurić, and Dubravka Novotni. 2022. "Development of High-Fibre and Low-FODMAP Crackers" Foods 11, no. 17: 2577. https://doi.org/10.3390/foods11172577

APA StyleRadoš, K., Čukelj Mustač, N., Varga, K., Drakula, S., Voučko, B., Ćurić, D., & Novotni, D. (2022). Development of High-Fibre and Low-FODMAP Crackers. Foods, 11(17), 2577. https://doi.org/10.3390/foods11172577