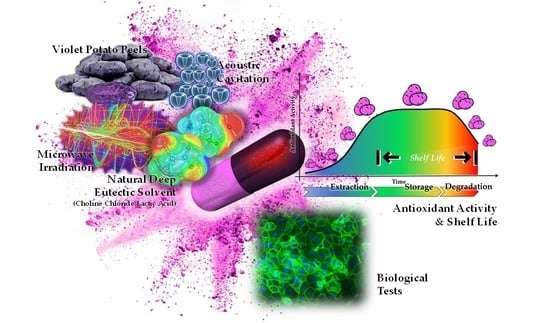

Food-Waste Valorisation: Synergistic Effects of Enabling Technologies and Eutectic Solvents on the Recovery of Bioactives from Violet Potato Peels

Abstract

:1. Introduction

2. Materials and Methods

2.1. Biomass Material and Chemicals

2.2. Conventional Extraction (Hydroalcoholic Extraction)

2.3. Microwave-Assisted Extraction (MAE)

2.4. Ultrasound-Assisted Extraction (UAE)

2.5. Antioxidant Activity—DPPH·Assay

2.6. Cell Proliferation Assay

2.7. DCF-DA Assay

3. Results and Discussion

3.1. Hydroalcoholic Extraction

3.1.1. Conventional Protocol—Hydroalcoholic Solution

3.1.2. Technology Screening—Hydroalcoholic Solution

3.1.3. US-Assisted Extraction (UAE)—Hydroalcoholic Solvent

3.1.4. MW-Assisted Extraction (MAE)—Hydroalcoholic Solvent

3.2. ChLA Extraction

3.2.1. Conventional Protocol—ChLA

3.2.2. Technology Screening—ChLA

3.2.3. US-Assisted Extraction (UAE)—ChLA

3.2.4. MW-Assisted Extraction (MAE)—ChLA

3.3. ChLA Stabilization Effects

3.3.1. Shelf-Life

3.3.2. Antioxidant Activity Modification: EtOH Addition and US Degradation Tests

3.4. Biological Activity

3.4.1. Antiproliferative Activity

3.4.2. In Vitro Antioxidant Activity

4. General Remarks and Perspectives

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Appendix A.1. Total Anthocyanin Content (TAC) Determination

Appendix A.2. Total Anthocyanin Content (TAC)—Shelf-Life

| Solvent | Storage | TAC (mg/g) | Degradation (%) |

|---|---|---|---|

| ChLa | Fresh | 1.95 | - |

| 24 months | 1.58 | 18.97 | |

| EtOH/H2O | Fresh | 2.49 | - |

| 24 months | 0.66 | 73.49 |

Appendix A.3. LC-MS Analysis

Appendix A.4. ChLa Extract: LC-MS Qualitative Determination

References

- Available online: http://fao.org/faostat/ (accessed on 20 April 2023).

- Oreopoulou, V.; Russ, W. Utilization of by-Products and Treatment of Waste in the Food Industry; Springer: New York, NY, USA, 2007. [Google Scholar]

- Akyol, H.; Riciputi, Y.; Capanoglu, E.; Caboni, M.F.; Verardo, V. Phenolic Compounds in the Potato and Its Byproducts: An Overview. Int. J. Mol. Sci. 2016, 17, 835. [Google Scholar] [CrossRef]

- Jeswani, H.K.; Figueroa-Torres, G.; Azapagic, A. The extent of food waste generation in the UK and its environmental impacts. Sustain. Prod. Consum. 2021, 26, 532–547. [Google Scholar] [CrossRef]

- Tawila, M.A.; Omer, H.A.A.; Gad, S.M. Partial replacing of concentrate feed mixture by potato processing waste in sheep rations. Am.-Eurasia J. Agric. Environ. Sci. 2008, 4, 156–164. [Google Scholar]

- Maske, N.S.; Satyanarayan, S. Effect of special fish feed prepared using potato peels on fresh water fish labeorohita. J. Indus. Pollut. Control 2012, 29, 33–38. [Google Scholar] [CrossRef]

- Chimonyo, M. A review of the utility of potato by-products as a feed resource for smallholder pig production. Anim. Feed. Sci. Technol. 2017, 227, 107–117. [Google Scholar] [CrossRef]

- Pandit, N.; Ahmad, N.; Maheshwari, S. Vermicomposting biotechnology an eco-loving approach for recycling of solid organic wastes into valuable biofertilizers. J. Biofertil. Biopestic. 2012, 3, 1–8. [Google Scholar] [CrossRef]

- Arapoglou, D.; Varzakas, T.; Vlyssides, A.; Israilides, C. Ethanol production from potato peel waste (PPW). Waste Manag. 2010, 30, 1898–1902. [Google Scholar] [CrossRef]

- Achinas, S.; Li, Y.; Achinas, V.; Euverink, G.J.W. Biogas Potential from the Anaerobic Digestion of Potato Peels: Process Performance and Kinetics Evaluation. Energies 2019, 12, 2311. [Google Scholar] [CrossRef]

- Despoudi, S.; Bucatariu, C.; Otles, S.; Kartal, C. Chapter 1—Food Waste Management, Valorization, and Sustainability in the Food Industry. In Food Waste Recovery, 2nd ed.; Galanakis, C.M., Ed.; Academic Press: Cambridge, MA, USA, 2021; pp. 3–19. ISBN 9780128205631. [Google Scholar] [CrossRef]

- Lacy, P.; Rutqvist, J. Waste to Wealth—The Circular Economy Advantage; Palgrave Macmillan: London, UK, 2015. [Google Scholar] [CrossRef]

- Sales, F.C.V.; De Souza, M.; Trento, L.R.; Pereira, G.M.; Borchardt, M.; Milan, G.S. Food Waste in Distribution: Causes and Gaps to Be Filled. Sustainability 2023, 15, 3598. [Google Scholar] [CrossRef]

- Wu, D. Recycle technology for potato peel waste processing: A review. Procedia Environ. Sci. 2016, 31, 103–107. [Google Scholar] [CrossRef]

- Samotyja, U. Potato peel as a sustainable resource of natural antioxidants for the food industry. Potato Res. 2019, 62, 435–451. [Google Scholar] [CrossRef]

- Eltayeb, E.A.; Al-Sinani, S.S.; Khan, I.A. Determination of the Glycoalkaloids α-Solanine and α-Chaconine Levels in 18 Varieties of Potato (Solarium Tuberosum L.) Grown in Oman. Potato Res. 2003, 46, 57. [Google Scholar] [CrossRef]

- Scharf, R.; Wang, W.; Maycock, J.; Ho, P.; Chen, S.; Orfila, C. Valorisation of Potato (Solanum tuberosum) Peel Waste: Extraction of Fibre, Monosaccharides and Uronic Acids. Waste Biomass Valor. 2020, 11, 2123–2128. [Google Scholar] [CrossRef]

- Calcio Gaudino, E.; Colletti, A.; Grillo, G.; Tabasso, S.; Cravotto, G. Emerging Processing Technologies for the Recovery of Valuable Bioactive Compounds from Potato Peels. Foods 2020, 3, 1598. [Google Scholar] [CrossRef]

- Xu, Q.; Wang, S.; Milliron, H.; Han, Q. The Efficacy of Phenolic Compound Extraction from Potato Peel Waste. Processes 2022, 10, 2326. [Google Scholar] [CrossRef]

- Singh, B.; Singh, J.; Singh, J.P.; Kaur, A.; Singh, N. Phenolic compounds in potato (Solanum tuberosum L.) peel and their health-promoting activities. Int. J. Food Sci. Technol. 2020, 55, 2273–2281. [Google Scholar] [CrossRef]

- Joly, N.; Souidi, K.; Depraetere, D.; Wils, D.; Martin, P. Potato By-Products as a Source of Natural Chlorogenic Acids and Phenolic Compounds: Extraction, Characterization, and Antioxidant Capacity. Molecules 2021, 26, 177. [Google Scholar] [CrossRef] [PubMed]

- Ru, W.; Pang, Y.; Gan, Y.; Liu, Q.; Bao, J. Phenolic Compounds and Antioxidant Activities of Potato Cultivars with White, Yellow, Red and Purple Flesh. Antioxidants 2019, 8, 419. [Google Scholar] [CrossRef]

- Arun, K.B.; Chandran, J.; Dhanya, R.; Krishna, P.; Jayamurthy, P.; Nisha, P. A comparative evaluation of antioxidant and antidiabetic potential of peel from young and matured potato. Food Biosci. 2015, 9, 36–46. [Google Scholar] [CrossRef]

- Chemat, F.; Vian, M.A.; Cravotto, G. Green Extraction of Natural Products: Concept and Principles. Int. J. Mol. Sci. 2012, 13, 8615–8627. [Google Scholar] [CrossRef]

- Picot-Allain, C.; Mahomoodally, M.F.; Ak, G.; Zengin, G. Conventional Versus Green Extraction Techniques—A Comparative Perspective. Curr. Opin. Food Sci. 2021, 40, 144–156. [Google Scholar] [CrossRef]

- Rifna, E.J.; Misra, N.N.; Madhuresh, D. Recent advances in extraction technologies for recovery of bioactive compounds derived from fruit and vegetable waste peels: A review. Crit. Rev. Food Sci. Nutr. 2023, 63, 719–752. [Google Scholar] [CrossRef]

- Aimone, C.; Grillo, G.; Boffa, L.; Giovando, S.; Cravotto, G. Tannin Extraction from Chestnut Wood Waste: From Lab Scale to Semi-Industrial Plant. Appl. Sci. 2023, 13, 2494. [Google Scholar] [CrossRef]

- Gunjevic, V.; Grillo, G.; Carnaroglio, D.; Binello, A.; Barge, A.; Cravotto, G. Selective recovery of terpenes, polyphenols and cannabinoids from Cannabis sativa L. inflorescences under microwaves. Ind. Crop. Prod. 2021, 162, 113247–113258. [Google Scholar] [CrossRef]

- Grillo, G.; Boffa, L.; Talarico, S.; Solarino, R.; Binello, A.; Cavaglià, G.; Bensaid, S.; Telysheva, G.; Cravotto, G. Batch and Flow Ultrasound-Assisted Extraction of Grape Stalks: Process Intensification Design up to a Multi-Kilo Scale. Antioxidants 2020, 9, 730. [Google Scholar] [CrossRef] [PubMed]

- Grillo, G.; Boffa, L.; Calcio, G.E.; Binello, A.; Rego, D.; Pereira, M.; Martínez, M.; Cravotto, G. Combined Ultrasound and Pulsed Electric Fields in Continuous-Flow Industrial Olive-Oil Production. Foods 2022, 28, 3419. [Google Scholar] [CrossRef]

- Zhou, J.; Gullón, B.; Wang, M.; Gullón, P.; Lorenzo, J.M.; Barba, F.J. The Application of Supercritical Fluids Technology to Recover Healthy Valuable Compounds from Marine and Agricultural Food Processing By-Products: A Review. Processes 2021, 9, 357. [Google Scholar] [CrossRef]

- Velusamy, M.; Rajan, A.; Radhakrishnan, M. Valorisation of food processing wastes using PEF and its economic advances—Recent update. Int. J. Food Sci. Technol. 2023, 58, 2021–2041. [Google Scholar] [CrossRef]

- Frontuto, D.; Carullo, D.; Harrison, S.M.; Brunton, N.P.; Ferrari, G.; Lyng, J.G.; Pataro, G. Optimization of Pulsed Electric Fields-Assisted Extraction of Polyphenols from Potato Peels Using Response Surface Methodology. Food Bioprocess Technol. 2019, 12, 1708–1720. [Google Scholar] [CrossRef]

- Cravotto, C.; Grillo, G.; Binello, A.; Gallina, L.; Olivares-Vicente, M.; Herranz-López, M.; Micol, V.; Barrajón-Catalán, E.; Cravotto, G. Bioactive Antioxidant Compounds from Chestnut Peels through Semi-Industrial Subcritical Water Extraction. Antioxidants 2022, 11, 988. [Google Scholar] [CrossRef]

- Singh, P.P.; Saldaña, M.D.A. Subcritical water extraction of phenolic compounds from potato peel. Food Res. Int. 2011, 44, 82452–82458. [Google Scholar] [CrossRef]

- Singh, A.; Nair, G.P.; Liplap, P.; Gariepy, Y.; Orsat, V.; Raghavan, G.S.V. Effect of Dielectric Properties of a Solvent-Water Mixture Used in Microwave-Assisted Extraction of Antioxidants from Potato Peels. Antioxidants 2014, 3, 99–113. [Google Scholar] [CrossRef]

- Patist, A.; Bates, D. Ultrasonic innovations in the food industry: From the laboratory to commercial production. Innov. Food Sci. Emerg. Technol. 2018, 9, 147–154. [Google Scholar] [CrossRef]

- Kumari, B.; Tiwari, B.K.; Hossain, M.B.; Rai, D.K.; Brunton, N.P. Ultrasound-assisted extraction of polyphenols from potato peels: Profiling and kinetic modelling. Int. J. Food Sci. Technol. 2017, 52, 1432–1439. [Google Scholar] [CrossRef]

- Clark, J.H.; Deswarte, F.E.I.; Farmer, T.J. The Integration of Green Chemistry into Future Biorefineries. Biofuels Bioprod. Biorefining 2009, 3, 72–90. [Google Scholar] [CrossRef]

- Glavič, P.; Pintarič, Z.N.; Bogataj, M. Process Design and Sustainable Development—A European Perspective. Processes 2021, 9, 148. [Google Scholar] [CrossRef]

- Clarke, C.J.; Tu, W.C.; Levers, O.; Bröhl, A.; Hallett, J.P. Green and Sustainable Solvents in Chemical Processes. Chem. Rev. 2018, 118, 747–800. [Google Scholar] [CrossRef] [PubMed]

- Putnik, P.; Bursać Kovačević, D.; Režek Jambrak, A.; Barba, F.J.; Cravotto, G.; Binello, A.; Lorenzo, J.M.; Shpigelman, A. Innovative “Green” and Novel Strategies for the Extraction of Bioactive Added Value Compounds from Citruswastes—A Review. Molecules 2017, 22, 680. [Google Scholar] [CrossRef]

- Carpentieri, S.; Soltanipour, F.; Ferrari, G.; Pataro, G.; Donsì, F. Emerging Green Techniques for the Extraction of Antioxidants from Agri-Food By-Products as Promising Ingredients for the Food Industry. Antioxidants 2021, 10, 1417. [Google Scholar] [CrossRef]

- Calcio Gaudino, E.; Tabasso, S.; Grillo, G.; Cravotto, G.; Dreyer, T.; Schories, G.; Altenberg, S.; Lauberte, L.; Telysheva, G. Wheat straw lignin extraction with bio-based solvents using enabling technologies. Comptes Rendus Chem. 2018, 21, 563. [Google Scholar] [CrossRef]

- Grillo, G.; Calcio Gaudino, E.; Rosa, R.; Leonelli, C.; Timonina, A.; Grygiškis, S.; Tabasso, S.; Cravotto, G. Green Deep Eutectic Solvents for Microwave-Assisted Biomass Delignification and Valorisation. Molecules 2021, 26, 798. [Google Scholar] [CrossRef]

- Bubalo, M.C.; Ćurko, N.; Tomašević, M.; Ganić, K.K.; Redovniković, I.R. Green extraction of grape skin phenolics by using deep eutectic solvents. Food Chem. 2016, 200, 159–166. [Google Scholar] [CrossRef]

- Liang, X.; Zhang, J.; Huang, Z.; Guo, Y. Sustainable recovery and recycling of natural deep eutectic solvent for biomass fractionation via industrial membrane-based technique. Ind. Crops Prod. 2023, 194, 116351. [Google Scholar] [CrossRef]

- Zhang, Q.; De Oliveira Vigier, K.; Royer, S.; Jérôme, F. Deep Eutectic Solvents: Syntheses, Properties and Applications. Chem. Soc. Rev. 2012, 41, 7108–7146. [Google Scholar] [CrossRef] [PubMed]

- Radošević, K.; Ćurko, N.; Srček, V.G.; Bubalo, M.C.; Tomašević, M.; Ganić, K.K.; Redovniković, I.R. Natural deep eutectic solvents as beneficial extractants for enhancement of plant extracts bioactivity. LWT 2016, 73, 45–51. [Google Scholar] [CrossRef]

- Grillo, G.; Gunjević, V.; Radošević, K.; Redovniković, I.R.; Cravotto, G. Deep Eutectic Solvents and Nonconventional Technologies for Blueberry-Peel Extraction: Kinetics, Anthocyanin Stability, and Antiproliferative Activity. Antioxidants 2020, 9, 1069. [Google Scholar] [CrossRef] [PubMed]

- Panić, M.; Andlar, M.; Tišma, M.; Rezić, T.; Šibalić, D.; Cvjetko Bubalo, M.; Radojčić Redovniković, I. Natural deep eutectic solvent as a unique solvent for valorisation of orange peel waste by the integrated biorefinery approach. Waste Manag. 2021, 120, 340–350. [Google Scholar] [CrossRef]

- Vanda, H.; Verpoorte, R.; Klinkhamer, P.G.L.; Choi, Y.H. Natural Deep Eutectic Solvents: From Their Discovery to Their Applications. In Deep Eutectic Solvents: Synthesis, Properties, and Applications, 1st ed.; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2020. [Google Scholar]

- Rodríguez Amado, I.; Franco, D.; Sánchez, M.; Zapata, C.; Vázquez, J.A. Optimisation of antioxidant extraction from Solanum tuberosum potato peel waste by surface response methodology. Food Chem. 2014, 165, 290–299. [Google Scholar] [CrossRef]

- Lévêque, J.M.; Cravotto, G.; Delattre, F.; Cintas, P. Organic Sonochemistry, Challenges and Perspectives for the 21st Century; Springer Nature: Chem, Switzerland, 2018. [Google Scholar] [CrossRef]

- Brand-Williams, W.; Cuvelier, M.E.; Berset, C. Use of a free radical method to evaluate antioxidant activity. Food Sci. Technol. 1995, 28, 25–30. [Google Scholar] [CrossRef]

- Locatelli, M.; Gindro, R.; Travaglia, F.; Coïsson, J.D.; Rinaldi, M.; Arlorio, M. Study of the DPPH—cavenging activity: Development of a free software for the correct interpretation of data. Food Chem. 2009, 114, 889–897. [Google Scholar] [CrossRef]

- Jiang, T.; Mao, Y.; Sui, L.; Yang, N.; Li, S.; Zhu, Z.; Wang, C.; Yin, S.; He, J.; He, Y. Degradation of anthocyanins and polymeric color formation during heat treatment of purple sweet potato extract at different pH. Food Chem. 2019, 274, 460–470. [Google Scholar] [CrossRef]

- Olivares, B.; Martínez, F.; Rivas, L.; Calderon, C.; Munita, J.M.; Campodonico, P.R. A Natural Deep Eutectic Solvent Formulated to Stabilize β-Lactam Antibiotics. Sci. Rep. 2018, 8, 14900. [Google Scholar] [CrossRef] [PubMed]

- Durand, E.; Lecomte, J.; Upasani, R.; Chabi, B.; Bayrasy, C.; Baréa, B.; Jublanc, E.; Clarke, M.J.; Moore, D.J.; Crowther, J.; et al. Evaluation of the ROS Inhibiting Activity and Mitochondrial Targeting of Phenolic Compounds in Fibroblast Cells Model System and Enhancement of Efficiency by Natural Deep Eutectic Solvent (NADES) Formulation. Pharm. Res. 2017, 34, 1134–1146. [Google Scholar] [CrossRef] [PubMed]

- Punzo, A.; Porru, E.; Silla, A.; Simoni, P.; Galletti, P.; Roda, A.; Tagliavini, E.; Samorì, C.; Caliceti, C. Grape Pomace for Topical Application: Green NaDES Sustainable Extraction, Skin Permeation Studies, Antioxidant and Anti-Inflammatory Activities Characterization in 3D Human Keratinocytes. Biomolecules 2021, 11, 1181. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez-Juan, E.; Rodríguez-Romero, C.; Fernández-Bolaños, J.; Florido, M.C.; Garcia-Borrego, A. Phenolic compounds from virgin olive oil obtained by natural deep eutectic solvent (NADES): Effect of the extraction and recovery conditions. J. Food Sci. Technol. 2021, 58, 552–561. [Google Scholar] [CrossRef]

- Ruesgas-Ramón, M.; Suárez-Quiroz, M.L.; González-Ríos, O.; Baréa, B.; Cazals, G.; Figueroa-Espinoza, M.C.; Durand, E. Bioactive Compounds from Cocoa Husk: Extraction, Analysis and Applications in Food Production Chain. J. Sci. Food Agric. 2020, 100, 798. [Google Scholar] [CrossRef]

- Rente, D.; Paiva, A.; Duarte, A.R. The Role of Hydrogen Bond Donor on the Extraction of Phenolic Compounds from Natural Matrices Using Deep Eutectic Systems. Molecules 2021, 26, 2336. [Google Scholar] [CrossRef]

- Kalhor, P.; Zheng, Y.-Z.; Ashraf, H.; Cao, B.; Yu, Z.-W. Influence of Hydration on the Structure and Interactions of Ethaline Deep-Eutectic Solvent: A Spectroscopic and Computational Study. ChemPhysChem 2020, 21, 995–1005. [Google Scholar] [CrossRef]

- Dai, Y.; van Spronsen, J.; Witkamp, G.-J.; Verpoorte, R.; Choi, Y.H. Natural deep eutectic solvents as new potential media for green technology. Anal. Chim. Acta 2013, 766, 61–68. [Google Scholar] [CrossRef]

- Silva, J.M.; Pereira, C.V.; Mano, F.; Silva, E.; Castro, V.I.B.; Sa-Nogueira, I.; Reis, R.L.; Paiva, A.; Matias, A.A.; Duarte, A.R.C. Therapeutic Role of Deep Eutectic Solvents Based on Menthol and Saturated Fatty Acids on Wound Healing. ACS Appl. Bio Mater. 2019, 2, 4346–4355. [Google Scholar] [CrossRef]

- Jeong, K.M.; Ko, J.; Zhao, J.; Jin, Y.; Yoo, D.E.; Han, S.Y.; Lee, J.L. Multi-functioning deep eutectic solvents as extraction and storage media for bioactive natural products that are readily applicable to cosmetic products. J. Clean. Prod. 2017, 151, 87–95. [Google Scholar] [CrossRef]

- Alcalde, R.; Atilhan, M.; Aparicio, S. On the properties of (choline chloride + lactic acid) deep eutectic solvent with methanol mixtures. J. Mol. Liq. 2018, 272, 815–820. [Google Scholar] [CrossRef]

- Mannucci, G.; Busato, M.; Tofoni, A.; D’Angelo, P. Structural evolution of the butylated hydroxytoluene/menthol hydrophobic eutectic solvent upon methanol and ethanol cosolvent addition. J. Mol. Liq. 2023, 375, 121302. [Google Scholar] [CrossRef]

- Bhosale, P.B.; Ha, S.E.; Vetrivel, P.; Kim, H.H.; Kim, S.M.; Kim, G.S. Functions of polyphenols and its anticancer properties in biomedical research: A narrative review. Transl. Cancer Res. 2020, 9, 7619–7631. [Google Scholar] [CrossRef] [PubMed]

- Rente, D.; Bubalo, M.C.; Panić, M.; Paiva, A.; Caprin, B.; Redovniković, I.R.; Duarte, A.R.C. Review of deep eutectic systems from laboratory to industry, taking the application in the cosmetics industry as an example. J. Clean. Prod. 2022, 380, 135147. [Google Scholar] [CrossRef]

- Salehi, B.; Azzini, E.; Zucca, P.; Maria Varoni, E.V.; Anil Kumar, N.; Dini, L.; Panzarini, E.; Rajkovic, J.; Valere Tsouh Fokou, P.; Peluso, I.; et al. Plant-Derived Bioactives and Oxidative Stress-Related Disorders: A Key Trend towards Healthy Aging and Longevity Promotion. Appl. Sci. 2020, 10, 947. [Google Scholar] [CrossRef]

- Cai, Z.; Qu, Z.; Lan, Y.; Zhao, S.; Ma, X.; Wan, Q.; Jing, P.; Li, P. Conventional, ultrasound-assisted, and accelerated-solvent extractions of anthocyanins from purple sweet potatoes. Food Chem. 2016, 197, 266–272. [Google Scholar] [CrossRef] [PubMed]

- Wijngaard, H.H.; Ballay, M.; Brunton, N. The Optimisation of Extraction of Antioxidants from Potato Peel by Pressurised Liquids. Food Chem. 2012, 133, 1123–1130. [Google Scholar] [CrossRef]

- Benavides-Guerrero, R.; Revelo-Cuarán, Y.A.; Arango-Bedoya, O.; Osorio-Mora, O. Ultrasound-Assisted Extraction of Phenolic Compounds from Two Varieties of an Andean Native Potato (Solanum Phureja) and Evaluation of Their Antioxidant Activity. Inf. Tecnol. 2020, 21, 43–50. [Google Scholar] [CrossRef]

- Singh, A.; Sabally, K.; Kubow, S.; Donnelly, D.J.; Gariepy, Y.; Orsat, V.; Raghavan, G.S.V. Microwave-Assisted Extraction of Phenolic Antioxidants from Potato Peels. Molecules 2011, 16, 2218–2232. [Google Scholar] [CrossRef]

- Palos-Hernández, A.; Gutiérrez Fernández, M.Y.; Escuadra Burrieza, J.; Pérez-Iglesias, J.L.; González-Paramás, A.M. Obtaining green extracts rich in phenolic compounds from underexploited food by-products using natural deep eutectic solvents. Opportunities and challenges. Sustain. Chem. Pharm. 2022, 29, 100773. [Google Scholar] [CrossRef]

- Ribéreau-Gayon, P.; Stonestreet, E. Le dosage des tannins du vin rouge et la détermination de leur structure. Chim. Analitique 1966, 48, 188–196. [Google Scholar]

- Lewis, C.E.; Walker, J.R.L.; Lancaster, J.E.; Sutton, K.H. Determination of anthocyanins, flavonoids and phenolic acids in potatoes. I: Coloured cultivars of Solanum tuberosum L. J. Sci. Food Agric. 2018, 77, 45–57. [Google Scholar] [CrossRef]

| Temperature (°C) | Time (h) | EC50 (μg/mL) | Trolox Eq. (µmolTE/gExtr) | Dry Yield % |

|---|---|---|---|---|

| 80 | 4 | 97.7 | 161.1 ± 8.3 | 10.36 ± 0.92 |

| RT | 66.8 | 235.7 ± 13.0 | 13.08 ± 0.88 | |

| 80 | 1 | 46.4 | 339.3 ± 15.9 | 13.55 ± 1.12 |

| Temperature (°C) | Technology | EC50 (μg/mL) | Trolox Eq. (µmolTE/gExtr) | Dry Yield % |

|---|---|---|---|---|

| 80 | Conv. | 46.4 | 339.3 ± 15.9 | 13.55 ± 1.12 |

| MW | 69.4 | 226.8 ± 12.5 | 15.67 ± 1.30 | |

| 40 | US (100 W) | 87.0 | 180.9 ± 10.7 | 14.17 ± 0.99 |

| Time (min) | Power (W) | EC50 (μg/mL) | Trolox Eq. (µmolTE/gExtr) | Dry Yield (%) |

|---|---|---|---|---|

| 30 | 100 | 87.0 | 180.9 ± 10.7 | 14.17 ± 0.99 |

| 60 | 88.0 | 178.9 ± 9.8 | 11.28 ± 1.15 | |

| 30 | 500 | 80.7 | 195.1 ± 10.8 | 11.76 ± 1.06 |

| 60 | 72.1 | 218.3 ± 12.9 | 10.08 ± 1.57 |

| Temperature (°C) | Time (min) | EC50 (μg/mL) | Trolox Eq. (µmolTE/gExtr) | Dry Yield (%) |

|---|---|---|---|---|

| 80 | 60 | 69.4 | 226.8 ± 12.5 | 15.67 ± 1.30 |

| 100 | 30 | 48.7 | 323.2 ± 22.2 | 4.04 ± 0.86 |

| 120 | 5 | 46.7 | 337.1 ± 20.6 | 10.54 ± 2.01 |

| Temperature (°C) | Time (h) | EC50 (mg/mL) | Trolox Eq. (mmolTE/gExtr) |

|---|---|---|---|

| 80 | 4 | 30.8 | 510.1 ± 42.2 |

| RT | 51.7 | 300.0 ± 18.8 | |

| 80 | 1 | 53.8 | 292.0 ± 11.7 |

| Temperature (°C) | Technology | EC50 (μg/mL) | Trolox Eq. (mmolTE/gExtr) |

|---|---|---|---|

| 80 | Conv. | 53.8 | 294.1 ± 19.2 |

| MW | 47.1 | 330.6 ± 17.9 | |

| 40 | US (100 W) | 57.4 | 274.5 ± 10.8 |

| Time (min) | Power (W) | EC50 (mg/mL) | Trolox Eq. (mmolTE/gExtr) |

|---|---|---|---|

| 15 | 100 | 74.9 | 210.1 ± 15.8 |

| 30 | 57.4 | 274.5 ± 10.8 | |

| 15 | 500 | 48.7 | 325.5 ± 19.72 |

| 30 | 8.4 | 1874.0 ± 44.6 |

| Temperature (°C) | Time (min) | EC50 (mg/mL) | Trolox Eq. (mmolTE/gExtr) |

|---|---|---|---|

| 80 | 60 | 47.1 | 335.1 ± 13.4 |

| 100 | 30 | 32.2 | 468.2 ± 22.0 |

| 120 | 5 | 34.2 | 493.7 ± 18.6 |

| System | EC50 (mg/mL) | Trolox Eq. (mmolTE/gExtr) | Antioxidant Activity Variation (%) |

|---|---|---|---|

| ChLA a | 32.2 | 493.7 ± 18.6 | - |

| ChLA (+1% w/v EtOH) | 24.4 | 645.2 ± 21.0 | +30.7 b |

| ChLA (+10% w/v EtOH) | 20.1 | 783.2 ± 23.4 | +58.6 b |

| ChLA Degradation Test (+10% w/v EtOH) c | 38.0 | 414.3 ± 15.9 | −47.1 d |

| Solvent | EC50 (mg/mL) | Trolox Eq. (mmolTE/gExtr) | Antioxidant Activity Variation (%) |

|---|---|---|---|

| ChLA | 8.4 | 1874.0 ± 44.6 | - |

| ChLA (+1% w/v EtOH) | 36.5 | 431.3 ± 16.7 | −77.1 |

| Potato Variety | PP Extraction Conditions | Antioxidant Activity (DPPH Assay) | Biological Activity (In Vitro Test) | Ref. |

|---|---|---|---|---|

| Conventional extraction | ||||

| Agria | 71.2% EtOH, 89.9 °C, 34 min | 3.2–10.3 mg/100 g db * | Soybean oil stabilisation under accelerated oxidation conditions | [53] |

| Lady Rosetta | 80% MeOH, 23 °C, 15 h | 3.51 mg TE/g db | n.d. | [38] |

| Lady Claire | MeOH and 75% EtOH, 80 °C, 22 min | 2.00 mg TE/g db | n.d | [74] |

| Purple sweet | 80% EtOH, acidified by 0.1% (v/v) HCl 60 °C, 90 min, | 1303.14 mg TE/100 g db | n.d. | [73] |

| Vitelotte | 70% EtOH, 80 °C, 1 h | 339.3 μmolTE/gExtr | Antiproliferative MTS assay (Caco-2 and HaCaT cell lines) | This work |

| Ultrasound-Assisted Extraction (UAE) | ||||

| Ratona Morada | 70% acetone, 50 °C, 50 min | 39.81 EA × 10−3 mg TE/g db | n.d. | [75] |

| Lady Rosetta | 80% MeOH, 30–45 °C, 30–900 min, 42–33 Hz | 5.86 mg TE/g db | n.d | [38] |

| Purple sweet | 90% EtOH, acidified by 0.1% (v/v) HCl 50 °C, 45 min, 200 W | 1303.14 mg TE/100 g db | n.d. | [73] |

| Vitelotte | ChLA, 40 °C, 30 min, 500 W | 1874.0 mmolTE/gExtr | Antiproliferative MTS assay (Caco-2 & HaCaT cell lines) | This work |

| Microwave-Assisted Extraction (MAE) | ||||

| Russett Burbank | 67.33% MeOH, 15 min, 1:20 S/L ratio, | 74 mg TE/g db ** | n.d | [36,76] |

| Vitelotte | ChLA 120 °C, 5 min | 493.7 mmolTE/gExtr | Antiproliferative MTS assay (Caco-2 & HaCaT cell lines) | This work |

| Pressurised Liquid Extraction (PLE) | ||||

| Lady Claire | 70% EtOH and 125 °C | 3.39 mg TE/g db | n.d. | [74] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grillo, G.; Tabasso, S.; Capaldi, G.; Radosevic, K.; Radojčić-Redovniković, I.; Gunjević, V.; Calcio Gaudino, E.; Cravotto, G. Food-Waste Valorisation: Synergistic Effects of Enabling Technologies and Eutectic Solvents on the Recovery of Bioactives from Violet Potato Peels. Foods 2023, 12, 2214. https://doi.org/10.3390/foods12112214

Grillo G, Tabasso S, Capaldi G, Radosevic K, Radojčić-Redovniković I, Gunjević V, Calcio Gaudino E, Cravotto G. Food-Waste Valorisation: Synergistic Effects of Enabling Technologies and Eutectic Solvents on the Recovery of Bioactives from Violet Potato Peels. Foods. 2023; 12(11):2214. https://doi.org/10.3390/foods12112214

Chicago/Turabian StyleGrillo, Giorgio, Silvia Tabasso, Giorgio Capaldi, Kristina Radosevic, Ivana Radojčić-Redovniković, Veronika Gunjević, Emanuela Calcio Gaudino, and Giancarlo Cravotto. 2023. "Food-Waste Valorisation: Synergistic Effects of Enabling Technologies and Eutectic Solvents on the Recovery of Bioactives from Violet Potato Peels" Foods 12, no. 11: 2214. https://doi.org/10.3390/foods12112214