Non-Destructive Detection of the Freshness of Air-Modified Mutton Based on Near-Infrared Spectroscopy

Abstract

1. Introduction

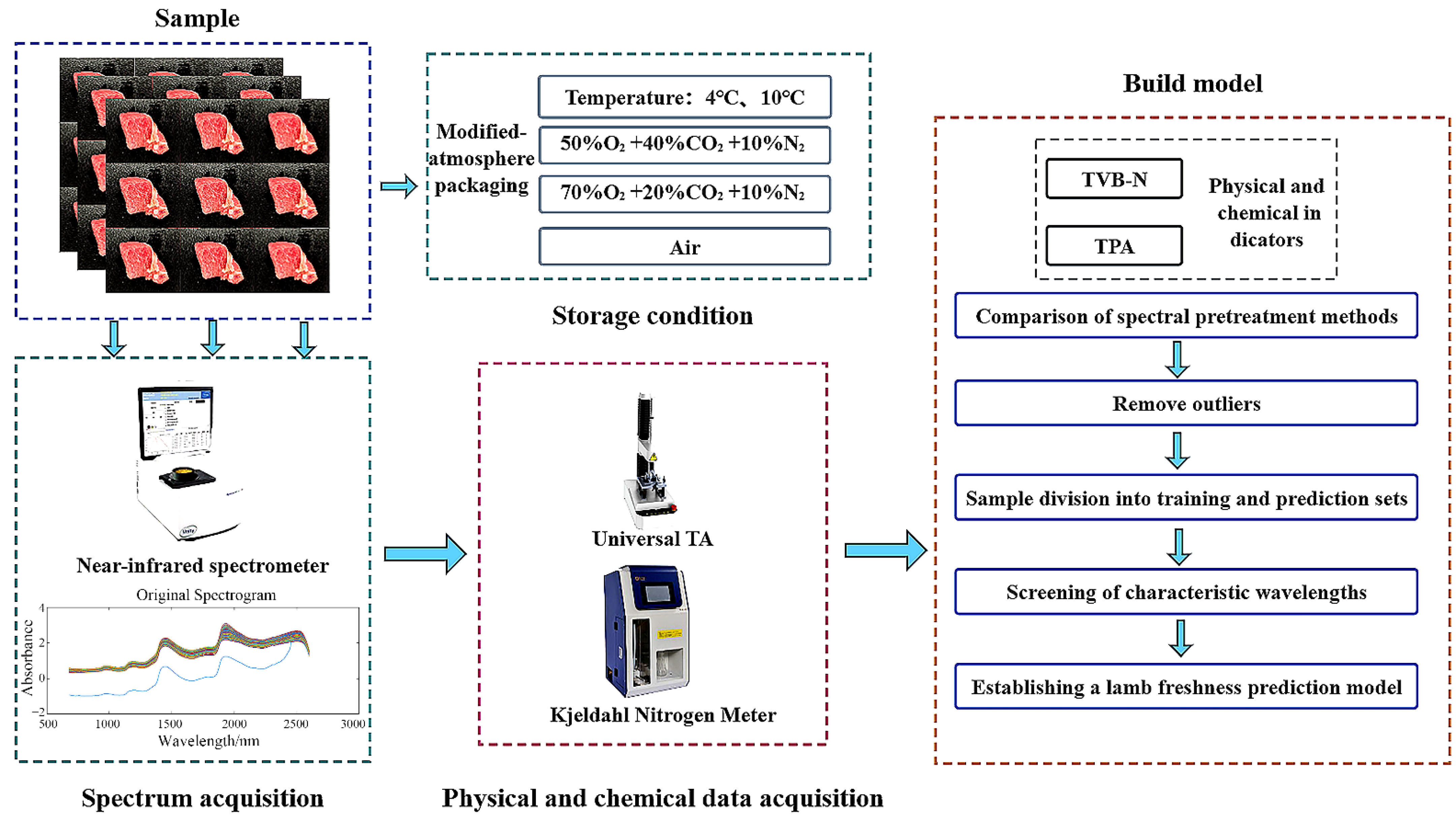

2. Materials and Methods

2.1. Experimental Methods

2.2. NIR Spectral Data Acquisition

2.3. Determination of Physical and Chemical Indexes

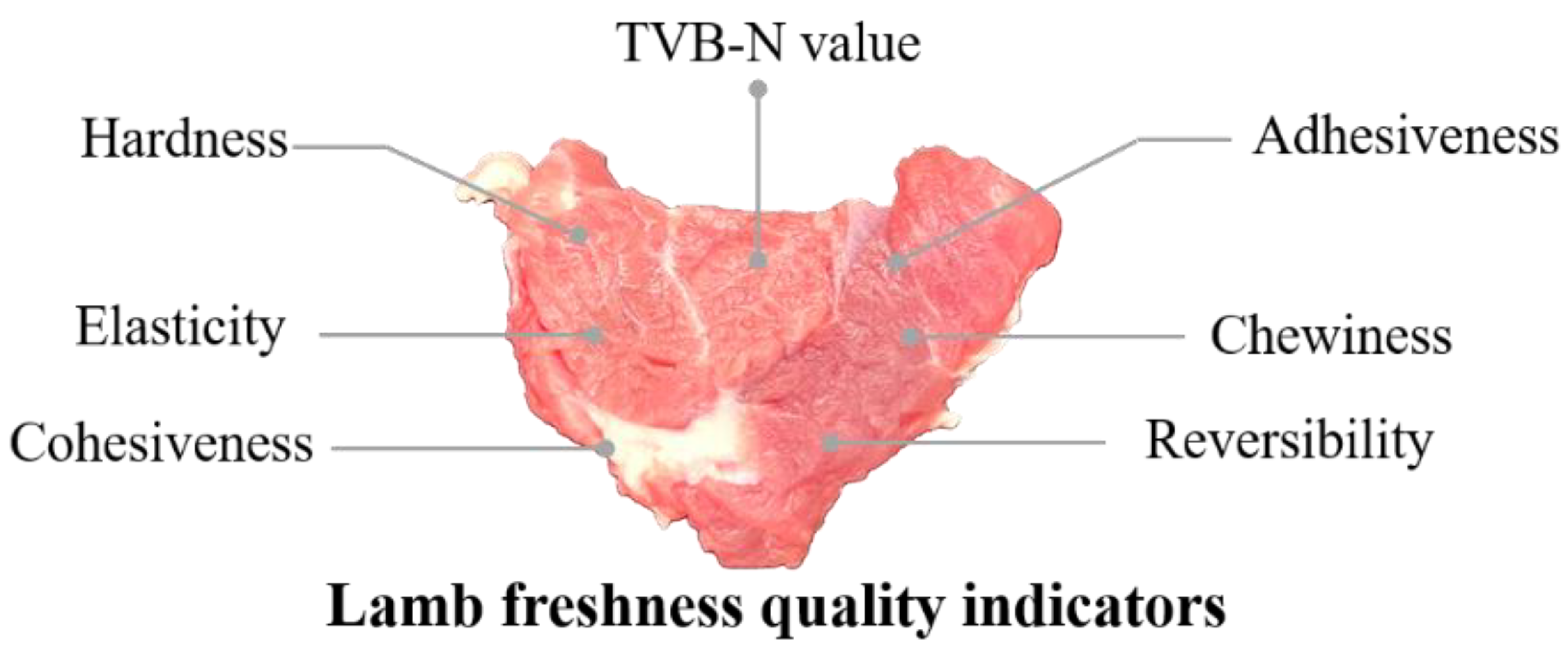

2.3.1. Determination of Texture Characteristics

2.3.2. TVB-N Content Determination

2.4. Statistical Analysis

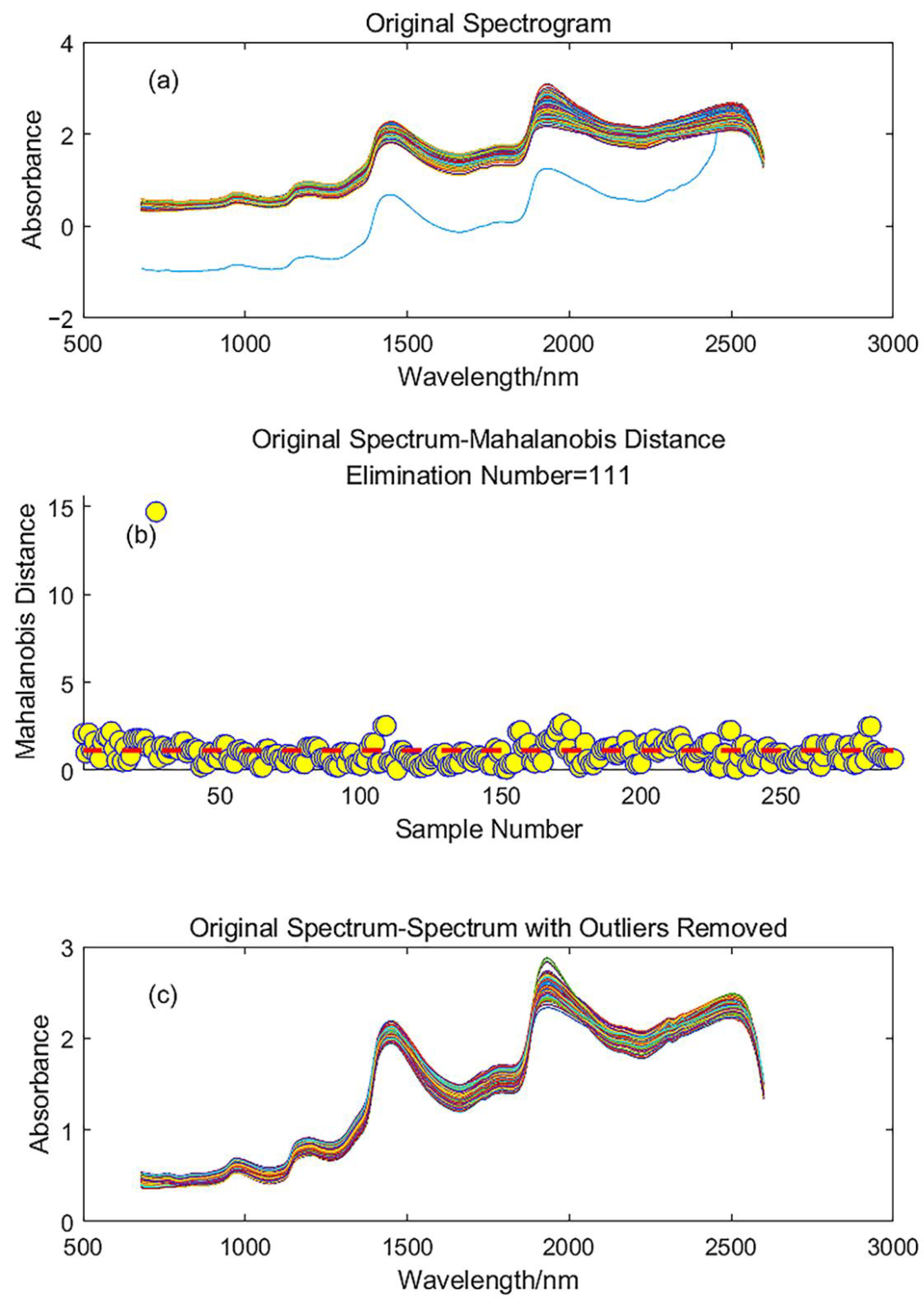

2.4.1. Abnormal Spectral Sample Rejection

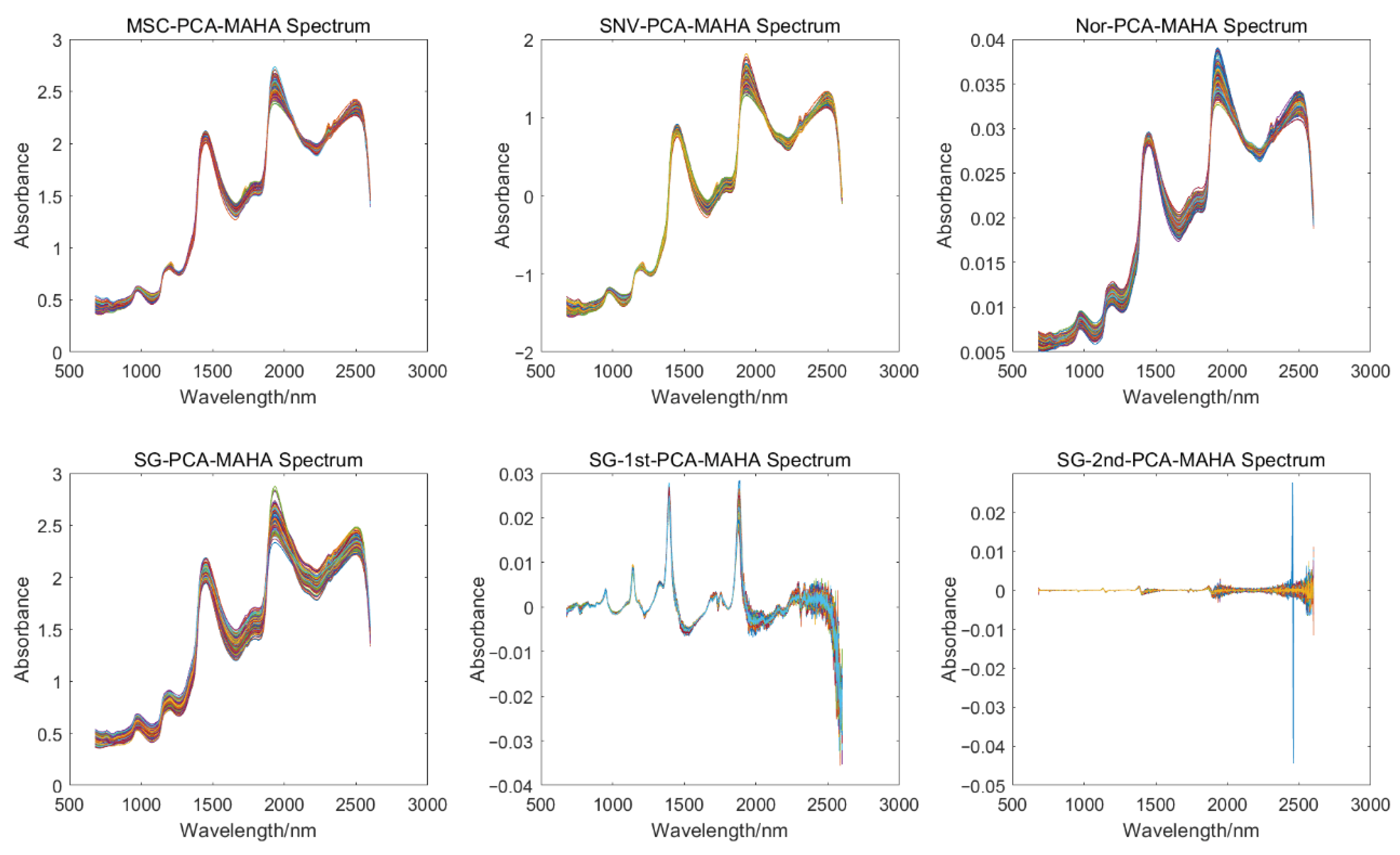

2.4.2. Spectral Preprocessing

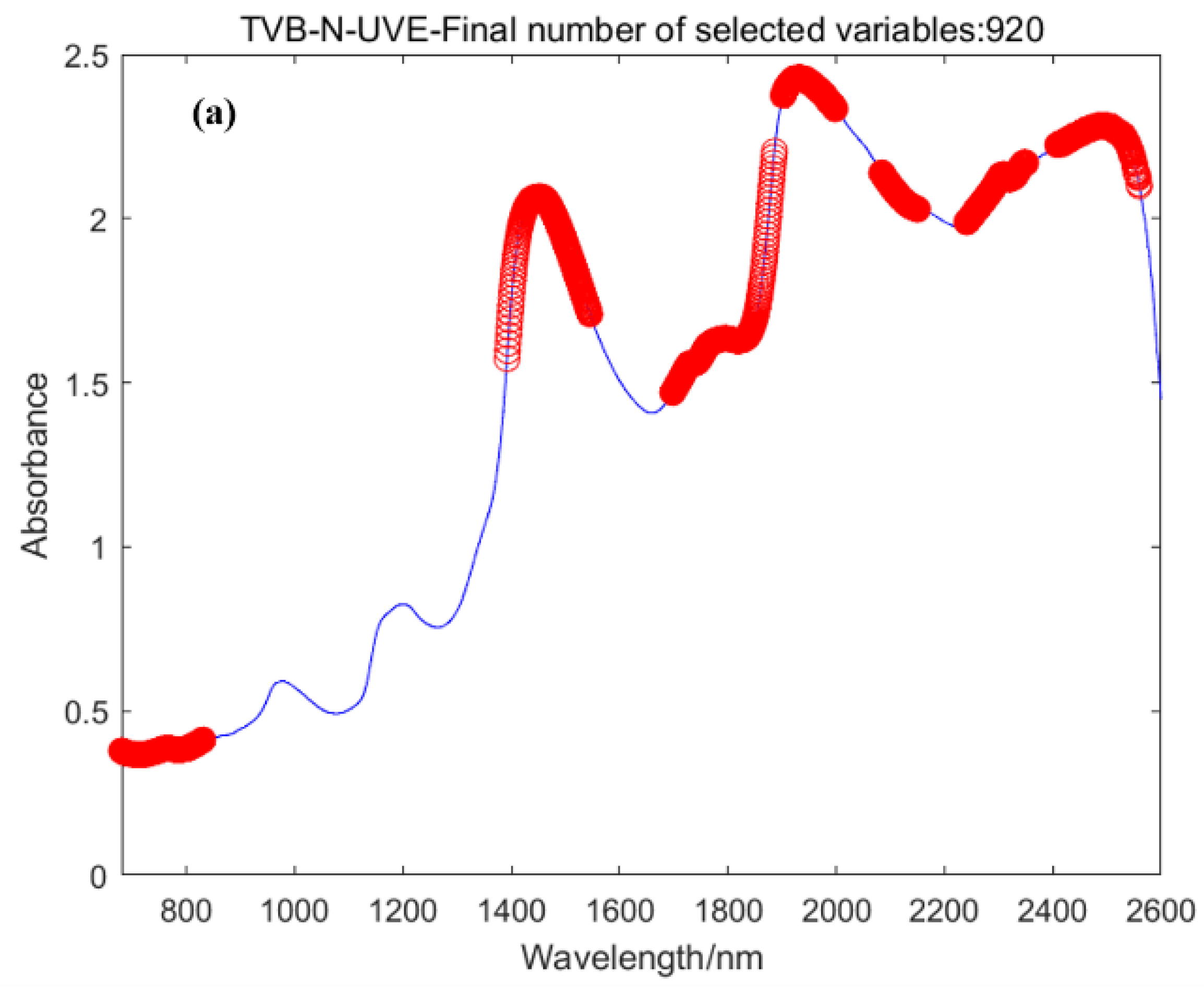

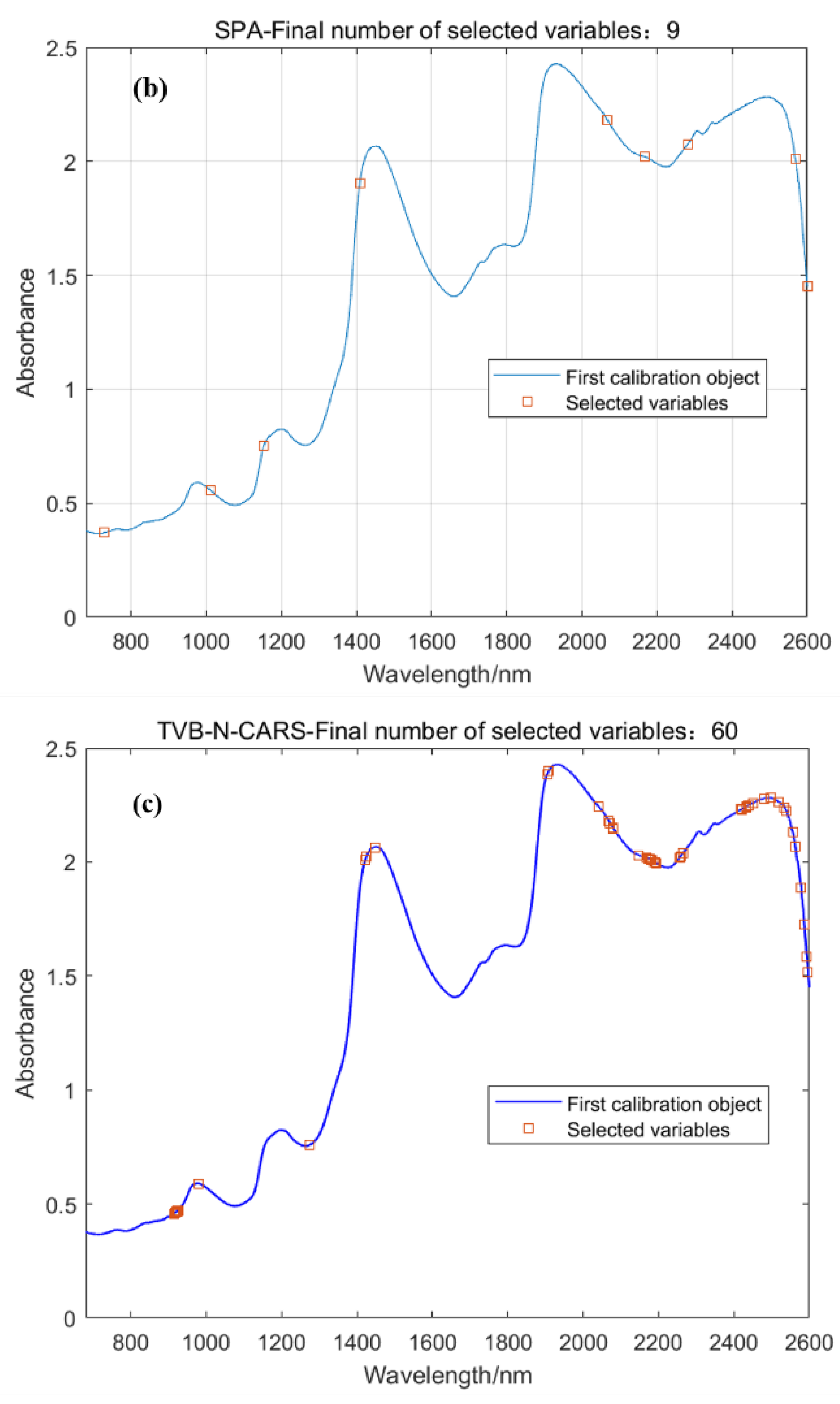

2.4.3. Selection of the Characteristic Wavelength

2.4.4. Division of the Sample Set

2.4.5. Model Construction

2.4.6. Reliability Verification of the Model

2.5. Software and Programs

3. Results and Discussion

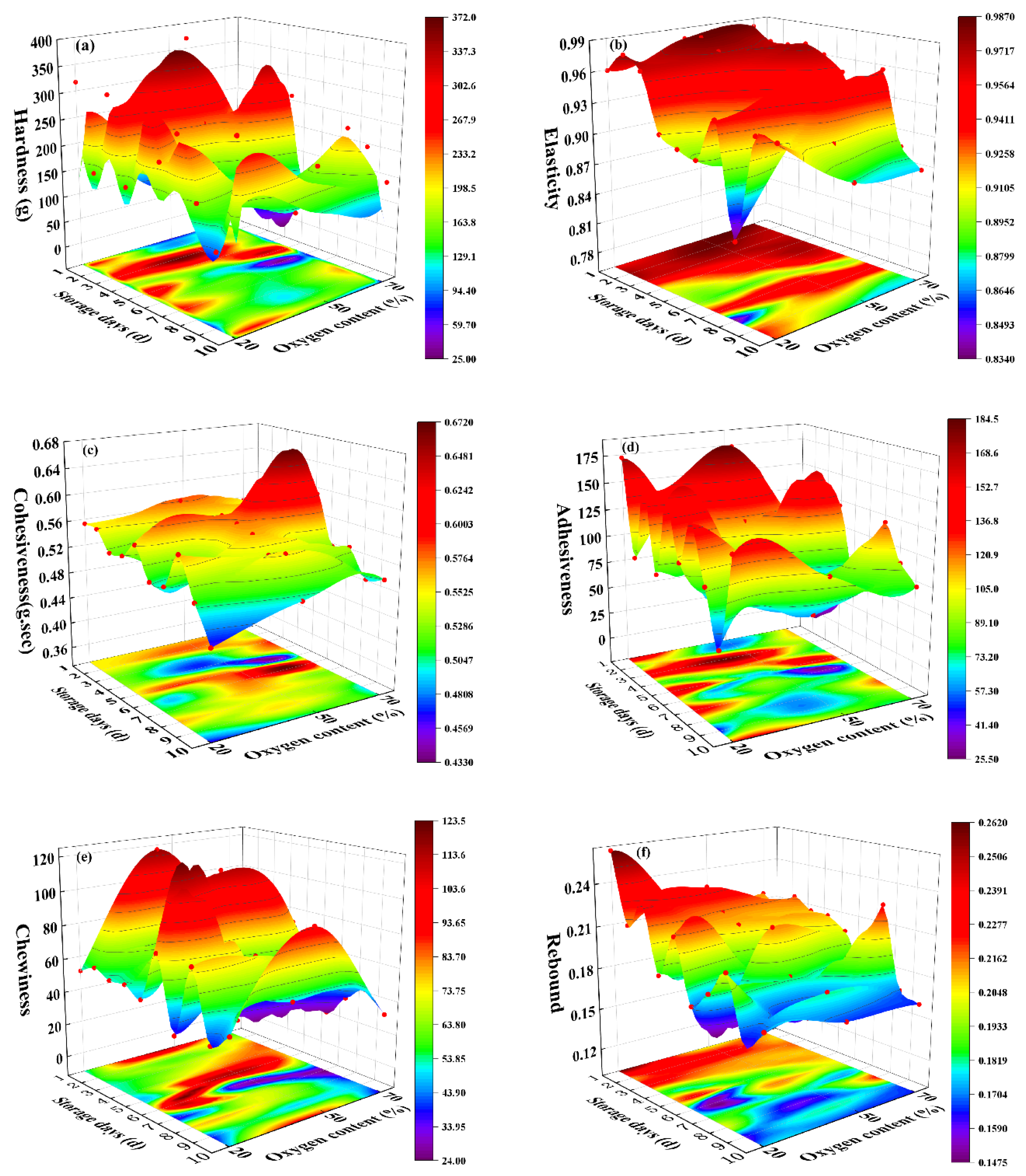

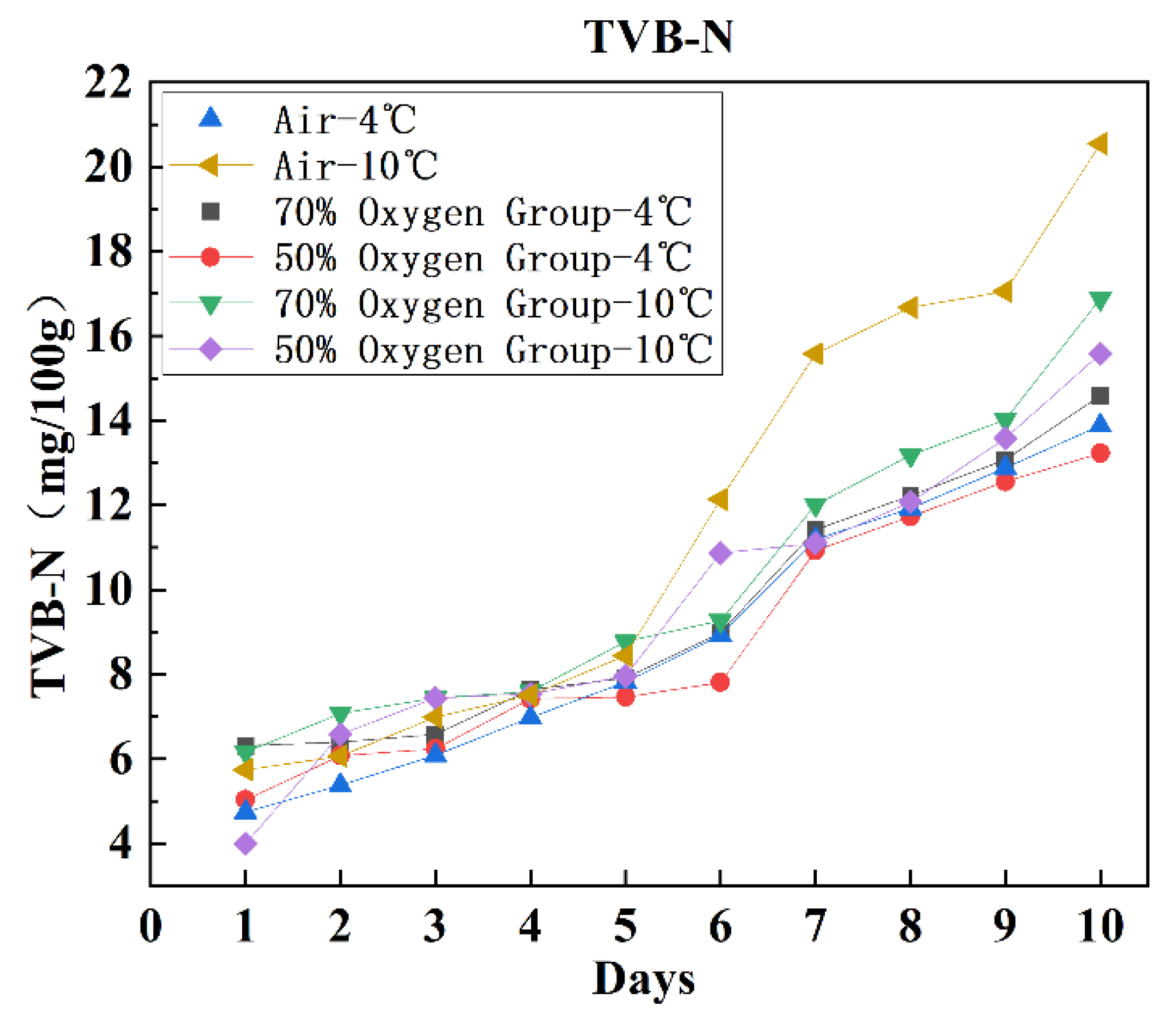

3.1. Textural Properties and TVB-N Value Analysis

3.2. Spectral Preprocessing Results

3.3. Results of Dividing the Sample Set

3.4. Feature Wavelength Selection Results

3.5. Prediction Modeling

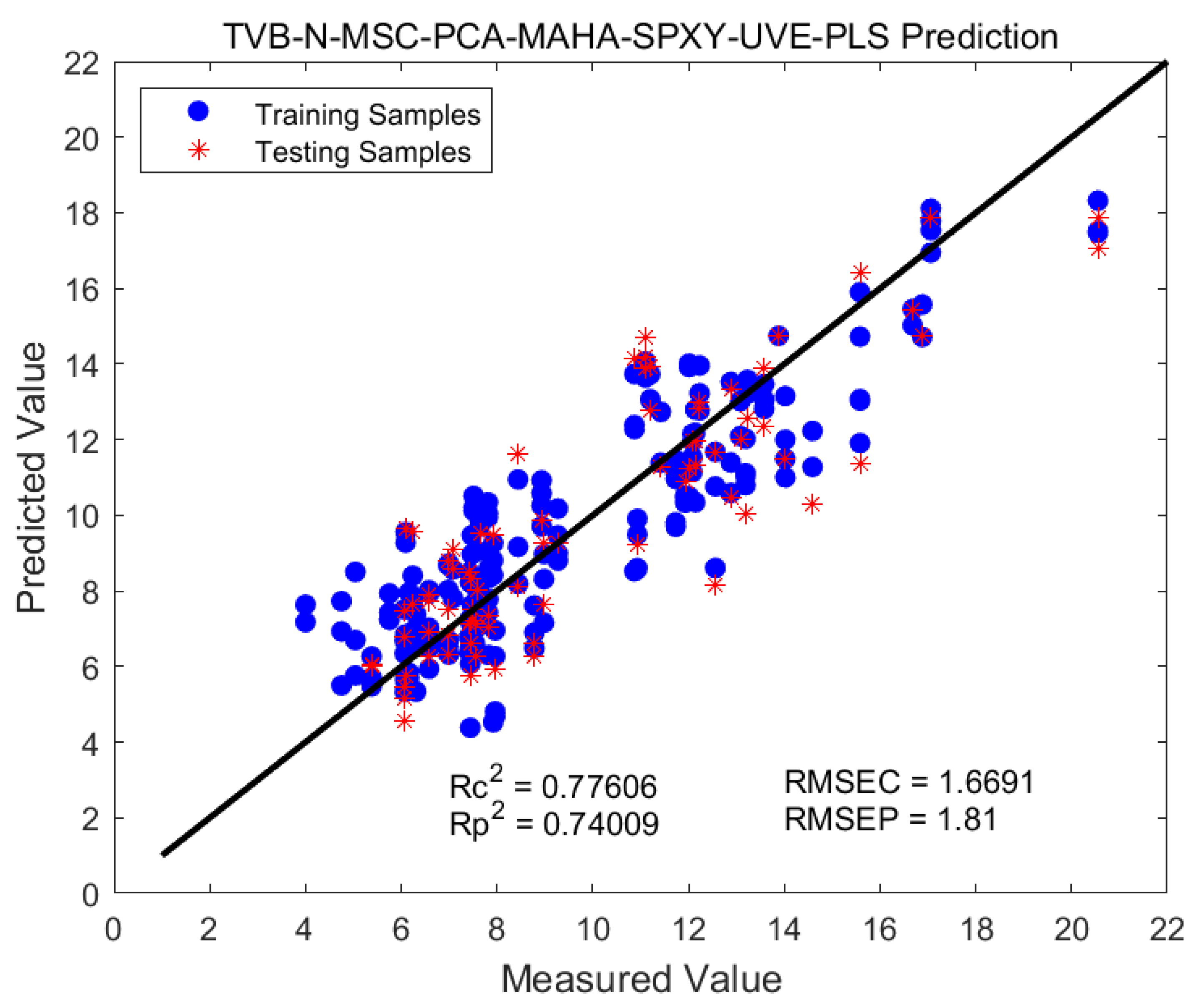

3.5.1. Results of PLS Model Based on Characteristic Waveform

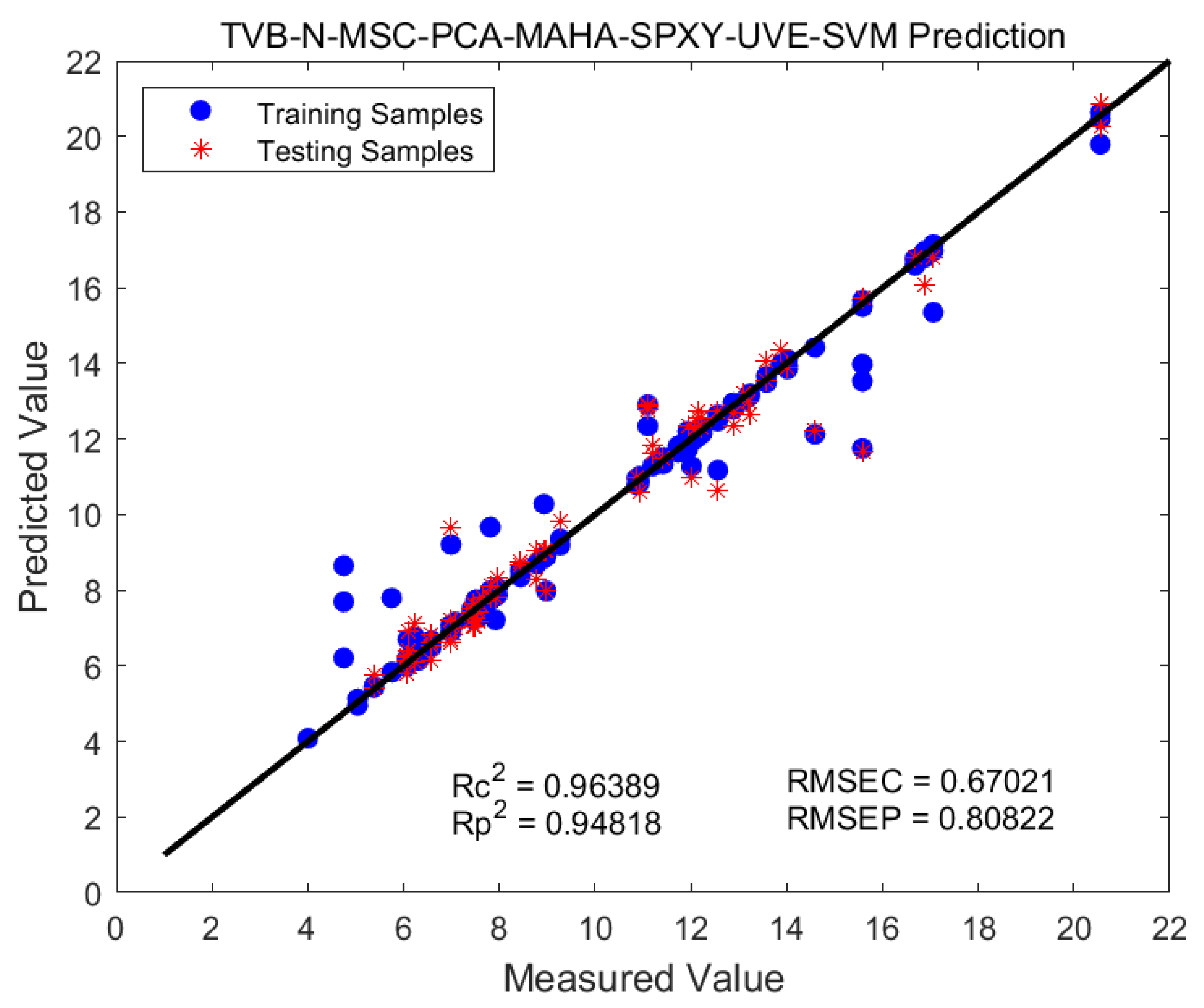

3.5.2. Results of the SVM Model Based on the Characteristic Waveform

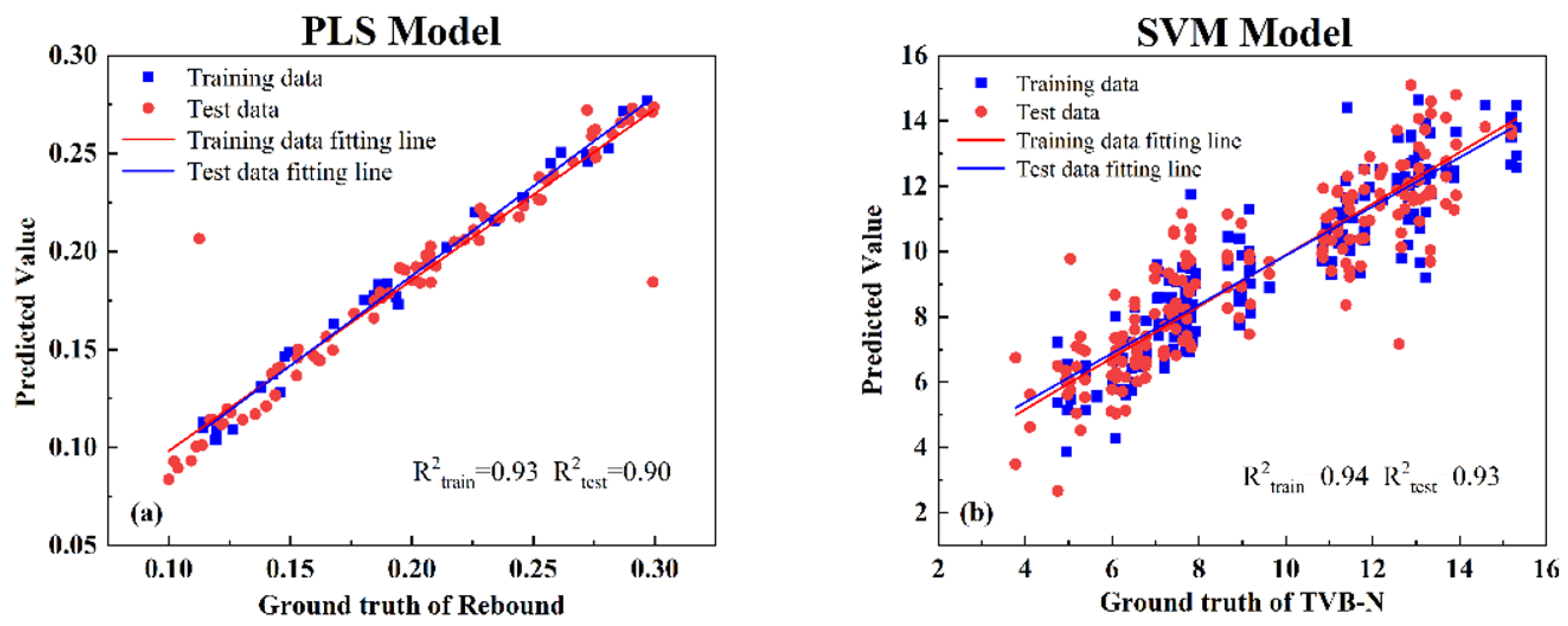

3.6. Comparison of PLS and SVM Models

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hoeksma, D.L.; Gerritzen, M.A.; Lokhorst, A.M.; Poortvliet, P.M. An extended theory of planned behavior to predict consumers’ willingness to buy mobile slaughter unit meat. Meat Sci. 2017, 128, 15–23. [Google Scholar] [CrossRef] [PubMed]

- Fiorentini, M.; Kinchla, A.J.; Nolden, A.A. Role of sensory evaluation in consumer acceptance of plant-based meat analogs and meat extenders: A scoping review. Foods 2020, 9, 1334. [Google Scholar] [CrossRef] [PubMed]

- Amaral, R.A.; Pinto, C.A.; Lima, V.; Tavares, J.; Martins, A.P.; Fidalgo, L.G.; Silva, A.M.; Gil, M.M.; Teixeira, P.; Barbosa, J.; et al. Chemical-Based methodologies to extend the shelf life of fresh fish—A review. Foods 2021, 10, 2300. [Google Scholar] [CrossRef] [PubMed]

- Osawa, C.C.; de Felício, P.E.; Gonçalves, L.A.G. Teste de TBA aplicado a carnes e derivados: Métodos tradicionais, modificados e alternativos. Química Nova 2005, 28, 655–663. [Google Scholar] [CrossRef]

- Hama, J.R.; Fitzsimmons-Thoss, V. Determination of unsaturated fatty acids composition in walnut (Juglans regia L.) oil using nmr spectroscopy. Food Anal. Methods 2022, 15, 1226–1236. [Google Scholar] [CrossRef]

- Cozzolino, D.; Murray, I. Identification of animal meat muscles by visible and near infrared reflectance speelroscopy. LWT Food Sci. Technol. 2004, 37, 447–452. [Google Scholar] [CrossRef]

- Gangidi, R.R.; Proctor, A.; Pohlman, F.W.; Meullenet, J.-F. Rapid determination of spinal cord content in ground beef by near-infrared spectroscopy. J. Food Sci. 2005, 70, c397–c400. [Google Scholar] [CrossRef]

- Wang, W.; Peng, Y.; Wang, F.; Sun, H. A portable nondestructive detection device of quality and nutritional parameters of meat using Vis/NIR spectroscopy. Sensing for Agriculture and Food Quality and Safety IX. SPIE 2017, 10217, 200–205. [Google Scholar]

- Leng, T.; Li, F.; Xiong, L.; Xiong, Q.; Zhu, M.; Chen, Y. Quantitative detection of binary and ternary adulteration of minced beef meat with pork and duck meat by NIR combined with chemometrics. Food Control. 2020, 113, 107203. [Google Scholar] [CrossRef]

- Zheng, X.; Li, Y.; Wei, W.; Peng, Y. Detection of adulteration with duck meat in minced lamb meat by using visible near-infrared hyperspectral imaging. Meat Sci. 2019, 149, 55–62. [Google Scholar] [CrossRef]

- Cheng, J.; Sun, J.; Yao, K.; Xu, M.; Dai, C. Multi-task convolutional neural network for simultaneous monitoring of lipid and protein oxidative damage in frozen-thawed pork using hyperspectral imaging. Meat Sci. 2023, 201, 109196. [Google Scholar] [CrossRef] [PubMed]

- He, H.J.; Wang, Y.; Ou, X.; Ma, H.; Liu, H.; Yan, J. Rapid determination of chemical compositions in chicken flesh by mining hyperspectral data. J. Food Compos. Anal. 2023, 116, 105069. [Google Scholar] [CrossRef]

- Chen, Y.F.; Li, Y.J.; Peng, M.M.; Yang, Y.J. Improvements of VIS-NIR Spectroscopy Model in the Prediction of TVB-N Using MIV Wavelength Selection. Spectrosc. Spectr. Anal. 2020, 40, 1413–1419. [Google Scholar]

- Deng, J.; Jiang, H.; Chen, Q. Characteristic wavelengths optimization improved the predictive performance of near-infrared spectroscopy models for determination of aflatoxin B1 in maize. J. Cereal Sci. 2022, 105, 103474. [Google Scholar] [CrossRef]

- Raghavendra, A.; Guru, D.; Rao, M.K. Mango internal defect detection based on optimal wavelength selection method using NIR spectroscopy. Artif. Intell. Agric. 2021, 5, 43–51. [Google Scholar] [CrossRef]

- Lei, T.; Sun, D.-W. A novel NIR spectral calibration method: Sparse coefficients wavelength selection and regression (SCWR). Anal. Chim. Acta 2020, 1110, 169–180. [Google Scholar] [CrossRef]

- Cheng, W.; Sørensen, K.M.; Engelsen, S.B.; Sun, D.-W.; Pu, H. Lipid oxidation degree of pork meat during frozen storage investigated by near-infrared hyperspectral imaging: Effect of ice crystal growth and distribution. J. Food Eng. 2019, 263, 311–319. [Google Scholar] [CrossRef]

- Cecchinato, A.; Pegolo, S.; Bittante, G. 379 ASAS-EAAP Talk: Precision Phenotyping using Infrared Spectroscopy to Improve the Quality of Animal Products. J. Anim. Sci. 2020, 98 (Suppl. S4), 140. [Google Scholar] [CrossRef]

- Cáceres-Nevado, J.; Garrido-Varo, A.; De Pedro-Sanz, E.; Tejerina-Barrado, D.; Pérez-Marín, D. Non-destructive Near Infrared Spectroscopy for the labelling of frozen Iberian pork loins. Meat Sci. 2021, 175, 108440. [Google Scholar] [CrossRef]

- Li, Q.; Wu, X.; Zheng, J.; Wu, B.; Jian, H.; Sun, C.; Tang, Y. Determination of Pork Meat Storage Time Using Near-Infrared Spectroscopy Combined with Fuzzy Clustering Algorithms. Foods 2022, 11, 2101. [Google Scholar] [CrossRef]

- Zhang, F.; Kang, T.; Sun, J.; Wang, J.; Zhao, W.; Gao, S.; Wang, W.; Ma, Q. Improving TVB-N prediction in pork using portable spectroscopy with just-in-time learning model updating method. Meat Sci. 2022, 188, 108801. [Google Scholar] [CrossRef] [PubMed]

- Lintvedt, T.A.; Andersen, P.V.; Afseth, N.K.; Heia, K.; Lindberg, S.-K.; Wold, J.P. Raman spectroscopy and NIR hyperspectral imaging for in-line estimation of fatty acid features in salmon fillets. Talanta 2023, 254, 124113. [Google Scholar] [CrossRef] [PubMed]

- Baracat, R.S.; Luchiari Filho, A.; Pereira, A.S.C.; Silva, S.L.; Cesar, A.S.M. Effects of modified atmosphere packaging in preserving portioned bovine meat. In Proceedings of the 42nd Annual Reunion of the Brazilian Society of Animal Science, Goiânia, Brazil, 2005. [Google Scholar]

- Yang, X.; Zhang, Y.; Zhu, L.; Han, M.; Gao, S.; Luo, X. Effect of packaging atmospheres on storage quality characteristics of heavily marbled beef longissimus steaks. Meat Sci. 2016, 117, 50–56. [Google Scholar] [CrossRef] [PubMed]

- de Paula Paseto Fernandes, R.; de Alvarenga Freire, M.T.; de Paula, E.S.M.; Kanashiro, A.L.S.; Catunda, F.A.P.; Rosa, A.F.; de Carvalho Balieiro, J.C.; Trindade, M.A. Stability of lamb loin stored under refrigeration and packed in different modified atmosphere packaging systems. Meat Sci. 2014, 96, 554–561. [Google Scholar] [CrossRef]

- Li, H.; Chen, Q.; Zhao, J.; Wu, M. Nondestructive detection of total volatile basic nitrogen (TVB-N) content in pork meat by integrating hyperspectral imaging and colorimetric sensor combined with a nonlinear data fusion. LWT Food Sci. Technol. 2015, 63, 268–274. [Google Scholar] [CrossRef]

- Xu, W.; He, Y.; Li, J.; Zhou, J.; Xu, E.; Wang, W.; Liu, D. Portable beef-freshness detection platform based on colorimetric sensor array technology and bionic algorithms for total volatile basic nitrogen (TVB-N) determination. Food Control 2023, 150. [Google Scholar] [CrossRef]

- Zhu, C.; Liu, Y.; Li, X.; Gong, W.; Guo, W. Detection Method of Freshness of Penaeus Vannamei Based on Hyperspectral. Spectrosc. Spectr. Anal. 2023, 43, 107–110. [Google Scholar]

- Zhang, J.; Ma, Y.; Liu, G.; Fan, N.; Li, Y.; Sun, Y. Rapid evaluation of texture parameters of Tan mutton using hyperspectral imaging with optimization algorithms. Food Control 2022, 135, 108815. [Google Scholar] [CrossRef]

- Rubio, B.; Vieira, C.; Martínez, B. Effect of post mortem temperatures and modified atmospheres packaging on shelf life of suckling lamb meat. LWT Food Sci. Technol. 2016, 69, 563–569. [Google Scholar] [CrossRef]

- You, M.; Liu, J.; Zhang, J.; Xv, M.; He, D. A novel chicken meat quality evaluation method based on color card localization and color cor-rection. IEEE Access 2020, 8, 170093–170100. [Google Scholar] [CrossRef]

- de Huidobro, F.R.; Miguel, E.; Blázquez, B.; Onega, E. A comparison between two methods (Warner–Bratzler and texture profile analysis) for testing either raw meat or cooked meat. Meat Sci. 2005, 69, 527–536. [Google Scholar] [CrossRef] [PubMed]

- Zhong, Y.; Liu, Y.; Xing, L.; Zhao, M.; Wu, W.; Wang, Q.; Ji, H.; Dong, J. Improving the quality of frozen lamb by microencapsulated apple polyphenols: Effects on cathepsin activity, texture, and protein oxidation stability. Foods 2022, 11, 537. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Tang, X.; Shen, Z.; Dong, J. Prediction of total volatile basic nitrogen (TVB-N) content of chilled beef for freshness evaluation by using viscoelasticity based on airflow and laser technique. Food Chem. 2019, 287, 126–132. [Google Scholar] [CrossRef] [PubMed]

- Li, J.H. National standards for food safety of meat foods. Meat Res. 2017, 31, 2–3. [Google Scholar]

- Karunasingha, D.S.K. Root mean square error or mean absolute error? Use their ratio as well. Inf. Sci. 2022, 585, 609–629. [Google Scholar] [CrossRef]

- Wang, J.; Wang, J.; Chen, Z.; Han, D. Development of multi-cultivar models for predicting the soluble solid content and firmness of European pear (Pyrus communis L.) using portable vis–NIR spectroscopy. Postharvest Biol. Technol. 2017, 129, 143–151. [Google Scholar] [CrossRef]

- Pematilleke, N.; Kaur, M.; Adhikari, B.; Torley, P.J. Relationship between masticatory variables and bolus characteristics of meat with different textures. J. Texture Stud. 2021, 52, 552–560. [Google Scholar] [CrossRef]

- Rinnan, Å.; van den Berg, F.; Engelsen, S.B. Review of the most common pre-processing techniques for near-infrared spectra. TrAC Trends Anal. Chem. 2009, 28, 1201–1222. [Google Scholar] [CrossRef]

- Xu, X.; Ren, M.; Cao, J.; Wu, Q.; Liu, P.; Lv, J. Spectroscopic diagnosis of zinc contaminated soils based on competitive adaptive reweighted sampling algorithm and an improved support vector machine. Spectrosc. Lett. 2019, 53, 86–99. [Google Scholar] [CrossRef]

- Soares, S.F.C.; Gomes, A.A.; Araujo, M.C.U.; Galvão Filho, A.R.; Galvão, R.K.H. The successive projections algorithm. TrAC Trends Anal. Chem. 2013, 42, 84–98. [Google Scholar] [CrossRef]

- Cai, W.; Li, Y.; Shao, X. A variable selection method based on uninformative variable elimination for multivariate calibration of near-infrared spectra. Chemom. Intell. Lab. Syst. 2008, 90, 188–194. [Google Scholar] [CrossRef]

- Saptoro, A.; Tadé, M.O.; Vuthaluru, H. A modified Kennard-Stone algorithm for optimal division of data for developing artificial neural network models. Chem. Prod. Process. Model. 2012, 7. [Google Scholar] [CrossRef]

- Tian, H.; Zhang, L.; Li, M.; Wang, Y.; Sheng, D.; Liu, J.; Wang, C. Weighted SPXY method for calibration set selection for composition analysis based on near-infrared spectroscopy. Infrared Phys. Technol. 2018, 95, 88–92. [Google Scholar] [CrossRef]

- Adedipe, O.E.; Johanningsmeier, S.D.; Truong, V.-D.; Yencho, G.C. Development and validation of a near-infrared spectroscopy method for the prediction of acrylamide content in french-fried potato. J. Agric. Food Chem. 2016, 64, 1850–1860. [Google Scholar] [CrossRef]

- Li, X.; Zhang, Y.; Cui, H.; Shen, T. Analysis of Near Infrared Spectra of Apple Soluble Solids Content Based on BP Neural Net-work. In Proceedings of the 2018 37th Chinese Control Conference (CCC); IEEE: Piscataway, NY, USA, 2018; pp. 8008–8012. [Google Scholar]

- Chen, H.; Zhang, Y.; Qi, H.; Li, D. Detection of ethanol content in ethanol diesel based on PLS and multispectral method. Optik 2019, 195, 162861. [Google Scholar] [CrossRef]

- Bo, D. An algorithm of image matching based on mahalanobis distance and weighted KNN graph. In Proceedings of the 2015 2nd International Conference on Information Science and Control Engineering, Shanghai, China, 24–26 April 2015; pp. 116–121. [Google Scholar]

| Group | Temperature (°C) | O2 (%) | CO2 (%) | N2 (%) |

|---|---|---|---|---|

| A | 4 | 70 | 20 | 10 |

| B | 4 | 50 | 40 | 10 |

| C | 4 | Air | Air | Air |

| D | 10 | 70 | 20 | 10 |

| E | 10 | 50 | 40 | 10 |

| F | 10 | Air | Air | Air |

| Preprocessing Methods | Number of Abnormal Rejection Samples |

|---|---|

| MSC * | 29 |

| SNV | 28 |

| Nor | 15 |

| SG | 111 |

| SG-1st | 109 |

| SG-2nd | 7 |

| Classification Method | Number of Principal Components | Training Set | Prediction Set | ||

|---|---|---|---|---|---|

| R2c * | RMSEC | R2p | RMSEP | ||

| Random division | 10 | 0.7706 | 1.6311 | 0.7199 | 2.0226 |

| 10 | 0.7835 | 1.6952 | 0.6581 | 1.8747 | |

| 8 | 0.7161 | 1.8673 | 0.7185 | 1.9128 | |

| 10 | 0.7188 | 1.5935 | 0.7139 | 1.9707 | |

| 10 | 0.8104 | 1.5934 | 0.5797 | 2.0873 | |

| KS | 10 | 0.7029 | 1.7040 | 0.6257 | 1.8912 |

| SPXY | 9 | 0.6552 | 1.8733 | 0.6257 | 1.7972 |

| Physical and Chemical Indicators | Preprocessing Methods | Number of Principal Components | Training Set Results | Prediction Set Results | ||||

|---|---|---|---|---|---|---|---|---|

| R2c * | RMSEC | R2p | RMSEP | LOD | LOQ | |||

| Rebound | None | 10 | 0.63 | 1.03 | 0.46 | 1.26 | 56.99 | 130.85 |

| SG-2nd | 9 | 0.90 | 0.06 | 0.886 | 0.07 | 120.82 | 370.83 | |

| SG-2nd-CARS | 9 | 0.93 | 0.05 | 0.91 | 0.06 | 12.81 | 45.36 | |

| SG-2nd-UVE | 8 | 0.94 | 0.05 | 0.91 | 0.06 | 13.56 | 47.42 | |

| SG-2nd-SPA | 7 | 0.95 | 0.04 | 0.94 | 0.05 | 15.93 | 53.65 | |

| TVB-N | None | 10 | 0.63 | 1.03 | 0.45 | 1.38 | 10.69 | 33.54 |

| MSC | 9 | 0.65 | 1.87 | 0.63 | 1.79 | 46.99 | 120.36 | |

| MSC-CARS | 9 | 0.78 | 1.64 | 0.73 | 1.82 | 46.98 | 140.94 | |

| MSC-UVE | 10 | 0.78 | 1.66 | 0.74 | 1.81 | 126.45 | 374.65 | |

| MSC-SPA | 9 | 0.71 | 1.89 | 0.72 | 1.89 | 13.26 | 80.83 | |

| Physical and Chemical Indicators | Preprocessing Methods | Wave Length Point | Training Set Results | Prediction Set Results | ||||

|---|---|---|---|---|---|---|---|---|

| R2c * | RMSEC | R2p | RMSEP | LOD | LOQ | |||

| Rebound | None | 1921 | 0.60 | 0.14 | 0.58 | 0.16 | 13.67 | 35.62 |

| SG-2nd | 1921 | 0.86 | 0.07 | 0.83 | 0.08 | 46.96 | 130.25 | |

| SG-2nd-CARS | 87 | 0.90 | 0.06 | 0.86 | 0.07 | 33.87 | 101.60 | |

| SG-2nd-UVE | 1034 | 0.91 | 0.05 | 0.87 | 0.07 | 27.20 | 81.61 | |

| SG-2nd-SPA | 14 | 0.94 | 0.05 | 0.90 | 0.06 | 37.18 | 111.54 | |

| TVB-N | None | 1921 | 0.70 | 0.92 | 0.59 | 1.19 | 27.70 | 86.16 |

| MSC | 1921 | 0.94 | 0.12 | 0.93 | 0.75 | 276.56 | 812.62 | |

| MSC-CARS | 60 | 0.92 | 0.98 | 0.88 | 1.22 | 16.36 | 46.98 | |

| MSC-UVE | 920 | 0.96 | 0.67 | 0.95 | 0.80 | 16.35 | 49.38 | |

| MSC-SPA | 9 | 0.89 | 1.16 | 0.87 | 1.28 | 120.34 | 315.32 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, P.; Fu, Y.; Niu, R.; Zhang, Q.; Zhang, M.; Li, Z.; Zhang, X. Non-Destructive Detection of the Freshness of Air-Modified Mutton Based on Near-Infrared Spectroscopy. Foods 2023, 12, 2756. https://doi.org/10.3390/foods12142756

Jin P, Fu Y, Niu R, Zhang Q, Zhang M, Li Z, Zhang X. Non-Destructive Detection of the Freshness of Air-Modified Mutton Based on Near-Infrared Spectroscopy. Foods. 2023; 12(14):2756. https://doi.org/10.3390/foods12142756

Chicago/Turabian StyleJin, Peilin, Yifan Fu, Renzhong Niu, Qi Zhang, Mingyue Zhang, Zhigang Li, and Xiaoshuan Zhang. 2023. "Non-Destructive Detection of the Freshness of Air-Modified Mutton Based on Near-Infrared Spectroscopy" Foods 12, no. 14: 2756. https://doi.org/10.3390/foods12142756

APA StyleJin, P., Fu, Y., Niu, R., Zhang, Q., Zhang, M., Li, Z., & Zhang, X. (2023). Non-Destructive Detection of the Freshness of Air-Modified Mutton Based on Near-Infrared Spectroscopy. Foods, 12(14), 2756. https://doi.org/10.3390/foods12142756