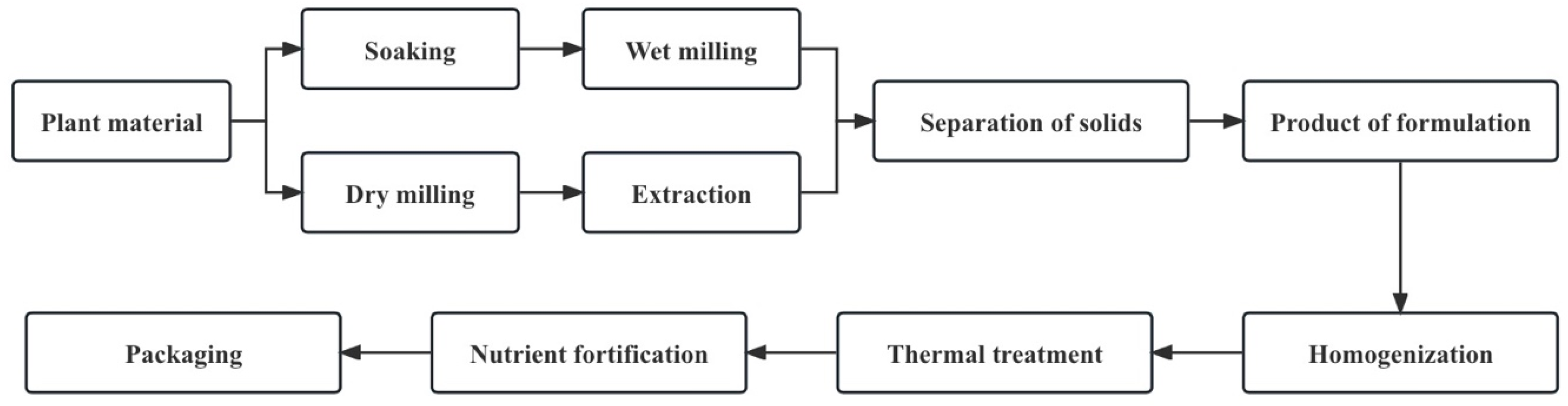

A plant-based drink is a colloidal suspension or emulsion consisting of dissolved and decomposed plant material [

7]. Although the exact processes vary, the same general outline applies to all plant-based drink processing methods (

Figure 2). Water extraction of plant-based drinks can be divided into two types: dry processes (the dry milling of raw materials and the extraction of flour from water) and wet processes (the soaking and wet milling of plant sources) [

1].

6.1. Pre-Treatment

Before making plant-based drinks, some pretreatment of raw materials may be required, including soaking, blanching, steaming, and baking. The purpose of pretreatment is to enhance extraction, increase nutritional quality, enhance organoleptic characteristics, and eliminate off-odors [

6,

16].

Soaking is an important pretreatment process in the production of plant-based drinks. The main purpose of soaking is to promote softening and expansion of raw materials including grains and nuts, and to facilitate the breaking of raw materials during the grinding process [

103]. This process reduces resistance to mechanical grinding and fully hydrates proteins, rendering them easier to leach and thereby increasing the extraction rate. Soaking also helps reduce the initial microbial load, eliminate off-odors, improve organoleptic properties, and enhance nutritional value [

77]. Some raw materials, including cowpeas, cashews, soybeans, oats, and sesame seeds, usually need to be soaked in water for 3–18 h. Some raw materials, including soybeans, peanuts, and tiger nuts, can be soaked in alkaline solutions with 0.2–2% NaHCO3 at ratios ranging from 1:2 to 1:12 to eliminate nutty or beany flavors [

7,

14,

104,

105].

Starch in raw materials is gelatinized during steaming or baking, and the peculiar smell of the raw plant materials can be effectively controlled. This process can remove heat-sensitive anti-nutritional factors and toxic and harmful substances (such as cyanogenic glycosides) from raw materials, as well as partially inactivate enzymes. In addition, Maillard and other reactions can occur during baking, which can change plant material flavors and impact aroma development [

106,

107]. Heating can also reduce protein solubility and extraction rates [

108].

6.2. Extraction

To improve the yield, extraction efficiency can be increased by increasing the temperature, adding enzymes, fermenting, germinating, or increasing the pH (using NaOH or bicarbonate). During the extraction process, an alkaline medium is used to increase the protein yield. Higher extraction temperatures also increase fat extraction, although protein denaturation reduces fat solubility and yield [

1].

Microwaves, such as ultra-high-frequency electromagnetic waves, promote high-frequency reciprocating dipole moments, generating “internal frictional heat”, which is absorbed by food and water to generate heat [

109]. It can realize simultaneous heating and temperature increase without fast and uniform heat conduction, and energy consumption is a small fraction of that required in traditional heating [

110]. Compared to the steam injection extraction method, microwave-assisted extraction can significantly improve the extraction yield of plant-based drinks, including protein content, total soluble solids, and protein solubility. It completely destroys plant cell and subcellular structure integrity, promoting the release of proteins, lipids, and other soluble solids [

111]. Microwave-assisted extraction can also help remove safety risk factors, including cyanogenic glycosides, facilitate aroma enhancement through Maillard reactions, and passivate endogenous oxidases in raw plant materials, to improve the oxidative stability of plant-based drinks [

112].

6.3. Enzymatic Processing

Enzymolysis technology functions under mild reaction conditions and exhibits low energy consumption, high efficiency, and low solvent consumption, promoting the release of intracellular compounds, increasing soluble sugar and protein contents, and improving product biological activity, thereby improving the stability and sensory qualities of plant-based drinks [

113]. Enzymatic hydrolysis is a key step in promoting nutrient dissolution during plant-based drink production. Carbohydrases and proteases are widely used in plant-based food processing [

114]. Carbohydrases hydrolyze glycosidic bonds in plant cell wall layers, promoting the breakdown of insoluble fibers, generating low-molecular-weight sugars, and releasing proteins and other intracellular compounds [

115]. For example, cellulase hydrolyzes primary cell walls, whereas pectinase hydrolyzes secondary cell walls [

116]. The disruption of the network structure of plant cell wall components via pectinase increases the release rate of proteins and fats into cereal beverages. Second, enzymatic hydrolysis can improve the stability and flavor of plant-based drinks. Carbohydrase treatment (1.2% Celluclast 1.5 L, 3 h) improves the physical stability of soybean drinks during storage and ameliorates bean flavor [

117]. It is generally believed that proteolysis will release low-molecular-weight peptides, resulting in bitter taste, but when Sahoo et al. immobilized two non-commercial proteases derived from sunflower seeds, added them to soybean drink, and incubated them at 30 °C for 1 h, they found that the beany smell decreased and the pleasant smell increased [

118]. Low-molecular-weight peptides produced after proteolysis are primarily composed of hydrophobic amino acids. Hydrophobicity, primary sequence, spatial structure, peptide chain length, and molecular size are all determinants of peptide bitterness. Therefore, specific proteolysis is required to prevent bitterness in plant-based drinks [

114]. Enzymatic hydrolysis can also enhance biological activities in plant-based products because this technology can degrade macromolecular substances into smaller molecular compounds with higher biological activity and increase the release of bioactive components (polyphenols, flavonoids, etc.). For example, after protease treatment of soybean drinks and flaxseed protein, hydrolysate showed antioxidant, anti-inflammatory, anti-obesity, and immunomodulatory activities [

119]. Additionally, because phenolic compounds in plant materials may form protein–phenolic complexes with globular proteins through hydrophobic interactions and hydrogen bonds, the release of total phenols increases after proteolysis of sesame seed extracts [

120].

6.4. Fermentation

The production of plant-based drinks using microbial fermentation generally involves mixed-culture fermentation using two or more microbial strains to enhance the fermentation effect and improve the quality of the final product [

82]. Lactic acid bacteria, bacilli, and yeasts are the most widely used microorganisms for this purpose [

121]. Fermentation can improve plant-based drink flavors by reducing undesirable odors or by creating pleasant aromas. After peanut drink fermentation, the beany flavor was mitigated by the reduction of n-hexanal and n-hexanol, and diacetyl and 2,3-butanedione, with a butterscotch aroma, were produced during fermentation [

114]. Fermentation can also improve the nutritional value of plant-based drinks by increasing nutrient content, improving nutrient bioavailability, and removing antinutritional factors [

122]. Fermentation can increase protein and vitamin contents [

82] as well as improve calcium and vitamin bioavailability. Significant increases in crude protein content and B vitamins, such as riboflavin and thiamine, have been observed in soybean drinks fermented with bifidobacteria [

123]. Additionally, vitamins (including vitamins B and K) are produced during the fermentation process. Yeast fermentation promotes vitamin B2 production [

82]. In addition, since lactic acid bacteria can produce phytase to catalyze the hydrolysis of phytate into inositol and phosphate, fermentation technology has the potential to reduce the content of anti-nutritional factors in raw plant materials and increase their utilization of minerals [

124]. Fermentation also enhances biological activities in plant-based drinks. Fermentation of almond drinks using lactic acid bacteria increases the content of phenolic compounds, conferring higher antioxidant capacity [

125]. Soybeans fermented using lactic acid bacteria can produce bioactive peptides that inhibit angiotensin-converting enzymes and display antihypertensive effects [

126]; β-glucosidase produced via lactic acid bacteria during fermentation can convert conjugated isoflavones in soy drinks into more bioactive glucoside ketones [

127,

128].

6.5. Germination

Germination is a common method for releasing the nutrients and phytonutrients of plant-based drinks, making them more readily available to digestive enzymes [

129]. Sprouted grains are more nutritious than raw grains, and rich in digestible energy, bioavailable vitamins, minerals, amino acids, proteins, and phytochemicals [

130]. Germination promotes the enzymatic decomposition of carbohydrates into simple sugars by activating endogenous enzymes such as α-amylase, thereby increasing the digestibility of starch degradation and providing energy for seed development [

131]. The effect of sprouting on carbohydrates is largely dependent on the activation of hydrolytic and amylolytic enzymes, resulting in a reduction in starch and an increase in simple sugars [

131]. The duration of the process is an important factor. When the amylase activity is at its maximum, the maximum hydrolysis time of starch is 48 to 72 h [

132]. Studies have shown that after germination, the phenolic activity and antioxidant activity of millet drink increased by 92 ± 1.99 and 33.42 ± 0.55%, respectively. The amalgamation of sonication with germination reduced the average antinutrient concentration to 23.31 ± 0.36% [

133]. The germination process enhances the functional properties of plant-based drinks. The application of germination processes combined with other technologies would be a potential processing technique to acquire nutritious plant-based drinks.

6.8. Homogenization

Plant-based drinks contain insoluble particles including proteins, starches, fibers, and other cellular materials. These particles are denser than water and, therefore, settle, making the product unstable. Suspension stability can be improved by reducing particle size to increase solubility, or by using hydrocolloids and emulsifiers. Homogenization improves plant-based drink stability by breaking up aggregates and lipid droplets, thereby reducing particle size and increasing their distribution [

16]. Mechanical devices used for homogenizing raw materials include high-shear mixers, colloid mills, high-pressure valve homogenizers, and microfluidizers [

1].

Ultra-high-pressure homogenization (UHPH) is a common homogenization method used in food processing [

135] that is widely used with plant-based drinks. UHPH can significantly improve the physical stability of almond and soy drinks and extend their shelf lives [

136]. It offers significant advantages, including the effective inactivation of microorganisms, the retention of micronutrients, green energy saving, and uniform processing [

137,

138]. In UHPH, the liquid sample is subjected to shear force and cavitation explosion force in the cavity of the homogenizer to produce high-speed fluid impact and vortex action. The structure within the liquid sample is destroyed, and particles within the emulsion become smaller, allowing a more stable suspension, thereby effectively improving the stability of plant-based drinks [

139]. Because high pressures can damage microorganisms, UHPH treatment can inhibit the growth of harmful microorganisms and achieve sterilization [

126]. Compared with UHT treatment, soybean drinks treated with UHPH (300 MPa, 80 °C) have higher colloidal stability, a stable primary oxidation level, and a significantly lower hexanal value, and can be stored at room temperature for up to 6 months [

140]. Both 200 and 300 MPa UHPH reduce the number of spores and Enterobacteriaceae and reduce particle size in plant-based drinks. At 200 MPa, soy drink proteins are partially denatured, whereas at 300 MPa, the degree of denaturation is the same as that observed after UHT treatment [

126]. After UHPH treatment, the product has a longer shelf life and better quality characteristics. It is, thus, expected to replace heat treatment in the production of plant-based drinks. UHPH equipment must be combined with sterile filling, requiring strict production equipment monitoring and process control procedures.

6.9. Heat Treatment

Heat treatment is applied to kill bacteria and thereby extend shelf life by reducing microorganism numbers and inactivating enzymes [

141]. An appropriate combination of time and temperature can ensure the destruction of microorganisms and enzymes in plant-based drinks while avoiding the aggregation of oil-coated droplets at high temperatures [

142]. Plant-based drinks usually undergo pasteurization, ultra-high-temperature instantaneous sterilization, high-temperature high-pressure sterilization, or other methods to extend shelf life, but high temperatures can cause changes in the structure and physical and chemical properties of plant-based drinks. In particular, the denaturation of proteins and polysaccharides in a stable solution will destabilize the system, and heating of starch in a system will significantly increase viscosity, which may also negatively impact the quality of plant-based drinks [

143,

144]. Therefore, the use of new food processing technologies, including pulsed electric fields, to extend shelf life is recommended [

108]. The use of emerging food processing techniques, including pulsed electric fields and ohmic heating, has been proposed to prolong the shelf life of plant-based drinks [

1].

Pulsed electric field (PEF) is a non-thermal food sterilization technique that exposes samples to pulses of high pressure at temperatures in the range of 30–40 °C [

145]. The application of high-intensity PEF (10–80 kV/cm) causes electroporation to increase the permeability of microbial cell membranes, eventually leading to cell damage or death [

146]. PEF can inactivate endogenous food enzymes and kill microorganisms, but exerts a less negative impact on food nutrition, texture, taste, and color [

147,

148]. It is mainly suitable for liquid foods with low conductivity and low viscosity, and has been gradually applied to an increasing number of liquid products, including plant-based drinks, to extend their shelf life [

45]. The application of PEF to soy drinks can effectively inactivate Escherichia coli and Staphylococcus aureus without affecting soy drink quality characteristics. This technology may, thus, be a favorable alternative to heat treatment for soy drink pasteurization [

149]. PEF treatment and parameter optimization (treatment time, pulse intensity, pulse frequency, and pulse width) also affect enzyme inactivation. Studies have shown that soybean lipoxygenase activity decreases with increasing treatment time, pulse intensity, pulse frequency, and pulse width, and stronger treatment parameters result in a higher degree of soybean lipoxygenase inactivation. The maximum inactivation of soybean lipoxygenase via PEF was 88% at 42 kV/cm (duration, 1036 μs; pulse frequency, 400 Hz; pulse width, 2 μs; temperature, 25 °C) [

150]. Additionally, studies have revealed that pulse type and treatment (soaking or cooking) have significant effects (

p < 0.0001) on soybean trypsin inhibitory activity, and the interactive effect of pulse type-by-treatment was also significant (

p < 0.0001) [

151]. While PEF does not inactivate spores, it can be inactivated by adding organic acids or nisin, adjusting pH, and other methods. Currently, the industrialization of this technology faces certain limitations, including the high cost and limited development of industrial PEF equipment [

152].

Ohmic heating is an advanced heat treatment technology that uses a low-frequency electric current to heat food, which can kill spoilage microorganisms and prolong shelf life [

153]. When a 50–60 Hz electric current is applied to the food matrix, electrical energy is transported through the resistive medium to promote ion recombination and increase the molecular motion speed to facilitate the release of thermal energy [

110]. Ohmic heating can extend the retention of heat-sensitive components, increase production and energy efficiency, and heat quickly and uniformly. Electric field strength, temperature, and time all influence the post-treatment effect [

154]. Saxena et al. studied the effect of ohmic heating on polyphenol oxidase activity in sugarcane beverages under three electric field intensities (24, 32, and 48 V/cm) and four temperatures (60–90 °C) with a treatment time of 5–20 min. At 60 °C, polyphenol oxidase activity decreased with increasing electric field strength, while at 70–90 °C, an increase in enzyme activity was observed at 32 and 48 V/cm [

155]. This technology has also been used in the production of soybean drinks, where it reduces the beany smell and reduces the activity of endogenous trypsin and chymotrypsin inhibitors due to combined electrochemical and thermal effects [

156,

157]. Studies have shown that ohmic heating (220 V, 50 Hz) for periods over 3 min efficiently inactivates TI when compared to induction cooker or electric stove methods over 3 min. The residual trypsin inhibitory activity was 13% (ohmic heating), which is significantly lower compared to 19% using an induction cooker and an electric stove [

157]. Additionally, lipoxygenase inactivation followed first-order kinetics during ohmic heating and conventional heating. However, a significant variation in rate constants was observed. Studies have shown that the electric field has an additional effect on lipoxygenase inactivation, with approximately 5 times lower D values. This means that for the same inactivation degree, the time required for thermal treatment is much lower when an ohmic heating process is applied, thus reducing negative thermal effects on the other food components [

158]. To date, risks including “cold spots” caused by uneven resistivity remain, complicating the industrial application of this process [

159]. The selection of electrode materials is a very important factor when considering the industrial application of ohmic heating. An electrode can be designed for specific ohmic heating conditions only, as the electro-chemical interactions of food and electrode may depend on the electric field strength as well as the frequency and type of wave. The composition of food material is also a challenge for food processors while considering ohmic heating because different types of plant-based drinks may contain different components with different properties, e.g., electrical conductivity. The ohmic heating behavior of the food material in such cases becomes complex, and may lead to the underheating of components with low electrical conductivity or vice versa [

160].

6.10. Packaging and Shelf Life

Plant-based drinks are packaged as needed for storage and distribution after processing, usually in plastic bottles or carton systems [

1]. Plant-based drinks can also be drum-dried or spray-dried to produce stable powders that can be reconstituted into the desired product [

161,

162]. However, liquid plant-based drinks must be stabilized before drying to obtain a stable product [

163]. For example, a calcium-fortified soy drink (200 mg/100 g) was formulated by adding water (85–90 °C), full-fat soy flour (10%), sucrose (2.75%), and soy protein isolate (2.25%). Following homogenization, the blend was twice clarified and pasteurized at 65 °C/30 min before refrigeration. The samples of the soy drink (45 °C) were adjusted to a pH of 8 before adding calcium lactogluconate (1.55%) and potassium citrate (1.25%). For successful calcium fortification, it is recommended to maintain a calcium-to-protein ratio < 38 mg/g and to use an appropriate sequestering agent at a molar ratio of 0.8/mole calcium [

164].

Plant-based drinks are rich in nutrients and are an ideal medium for microbial growth. Therefore, their quality will be adversely affected by the rapid growth of microorganisms. Heat treatment has been used to extend the shelf life of plant-based drinks while increasing the total solid output and improving the flavor. Overheating will adversely affect the development of nutrients (vitamins and amino acids), browning, and the development of cooked flavors [

165]. In order to eliminate or reduce the destructive impact on plant-based drinks, various time and temperature combinations have been practiced to obtain the best quality products. Different heat treatments, such as pasteurization (heating to below 100 °C to destroy pathogenic microorganisms), container sterilization (121 °C for 15–20 min to achieve commercial sterility), and ultra-high-temperature treatment (at high temperatures of 135–150 °C for several seconds) have been widely studied [

166]. Ultra-high-temperature treatment involves direct heating methods, including steam injection, or indirect heating in plate or tube heat exchangers. After any of the above treatments, packaging needs to be carried out under sterile conditions to maintain sterility. After pasteurization, plant-based drinks need to be stored under refrigerated conditions, while after sterilization in a container or ultra-high-temperature sterilization treatment, the plant-based drinks can be stored at room temperature for several weeks [

7]. The effect of pasteurization on soybean drinks has been studied, and the results showed that pasteurized soybean drinks can be stored for 3 days after being heated at 60 °C for 30 min without obvious deterioration, and sterilized soybean drinks can be stored for 1 year after being heat treated at 120 °C for 5 min [

167]. Heat treatment is widely applied to extend the shelf life of plant-based drinks, such as soybean drinks and peanut drinks. However, the existence of medium and high starch concentrations in oat drinks and rice drinks restricts their application [

7]. Therefore, these types of plant-based drinks need to apply non-heat treatment technology to extend their shelf life. Some non-heat treatment technologies, including high-pressure throttling, ultra-high-pressure homogenization (UHPH), and high-pressure processing, have been studied to extend the shelf life of plant-based drinks [

126,

168,

169,

170]. The effect of ultra-high-pressure homogenization combined with heat treatment on the microbial stability of almond drinks has been studied. The microbiological analysis, physical stability, and chemical analysis results showed that when comparing UHPH treatment with pasteurization and UHT treatment, the product quality was higher compared to samples treated with pasteurization or UHT. After incubation at 30 °C for 20 days at a pressure of 300 MPa, a temperature of 65 and/or 75 °C, and a holding time of less than 0.7 s, the product showed no bacterial growth [

171]. These results show the potential of non-heat treatment for extending the shelf life of plant-based drinks. However, the antiseptic effects and mechanisms of pulsed electric fields and other non-thermal technologies, such as pulsed light and ultrasound, on different types of plant-based drinks need to be further explored.