Short-Term Hermetic Storage of Wet Maize and Its Effect on Quality

Abstract

:1. Introduction

2. Material and Methods

2.1. Grain Sample Preparation

2.2. Experimental Setup and Gas Monitoring

2.3. Data Collection on Maize Samples

2.3.1. Germination and Seedling Growth Assessment

2.3.2. Moisture Content (m.c.)

2.3.3. pH Measurement

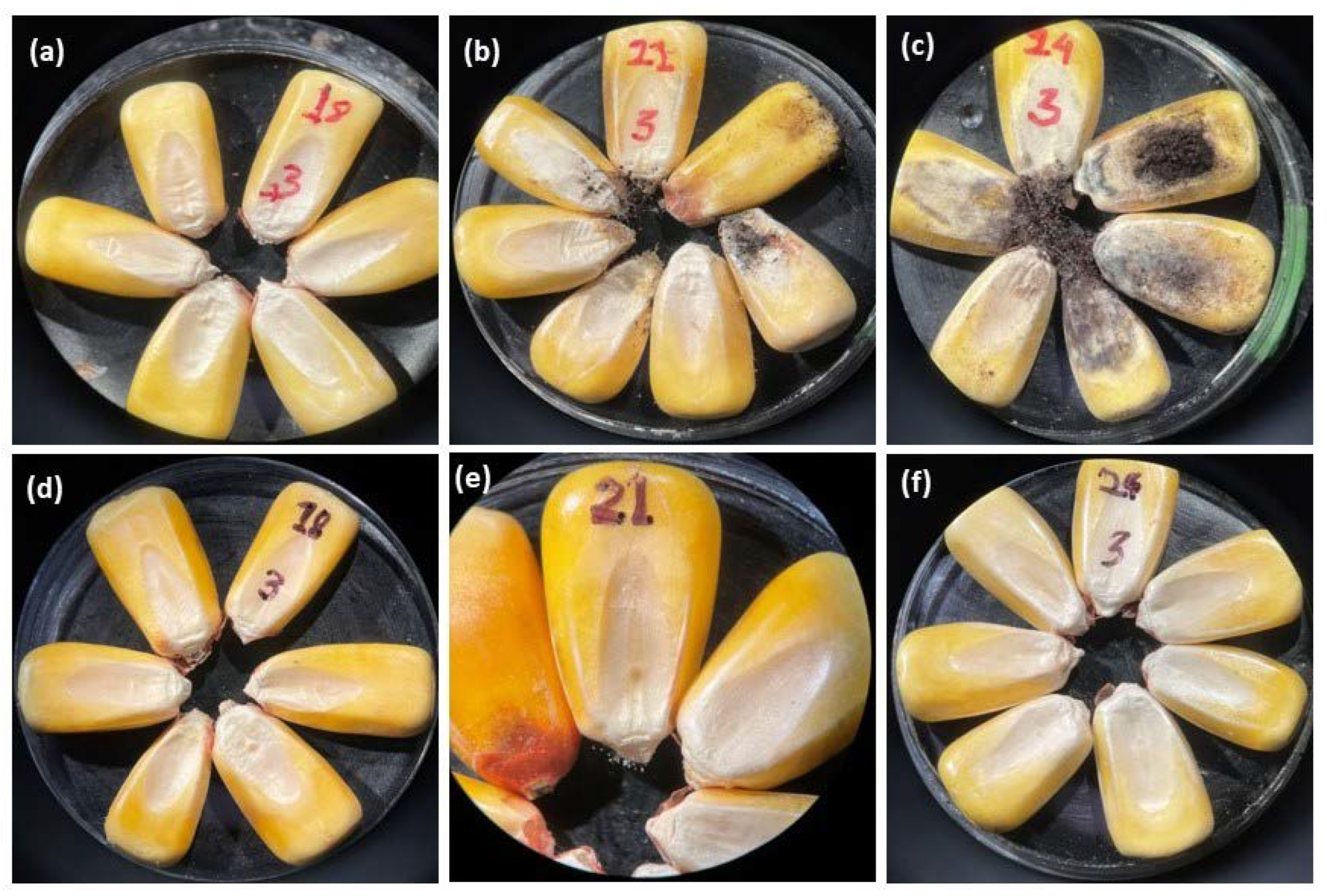

2.3.4. Visual Mold Assessment

2.4. Data Analysis

3. Results

3.1. Germination, Shoot Length, and Root Length

3.2. Gas Composition in the Jars

3.3. Grain Moisture Content

3.4. pH

3.5. Mold Assessment

4. Discussion

4.1. Effect of Short-Term Hermetic Storage of Wet Maize on Germination and Physiological Growth

4.2. Effect of Short-Term Hermetic Storage of Wet Grain on Other Maize Quality Attributes

4.3. Implications of Short-Term Hermetic Storage of Wet Maize on Smallholder Farms

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gwirtz, J.A.; Garcia-Casal, M.N. Processing maize flour and corn meal food products. Ann. N. Y. Acad. Sci. 2014, 1312, 66–75. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ranum, P.; Peña-Rosas, J.P.; Garcia-Casal, M.N. Global maize production, utilization, and consumption. Ann. N. Y. Acad. Sci. 2014, 1312, 105–112. [Google Scholar] [CrossRef] [PubMed]

- USADA-FAS. World Agricultural Production; Foreign Agricultural Service, United States Department of Agriculture: Washington, DC, USA, 2022. [Google Scholar]

- Affognon, H.; Mutungi, C.; Sanginga, P.; Borgemeister, C. Unpacking Postharvest Losses in Sub-Saharan Africa: A Meta-Analysis. World Dev. 2015, 66, 49–68. [Google Scholar] [CrossRef] [Green Version]

- Kumar, D.; Kalita, P. Reducing Postharvest Losses during Storage of Grain Crops to Strengthen Food Security in Developing Countries. Foods 2017, 6, 8. [Google Scholar] [CrossRef] [Green Version]

- Bradford, K.J.; Dahal, P.; Van Asbrouck, J.; Kunusoth, K.; Bello, P.; Thompson, J.; Wu, F. The dry chain: Reducing postharvest losses and improving food safety in humid climates. Trends Food Sci. Technol. 2018, 71, 84–93. [Google Scholar] [CrossRef]

- Tefera, T. Post-harvest losses in African maize in the face of increasing food shortage. Food Secur. 2012, 4, 267–277. [Google Scholar] [CrossRef]

- Abdoulaye, T.; Ainembabazi, J.H.; Alexander, C.; Baributsa, D.; Kadjo, D.; Moussa, B.; Omotilewa, O.; Ricker-Gilbert, J.; Shiferaw, F. Postharvest Loss of Maize and Grain Legumes in Sub-Saharan Africa: Insights from Household Survey Data in Seven Countries; Purdue University: West Lafayette, IN, USA, 2016. [Google Scholar]

- Njoroge, A.W.; Baoua, I.; Baributsa, D. Postharvest Management Practices of Grains in the Eastern Region of Kenya. J. Agric. Sci. 2019, 11, 33. [Google Scholar] [CrossRef]

- Díaz-Valderrama, J.R.; Njoroge, A.; Macedo-Valdivia, D.; Orihuela-Ordóñez, N.; Smith, B.W.; Casa-Coila, V.; Ramírez-Calderón, N.; Zanabria-Gálvez, J.; Woloshuk, C.; Baributsa, D. Postharvest practices, challenges and opportunities for grain producers in Arequipa, Peru. PLoS ONE 2020, 15, e.0240857. [Google Scholar] [CrossRef]

- Baributsa, D.; Díaz-Valderrama, J.R.; Mughanda, D.; Lubanzadio, A.; Nshombo, J.P.C.; Sperling, L.; Baoua, I.B. Grain Handling and Storage in Lubero and Rutshuru Territories in the North Kivu Province, the Democratic Republic of Congo. Sustainability 2021, 13, 9580. [Google Scholar] [CrossRef]

- Obeng-Ofori, D. The use of botanicals by resource poor farmers in Africa and Asia for the protection of stored agricultural products. Stewart Postharvest Rev. 2007, 3, 1–8. [Google Scholar] [CrossRef]

- Baoua, I.B.; Amadou, L.; Margam, V.; Murdock, L.L. Comparative evaluation of six storage methods for postharvest preservation of cowpea grain. J. Stored Prod. Res. 2012, 49, 171–175. [Google Scholar] [CrossRef]

- Osei-Asibey, R.K.; Wireko-Manu, F.D.; Aidoo, R.; Boakye-Achampong, S.; Mills-Robertson, F.C.; Baributsa, D. Farmers’ Perception of the Use and Benefits of Cowpea Storage Methods in Northern Ghana. Sustainability 2022, 14, 5129. [Google Scholar] [CrossRef]

- Weinberg, Z.G.; Yan, Y.; Chen, Y.; Finkelman, S.; Ashbell, G.; Navarro, S. The effect of moisture level on high-moisture maize (Zea mays L.) under hermetic storage conditions—In vitro studies. J. Stored Prod. Res. 2008, 44, 136–144. [Google Scholar] [CrossRef]

- Williams, S.B.; Baributsa, D.; Woloshuk, C. Assessing Purdue Improved Crop Storage (PICS) bags to mitigate fungal growth and aflatoxin contamination. J. Stored Prod. Res. 2014, 59, 190–196. [Google Scholar] [CrossRef]

- Tubbs, T.; Baributsa, D.; Woloshuk, C. Impact of opening hermetic storage bags on grain quality, fungal growth and aflatoxin accumulation. J. Stored Prod. Res. 2016, 69, 276–281. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Baoua, I.B.; Amadou, L.; Ousmane, B.; Baributsa, D.; Murdock, L.L. PICS bags for post-harvest storage of maize grain in West Africa. J. Stored Prod. Res. 2014, 58, 20–28. [Google Scholar] [CrossRef]

- Yewle, N.; Charpe, A.M.; Gupta, S.; Vidyapeeth, P.D.K.; Bhagyashree Patil, I.; Tushir, S.; Mann, S.; Patil, B. Impact of hermetic packaging on green gram (Vigna radiata) insect and microbial damage under environmental storage condition. 1883 J. Entomol. Zool. Stud. 2020, 8, 1883–1887. [Google Scholar] [CrossRef]

- Baributsa, D.; Bakoye, O.N.; Ibrahim, B.; Murdock, L.L.L. Performance of Five Postharvest Storage Methods for Maize Preservation in Northern Benin. Insects 2020, 11, 541. [Google Scholar] [CrossRef]

- Odjo, S.; Palacios-Rojas, N.; Burgueño, J.; Corrado, M.; Ortner, T.; Verhulst, N. Hermetic storage technologies preserve maize seed quality and minimize grain quality loss in smallholder farming systems in Mexico. J. Stored Prod. Res. 2022, 96, 101954. [Google Scholar] [CrossRef]

- Likhayo, P.; Bruce, A.Y.; Tefera, T.; Mueke, J. Maize grain stored in hermetic bags: Effect of moisture and pest infestation on grain quality. J. Food Qual. 2018, 2018, 2515698. [Google Scholar] [CrossRef]

- Marcos Valle, F.J.; Gastón, A.; Abalone, R.M.; de la Torre, D.A.; Castellari, C.C.; Bartosik, R.E. Study and modelling the respiration of corn seeds (Zea mays L.) during hermetic storage. Biosyst. Eng. 2021, 208, 45–57. [Google Scholar] [CrossRef]

- Villers, P.; De Bruin, T.; Navarro, S. Development and applications of the hermetic storage technology. In Proceedings of the 9th International Working Conference on Stored Product Protection, São Paulo, Brazil, 15–18 October 2006; pp. 719–729. [Google Scholar]

- ISTA. International Rules for Seed Testing, Vol. 215, Introduction, i-1-6 (10). The International Seed Testing Association, Bassersdorf; Scientific Research Publishing: Irvine, CA, USA, 2015. [Google Scholar]

- Dehnavi, A.R.; Zahedi, M.; Ludwiczak, A.; Perez, S.C.; Piernik, A. Effect of Salinity on Seed Germination and Seedling Development of Sorghum (Sorghum bicolor (L.) Moench) Genotypes. Agron. 2020, 10, 859. [Google Scholar] [CrossRef]

- ASABE. ASABE Standards. Available online: https://engineering.purdue.edu/~abe305/moisture/html/page12.htm (accessed on 4 July 2022).

- Njoroge, A.W.; Affognon, H.D.; Mutungi, C.M.; Manono, J.; Lamuka, P.O.; Murdock, L.L. Triple bag hermetic storage delivers a lethal punch to Prostephanus truncatus (Horn) (Coleoptera: Bostrichidae) in stored maize. J. Stored Prod. Res. 2014, 58, 12–19. [Google Scholar] [CrossRef]

- Yewle, N.R.; Gupta, S.V.; Patil, B.N.; Kandasamy, P.; Mann, S.; Tushir, S. Evaluation of Proximate composition, Microbial load and colour of Green gram during storage under flexible hermetic and Conventional packaging materials. Adv. Biores. 2019, 10, 72–77. [Google Scholar] [CrossRef]

- Moog, D.J.P.; Stroshine, R.L.; Seitz, L.M. Relationship of Shelled Corn Fungal Susceptibility to Carbon Dioxide Evolution and Kernel Attributes 1. Cereal Chem. 2008, 85, 19. [Google Scholar] [CrossRef] [Green Version]

- Sauer, D.B. Effects of fungal deterioration on grain: Nutritional value, toxicity, germination. Int. J. Food Microbiol. 1988, 7, 267–275. [Google Scholar] [CrossRef]

- Dhakal, K.; Springer, T.L. Recurrent selection for improved seed germination results in greater seedling growth potential. Crop Sci. 2020, 60, 2180–2185. [Google Scholar] [CrossRef]

- Afzal, I.; Bakhtavar, M.A.M.A.; Ishfaq, M.; Sagheer, M.; Baributsa, D. Maintaining dryness during storage contributes to higher maize seed quality. J. Stored Prod. Res. 2017, 72, 49–53. [Google Scholar] [CrossRef]

- Dawson, T.E.; Rust, S.R.; Yokoyama, M.T. Improved Fermentation and Aerobic Stability of Ensiled, High Moisture Corn with the Use of Propionibacterium acidipropionici. J. Dairy Sci. 1998, 81, 1015–1021. [Google Scholar] [CrossRef]

- Wardynski, F.A.; Rust, S.R.; Yokoyama, M.T. Effect of microbial inoculation of high-moisture corn on fermentation characteristics, aerobic stability, and cattle performance. J. Anim. Sci. 1993, 71, 2246–2252. [Google Scholar] [CrossRef] [Green Version]

- Taylor, C.C.; Kung, L. The Effect of Lactobacillus buchneri 40788 on the Fermentation and Aerobic Stability of High Moisture Corn in Laboratory Silos 1. J. Dairy Sci. 2002, 85, 1526–1532. [Google Scholar] [CrossRef] [PubMed]

| Storage Time (Days) | |||||

|---|---|---|---|---|---|

| Variable | Treatment * | 0 (Initial) | 7 | 14 | 21 |

| H-m.c.18% | 99.5aA ** | 97.07aA | 95.16aA | 71aB | |

| H-m.c.21% | 97.24aA | 96.44aA | 92.32abA | 72aB | |

| Germination | H-m.c.24% | 95.5aA | 88.73bB | 84.49bB | 0bC |

| (%) | NH-m.c.18% | 99.5aA | 98.66aA | 96.32aA | 88aB |

| NH-m.c.21% | 97.24aA | 94.32abA | 94.31aA | 68aB | |

| NH-m.c.24% | 95.5aA | 93abAB | 83bB | 4bC | |

| H-m.c.18% | 9.44aB | 21.79aA | 11.90aB | 16.01aAB | |

| H-m.c.21% | 15.30aB | 20.92aA | 15.07aB | 10.92aC | |

| Shoot Length | H-m.c.24% | 14.61aA | 17.175aA | 12.01aA | 0bB |

| (mm) | NH-m.c.18% | 10.32aB | 18.80aA | 12.64aB | 13.2aAB |

| NH-m.c.21% | 16.48aA | 35.54aA | 14.75aA | 11.23aA | |

| NH-m.c.24% | 15.11aA | 18.13aA | 12.86aA | 0bB | |

| H-m.c.18% | 55.55aB | 74.45aA | 47.54aB | 43.60aB | |

| H-m.c.21% | 46.51aAB | 60.89abA | 42.10abA | 29.51bB | |

| Root Length | H-m.c.24% | 46.17aA | 48.43abA | 28.42bcA | 0cB |

| (mm) | NH-m.c.18% | 55.68aA | 56.96abA | 40.21abA | 35.0abA |

| NH-m.c.21% | 47.51aAA | 53.74abA | 41.77abAB | 27.77bB | |

| NH-m.c.24% | 57.92aA | 39.57bAB | 20.91cB | 2.81cB | |

| Storage Time (Days) | |||||

|---|---|---|---|---|---|

| Variable | Treatment * | 0 (Initial) | 7 | 14 | 21 |

| H-m.c.18% | 17.59cA ** | 17.46cA | 17.44cA | 17.33cA | |

| H-m.c.21% | 21.03bA | 21.10bA | 21.03bA | 20.68bA | |

| Moisture | H-m.c.24% | 24.07aA | 23.88aA | 24.05aA | 23.93aA |

| (%) | NH-m.c.18% | 17.59cA | 17.13cA | 17.08cA | 17.40cA |

| NH-m.c.21% | 21.03bA | 20.81bA | 20.84bA | 20.78bA | |

| NH-m.c.24% | 24.07aA | 23.46aA | 23.80aA | 23.87aA | |

| H-m.c.18% | 5.12aA | 5.13bA | 4.93cC | 5.02cB | |

| H-m.c.21% | 5.20aA | 5.03bB | 4.79dC | 4.13dD | |

| pH | H-m.c.24% | 5.2aA | 5.03bB | 4.76dC | 3.97eD |

| NH-m.c.18% | 5.15aA | 5.27aA | 5.15bA | 5.15bA | |

| NH-m.c.21% | 5.24aA | 5.03bB | 5.34aA | 5.35aA | |

| NH-m.c.24% | 5.25aA | 5.09bB | 5.15bAB | 5.05bcB | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yewle, N.R.; Stroshine, R.L.; Ambrose, R.K.; Baributsa, D. Short-Term Hermetic Storage of Wet Maize and Its Effect on Quality. Foods 2023, 12, 891. https://doi.org/10.3390/foods12040891

Yewle NR, Stroshine RL, Ambrose RK, Baributsa D. Short-Term Hermetic Storage of Wet Maize and Its Effect on Quality. Foods. 2023; 12(4):891. https://doi.org/10.3390/foods12040891

Chicago/Turabian StyleYewle, Nileshwari Raju, Richard L. Stroshine, RP Kingsly Ambrose, and Dieudonne Baributsa. 2023. "Short-Term Hermetic Storage of Wet Maize and Its Effect on Quality" Foods 12, no. 4: 891. https://doi.org/10.3390/foods12040891