IV-Range Carrot Waste Flour Enhances Nutritional and Functional Properties of Rice-Based Gluten-Free Muffins †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials and Ingredients

2.2. Muffin Preparation

2.3. Characterization of Rice Flour and Flour Blends

2.3.1. Physicochemical Properties

2.3.2. Pasting Properties of Flour Blends

2.4. Characterization of Muffin Batters and Products

2.4.1. Rheological Measurements

2.4.2. Physicochemical Characterization of Muffins

2.5. Antioxidant Activity, Total Phenolic and Reducing Sugar Contents

2.6. Evolution of Muffin Properties during Cold Storage

2.7. Statistical Analyses

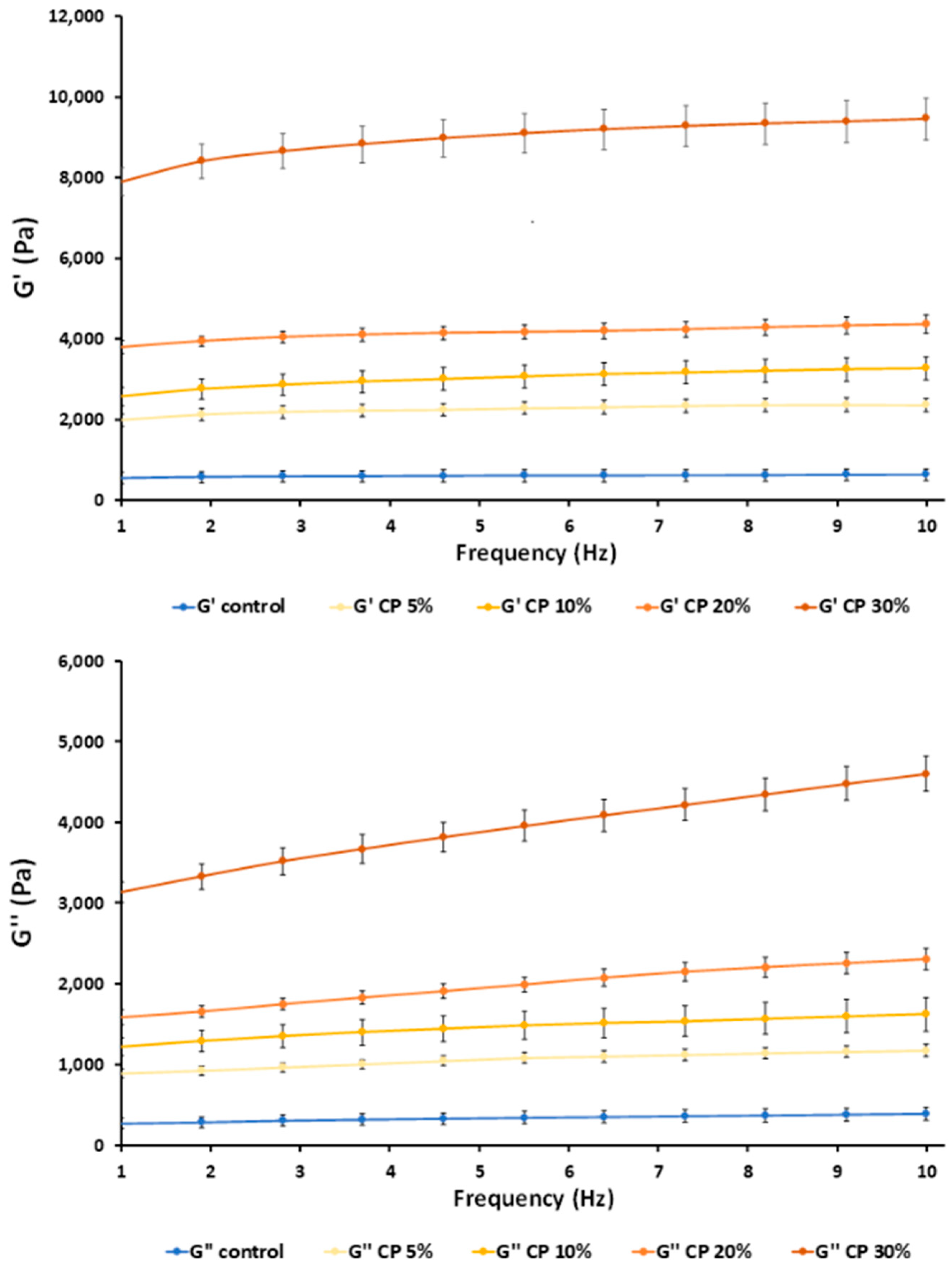

3. Results and Discussion

3.1. Characterization of Flour Blends

3.2. Muffin Dough and Product Characterization

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- FAO; WHO. Sustainable Healthy Diets—Guiding Principles; Food and Agriculture Organization of the United Nations and World Health Organization: Rome, Italy, 2019. [Google Scholar] [CrossRef]

- Egea, M.B.; De Sousa, T.L.; Dos Santos, D.C.; Filho, J.G.D.O.; Guimarães, R.M.; Yoshiara, L.Y.; Lemes, A.C. Application of Soy, Corn, and Bean By-products in the Gluten-free Baking Process: A Review. Food Bioprocess Technol. 2023, 16, 1429–1450. [Google Scholar] [CrossRef]

- van Zanten, H.H.E.; Simon, W.; van Selm, B.; Wacker, J.; Maindl, T.I.; Frehner, A.; Hijbeek, R.; van Ittersum, M.K.; Herrero, M. Circularity in Europe strengthens the sustainability of the global food system. Nat. Food 2023, 4, 320–330. [Google Scholar] [CrossRef]

- FAO. Global Food Losses and Food Waste—Extent, Causes and Prevention; Save Food Congress: Rome, Italy, 2011. [Google Scholar]

- Bas-Bellver, C.; Barrera, C.; Betoret, N.; Seguí, L. Physicochemical, Technological and Functional Properties of Upcycled Vegetable Waste Ingredients as Affected by Processing and Storage. Plant Foods Hum. Nutr. 2023, 78, 710–719. [Google Scholar] [CrossRef]

- Bas-Bellver, C.; Barrera, C.; Betoret, N.; Seguí, L. Turning Agri-Food Cooperative Vegetable Residues into Functional Powdered Ingredients for the Food Industry. Sustainability 2020, 12, 1284. [Google Scholar] [CrossRef]

- Ferreira, M.S.L.; Santos, M.C.P.; Moro, T.M.A.; Basto, G.J.; Andrade, R.M.S.; Gonçalves, C.B.A. Formulation and characterization of functional foods based on fruit and vegetable residue flour. J. Food Sci. Technol. 2015, 52, 822–830. [Google Scholar] [CrossRef]

- Neacsu, M.; Vaughan, N.; Raikos, V.; Multari, S.; Duncan, G.J.; Duthie, G.G.; Russell, W.R. Phytochemical profile of commercially available food plant powders: Their potential role in healthier food reformulations. Food Chem. 2015, 179, 159–169. [Google Scholar] [CrossRef]

- Ikram, A.; Rasheed, A.; Khan, A.A.; Khan, R.; Ahmad, M.; Bashir, R.; Mohamed, M.H. Exploring the health benefits and utility of carrots and carrot pomace: A systematic review. Int. J. Food Prop. 2024, 27, 180–193. [Google Scholar] [CrossRef]

- Müller-Maatsch, J.; Sprenger, J.; Hempel, J.; Kreiser, F.; Carle, R.; Schweiggert, R.M. Carotenoids from gac fruit aril (Momordica cochinchinensis [Lour.] Spreng.) are more bioaccessible than those from carrot root and tomato fruit. Food Res. Int. 2017, 99, 928–935. [Google Scholar] [CrossRef]

- Pinazo-Durán, M.D.; Bendala-Tufanisco, E. Capítulo IV. Las vitaminas, carotenoides y minerales. In Guía Sobre Alimentación en las Enfermedades de la Retina; BRUDYLAB S.L.: Riera de Sant Miquel, Spain, 2017; pp. 37–47. [Google Scholar]

- Adadi, P.; Barakova, N.V.; Krivoshapkina, E.F. Selected Methods of Extracting Carotenoids, Characterization, and Health Concerns: A Review. J. Agric. Food Chem. 2018, 66, 5925–5947. [Google Scholar] [CrossRef]

- Tiwari, H.; Singh, P.K.; Naresh, R.K.; Islam, A.; Kumar, S.; Singh, K.V.; Pandey, A.K.; Shukla, A. Millets Based Integrated Farming System for Food and Nutritional Security, Constraints and Agro-Diversification Strategies to Fight Global Hidden Hunger: A Review. Int. J. Plant Soil Sci. 2023, 35, 630–643. [Google Scholar] [CrossRef]

- Bianchi, F.; Lomuscio, E.; Rizzi, C.; Simonato, B. Predicted Shelf-Life, Thermodynamic Study and Antioxidant Capacity of Breadsticks Fortified with Grape Pomace Powders. Foods 2021, 10, 2815. [Google Scholar] [CrossRef]

- Hooda, S.; Jood, S. Organoleptic and nutritional evaluation of wheat biscuits supplemented with untreated and treated fenugreek flour. Food Chem. 2005, 90, 427–435. [Google Scholar] [CrossRef]

- Olawuyi, I.F.; Lee, W.Y. Quality and antioxidant properties of functional rice muffins enriched with shiitake mushroom and carrot pomace. Int. J. Food Sci. Technol. 2019, 54, 2321–2328. [Google Scholar] [CrossRef]

- Kırbaş, Z.; Kumcuoglu, S.; Tavman, S. Effects of apple, orange and carrot pomace powders on gluten-free batter rheology and cake properties. J. Food Sci. Technol. 2019, 56, 914–926. [Google Scholar] [CrossRef]

- Aguiar, E.V.; Santos, F.G.; Krupa-Kozak, U.; Capriles, V.D. Nutritional facts regarding commercially available gluten-free bread worldwide: Recent advances and future challenges. Crit. Rev. Food Sci. Nutr. 2023, 63, 693–705. [Google Scholar] [CrossRef] [PubMed]

- Gularte, M.A.; de la Hera, E.; Gómez, M.; Rosell, C.M. Effect of different fibers on batter and gluten-free layer cake properties. LWT-Food Sci. Technol. 2012, 48, 209–214. [Google Scholar] [CrossRef]

- Ranasinghe, M.; Manikas, I.; Maqsood, S.; Stathopoulos, C. Date Components as Promising Plant-Based Materials to Be Incorporated into Baked Goods—A Review. Sustainability 2022, 14, 605. [Google Scholar] [CrossRef]

- Ben Jeddou, K.; Bouaziz, F.; Zouari-Ellouzi, S.; Chaari, F.; Ellouz-Chaabouni, S.; Ellouz-Ghorbel, R.; Nouri-Ellouz, O. Improvement of texture and sensory properties of cakes by addition of potato peel powder with high level of dietary fiber and protein. Food Chem. 2017, 217, 668–677. [Google Scholar] [CrossRef]

- Chen, Y.; Zhao, L.; He, T.; Ou, Z.; Hu, Z.; Wang, K. Effects of mango peel powder on starch digestion and quality characteristics of bread. Int. J. Biol. Macromol. 2019, 140, 647–652. [Google Scholar] [CrossRef]

- Khaleel, G.; Sharanagat, V.S.; Singh, L.; Kumar, Y.; Kumar, K.; Kishore, A.; Saikumar, A.; Mani, S. Characterization of kinnow (citrus reticulate) peel and its effect on the quality of muffin. J. Food Process. Preserv. 2022, 46, e16716. [Google Scholar] [CrossRef]

- Rafiq, S.; Sofi, S.A.; Kaul, R.; Dar, B.N. Effect of freeze-dried kinnow peel powder incorporation on nutritional, quality characteristics, baking, sensorial properties, and storage stability of traditional wheat-based soup sticks. J. Food Process. Preserv. 2022, 46, e16652. [Google Scholar] [CrossRef]

- Topkaya, C.; Isik, F. Effects of pomegranate peel supplementation on chemical, physical, and nutritional properties of muffin cakes. J. Food Process. Preserv. 2019, 43, e13868. [Google Scholar] [CrossRef]

- Djeghim, F.; Bourekoua, H.; Różyło, R.; Bieńczak, A.; Tanaś, W.; Zidoune, M.N. Effect of By-Products from Selected Fruits and Vegetables on Gluten-Free Dough Rheology and Bread Properties. Appl. Sci. 2021, 11, 4605. [Google Scholar] [CrossRef]

- Bas-Bellver, C.; Barrera, C.; Betoret, N.; Seguí, L. Effect of Processing and In Vitro Digestion on Bioactive Constituents of Powdered IV Range Carrot (Daucus carota, L.) Wastes. Foods 2023, 12, 731. [Google Scholar] [CrossRef]

- Bas-Bellver, C.; Barrera, C.; Betoret, N.; Seguí, L.; Harasym, J. White Cabbage Waste Powder Improves the Gluten-Free Rice-Based Breadsticks Functional and Nutritional Characteristics. 2024; unpublished data. [Google Scholar]

- Harasym, J.; Satta, E.; Kaim, U. Ultrasound Treatment of Buckwheat Grains Impacts Important Functional Properties of Resulting Flour. Molecules 2020, 25, 3012. [Google Scholar] [CrossRef]

- Hu, R.; Lin, L.; Liu, T.; Ouyang, P.; He, B.; Liu, S. Reducing Sugar Content in Hemicellulose Hydrolysate by DNS Method: A Revisit. J. Biobased Mater. Bioenergy 2008, 2, 156–161. [Google Scholar] [CrossRef]

- Başkan, K.S.; Tütem, E.; Akyüz, E.; Özen, S.; Apak, R. Spectrophotometric total reducing sugars assay based on cupric reduction. Talanta 2016, 147, 162–168. [Google Scholar] [CrossRef]

- Harasym, J.; Olędzki, R. The Mutual Correlation of Glucose, Starch, and Beta-Glucan Release During Microwave Heating and Antioxidant Activity of Oat Water Extracts. Food Bioprocess Technol. 2018, 11, 874–884. [Google Scholar] [CrossRef]

- Ahmad, M.; Wani, T.A.; Wani, S.M.; Masoodi, F.A.; Gani, A. Incorporation of carrot pomace powder in wheat flour: Effect on flour, dough and cookie characteristics. J. Food Sci. Technol. 2016, 53, 3715–3724. [Google Scholar] [CrossRef]

- Kultys, E.; Moczkowska-Wyrwisz, M. Effect of using carrot pomace and beetroot-apple pomace on physicochemical and sensory properties of pasta. LWT 2022, 168, 113858. [Google Scholar] [CrossRef]

- Mir, S.A.; Bosco, S.J.D.; Shah, M.A. Technological and nutritional properties of gluten-free snacks based on brown rice and chestnut flour. J. Saudi Soc. Agric. Sci. 2019, 18, 89–94. [Google Scholar] [CrossRef]

- Zhu, F. Interactions between starch and phenolic compound. Trends Food Sci. Technol. 2015, 43, 129–143. [Google Scholar] [CrossRef]

- Zhou, S.; Reddy, C.K.; Du, B.; Xu, B. Pasting, thermal, and functional properties of wheat flour and rice flour formulated with chestnut flour. Bioact. Carbohydrates Diet. Fibre 2021, 26, 100290. [Google Scholar] [CrossRef]

- Matos, M.E.; Sanz, T.; Rosell, C.M. Establishing the function of proteins on the rheological and quality properties of rice based gluten free muffins. Food Hydrocoll. 2014, 35, 150–158. [Google Scholar] [CrossRef]

- Fetouhi, A.; Benatallah, L.; Nawrocka, A.; Szymańska-Chargot, M.; Bouasla, A.; Tomczyńska-Mleko, M.; Zidoune, M.N.; Sujak, A. Investigation of viscoelastic behaviour of rice-field bean gluten-free dough using the biophysical characterization of proteins and starch: A FT-IR study. J. Food Sci. Technol. 2019, 56, 1316–1327. [Google Scholar] [CrossRef] [PubMed]

- Mrabet, A.; Rodríguez-Gutiérrez, G.; Rodríguez-Arcos, R.; Guillén-Bejarano, R.; Ferchichi, A.; Sindic, M.; Jiménez-Araujo, A. Quality Characteristics and Antioxidant Properties of Muffins Enriched with Date Fruit (Phoenix Dactylifera L.) Fiber Concentrates. J. Food Qual. 2016, 39, 237–244. [Google Scholar] [CrossRef]

- Nath, P.; Kale, S.J.; Kaur, C.; Chauhan, O.P. Phytonutrient composition, antioxidant activity and acceptability of muffins incorporated with red capsicum pomace powder. J. Food Sci. Technol. 2018, 55, 2208–2219. [Google Scholar] [CrossRef]

- Beegum, S.; Sharma, M.; Manikantan, M.R.; Gupta, R.K. Effect of virgin coconut oil cake on physical, textural, microbial and sensory attributes of muffins. Int. J. Food Sci. Technol. 2017, 52, 540–549. [Google Scholar] [CrossRef]

- Bhatt, S.; Kumari, N.; Abhishek, V.; Gupta, M. Elucidating the role of amaranth flour in formulation of gluten free black rice muffins and its premix: Nutritional, physico-chemical and textural characteristics. J. Food Meas. Charact. 2021, 15, 675–685. [Google Scholar] [CrossRef]

- Sanika, B.; Poojitha, P.; Gurumorrthi, P.; Athmaselvi, K. Drying kinetics and quality of tray dried peanut milk residue. Food Res. 2021, 5, 106–112. [Google Scholar] [CrossRef]

- Marchetti, L.; Acuña, M.; Andrés, S. Effect of pecan nut expeller meal on quality characteristics of gluten-free muffins. LWT 2021, 146, 111426. [Google Scholar] [CrossRef]

- Talens, C.; Álvarez-Sabatel, S.; Rios, Y.; Rodríguez, R. Effect of a new microwave-dried orange fibre ingredient vs. a commercial citrus fibre on texture and sensory properties of gluten-free muffins. Innov. Food Sci. Emerg. Technol. 2017, 44, 83–88. [Google Scholar] [CrossRef]

- Wang, S.; Li, C.; Copeland, L.; Niu, Q.; Wang, S. Starch Retrogradation: A Comprehensive Review. Compr. Rev. Food Sci. Food Saf. 2015, 14, 568–585. [Google Scholar] [CrossRef]

- Singh, B.; Ezekiel, R.; Kumar, D.; Kumar, M.A.S. Reducing sugar content and chipping quality of tubers of potato cultivars after storage and reconditioning. Potato J. 2008, 35, 23–30. [Google Scholar]

- Ajila, C.; Leelavathi, K.; Rao, U.P. Improvement of dietary fiber content and antioxidant properties in soft dough biscuits with the incorporation of mango peel powder. J. Cereal Sci. 2008, 48, 319–326. [Google Scholar] [CrossRef]

- Croitoru, C.; Mureșan, C.; Turturică, M.; Stănciuc, N.; Andronoiu, D.G.; Dumitrașcu, L.; Barbu, V.; Enachi, E.; Horincar (Parfene), G.; Râpeanu, G. Improvement of Quality Properties and Shelf Life Stability of New Formulated Muffins Based on Black Rice. Molecules 2018, 23, 3047. [Google Scholar] [CrossRef]

| Flour Blend | xw (gw/100 g) | WAC (mL/g) | OAC (mL/g) | HLI |

|---|---|---|---|---|

| Rice flour | 12.282 ± 0.002 c | 2.25 ± 0.03 a | 1.57 ± 0.03 a | 1.43 ± 0.04 a |

| CP5% | 10.16 ± 0.03 a | 2.43 ± 0.05 b | 1.66 ± 0.02 b | 1.47 ± 0.02 a |

| CP10% | 10.13 ± 0.08 a | 2.62 ± 0.02 c | 1.64 ± 0.03 b | 1.60 ± 0.04 b |

| CP20% | 10.63 ± 0.02 b | 3.07 ± 0.12 d | 1.66 ± 0.05 b | 1.85 ± 0.12 c |

| CP30% | 10.5 ± 0.4 ab | 3.56 ± 0.12 e | 1.680 ± 0.010 b | 2.12 ± 0.06 d |

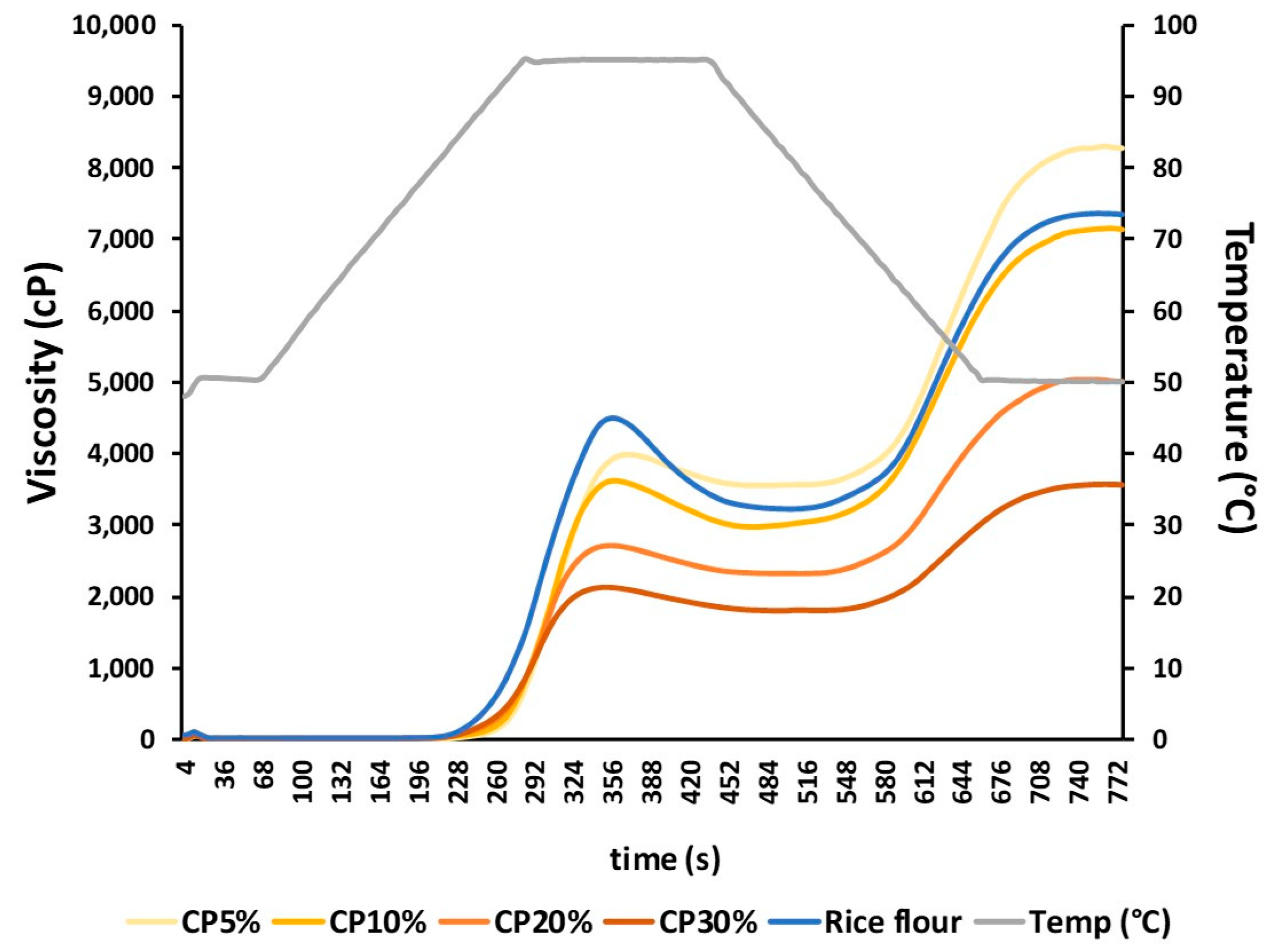

| PV (cP) | TV (cP) | BD (cP) | FV (cP) | ST (cP) | PTp (°C) | Ptime (min) | |

|---|---|---|---|---|---|---|---|

| Rice flour | 4498 ± 93 e | 3222 ± 66 c | 1276 ± 27 b | 7353 ± 179 c | 4131 ± 112 c | 90.55 ± 0.07 a | 5.93 ± 0.02 a |

| CP5% | 4033 ± 49 d | 3563 ± 5 d | 540 ± 54 a | 8378 ± 132 d | 4816 ± 136 d | 89.3 ± 0.7 a | 6.4 ± 0.4 b |

| CP10% | 3665 ± 74 c | 3130 ± 232 c | 535 ± 158 a | 7160 ± 35 c | 4030 ± 197 c | 88.5 ± 0.5 a | 6.3 ± 0.5 b |

| CP20% | 3308 ± 21 b | 2806 ± 81 b | 502 ± 60 a | 5803 ± 47 b | 2997 ± 127 b | 86.8 ± 0.6 a | 5.90 ± 0.14 a |

| CP30% | 2782 ± 84 a | 2310 ± 56 a | 472 ± 28 a | 4398 ± 61 a | 2089 ± 5 a | 85.58 ± 0.04 a | 5.89 ± 0.02 a |

| Flour Blend | Reducing Sugars (mg GE/gdm) | Phenols (mg GAE/gdm) | DPPH (µmol TE/gdm) |

|---|---|---|---|

| Rice flour | 1.257 ± 0.019 a | 0.320 ± 0.008 a | 4.64 ± 0.05 a |

| CP5% | 8.195 ± 0.018 b | 0.677 ± 0.011 b | 4.6 ± 0.2 a |

| CP10% | 11.09 ± 0.05 c | 1.085 ± 0.002 c | 4.54 ± 0.05 a |

| CP20% | 19.14 ± 0.10 d | 1.70 ± 0.02 d | 5.67 ± 0.05 b |

| CP30% | 21.82 ± 0.12 e | 2.30 ± 0.02 e | 6.25 ± 0.12 c |

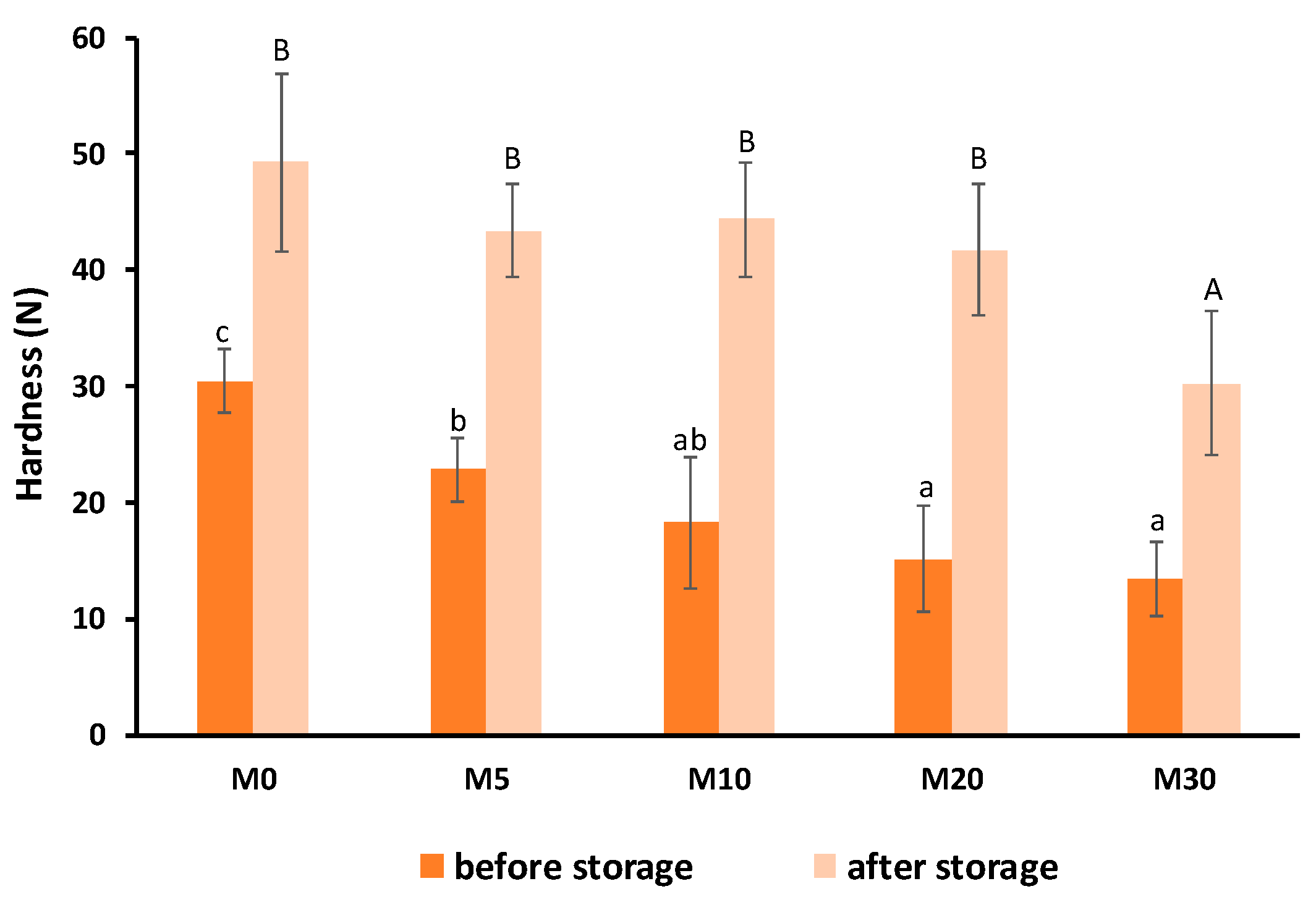

| aw | aw storage | Weight (g) | Volume (mm3) | |

|---|---|---|---|---|

| M0 | 0.895 ± 0.007 c | 0.894 ± 0.008 c | 42.81 ± 0.07 c | 84.3 ± 0.3 ab |

| M5 | 0.879 ± 0.004 bc | 0.89 ± 0.02 bc | 43.0 ± 1.2 c | 98 ± 8 c |

| M10 | 0.84 ± 0.03 ab | 0.866 ± 0.15 abc | 41.1 ± 0.7 ab | 89 ± 3 b |

| M20 | 0.87 ± 0.04 bc | 0.86 ± 0.03 ab | 42.1 ± 0.3 bc | 83 ± 2 ab |

| M30 | 0.814 ± 0.007 a | 0.846 ± 0.013 a | 40.7 ± 0.3 a | 81.2 ± 0.4 a |

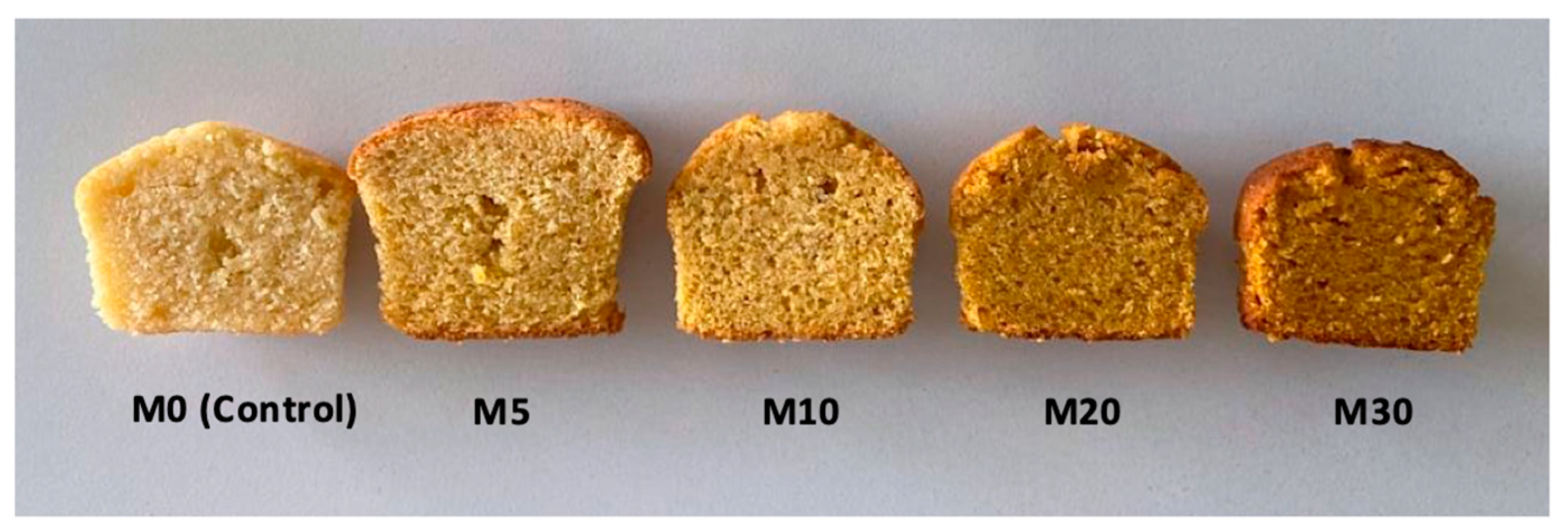

| L* | a* | b* | ∆E | ||

|---|---|---|---|---|---|

| CRUMB | M0 | 63 ± 4 d | −3.1 ± 0.2 a | 25.1 ± 0.8 a | 8 ± 3 a |

| M5 | 57 ± 3 c | −0.45 ± 0.10 b | 32.835 ± 1.006 b | 8.7 ± 1.9 a | |

| M10 | 58 ± 3 c | 1.5 ± 0.5 c | 39 ± 4 c | 7.0 ± 3 a | |

| M20 | 54.2 ± 1.9 b | 4.02 ± 0.50 d | 44.6 ± 1.5 d | 8.3 ± 1.3 a | |

| M30 | 50.0 ± 1.6 a | 6.1 ± 0.5 e | 47.7 ± 1.4 e | 9 ± 2 a | |

| CRUST | M0 | 60 ± 2 d | 4.7 ± 1.4 a | 34.8 ± 0.4 ab | 7.9 ± 1.2 a |

| M5 | 46 ± 3 b | 15 ± 4 b | 32 ± 4 a | 12.1 ± 6 ab | |

| M10 | 47.7 ± 0.8 bc | 16.2 ± 1.6 b | 35.8 ± 0.8 ab | 13 ± 2 ab | |

| M20 | 50.52 ± 1.17 c | 15.5 ± 1.9 b | 39 ± 2 b | 16 ± 5 b | |

| M30 | 40.5 ± 1.5 a | 16.5 ± 1.4 b | 32.5 ± 0.5 a | 11.8 ± 1.3 ab |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bas-Bellver, C.; Barrera, C.; Betoret, N.; Seguí, L.; Harassym, J. IV-Range Carrot Waste Flour Enhances Nutritional and Functional Properties of Rice-Based Gluten-Free Muffins. Foods 2024, 13, 1312. https://doi.org/10.3390/foods13091312

Bas-Bellver C, Barrera C, Betoret N, Seguí L, Harassym J. IV-Range Carrot Waste Flour Enhances Nutritional and Functional Properties of Rice-Based Gluten-Free Muffins. Foods. 2024; 13(9):1312. https://doi.org/10.3390/foods13091312

Chicago/Turabian StyleBas-Bellver, Claudia, Cristina Barrera, Noelia Betoret, Lucía Seguí, and Joanna Harassym. 2024. "IV-Range Carrot Waste Flour Enhances Nutritional and Functional Properties of Rice-Based Gluten-Free Muffins" Foods 13, no. 9: 1312. https://doi.org/10.3390/foods13091312