Fermented Brown Rice Flour as Functional Food Ingredient

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Fermentation Process

2.3. Steamed Bread Making Process

2.4. Determination of Flour Pasting Properties

2.5. Determination of Dynamic Rheological Properties of White Rice Batter

2.6. Measurement of Steamed Bread Volume

2.7. Texture Profile Analysis

2.8. Statistical Analyses

3. Results and Discussion

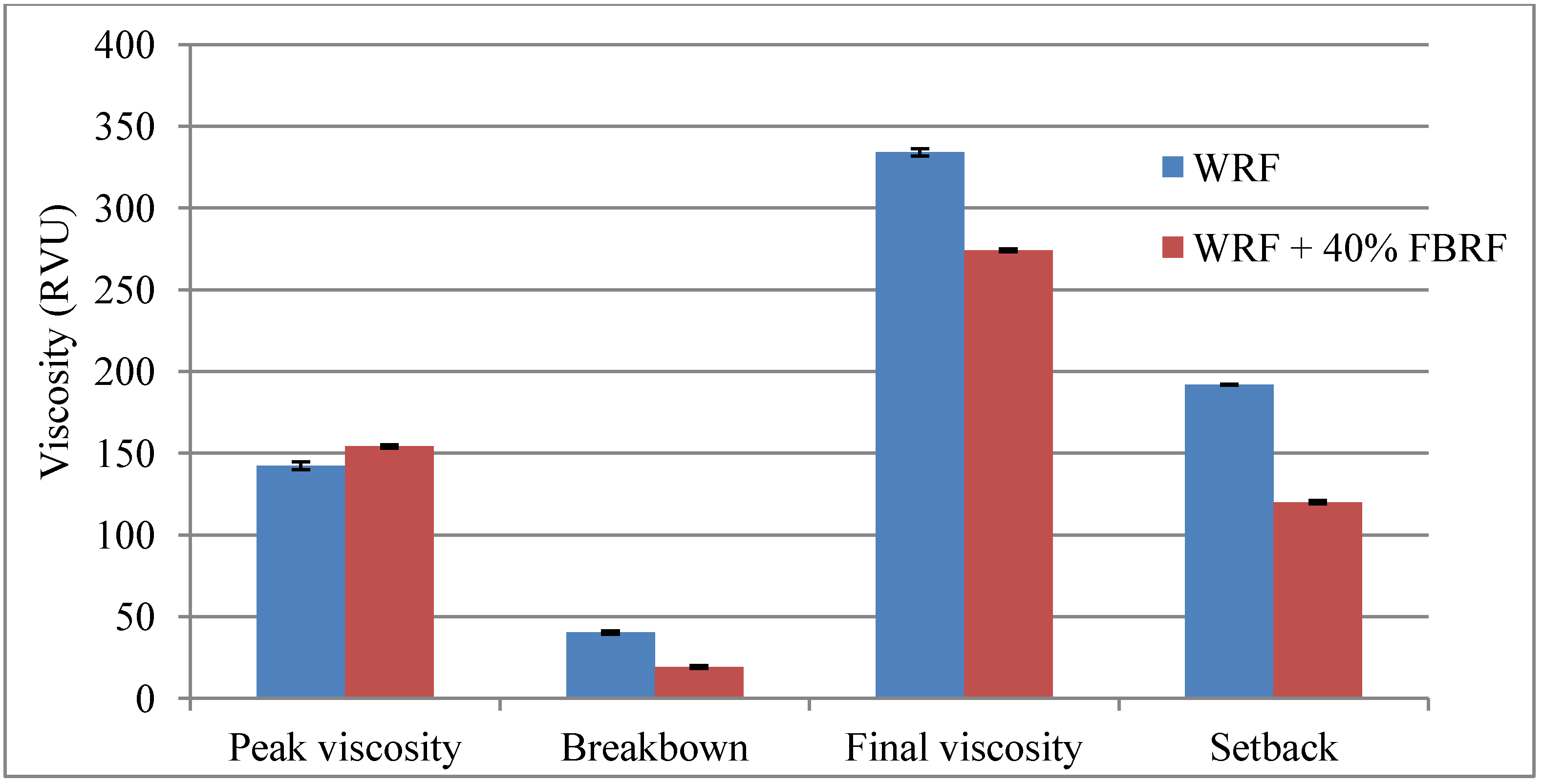

3.1. Pasting Properties of White Rice Flour (WRF) and White Rice Flour Supplemented with 40% FBRF

3.2. Viscoelastic Properties of White Rice Batter (WRB) and White Rice Batter Supplemented with 40% FBRF

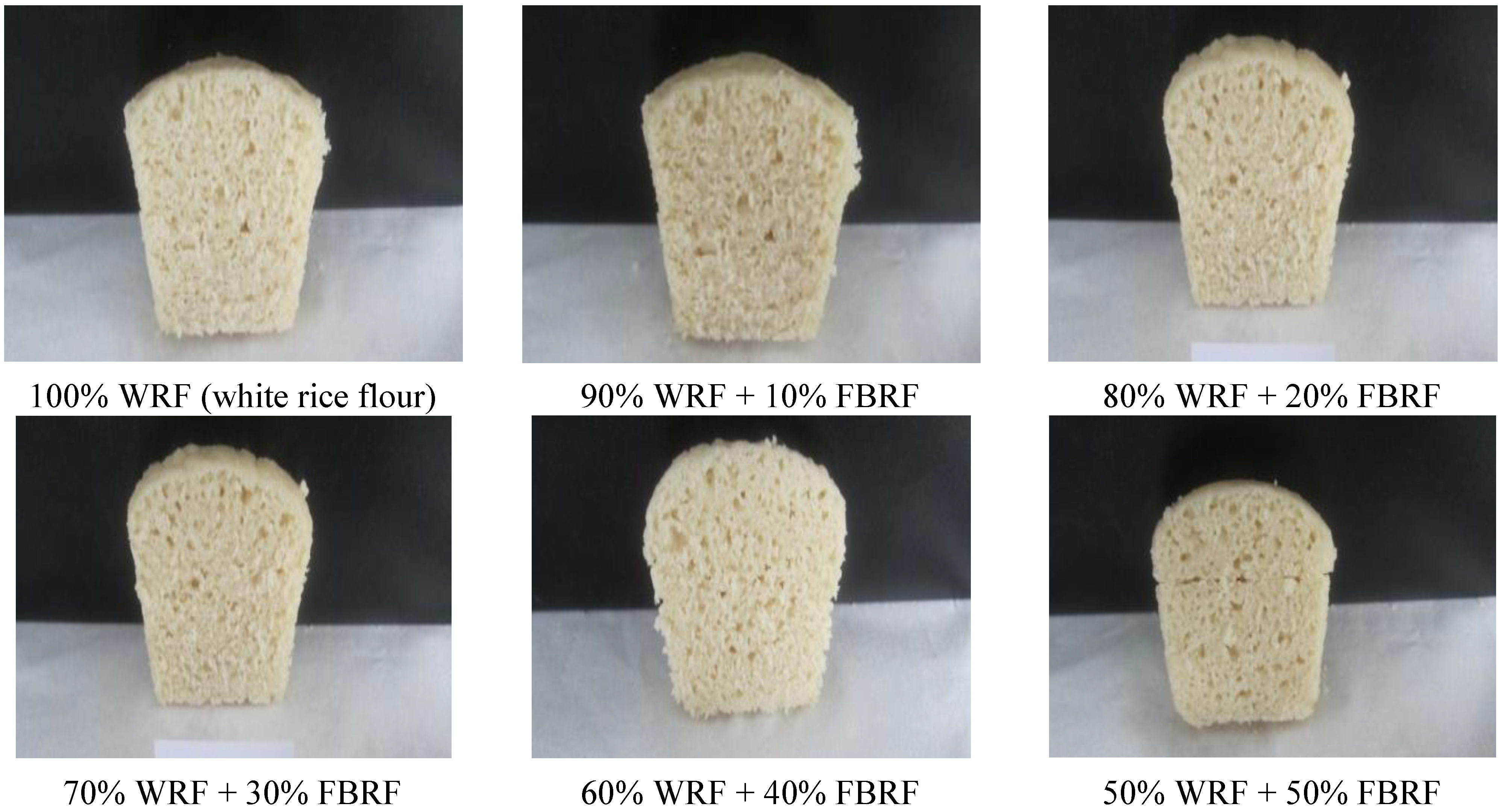

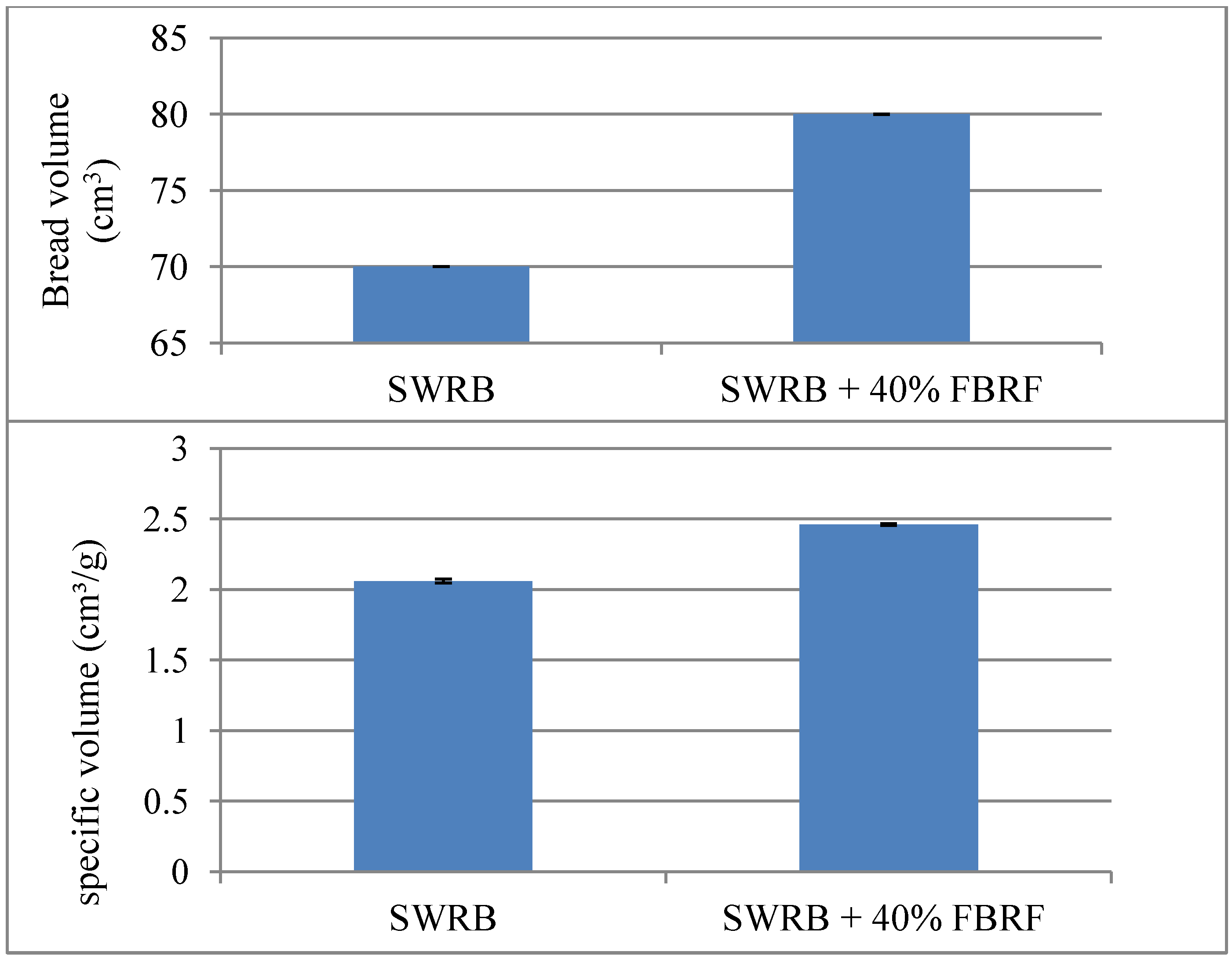

3.3. Steamed Bread Volume

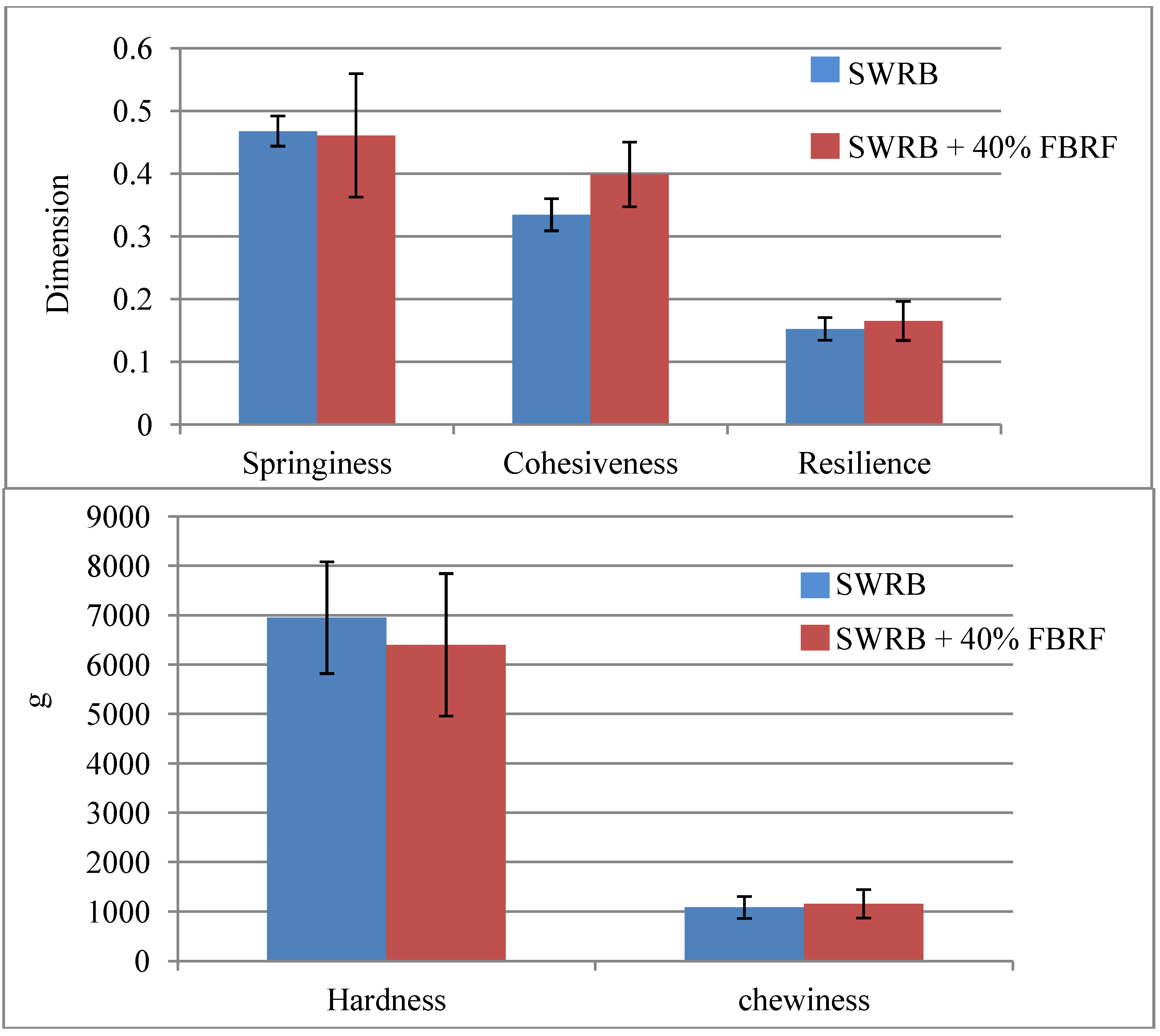

3.4. Steamed Bread Texture

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Slavin, J. Whole grains and human health. Nutr. Res. Rev. 2004, 17, 99–110. [Google Scholar] [CrossRef]

- Topping, D.J. Cereal complex carbohydrates and their contribution to human health. Cereal Sci. 2007, 46, 220–229. [Google Scholar] [CrossRef]

- Salmenkallio-Marttila, M.; Katina, K.; Autio, K. Effects of bran fermentation on quality and microstructure of high-fiber wheat bread. Cereal Chem. 2001, 78, 429–435. [Google Scholar] [CrossRef]

- Gujral, H.S.; Guardiola, I.; Carbonell, J.V.; Rosell, C.M. Effect of cyclodextrinase on dough rheology and bread quality from rice flour. J. Agric. Food Chem. 2003, 51, 3814–3818. [Google Scholar] [CrossRef]

- Marcoa, C.; Rosell, C.M. Effect of different protein isolates and transglutaminase on rice flour properties. J. Food Eng. 2008, 84, 132–139. [Google Scholar] [CrossRef]

- Alvarez-Jubete, L.; Arendt, E.K.; Gallagher, E. Nutritive value and chemical composition of pseudocereals as gluten-free ingredients. Int. J. Food Sci. Nutr. 2010, 21, 106–113. [Google Scholar]

- Repo-Carrasco-Valencia, R.; Hellström, J.K.; Pihlava, J.M.; Mattila, P.H. Flavonoids and other phenolic compounds in Andean indigenous grains: Quinoa (Chenopodium quinoa), kañiwa (Chenopodium pallidicaule) and kiwicha (Amaranthus caudatus). Food Chem. 2010, 120, 128–133. [Google Scholar] [CrossRef]

- Katina, K.; Juvonen, R.; Laitila, A.; Flander, L.; Nordlund, E.; Kariluoto, S.; Poutanen, K. Fermented wheat bran as a functional ingredient in baking. Cereal Chem. 2012, 89, 126–134. [Google Scholar] [CrossRef]

- De Vuyst, L.; Vancanneyt, M. Biodiversity and identification of sourdough lactic acid bacteria. Food Microbiol. 2007, 24, 120–127. [Google Scholar] [CrossRef]

- Clarke, C.I.; Schober, T.J.; Arendt, E.K. Effect of single strain and traditional mixed strain starter cultures on rheological properties of wheat dough and on bread quality. Cereal Chem. 2002, 79, 640–647. [Google Scholar] [CrossRef]

- AACC Method 61–02: Determination of the Pasting Properties of Rice with Rapid Visco-Analyser. In Approved Methods of Analysis, 9th ed.; American Association of Cereal Chemists International: St. Paul, MN, USA, 1995.

- Hallén, E.; İbanoğlu, Ş.; Ainsworth, P.J. Effect of fermented/germinated cowpea flour addition on the rheological and baking properties of wheat flour. Food Eng. 2004, 63, 177–184. [Google Scholar] [CrossRef]

- Schober, T.J.; Messerschmidt, M.; Bean, S.R.; Park, S.H.; Arendt, E.K. Gluten-free bread from sorghum: Quality differences among hybrids. Cereal Chem. 2005, 82, 394–404. [Google Scholar] [CrossRef]

- Zhu, L.J.; Liu, Q.Q.; Sang, Y.; Gu, M.H.; Shi, Y.C. Underlying reasons for waxy rice flours having different pasting properties. Food Chem. 2010, 120, 94–100. [Google Scholar] [CrossRef]

- Wang, H.H.; Sun, D.W.; Zeng, Q.; Lu, Y. Effect of pH, corn starch and phosphates on the pasting properties of rice flour. J. Food Eng. 2000, 46, 133–138. [Google Scholar] [CrossRef]

- Rieder, A.; Holtekjølen, A.K.; Sahlstrøm, S.; Moldestad, A. Effect of barley and oat flour types and sourdoughs on dough rheology and bread quality of composite wheat bread. J. Cereal Sci. 2012, 55, 44–52. [Google Scholar] [CrossRef]

- Wehrle, K.; Grau, H.E.; Arendt, K. Effects of lactic acid, acetic acid, and table salt on fundamental rheological properties of wheat dough. Cereal Chem. 1997, 74, 739–744. [Google Scholar] [CrossRef]

- Gocmen, D.; Gurbuz, O.; Kumral, A.Y.; Dagdelen, A.F.; Sahin, I. The effects of wheat sourdough on glutenin patterns, dough rheology and bread properties. Eur. Food Res. Technol. 2007, 225, 821–830. [Google Scholar] [CrossRef]

- Bourne, M.C. Texture profile analysis. Food Technol. 1978, 32, 62–66. [Google Scholar]

- Rizzello, C.G.; Coda, R.; Mazzacane, F.; Minervini, D.; Gobbetti, M. Micronized by-products from debranned durum wheat and sourdough fermentation enhanced the nutritional, textural and sensory features of bread. Food Res. Int. 2012, 46, 304–313. [Google Scholar] [CrossRef]

- Rizzello, C.G.; Nionelli, L.; Coda, R.; Di Cagno, R.; Gobbetti, M. Use of sourdough fermented wheat germ for enhancing the nutritional, texture and sensory characteristics of the white bread. Eur. Food Res. Technol. 2010, 230, 645–654. [Google Scholar] [CrossRef]

- Katina, K.; Arendt, E.; Liukkonen, K.H.; Autio, K.; Flander, L.; Poutanen, K. Potential of sourdough for healthier cereal products. Trends Food Sci. Technol. 2005, 16, 104–112. [Google Scholar] [CrossRef]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Ilowefah, M.; Chinma, C.; Bakar, J.; Ghazali, H.M.; Muhammad, K.; Makeri, M. Fermented Brown Rice Flour as Functional Food Ingredient. Foods 2014, 3, 149-159. https://doi.org/10.3390/foods3010149

Ilowefah M, Chinma C, Bakar J, Ghazali HM, Muhammad K, Makeri M. Fermented Brown Rice Flour as Functional Food Ingredient. Foods. 2014; 3(1):149-159. https://doi.org/10.3390/foods3010149

Chicago/Turabian StyleIlowefah, Muna, Chiemela Chinma, Jamilah Bakar, Hasanah M. Ghazali, Kharidah Muhammad, and Mohammad Makeri. 2014. "Fermented Brown Rice Flour as Functional Food Ingredient" Foods 3, no. 1: 149-159. https://doi.org/10.3390/foods3010149

APA StyleIlowefah, M., Chinma, C., Bakar, J., Ghazali, H. M., Muhammad, K., & Makeri, M. (2014). Fermented Brown Rice Flour as Functional Food Ingredient. Foods, 3(1), 149-159. https://doi.org/10.3390/foods3010149