Effect of Radio Frequency Heating on Yoghurt, II: Microstructure and Texture

Abstract

:1. Introduction

2. Experimental Section

2.1. Yoghurt

2.2. Heat Treatment

2.2.1. Radio Frequency (RF) Treatment

2.2.2. Convectional (CV) Treatment

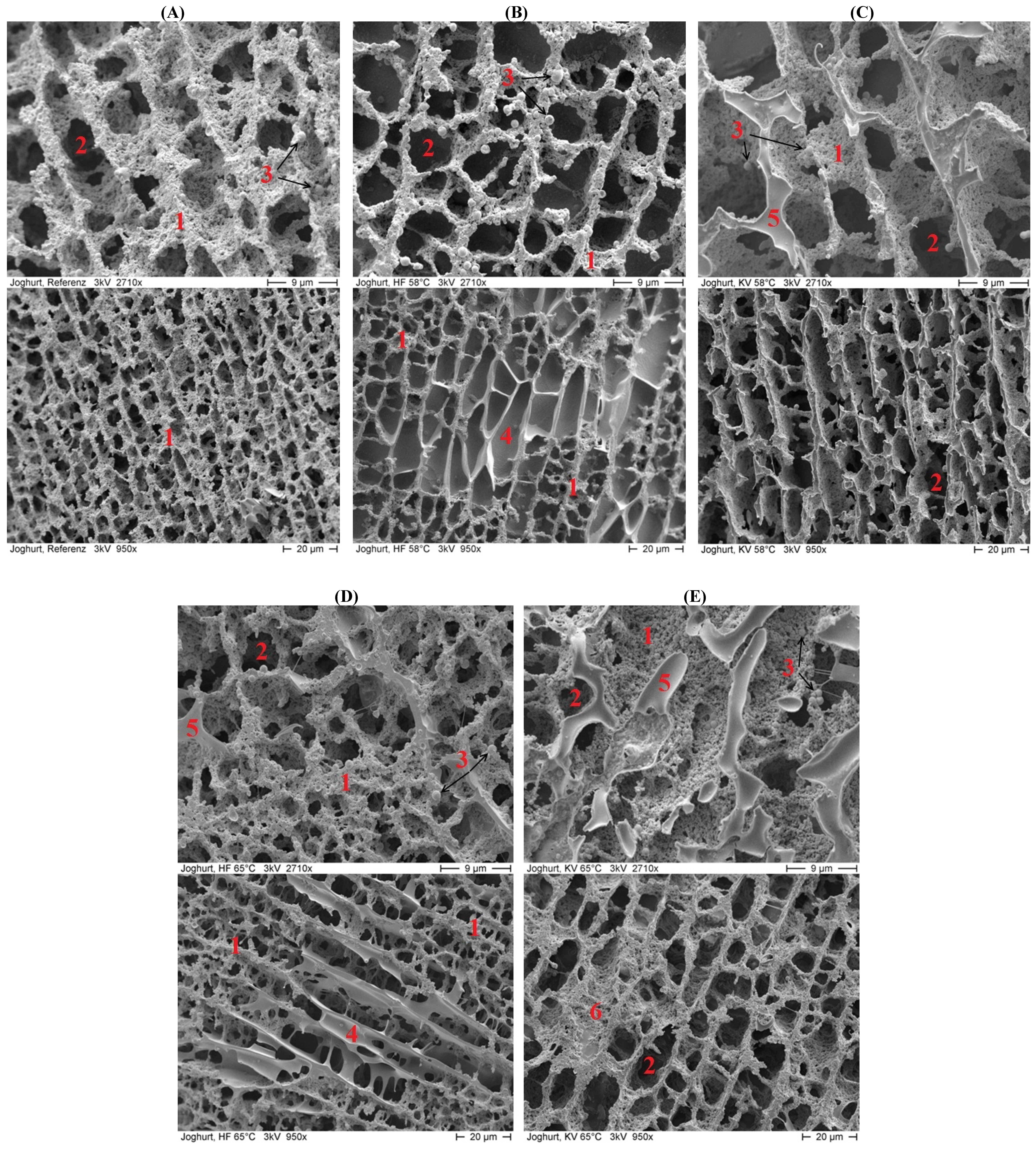

2.3. Structural Analysis via Cryo-Scanning Electron Microscopy (Cryo-SEM)

2.4. Whey Separation (Syneresis)

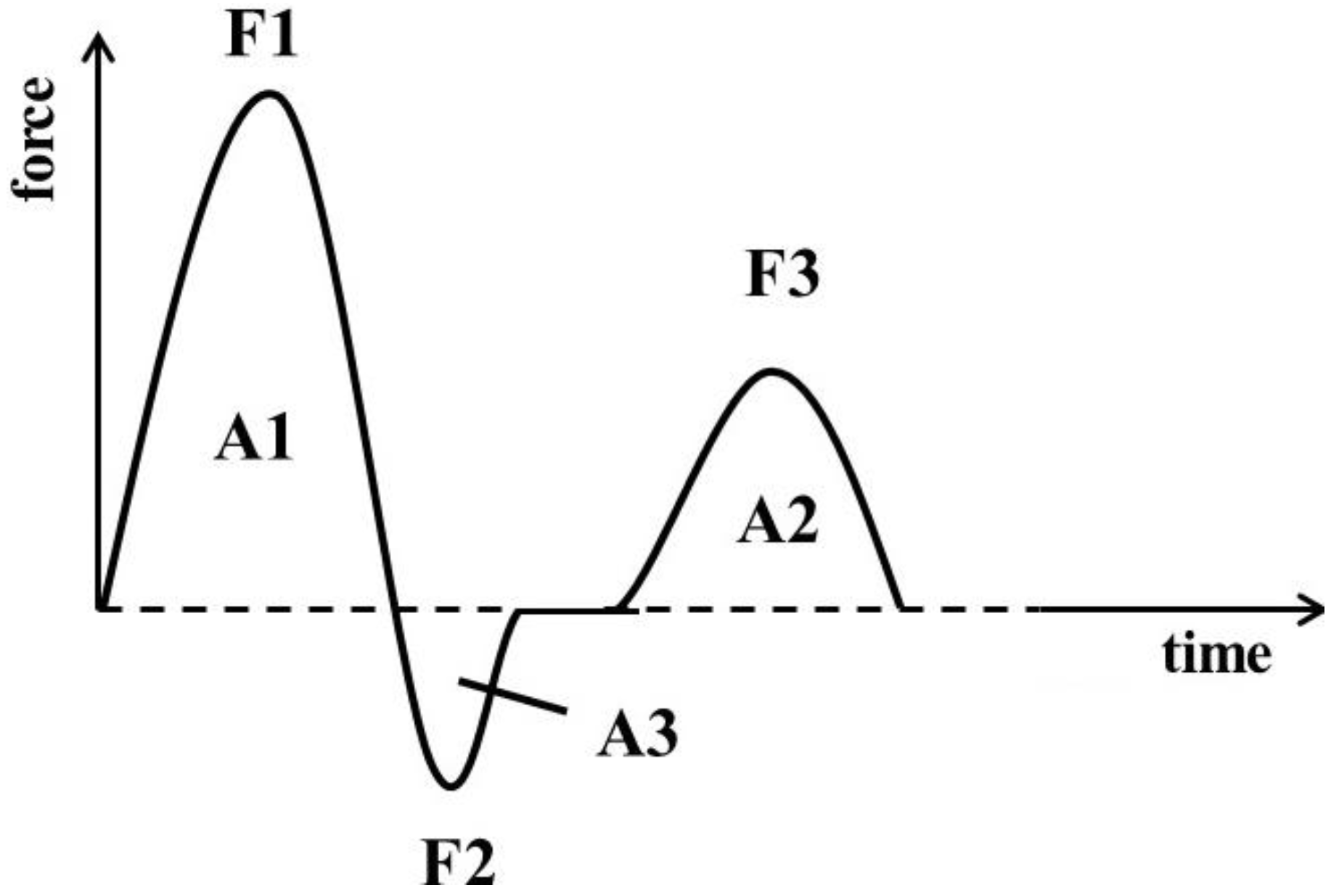

2.5. Textural Analysis via Texture Analyzer and Rheometer

2.5.1. Intact Yoghurt Gels

2.5.2. Stirred Yoghurt Gels

2.6. Sensory Texture Profile Analysis (STPA) and Hedonic Rating

2.7. Statistical Analysis

3. Results and Discussion

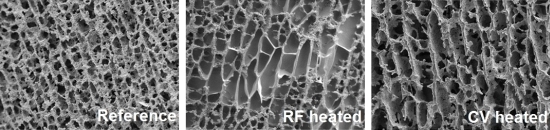

3.1. Microstructural Analysis via Cryo-SEM

3.2. Whey Separation (Syneresis)

3.3. Textural Analysis via Instrumental Assessment

3.3.1. TPA on Intact Yoghurt Gels

| Whey Separation (mL) | Reference Yoghurt | RF-Treated Yoghurts | CV-Treated Yoghurts | ANOVA Results | |||||

|---|---|---|---|---|---|---|---|---|---|

| 58 °C | 65 °C | 72 °C | 58 °C | 65 °C | 72 °C | F Value | p Value | ||

| Week 0 | ND (0.0 ± 0.0) | 9.5 ± 1.4a,b | 6.7 ± 0.7a | 56.2 ± 10.0d | 7.6 ± 2.0a | 13.7 ± 1.0b | 19.3 ± 4.2c | 74.88 | 1.59 × 10−10 |

| Week 2 | ND (0.0 ± 0.0) | 9.2 ± 0.2a | 8.5 ± 2.7a 1 | - | 18.5 ± 1.5b | 20.0 ± 8.1b 1 | - | 6.75 | 7.57 × 10−3 |

| Week 4 | ND (0.0 ± 0.0) | 9.6 ± 7.6a 1 | 12.8 ± 2.9a | - | 14.0 ± 1.5a | 22.9 ± 3.5b | - | 6.45 | 7.56 × 10−3 |

| Week 5 | ND (0.0 ± 0.0) | 16.1 ± 2.0b | 15.4 ± 1.5a,b | - | 11.2 ± 4.3a 1 | 15.1 ± 1.0a,b | - | 2.92 | 8.16 × 10−2 |

| Texture Profile Analysis (TPA) | Reference Yoghurt | RF-Treated Yoghurts | CV-Treated Yoghurts | Set Reference Yoghurt | ANOVA Results | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| 58 °C | 65 °C | 72 °C | 58 °C | 65 °C | 72 °C | F Value | p Value | |||

| Hardness HD (g) | 32.961 ± 2.660a | 57.271 ± 1.577b | 99.066 ± 12.430d | 86.605 ± 6.814c | 112.142 ± 4.848e | 107.038 ± 3.689de | 142.693 ± 11.755f | 160.936 ± 5.282g | 102.38 | 2.22 × 10−16 |

| Cohesiveness CO | 0.617 ± 0.016a | 0.543 ± 0.040b | 0.487 ± 0.007c | 0.570 ± 0.011b | 0.466 ± 0.019c | 0.489 ± 0.015c | 0.455 ± 0.025c | 0.390 ± 0.031d | 33.33 | 7.28 × 10−11 |

| Adhesiveness AD (g·s) | 73.000 ± 12.268bc | 126.000 ± 11.591d | 115.522 ± 21.873d | 0.003 ± 0.005a1 | 81.566 ± 18.221bc | 49.537 ± 10.743b | 54.465 ± 38.268b1 | 101.750 ± 20.092cd | 13.03 | 8.25 × 10−7 |

| Gumminess GU (g) | 20.293 ± 1.176a | 33.064 ± 1.295b | 48.215 ± 5.769c | 49.331 ± 3.489c | 51.356 ± 0.582c | 51.643 ± 2.293c | 64.648 ± 2.525d | 62.818 ± 5.263d | 60.36 | 1.08 × 10−13 |

| Texture Profile Analysis (TPA) | Reference Yoghurt | RF-Treated Yoghurts | CV-Treated Yoghurts | ANOVA Results | ||||

|---|---|---|---|---|---|---|---|---|

| 58 °C | 65 °C | 58 °C | 65 °C | F Value | p Value | |||

| Week 2 | HD (g) | 33.379 ± 0.962a | 57.646 ± 3.626b | 96.335 ± 13.917c | 90.643 ± 2.195c | 114.678 ± 13.599d | 40.19 | 7.57 × 10−8 |

| CO | 0.596 ± 0.010a | 0.532 ± 0.015b | 0.487 ± 0.011c | 0.495 ± 0.011c | 0.480 ± 0.022c | 38.90 | 9.44 × 10−8 | |

| AD (g·s) | 89.750 ± 20.584a | 113.000 ± 14.612b | 89.750 ± 19.434a | 65.000 ± 4.583a | 83.750 ± 21.487a 1 | 2.95 | 5.54 × 10−2 | |

| GU (g) | 19.771 ± 0.357a | 30.621 ± 1.274b | 46.818 ± 6.050c | 44.847 ± 1.453c | 58.031 ± 1.445d | 80.68 | 5.87 × 10−10 | |

| Week 4 | HD (g) | 32.037 ± 0.723a | 81.367 ± 2.685b | 104.357 ± 17.762c | 104.933 ± 7.409c | 121.986 ± 11.941c | 35.28 | 1.82 × 10−7 |

| CO | 0.602 ± 0.014a | 0.511 ± 0.016b | 0.483 ± 0.015c | 0.483 ± 0.012c | 0.473 ± 0.014c | 46.50 | 2.80 × 10−8 | |

| AD (g·s) | 69.000 ± 11.247a | 120.000 ± 9.721b | 77.750 ± 46.885a 1 | 82.500 ± 11.715ab | 69.250 ± 15.610a | 2.38 | 9.78 × 10−2 | |

| GU (g) | 19.265 ± 0.053a | 41.598 ± 1.457b | 50.247 ± 7.780c | 50.596 ± 2.700c | 57.523 ± 4.429c | 37.19 | 1.28 × 10−7 | |

| Week 5 | HD (g) | 42.390 ± 2.285a | 80.797 ± 0.986b | 98.642 ± 16.684c | 101.107 ± 8.037c | 135.789 ± 2.174d | 51.64 | 1.36 × 10−8 |

| CO | 0.545 ± 0.004a | 0.503 ± 0.012bc | 0.509 ± 0.047ab | 0.486 ± 0.014bc | 0.466 ± 0.013c | 4.95 | 9.53 × 10−3 | |

| AD (g·s) | 103.000 ± 6.595bc | 104.250 ± 23.626c | 62.500 ± 9.206a | 65.250 ± 19.227a 1 | 77.250 ± 6.942ab | 5.50 | 6.28 × 10−3 | |

| GU (g) | 23.078 ± 1.099a | 40.596 ± 0.726b | 49.489 ± 4.825c | 49.018 ± 2.725c | 63.196 ± 0.840d | 104.99 | 8.88 × 10−11 | |

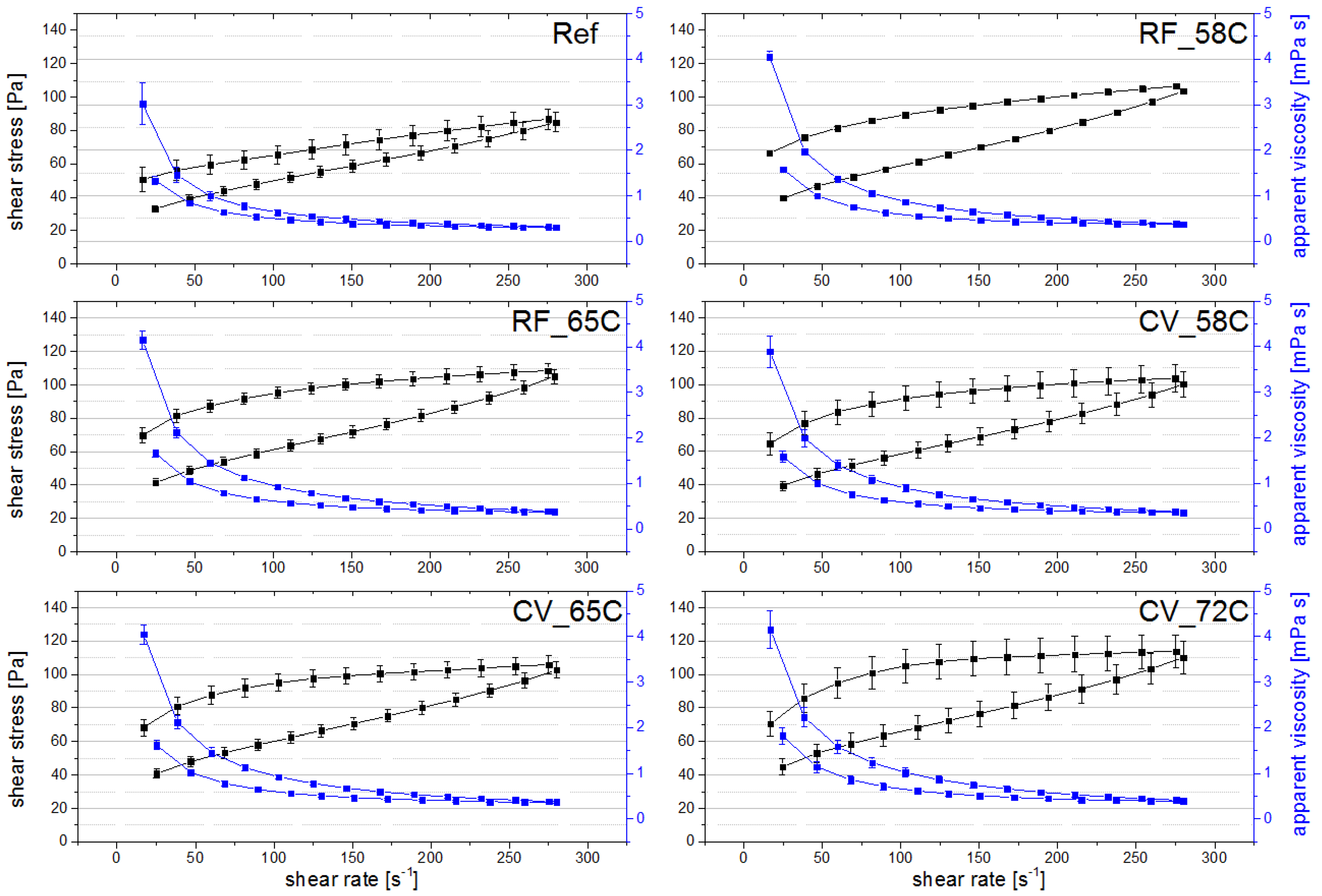

3.3.2. Texture Analysis on Stirred Yoghurt Gels

| Rotation and Oscillation Analysis | Reference Yoghurt | RF-Treated Yoghurts | CV-Treated Yoghurts | Set Reference Yoghurt | ANOVA Results | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 58 °C | 65 °C | 72 °C | 58 °C | 65 °C | 72 °C | F Value | p Value | ||||

| Apparent viscosity (Pa·s) | Initial | 0.852 ± 0.014a | 1.079 ± 0.039c | 1.141 ± 0.043cd | 1.317 ± 0.090e | 1.198 ± 0.038d | 1.318 ± 0.005e | 1.457 ± 0.042f | 0.971 ± 0.065b | 58.57 | 1.51 × 10−13 |

| Final | 0.555 ± 0.021b | 0.621 ± 0.017c | 0.632 ± 0.021c | 0.449 ± 0.057a | 0.653 ± 0.018c | 0.698 ± 0.003d | 0.737 ± 0.025d | 0.453 ± 0.025a | 55.78 | 2.61 × 10−13 | |

| % Broken structure | 34.875 ± 1.560a | 42.464 ± 1.628b | 44.588 ± 0.665bc | 65.609 ± 5.440f | 45.444 ± 0.730bc | 47.028 ± 0.317cd | 49.434 ± 0.643d | 53.273 ± 0.712e | 52.52 | 5.10 × 10−13 | |

| Oscillatory test (Pa) | G’ | 385.128 ± 141.595a 1 | 400.585 ± 60.124a | 561.600 ± 60.186a | 1401.226 ± 389.870c 1 | 591.024 ± 59.334a | 576.934 ± 99.024a | 868.278 ± 12.132b | 644.001 ± 61.057ab | 13.23 | 7.19 × 10−7 |

| G’’ | 144.374 ± 51.547 a 1 | 124.086 ± 16.562a | 173.494 ± 13.801a | 436.935 ± 112.452c 1 | 178.469 ± 16.495a | 175.900 ± 29.154a | 268.420 ± 6.590b | 201.644 ± 18.500ab | 13.96 | 4.40 × 10−7 | |

| Rotation and Oscillation Analysis | Reference Yoghurt | RF-Treated Yoghurts | CV-Treated Yoghurts | ANOVA Results | |||||

|---|---|---|---|---|---|---|---|---|---|

| 58 °C | 65 °C | 58 °C | 65 °C | F Value | p Value | ||||

| Week 2 | Apparent viscosity (mPa·s) | Initial | 0.807 ± 0.043a | 1.180 ± 0.034b | 1.291 ± 0.035b | 1.472 ± 0.062c | 1.427 ± 0.137c | 42.23 | 5.41 × 10−8 |

| Final | 0.523 ± 0.024a | 0.615 ± 0.010b | 0.657 ± 0.033b | 0.723 ± 0.027c | 0.713 ± 0.055c | 19.18 | 9.19 × 10−6 | ||

| % Broken structure | 35.139 ± 0.813a | 47.792 ± 1.568b | 49.123 ± 1.389bc | 50.816 ±1.676c | 50.032 ± 1.083bc | 69.79 | 1.64 × 10−9 | ||

| Oscillatory test (Pa) | G’ | 177.643 ± 22.163a | 464.479 ± 264.951b 1 | 829.497 ± 144.263c | 671.827 ± 37.555bc | 614.750 ± 168.148bc 1 | 7.55 | 1.53 × 10−3 | |

| G’’ | 58.985 ± 6.280a | 178.843 ± 11.699b | 252.599 ± 52.660c | 201.149 ± 10.039bc | 189.612 ± 46.672b | 14.72 | 4.47 × 10−5 | ||

| Week 4 | Apparent viscosity (mPa·s) | Initial | 0.909 ± 0.005a | 1.304 ± 0.038b | 1.369 ± 0.046c | 1.389 ± 0.023c | 1.452 ± 0.049d | 120.27 | 3.32 × 10−11 |

| Final | 0.568 ± 0.004a | 0.711 ± 0.009bc | 0.705 ± 0.005b | 0.726 ± 0.011c | 0.763 ± 0.021d | 129.52 | 1.94 × 10−11 | ||

| % Broken structure | 37.541 ± 0.463a | 45.474 ± 1.531b | 48.499 ± 1.218c | 47.719 ± 0.255c | 47.441 ± 0.717c | 65.69 | 2.52 × 10−9 | ||

| Oscillatory test (Pa) | G’ | 311.313 ± 121.421a 1 | 461.110 ± 89.371ab | 696.739 ± 6.195c | 652.366 ± 68.599bc | 526.338 ± 187.800bc 1 | 5.70 | 5.39 × 10−3 | |

| G’’ | 95.718 ± 33.897a 1 | 142.018 ± 23.555ab | 213.894 ± 2.990c | 194.065 ± 19.226bc | 162.922 ± 52.584bc 1 | 6.59 | 2.87 × 10−3 | ||

| Week 5 | Apparent viscosity (mPa·s) | Initial | 0.922 ± 0.031a | 1.327 ± 0.059b | 1.332 ± 0.022b | 1.391 ± 0.035bc | 1.428 ± 0.045c | 80.28 | 6.08 × 10−10 |

| Final | 0.580 ± 0.023a | 0.712 ± 0.030b | 0.706 ± 0.004b | 0.731 ± 0.003b | 0.736 ± 0.014b | 38.04 | 1.10 × 10−7 | ||

| % Broken structure | 37.088 ± 0.963a | 46.318 ± 1.656b | 46.966 ± 0.778bc | 47.415 ± 0.987bc | 48.440 ± 0.678c | 56.19 | 7.54 × 10−9 | ||

| oscillatory test (Pa) | G’ | 173.049± 1.544a | 564.869 ± 151.042bc 1 | 534.679 ± 163.877b 1 | 723.439 ± 31.596cd | 830.820 ± 27.264d | 18.41 | 1.18 × 10−5 | |

| G’’ | 59.458± 2.488a | 169.716 ± 41.109bc | 164.178 ± 45.164b 1 | 213.616 ± 8.514cd | 245.669 ± 8.373d | 19.40 | 8.58 × 10−6 | ||

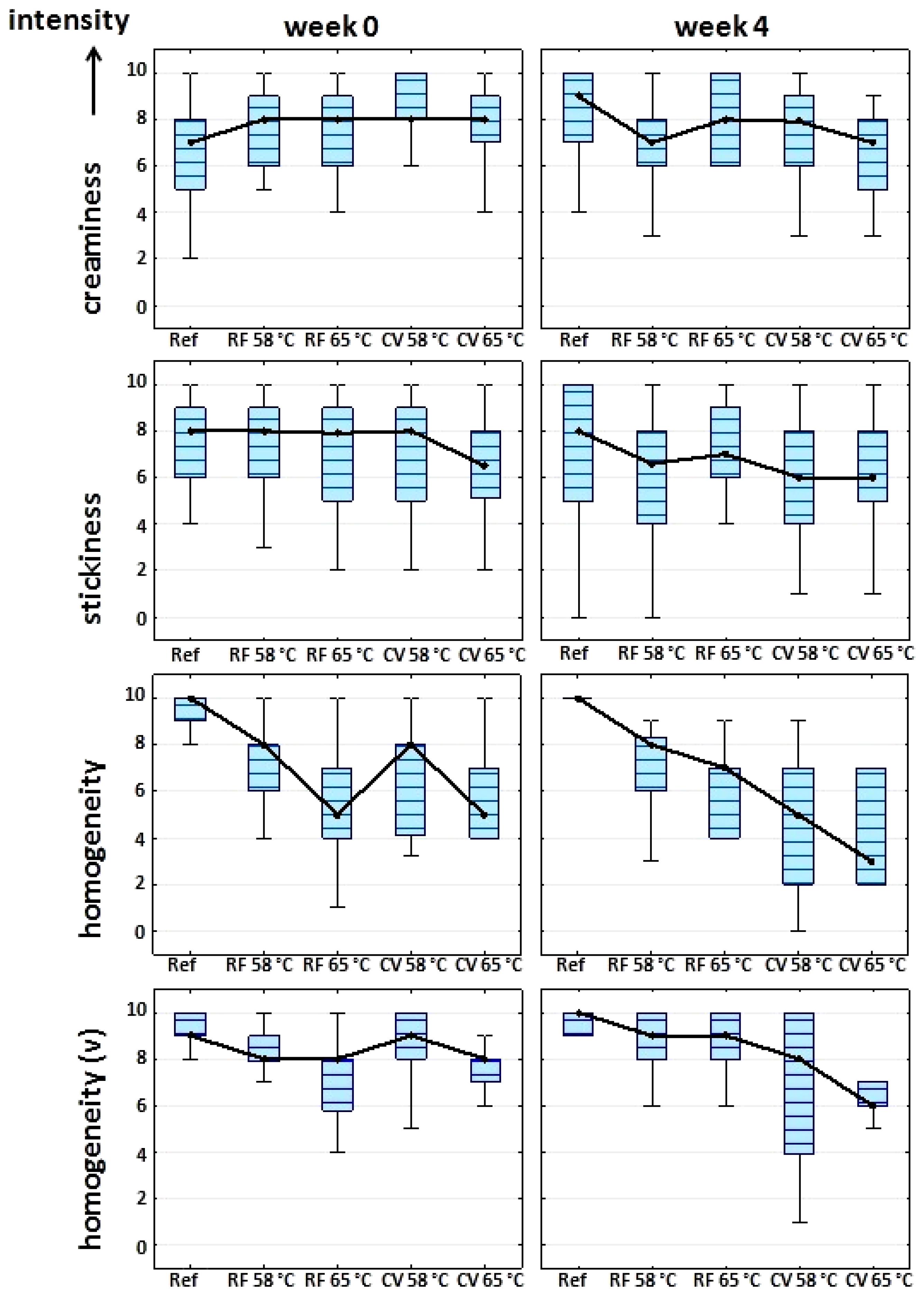

3.4. Texture Profile Analysis by Sensory Evaluation

| Sensory Texture Profile Analysis (STPA) (Visual Analogue Scale, Mean Values) | Reference Yoghurt | RF-Treated Yoghurts | CV-Treated Yoghurts | Set Reference | ANOVA Results | ||||

|---|---|---|---|---|---|---|---|---|---|

| 58 °C | 65 °C | 58 °C | 65 °C | F Value | p Value | ||||

| Week 0 | Creaminess | 6.6b | 7.7ab | 7.5ab | 8.3a | 7.7ab | 4.8c | 5.49 | 2.47 × 10−4 |

| Stickiness | 7.6 | 7.5 | 7.1 | 6.8 | 6.5 | 6.9 | 0.41 | 8.42 × 10−1 * | |

| Homogeneity | 8.8a | 6.8b | 5.3b | 6.9b | 5.9b | 1.7c | 14.80 | 5.69 × 10−10 | |

| Homogeneity (v) | 9.2a | 8.3abc | 7.3c | 8.8ab | 7.6bc | 4.0d | 16.30 | 1.00 × 10−10 | |

| Week 2 | Creaminess | 7.7ab | 7.3abc | 5.7c | 8.2a | 5.9bc | - | 2.94 | 2.76 × 10−2 |

| Stickiness | 7.7a | 5.6b | 4.8b | 5.8ab | 5.4b | - | 2.43 | 5.76 × 10−2 | |

| Homogeneity | 8.2a | 4.2bc | 2.5c | 5.2b | 3.5bc | - | 7.60 | 5.05 × 10−5 | |

| Homogeneity (v) | 9.5a | 7.2b | 3.8d | 6.8bc | 5.2cd | - | 8.86 | 1.09 × 10−5 | |

| Week 4 | Creaminess | 8.1 | 7.0 | 8.2 | 7.4 | 6.5 | - | 1.43 | 0.24 * |

| Stickiness | 7.2 | 6.0 | 7.3 | 5.7 | 6.4 | - | 0.75 | 0.56 * | |

| Homogeneity | 10.0a | 7.1b | 6.2bc | 4.7cd | 4.2d | - | 15.31 | 3.07 × 10−8 | |

| Homogeneity (v) | 9.7a | 8.5ab | 8.5a | 6.8bc | 6.5c | - | 5.23 | 1.34 × 10−3 | |

3.5. Hedonic Rating of Stirred Yoghurt Gels

4. Conclusions

Abbreviations

| A | area under curve |

| AD | adhesiveness (g·s) |

| ANOVA | analysis of variance |

| CO | cohesiveness |

| cryo-SEM | cryo-scanning electron microscopy |

| CV | convectional heating |

| F | force (g) |

| GU | gumminess (g) |

| HD | hardness (g) |

| ND | not detected |

| n.s. | not significant |

| RF | radio frequency heating |

| sig. | significant |

| STPA | sensory texture profile analysis |

| TPA | texture profile analysis |

Acknowledgements

Author Contributions

Conflicts of Interest

References

- Walstra, P. On the stability of casein micelles. J. Dairy Sci. 1990, 73, 1965–1979. [Google Scholar] [CrossRef]

- Walstra, P.; Wouters, J.T.M.; Geurts, T.J. Dairy Science and Technology, 2nd ed.; Taylor & Francis: Boca Raton, FL, USA, 2006. [Google Scholar]

- Walstra, P. Relation between structure and texture of cultured milk products. In Texture of Fermented Milk Products and Dairy Desserts, Proceedings IDF Symposium 1997; International Dairy Federation: Brussels, Belgium, 1998; pp. 9–15. [Google Scholar]

- Chandan, R.C.; O’Rell, K.R. Manufacture of various types of yogurt. In Manufacturing Yogurt and Fermented Milks, 1st ed.; Chandan, R.C., White, C.H., Kilara, A., Hui, Y.H., Eds.; Blackwell Publishing: Oxford, UK, 2006; pp. 211–236. [Google Scholar]

- Chandan, R.C.; Kilara, A. Manufacturing Yogurt and Fermented Milks, 2nd ed.; Wiley-Blackwell: Hoboken, NJ, USA, 2013; pp. 294–295. [Google Scholar]

- Barua, N.N.; Hampton, R.J. Aseptic Yoghurt. US Patent 4609554 A, 2 September 1986. [Google Scholar]

- Keefer, D.K.; Murray, M.E. Process for Production of a No-Starch Shelf Stable Yogurt Product. US Patent 4748026 A, 31 May 1988. [Google Scholar]

- Egli, F.; Egli, F. Production of Sterile Yoghurt. US Patent 4235934-A, 25 November 1980. [Google Scholar]

- Amrein, R.; Widmer, W. Sterile Yoghurt Production. Swiss Patent 634464 A, 1983. [Google Scholar]

- Güldas, M.; Atamer, M. Effect of pasteurization norm and storage temperature on the quality of long-life yoghurt. GIDA 1995, 20, 313–319. [Google Scholar]

- Bach, J. Improvements in or relating to methods for effecting uniform heating of organic products. British Patent 1507069-A, 1978. [Google Scholar]

- Siefarth, C.; Tran, T.B.T.; Mittermaier, P.; Pfeiffer, T.; Buettner, A. Effect of radio frequency heating on yoghurt, I: Technological applicability, shelf-life and sensorial quality. Foods 2014, 3, 318–335. [Google Scholar]

- Kessler, H.G. The structure of fermented milk products as influenced by technology and composition. In Texture of Fermented Milk Products and Dairy Desserts, Proceedings IDF Symposium 1997; International Dairy Federation: Brussels, Belgium, 1998; pp. 93–105. [Google Scholar]

- Bourne, M.C. Food Texture and Viscosity: Concept and Measurement, 2nd ed.; Academic Press: San Diego, CA, USA, 2002. [Google Scholar]

- Kaur, H.; Mishra, H.N.; Kumar, P. Textural properties of mango soy fortified probiotic yoghurt: Optimisation of inoculum level of yoghurt and probiotic culture. Int. J. Food Sci. Technol. 2009, 44, 415–424. [Google Scholar] [CrossRef]

- Rosenthal, A.J. Food Texture: Measurement and Perception; Springer: New York, NY, USA, 1999. [Google Scholar]

- Everett, D.W.; McLeod, R.E. Interactions of polysaccharide stabilisers with casein aggregates in stirred skim-milk yoghurt. Int. Dairy J. 2005, 15, 1175–1183. [Google Scholar] [CrossRef]

- Vercet, A.; Oria, R.; Marquina, P.; Crelier, S.; Lopez-Buesa, P. Rheological properties of yoghurt made with milk submitted to manothermosonication. J. Agric. Food Chem. 2002, 50, 6165–6171. [Google Scholar] [CrossRef]

- Afonso, I.M.; Maia, J.M. Rheological monitoring of structure evolution and development in stirred yoghurt. J. Food Eng. 1999, 42, 183–190. [Google Scholar] [CrossRef]

- Tribby, D. Yogurt. In The Sensory Evaluation of Dairy Products, 2nd ed.; Clark, S., Costello, M., Bodyfelt, F., Drake, M.A, Eds.; Springer: New York, NY, USA, 2009; pp. 205–218. [Google Scholar]

- Kalab, M. Practical aspects of electron-microscopy in dairy research. Food Struct. 1993, 12, 95–114. [Google Scholar]

- Hassan, A.N.; Frank, J.F.; Elsoda, M. Observation of bacterial exopolysaccharide in dairy products using cryo-scanning electron microscopy. Int. Dairy J. 2003, 13, 755–762. [Google Scholar] [CrossRef]

- Sandoval-Castilla, O.; Lobato-Calleros, C.; Aguirre-Mandujano, E.; Vernon-Carter, E.J. Microstructure and texture of yogurt as influenced by fat replacers. Int. Dairy J. 2004, 14, 151–159. [Google Scholar] [CrossRef]

- Lee, W.J.; Lucey, J.A. Formation and physical properties of yogurt. Aust. J. Anim. Sci. 2010, 23, 1127–1136. [Google Scholar] [CrossRef]

- Soukoulis, C.; Panagiotidis, P.; Koureli, R.; Tzia, C. Industrial yogurt manufacture: Monitoring of fermentation process and improvement of final product quality. J. Dairy Sci. 2007, 90, 2641–2654. [Google Scholar] [CrossRef]

- Töpel, A. Chemie und Physik der Milch: Naturstoff, Rohstoff, Lebensmittel, 1st ed.; Behr’s Verlag: Hamburg, Germany, 2004; pp. 402–430. (in German) [Google Scholar]

- Lucey, J.A. Cultured dairy products: An overview of their gelation and texture properties. Int. J. Dairy Technol. 2004, 57, 77–84. [Google Scholar] [CrossRef]

- Lucey, J.A.; Singh, H. Formation and physical properties of acid milk gels: A review. Food Res. Int. 1997, 30, 529–542. [Google Scholar] [CrossRef]

- Weidendorfer, K.; Bienias, A.; Hinrichs, J. Investigation of the effects of mechanical post-processing with a colloid mill on the texture properties of stirred yogurt. Int. J. Dairy Technol. 2008, 61, 379–384. [Google Scholar] [CrossRef]

- Salvador, A.; Fiszman, S.M. Textural and sensory characteristics of whole and skimmed flavored set-type yogurt during long storage. J. Dairy Sci. 2004, 87, 4033–4041. [Google Scholar] [CrossRef]

- Roefs, S.P.F.M.; de Groot-Mostert, A.E.A.; van Vliet, T. Structure of acid casein gels 1. Formation and model of gel network. Coll. Surf. 1990, 50, 141–159. [Google Scholar] [CrossRef]

- Parnell-Clunies, E.M.; Kakuda, Y.; Deman, J.M. Influence of heat treatment of milk on the flow properties of yoghurt. J. Food Sci. 1986, 51, 1459–1462. [Google Scholar] [CrossRef]

- Mezger, T.G. Das Rheologie Handbuch: Für Anwender von Rotations- und Oszillations-Rheometern, 2nd ed.; Vincentz Network: Hannover, Germany, 2007. (in German) [Google Scholar]

- Serra, M.; Trujillo, A.J.; Guamis, B.; Ferragut, V. Evaluation of physical properties during storage of set and stirred yogurts made from ultra-high pressure homogenization-treated milk. Food Hydrocoll. 2009, 23, 82–91. [Google Scholar] [CrossRef]

- Damin, M.R.; Minowa, E.; Alcântara, M.R.; Oliveira, M.N. Effect of cold storage on culture viability and some rheological properties of fermented milk prepared with yogurt and probiotic bacteria. J. Texture Stud. 2008, 39, 40–55. [Google Scholar] [CrossRef]

- Chandan, R.C. Dairy: Yoghurt. In Food Processing: Principles and Applications, 1st ed.; Smith, J.S., Hui, Y.H., Eds.; Blackwell Publishing: Oxford, UK, 2004; pp. 297–318. [Google Scholar]

- Lucey, J.A.; Munro, P.A.; Singh, H. Rheological properties and microstructure of acid milk gels as affected by fat content and heat treatment. J. Food Sci. 1998, 63, 660–664. [Google Scholar] [CrossRef]

- Robinson, R.K.; Itsaranuwat, P. Properties of yoghurt and their appraisal. In Fermented Milks; Tamime, A.Y., Ed.; Blackwell Publishing: Oxford, UK, 2008; pp. 79–84. [Google Scholar]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Siefarth, C.; Tran, T.B.T.; Mittermaier, P.; Pfeiffer, T.; Buettner, A. Effect of Radio Frequency Heating on Yoghurt, II: Microstructure and Texture. Foods 2014, 3, 369-393. https://doi.org/10.3390/foods3020369

Siefarth C, Tran TBT, Mittermaier P, Pfeiffer T, Buettner A. Effect of Radio Frequency Heating on Yoghurt, II: Microstructure and Texture. Foods. 2014; 3(2):369-393. https://doi.org/10.3390/foods3020369

Chicago/Turabian StyleSiefarth, Caroline, Thi Bich Thao Tran, Peter Mittermaier, Thomas Pfeiffer, and Andrea Buettner. 2014. "Effect of Radio Frequency Heating on Yoghurt, II: Microstructure and Texture" Foods 3, no. 2: 369-393. https://doi.org/10.3390/foods3020369