Effects of High-Pressure Homogenization on the Structural, Physical, and Rheological Properties of Lily Pulp

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Sample Preparation

2.2. Homogenization of Lily Pulp

2.3. Particle Size Analysis

2.4. Microstructure of Homogenized Lily Pulp

2.5. Pulp Sedimentation

2.6. Serum Cloudiness

2.7. Rheological Behavior

2.8. Determination of Color and Total Soluble Solids

2.9. Statistical Analysis

3. Results and Discussion

3.1. Changes in the Particle Size Distribution of Lily Pulp Treated with HPH

3.2. Changes in the Microstructure of Lily Pulp Treated with HPH

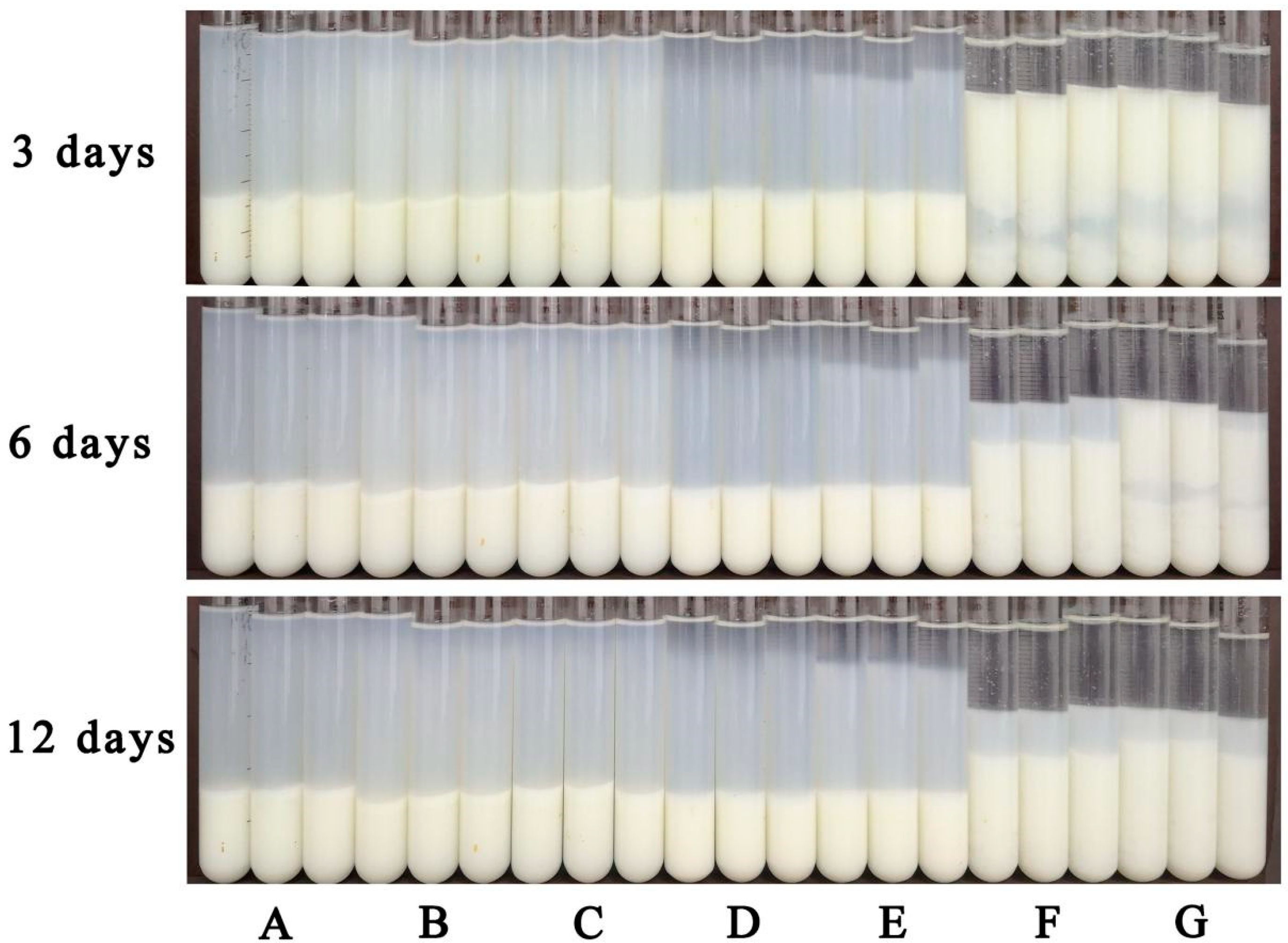

3.3. Changes in the Pulp Sedimentation of Lily Pulp Treated with HPH

3.4. Changes in Serum Cloudiness of Lily Pulp Treated with HPH

3.5. Changes in the Total Soluble Solids and Color of Lily Pulp Treated with HPH

3.6. Changes in the Rheological Properties of Lily Pulp Treated with HPH

4. Conclusions

Supplementary Materials

Supplementary File 1Author Contributions

Funding

Conflicts of Interest

References

- Jin, L.; Zhang, Y.L.; Yan, L.M.; Guo, Y.L.; Niu, L.X. Phenolic compounds and antioxidant activity of bulb extracts of six Lilium species native to China. Molecules 2012, 17, 9361–9378. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.T.; Huang, H.H.; Zhang, Y.; Li, X.; Li, H.F.; Jiang, Q.Q.; Gao, W.Y. Role of effective composition on antioxidant, anti-inflammatory, sedative-hypnotic capacities of 6 common edible Lilium varieties. J. Food Sci. 2015, 80, H857–H868. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.G.; Zhang, D.N.; Zhu, Q.; Yang, Q.H.Z.; Han, Y.B. Purification, preliminary characterization and in vitro immunomodulatory activity of tiger lily polysaccharide. Carbohydr. Polym. 2014, 106, 217–222. [Google Scholar] [CrossRef] [PubMed]

- Kwon, O.K.; Lee, M.Y.; Yuk, J.E.; Oh, S.R.; Chin, Y.W.; Lee, H.K.; Ahn, K.S. Anti-inflammatory effects of methanol extracts of the root of Lilium lancifolium on LPS-stimulated Raw264.7 cells. J. Ethnopharmacol. 2010, 130, 28–34. [Google Scholar] [CrossRef] [PubMed]

- Pan, G.; Xie, Z.; Huang, S.; Tai, Y.; Cai, Q.; Jiang, W.; Yuan, Y. Immune-enhancing effects of polysaccharides extracted from Lilium lancifolium Thunb. Int. Immunopharmacol. 2017, 52, 119–126. [Google Scholar] [CrossRef] [PubMed]

- Yu, X.R.; Zhang, J.; Shao, S.S.; Yu, H.; Xiong, F.; Wang, Z. Morphological and physicochemical properties of bulb and bulbil starches from Lilium lancifolium. Starch/Stärke 2015, 67, 448–458. [Google Scholar] [CrossRef]

- Okazaki, Y.; Chiji, H.; Kato, N. Protective effect of dietary lily bulb on dextran sulfate sodium-induced colitis in rats fed a high-fat diet. J. Nutr. Sci. Vitaminol. 2016, 62, 206–212. [Google Scholar] [CrossRef] [PubMed]

- Bernat, N.; Cháfer, M.; Rodríguez-García, J.; Chiralt, A.; González-Martínez, C. Effect of high pressure homogenisation and heat treatment on physical properties and stability of almond and hazelnut milks. LWT-Food Sci. Technol. 2015, 62, 488–496. [Google Scholar] [CrossRef]

- Yu, Z.Y.; Jiang, S.W.; Cai, X.M.; Jiang, S.T.; Pan, L.J. Effect of high pressure homogenization (HPH) on the physical properties of taro (Colocasia esculenta (L). Schott) pulp. J. Food Eng. 2016, 177, 1–8. [Google Scholar] [CrossRef]

- Kubo, M.T.K.; Augusto, P.E.D.; Cristianini, M. Effect of high pressure homogenization (HPH) on the physical stability of tomato juice. Food Res. Int. 2013, 51, 170–179. [Google Scholar] [CrossRef] [Green Version]

- Wei, B.X.; Cai, C.X.; Xu, B.G.; Jin, Z.Y.; Tian, Y.Q. Disruption and molecule degradation of waxy maize starch granules during high pressure homogenization process. Food Chem. 2018, 240, 165–173. [Google Scholar] [CrossRef] [PubMed]

- Pereda, J.; Ferragut, V.; Quevedo, J.M.; Guamis, B.; Trujillo, A.J. Heat damage evaluation in ultra-high pressure homogenised milk. Food Hydrocoll. 2009, 23, 1974–1979. [Google Scholar] [CrossRef]

- Nguyen, H.T.H.; Ong, L.; Kentish, S.E.; Gras, S.L. Homogenisation improves the microstructure, syneresis and rheological properties of buffalo yoghurt. Int. Dairy J. 2015, 46, 78–87. [Google Scholar] [CrossRef]

- Leite, T.S.; Augusto, P.E.D.; Cristianini, M. The use of high pressure homogenization (HPH) to reduce consistency of concentrated orange juice (COJ). Innov. Food Sci. Emerg. Technol. 2014, 26, 124–133. [Google Scholar] [CrossRef]

- Augusto, P.E.D.; Ibarz, A.; Cristianini, M. Effect of high pressure homogenization (HPH) on the rheological properties of tomato juice: Viscoelastic properties and the Cox–Merz rule. J. Food Eng. 2013, 114, 57–63. [Google Scholar] [CrossRef]

- Augusto, P.E.D.; Ibarz, A.; Cristianini, M. Effect of high pressure homogenization (HPH) on the rheological properties of tomato juice: Time-dependent and steady-state shear. J. Food Eng. 2012, 111, 570–579. [Google Scholar] [CrossRef] [Green Version]

- Leite, T.S.; Augusto, P.E.D.; Cristianini, M. Using high pressure homogenization (HPH) to change the physical properties of cashew apple juice. Food Biophys. 2015, 10, 169–180. [Google Scholar] [CrossRef]

- Patrignani, F.; Vannini, L.; Kamdem, S.L.S.; Lanciotti, R.; Guerzoni, M.E. Potentialites of high pressure homogenization to inactivate Zygosaccharomyces bailii in fruit juices. J. Food Sci. 2010, 75, M116–M120. [Google Scholar] [CrossRef]

- Buggenhout, S.V.; Wallecan, J.; Christiaens, S.; Debon, S.J.J.; Desmet, C.; Loey, A.V.; Hendrickx, M.; Mazoyer, J. Influence of high-pressure homogenization on functional properties of orange pulp. Innov. Food Sci. Emerg. Technol. 2015, 30, 51–60. [Google Scholar] [CrossRef]

- Castro, A.; Bergenståhl, B.; Tornberg, E. Effect of heat treatment and homogenization on the rheological properties of aqueous parsnip suspensions. J. Food Eng. 2013, 117, 383–392. [Google Scholar] [CrossRef]

- Sato, A.C.K.; Cunha, R.L. Effect of particle size on rheological properties of jaboticaba pulp. J. Food Eng. 2009, 91, 566–570. [Google Scholar] [CrossRef]

- Yu, Z.Y.; Jiang, S.W.; Cai, J.; Cao, X.M.; Zheng, Z.; Jiang, S.T.; Wang, H.L.; Pan, L.J. Effect of high pressure homogenization (HPH) on the rheological properties of taro (Colocasia esculenta (L). Schott) pulp. Innov. Food Sci. Emerg. Technol. 2018, 50, 160–168. [Google Scholar] [CrossRef]

- Guo, Z.; Zeng, S.; Zhang, Y.; Lu, X.; Tian, Y.; Zheng, B. The effects of ultra-high pressure on the structural, rheological and retrogradation properties of lotus seed starch. Food Hydrocoll. 2015, 44, 285–291. [Google Scholar] [CrossRef]

- Alvarez, M.D.; Fuentes, R.; Olivares, M.D.; Canet, W. Effects of high hydrostatic pressure on rheological and thermal properties of chickpea (Cicer arietinum L.) flour slurry and heat-induced paste. Innov. Food Sci. Emerg. Technol. 2014, 21, 12–23. [Google Scholar] [CrossRef]

- Ramaswamy, H.S.; Gundurao, A. Effect of soluble solids and high pressure treatment on rheological properties of protein enriched mango puree. Foods 2019, 8, 39. [Google Scholar] [CrossRef] [PubMed]

- Mert, B. Using high pressure microfluidization to improve physical properties and lycopene content of ketchup type products. J. Food Eng. 2012, 109, 579–587. [Google Scholar] [CrossRef]

- Silva, V.M.; Sato, A.C.K.; Barbosa, G.; Dacanal, G.; Ciro-Velasquez, H.J.; Cunha, R.L. The effect of homogenisation on the stability of pineapple pulp. Int. J. Food Sci. Technol. 2010, 45, 2127–2133. [Google Scholar] [CrossRef]

- Okoth, M.W.; Kaahwa, A.R.; Imungi, J.K. The effect of homogenisation, stabiliser and amylase on cloudiness of passion fruit juice. Food Control. 2000, 11, 305–311. [Google Scholar] [CrossRef]

- Calligaris, S.; Foschia, M.; Bartolomeoli, I.; Maifreni, M.; Manzocco, L. Study on the applicability of high-pressure homogenization for the production of banana juices. LWT-Food Sci. Technol. 2012, 45, 117–121. [Google Scholar] [CrossRef]

- Zhou, D.N.; Zhang, B.; Chen, B.; Chen, H.Q. Effects of oligosaccharides on pasting, thermal and rheological properties of sweet potato starch. Food Chem. 2017, 230, 516–523. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, J.; Al-Jassar, S.; Thomas, L. A comparison in rheological, thermal, and structural properties between Indian Basmati and Egyptian Giza rice flour dispersions as influenced by particle size. Food Hydrocoll. 2015, 48, 72–83. [Google Scholar] [CrossRef]

- Bayod, E.; Willers, E.P.; Tornberg, E. Rheological and structural characterization of tomato paste and its influence on the quality of ketchup. LWT-Food Sci. Technol. 2008, 41, 1289–1300. [Google Scholar] [CrossRef]

- Bayod, E.; Tornberg, E. Microstructure of highly concentrated tomato suspensions on homogenisation and subsequent shearing. Food Res. Int. 2011, 44, 755–764. [Google Scholar] [CrossRef]

- Bengtsson, H.; Tornberg, E. Physicochemical characterization of fruit and vegetable fiber suspensions. I: Effect of homogenization. J. Texture Stud. 2011, 42, 268–280. [Google Scholar] [CrossRef]

- Lopez-Sanchez, P.; Nijsse, J.; Blonk, H.C.G.; Bialek, L.; Schumm, S.; Langton, M. Effect of mechanical and thermal treatments on the microstructure and rheological properties of carrot, broccoli and tomato dispersions. J. Sci. Food Agric. 2011, 91, 207–217. [Google Scholar] [CrossRef] [PubMed]

- Donsì, F.; Esposito, L.; Lenza, E.; Senatore, B.; Ferrari, G. Production of shelf-stable annurca apple juice with pulp by high pressure homogenization. Int. J. Food Eng. 2009, 5. [Google Scholar] [CrossRef]

- Carbonell, J.V.; Navarro, J.L.; Izquierdo, L.; Sentandreu, E. Influence of high pressure homogenization and pulp reduction on residual pectinmethylesterase activity, cloud stability and acceptability of Lane Late orange juice: A study to obtain high quality orange juice with extended shelf life. J. Food Eng. 2013, 119, 696–700. [Google Scholar] [CrossRef]

- Betoret, E.; Betoret, N.; Carbonell, J.V.; Fito, P. Effects of pressure homogenization on particle size and the functional properties of citrus juices. J. Food Eng. 2009, 92, 18–23. [Google Scholar] [CrossRef]

- Zamora, A.; Ferragut, V.; Guamis, B.; Trujillo, A.J. Changes in the surface protein of the fat globules during ultra-high pressure homogenisation and conventional treatments of milk. Food Hydrocoll. 2012, 29, 135–143. [Google Scholar] [CrossRef]

- Wu, J.; Du, B.Q.; Li, J.; Zhang, H.B. Influence of homogenisation and the degradation of stabilizer on the stability of acidified milk drinks stabilized by carboxymethylcellulose. LWT-Food Sci. Technol. 2014, 56, 370–376. [Google Scholar] [CrossRef]

- Tan, J.; Kerr, W.L. Rheological properties and microstructure of tomato puree subject to continuous high pressure homogenization. J. Food Eng. 2015, 166, 45–54. [Google Scholar] [CrossRef]

- Chen, Y.M.; Lu, Y.Q.; Yu, A.X.; Kong, X.Z.; Hua, Y.F. Stable mixed beverage is produced from walnut milk and raw soymilk by homogenization with subsequent heating. Food Sci. Technol. Res. 2014, 20, 583–591. [Google Scholar] [CrossRef]

- Ciron, C.I.E.; Gee, V.L.; Kelly, A.L.; Auty, M.A.E. Comparison of the effects of high-pressure microfluidization and conventional homogenization of milk on particle size, water retention and texture of non-fat and low-fat yoghurts. Int. Dairy J. 2010, 20, 314–320. [Google Scholar] [CrossRef]

- Njintang, N.Y.; Parker, M.L.; Moates, G.K.; Faulds, C.B.; Smith, A.C.; Waldron, K.W.; Mbofung, C.M.F.; Scher, J. Microstructure and creep-recovery characteristics of achu (a taro based paste) made from freeze dried taro chips as affected by moisture content and variety. J. Food Eng. 2008, 87, 172–180. [Google Scholar] [CrossRef]

- Qiu, S.; Li, Y.Y.; Chen, H.; Liu, Y.; Yin, L.J. Effects of high-pressure homogenization on thermal and electrical properties of wheat starch. J. Food Eng. 2014, 128, 53–59. [Google Scholar] [CrossRef]

- Che, L.M.; Li, D.; Wang, L.J.; Özkan, N.; Chen, X.D.; Mao, Z.H. Effect of high-pressure homogenization on the structure of cassava starch. Int. J. Food Prop. 2007, 10, 911–922. [Google Scholar] [CrossRef]

- Wang, B.; Li, D.; Wang, L.J.; Chiu, Y.L.; Chen, X.D.; Mao, Z.H. Effect of high-pressure homogenization on the structure and thermal properties of maize starch. J. Food Eng. 2008, 87, 436–444. [Google Scholar] [CrossRef]

- Caponio, F.; Difonzo, G.; Squeo, G.; Fortunato, S.; Silletti, R.; Summo, C.; Paradiso, V.M.; Pasqualone, A. Influence of homogenization time and speed on rheological and volatile composition in olive-based pâtés. Foods 2019, 8, 115. [Google Scholar] [CrossRef]

- Zhou, L.Y.; Guan, Y.J.; Bi, J.F.; Liu, X.; Yi, J.Y.; Chen, Q.Q.; Wu, X.Y.; Zhou, M. Change of the rheological properties of mango juice by high pressure homogenization. LWT-Food Sci. Technol. 2017, 82, 121–130. [Google Scholar] [CrossRef]

- Cserhalmi, Z.; Sass-Kiss, A.; Toth-Markus, M.; Lechner, N. Study of pulsed electric field treated citrus juices. Innov. Food Sci. Emerg. Technol. 2006, 7, 49–54. [Google Scholar] [CrossRef]

- Ahmed, J.; Ramaswamy, H.S.; Hiremath, N. The effect of high pressure treatment on rheological characteristic and colour of mango pulp. Int. J. Food Sci. Technol. 2005, 40, 885–895. [Google Scholar] [CrossRef]

- Leite, T.S.; Augusto, P.E.; Cristianini, M. Frozen concentrated orange juice (FCOJ) processed by the high pressure homogenization (HPH) technology: Effect on the ready-to-drink juice. Food Bioprocess Technol. 2016, 9, 1070–1078. [Google Scholar] [CrossRef]

- Augusto, P.E.D.; Ibarz, A.; Cristianini, M. Effect of high pressure homogenization (HPH) on the rheological properties of a fruit juice serum model. J. Food Eng. 2012, 111, 474–477. [Google Scholar] [CrossRef] [Green Version]

- Servais, C.; Jones, R.; Roberts, I. The influence of the particle size distribution on the processing of food. J. Food Eng. 2002, 51, 201–208. [Google Scholar] [CrossRef]

- Liu, F.X.; Wang, Y.T.; Li, R.J.; Bi, X.F.; Guo, X.F.; Fu, S.F.; Liao, X.J. Comparison of microbial inactivation and rheological characteristics of mango pulp after high hydrostatic pressure treatment and high temperature short time treatment. Food Bioprocess Technol. 2013, 6, 2675–2684. [Google Scholar] [CrossRef]

| Treatments | IS = ISequilibrium + (ISinitial − ISequilibrium)·e−k·t | |||

|---|---|---|---|---|

| ISequilibrium | ISinitial | k | R2 | |

| 20 MPa | 28.00 | 64.09 | 0.77 | 0.95 |

| 40 MPa | 28.67 | 75.69 | 0.86 | 0.99 |

| 60 MPa | 32.33 | 44.91 | 0.38 | 0.98 |

| 80 MPa | 31.67 | 47.78 | 0.52 | 0.99 |

| 100 MPa | 33.33 | 62.97 | 0.78 | 0.99 |

| Model | SC = SCequilibrium + (SCinitial − SCequilibrium)·e−k·p |

|---|---|

| SCequilibrium | 0.27 |

| SCinitial | 0.95 |

| K | 0.03 |

| R2 | 0.93 |

| Treatments | L* | a* | b* | ΔE |

|---|---|---|---|---|

| NH | 67.03 ± 0.19 c | −3.30 ± 0.03 ab | 2.48 ± 0.10 a | - |

| 0 MPa | 67.78 ± 0.26 b | −3.31 ± 0.03 ab | 2.02 ± 0.03 b | 0.88 ± 0.08 d |

| 20 MPa | 67.81 ± 0.28 b | −3.32 ± 0.04 bc | 1.99 ± 0.03 b | 0.92 ± 0.10 d |

| 40 MPa | 68.80 ± 0.27 a | −3.32 ± 0.02 bc | 1.53 ± 0.01 c | 2.01 ± 0.09 b |

| 60 MPa | 69.11 ± 0.16 a | −3.26 ± 0.02 a | 1.40 ± 0.04 de | 2.34 ± 0.05 a |

| 80 MPa | 68.60 ± 0.22 a | −3.38 ± 0.03 d | 1.51 ± 0.02 cd | 1.85 ± 0.06 c |

| 100 MPa | 68.67 ± 0.06 a | −3.37 ± 0.02 cd | 1.44 ± 0.05 d | 1.94 ± 0.01 bc |

| Treatments | σ0 (Pa) | k (Pa.sn) | n | R2 |

|---|---|---|---|---|

| NH | 0.772 ± 0.030 a | 0.088 ± 0.007 a | 0.826 ± 0.015 f | 0.996 |

| 0 MPa | 0.497 ± 0.011 b | 0.053 ± 0.004 b | 0.870 ± 0.014 e | 0.997 |

| 20 MPa | 0.234 ±0.008 c | 0.023 ± 0.002 c | 0.947 ± 0.017 d | 0.996 |

| 40 MPa | 0.218 ± 0.007 d | 0.019 ± 0.002 d | 0.972 ± 0.015 c | 0.997 |

| 60 MPa | 0.167 ± 0.007 e | 0.015 ± 0.001 e | 0.980 ± 0.017 b | 0.996 |

| 80 MPa | 0.142 ± 0.005 f | 0.013 ± 0.001 f | 0.984 ± 0.019 a | 0.995 |

| 100 MPa | 0.125 ± 0.006 g | 0.012 ± 0.001 f | 0.986 ± 0.017 a | 0.996 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Wang, R.; Wang, X.; Yang, L.; Shan, Y.; Zhang, Q.; Ding, S. Effects of High-Pressure Homogenization on the Structural, Physical, and Rheological Properties of Lily Pulp. Foods 2019, 8, 472. https://doi.org/10.3390/foods8100472

Liu J, Wang R, Wang X, Yang L, Shan Y, Zhang Q, Ding S. Effects of High-Pressure Homogenization on the Structural, Physical, and Rheological Properties of Lily Pulp. Foods. 2019; 8(10):472. https://doi.org/10.3390/foods8100472

Chicago/Turabian StyleLiu, Jie, Rongrong Wang, Xinyu Wang, Lvzhu Yang, Yang Shan, Qun Zhang, and Shenghua Ding. 2019. "Effects of High-Pressure Homogenization on the Structural, Physical, and Rheological Properties of Lily Pulp" Foods 8, no. 10: 472. https://doi.org/10.3390/foods8100472