Compression Test of Soft Food Gels Using a Soft Machine with an Artificial Tongue

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Gellan Gum Gels

3.2. Artificial Tongues

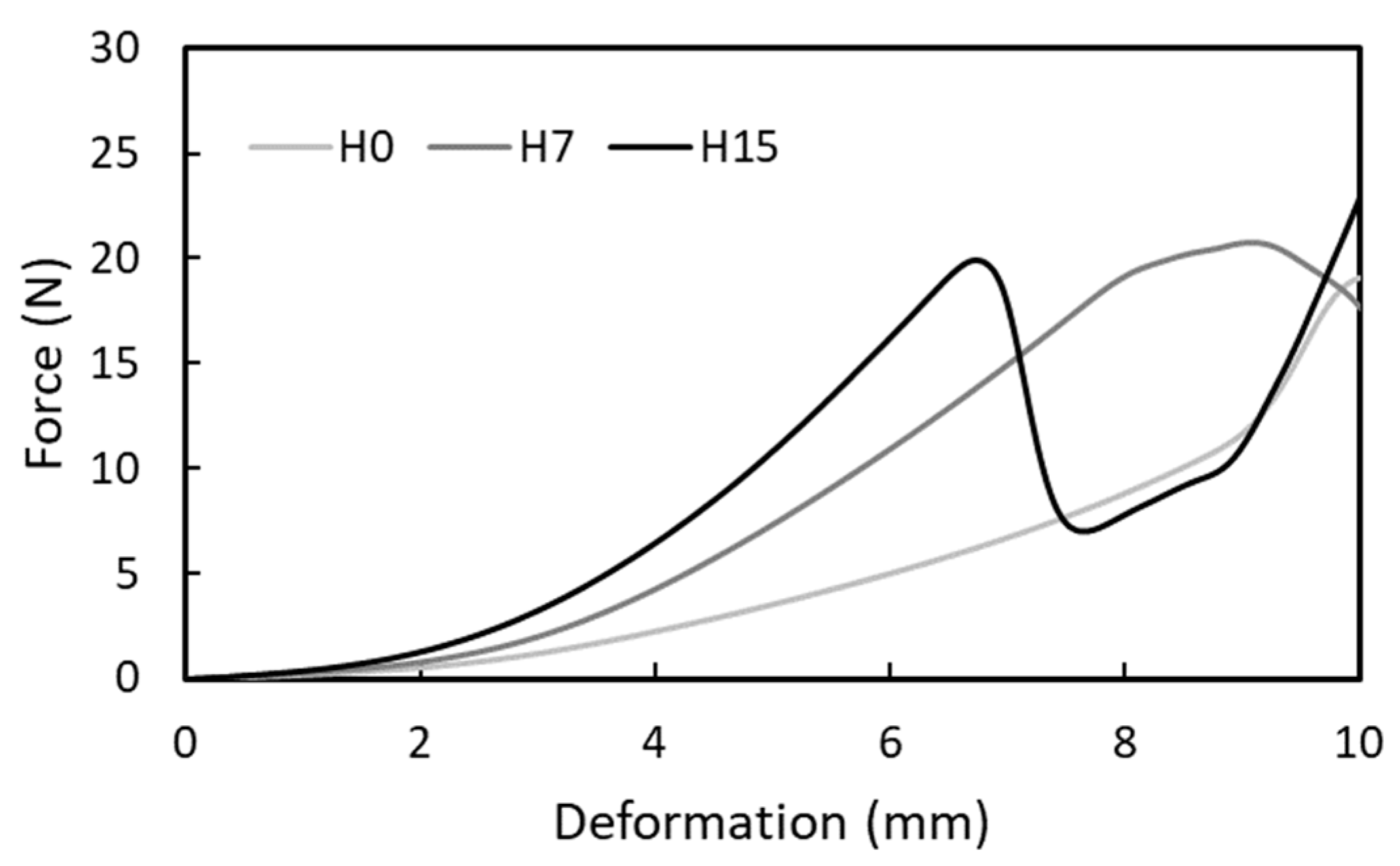

3.3. Compression of Gellan Gum Gels Placed on An Artificial Tongue

3.4. Mechanical Properties of Gellan Gum Gels Measured Using the Soft Machine

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Annual Report on the Aging Society: 2017 (Summary). Available online: https://www8.cao.go.jp/kourei/english/annualreport/2017/2017pdf_e.html (accessed on 28 February 2019).

- Efforts relating to “Smile Care Food”. Available online: http://www.maff.go.jp/e/policies/food_ind/attach/pdf/index-9.pdf (accessed on 28 February 2019).

- Ono, T.; Hori, K.; Masuda, Y.; Hayashi, T. Recent advances in sensing oropharyngeal swallowing function in Japan. Sensors 2010, 10, 176–202. [Google Scholar] [CrossRef] [PubMed]

- Clark, H.M.; Henson, P.A.; Barber, W.D.; Stierwalt, J.A.G.; Sherrill, M. Relationships among subjective and objective measures of tongue strength and oral phase swallowing impairments. Am. J. Speech Lang. Pathol. 2003, 12, 40–50. [Google Scholar] [CrossRef]

- Youmans, S.R.; Youmans, G.L.; Stierwalt, J.A. Differences in tongue strength across age and gender: Is there a diminished strength reserve? Dysphagia 2009, 24, 57–65. [Google Scholar] [CrossRef] [PubMed]

- Alsanei, W.A.; Chen, J.; Ding, R. Food oral breaking and the determining role of tongue muscle strength. Food Res. Int. 2015, 67, 331–337. [Google Scholar] [CrossRef]

- Magalhães, H.V., Jr.; Tavares, J.C.; Magalhães, A.A.B.; Galvão, H.C.; Ferreira, M.A.F. Characterization of tongue pressure in the elderly. Audiol. Commun. Res. 2014, 19, 375–379. [Google Scholar] [CrossRef]

- Jeong, D.-M.; Shin, Y.-J.; Lee, N.-R.; Lim, H.-K.; Choung, H.-W.; Pang, K.-M.; Kim, B.-J.; Kim, S.-M.; Lee, J.-H. Maximal strength and endurance scores of the tongue, lip, and cheek in healthy, normal Koreans. J. Korean Assoc. Oral Maxillofac. Surg. 2017, 43, 221–228. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- van Ravenhorst-Bell, H.A.; Mefferd, A.S.; Coufal, K.L.; Scudder, R.; Patterson, J. Tongue strength and endurance: Comparison in active and non-active young and older adults. Int. J. Speech Lang. Pathol. 2017, 19, 77–86. [Google Scholar] [CrossRef]

- Sakai, K.; Nakayama, E.; Tohara, H.; Maeda, T.; Sugimoto, M.; Takehisa, T.; Takehisa, Y.; Ueda, K. Tongue strength is associated with grip strength and nutritional status in older adult inpatients of a rehabilitation hospital. Dysphagia 2017, 32, 241–249. [Google Scholar] [CrossRef] [PubMed]

- Nagayoshi, M.; Higashi, M.; Takamura, N.; Tamai, M.; Koyamatsu, J.; Yamanashi, H.; Kadota, K.; Sato, S.; Kawashiri, S.; Koyama, Z.; et al. Social networks, leisure activities and maximum tongue pressure: Cross-sectional associations in the Nagasaki Islands Study. BMJ Open 2017, 7, e014878. [Google Scholar] [CrossRef] [PubMed]

- Yamanashi, H.; Shimizu, Y.; Higashi, M.; Koyamatsu, J.; Sato, S.; Nagayoshi, M.; Kadota, K.; Kawashiri, S.; Tamai, M.; Takamura, N.; et al. Validity of maximum isometric tongue pressure as a screening test for physical frailty: Cross-sectional study of Japanese community-dwelling older adults. Geriatr. Gerontol. Int. 2018, 18, 240–249. [Google Scholar] [CrossRef] [PubMed]

- Kikutani, T.; Tamura, F.; Nishiwaki, K.; Kodama, M.; Suda, M.; Fukui, T.; Takahashi, N.; Yoshida, M.; Akagawa, Y.; Kimura, M. Oral motor function and masticatory performance in the community-dwelling elderly. Odontology 2009, 97, 38–42. [Google Scholar] [CrossRef] [PubMed]

- Steele, S.M.; Cichero, J.A.Y. Physiological factors related to aspiration risk: A systematic review. Dysphagia 2014, 29, 295–304. [Google Scholar] [CrossRef] [PubMed]

- Utanohara, Y.; Hayashi, R.; Yoshikawa, M.; Yoshida, M.; Tsuga, K.; Akagawa, Y. Standard values of maximum tongue pressure taken using newly developed disposable tongue pressure measurement devise. Dysphagia 2008, 23, 286–290. [Google Scholar] [CrossRef] [PubMed]

- Ishihara, S.; Nakao, S.; Nakauma, M.; Funami, T.; Hori, K.; Ono, T.; Kohyama, K.; Nishinari, K. Compression test of food gels on artificial tongue and its comparison with human test. J. Texture Stud. 2013, 44, 104–114. [Google Scholar] [CrossRef]

- Shibata, A.; Higashimori, M.; Ramirez-Alpizar, I.G.; Kaneko, M. Tongue elasticity sensing with muscle contraction monitoring. 2012. Tongue elasticity sensing with muscle contraction monitoring. In Proceedings of the 2012 ICME International Conference on Complex Medical Engineering, Kobe, Japan, 1–4 July 2012; pp. 511–516. [Google Scholar]

- Ishihara, S.; Isono, M.; Nakao, S.; Nakauma, M.; Funami, T.; Hori, K.; Ono, T.; Kohyama, K.; Nishinari, K. Instrumental uniaxial compression test of gellan gels of various mechanical properties using artificial tongue and its comparison with human oral strategy for the first size reduction. J. Texture Stud. 2014, 45, 354–366. [Google Scholar] [CrossRef]

- Kohyama, K.; Gao, Z.; Watanabe, T.; Ishihara, S.; Nakao, S.; Funami, T. Relationships between mechanical properties obtained from compression test and electromyography variables during natural oral processing of gellan gum gels. J. Texture Stud. 2017, 48, 66–75. [Google Scholar] [CrossRef]

- Gao, Z.; Nakao, S.; Ishihara, S.; Funami, T.; Kohyama, K. A pilot study on ultrasound elastography for evaluation of mechanical characteristics and oral strategy of gels. J. Texture Stud. 2016, 47, 152–160. [Google Scholar] [CrossRef]

- Gao, Z.; Ishihara, S.; Nakao, S.; Hayakawa, F.; Funami, T.; Kohyama, K. Texture evaluation of soft gels with different fracture strains using an artificial tongue. J. Texture Stud. 2016, 47, 496–503. [Google Scholar] [CrossRef]

| Gellan Gel (% w/w) | A15 | BC15 | D15 | A20 | BC20 | D20 |

|---|---|---|---|---|---|---|

| Mixture of gellan gum | 0.32 | 0.35 | 0.30 | 0.45 | 0.45 | 0.43 |

| Low-acylated gellan gum | 0.32 | 0.2625 | 0.15 | 0.45 | 0.3375 | 0.215 |

| High-acylated gellan gum | 0.00 | 0.0875 | 0.15 | 0.00 | 0.1125 | 0.215 |

| Gellan Gel | A15 | BC15 | D15 | A20 | BC20 | D20 |

|---|---|---|---|---|---|---|

| Fracture force (N) | 15.7 a ± 1.1 | 15.9 a ± 0.6 | 16.8 a ± 1.2 | 22.5 b ± 0.9 | 24.2 bc ± 2.1 | 25.0 c ± 1.5 |

| Fracture strain (%) | 49.0 a ± 2.3 | 62.0 b ± 0.4 | 74.4 c ± 1.5 | 49.3 a ± 2.1 | 64.1 b ± 2.4 | 75.8 c ± 1.0 |

| Gel Sample | H0 | H7 | H15 |

|---|---|---|---|

| Asker FP hardness | 43.8 a ± 1.5 | 69.7 b ± 0.6 | 89.5 c ± 0.6 |

| Apparent modulus (kPa) | 23.3 a ± 0.3 | 55.1 b ± 0.9 | 160.9 c ± 2.2 |

| Gel Sample | H0 | H7 | H15 |

|---|---|---|---|

| A15 | 0.83 | 1.00 | 1.00 |

| BC15 | 0.33 | 1.00 | 1.00 |

| D15 | 0.29 | 1.00 | 1.00 |

| A20 | 0.00 | 1.00 | 1.00 |

| BC20 | 0.00 | 1.00 | 1.00 |

| D20 | 0.00 | 1.00 | 1.00 |

| Gellan Gel | A15 | BC15 | D15 | A20 | BC20 | D20 |

|---|---|---|---|---|---|---|

| on H15 artificial tongue | ||||||

| Apparent modulus (kPa) | 13.4 ab ± 4.7 | 13.2 abB ± 0.3 | 2.6 a ± 0.9 | 32.7 c ± 12.2 | 18.5 bcB ± 1.2 | 5.0 abA ± 0.8 |

| Fracture force (N) | 10.9 aA ± 3.5 | 12.7 ab ± 1.4 | 12.5 a ± 0.3 | 17.2 abc ± 3.5 | 19.3 bc ± 0.5 | 22.6 c ± 2.8 |

| Fracture deformation (mm) | 5.95 aA ± 0.83 | 6.53 abA ± 0.13 | 7.75 cdA ± 0.15 | 5.55 abA ± 0.48 | 6.89 bcA ± 0.19 | 8.17 dA ± 0.38 |

| Fracture work (N.mm) | 21.8 aA ± 3.3 | 27.5 a ± 1.3 | 23.0 a ± 1.6 | 32.0 bA ± 9.1 | 42.1 bcA ± 1.2 | 44.8 c ± 5.4 |

| Area ratio at fracture to initial | 1.49 abB ± 0.10 | 1.76 ab ± 0.10 | 2.00 ab ± 0.70 | 1.42 a ± 0.13 | 1.75 ab ± 0.31 | 2.42 b ± 0.11 |

| True fracture stress (kPa) | 27.1 aA ± 5.9 | 23.0 a ± 2.0 | 22.1 a ± 9.7 | 38.3 aA ± 5.3 | 35.9 a ± 6.3 | 29.6 a ± 3.3 |

| on H7 artificial tongue | ||||||

| Apparent modulus (kPa) | 23.1 c ± 3.4 | 5.4 aA ± 4.6 | 2.3 a ± 1.0 | 20.0 bc ± 10.4 | 8.3 abA ± 1.5 | 2.6 aA ± 1.4 |

| Fracture force (N) | 13.0 a ± 1.7 | 12.9 a ± 4.5 | 14.6 ab ± 3.4 | 21.7 ab ± 2.1 | 20.8 ab ± 5.7 | 23.7 b ± 5.5 |

| Fracture deformation (mm) | 7.00 aA ± 0.27 | 7.78 abB ± 0.49 | 9.16 cB ± 0.85 | 8.82 bcB ± 0.46 | 9.41 cB ± 0.32 | 9.93 cB ± 0.37 |

| Fracture work (N.mm) | 35.5 abB ± 5.4 | 29.9 a ± 13.4 | 34.0 ab ± 10.5 | 71.6 cB ± 5.7 | 68.4 cB ± 15.7 | 61.6 bc ± 10.5 |

| Area ratio at fracture to initial | 1.42 aAB ± 0.04 | 1.60 ab ± 0.36 | 2.00 b ± 0.16 | 1.33 a ± 0.06 | 1.50 a ± 0.05 | 2.59 c ± 0.14 |

| True fracture stress (kPa) | 29.2 abA ± 3.9 | 25.0 a ± 5.0 | 23.1 a ± 4.6 | 52.3 cB ± 5.6 | 43.8 bc ± 10.8 | 29.3 ab ± 8.2 |

| on H0 artificial tongue; part of A15, BC15, D15 gels fractured, A20, BC20 and D20 not fractured | ||||||

| Apparent modulus (kPa) | 11.3 a ± 6.9 | 7.0 aAB ± 2.6 | 2.4 a ± 1.6 | 10.3 a ± 3.3 | 9.9 aA ± 3.0 | 4.4 aA ± 1.1 |

| Fracture force (N) | 19.8 B ± 1.39 | - | - | NF | NF | NF |

| Fracture deformation (mm) | 10.3 B ± 0.39 | - | - | NF | NF | NF |

| Fracture work (N.mm) | 56.1 C ± 6.7 | - | - | NF | NF | NF |

| Area ratio at fracture to initial | 1.29 A ± 0.05 | - | - | NF | NF | NF |

| True fracture stress (kPa) | 49.2 B ± 4.1 | - | - | NF | NF | NF |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kohyama, K.; Ishihara, S.; Nakauma, M.; Funami, T. Compression Test of Soft Food Gels Using a Soft Machine with an Artificial Tongue. Foods 2019, 8, 182. https://doi.org/10.3390/foods8060182

Kohyama K, Ishihara S, Nakauma M, Funami T. Compression Test of Soft Food Gels Using a Soft Machine with an Artificial Tongue. Foods. 2019; 8(6):182. https://doi.org/10.3390/foods8060182

Chicago/Turabian StyleKohyama, Kaoru, Sayaka Ishihara, Makoto Nakauma, and Takahiro Funami. 2019. "Compression Test of Soft Food Gels Using a Soft Machine with an Artificial Tongue" Foods 8, no. 6: 182. https://doi.org/10.3390/foods8060182