3.3. Influence of Flaxseed on MixolabDough Rheological Properties

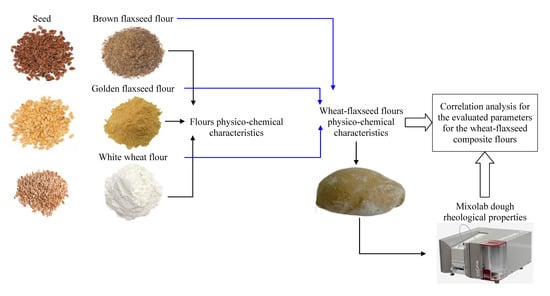

Incorporation of flaxseed from different varieties, brown and golden addition at 0, 5, 10, 15 and 20% in two categories of WF, namely strong (F1) and medium (F2), for bread-making, showed significant differences (

p< 0.001) in terms of water absorption values. As it may be seen, the addition of brown flaxseed (BFs) and golden flaxseed (GFs), respectively in WF F1 and F2, decreased the water absorption (CH) values (

Figure 1a). The lowest decreased in water absorption was found when the brown flaxseed was added in WF F2, from the level of 10% to 15% (55.2–54.6%). The decrease in water absorption in the case of golden flaxseed addition in F2 is in the same trend as the decrease in water absorption in F1. Similar effects on water absorption were observed by Roozegar et al. [

16,

17] and Codină et al. [

12] when brown flaxseed or golden flaxseed were added, respectively. Kundu et al. [

27] reported that the difference in water absorption is mainly caused by the gluten dilution, which needs less hydration, and therefore the wheat–flaxseed composite flours require lower amounts of water in the dough system in order to obtain the optimum consistency. As compared to the control samples (the sample without flaxseed flour addition), water absorption decreased in all the mixes made from wheat flour in which the golden or brown flaxseeds were incorporated. The lowest value for water absorption was obtained in the case when 20% level of brown flaxseed was incorporated in the flour of a medium quality for bread-making which decreased by 3.87% as compared to the control sample.

Compared to the wheat flour sample without flaxseed addition, highly significant effects (

p < 0.001) were noticed in relation to dough development time (DT) values. The highest decreased in DT was observed for the sample with 20% flaxseed addition levels for both BFs and GFs varieties incorporated in F1 and F2, respectively (

Figure 1b). These decreases may be due to gluten dilution in the dough system by flaxseed addition. Therefore, the amount of free water will increase, leading to a DT decrease due to the fact that in a dough system the highest amount of water is absorbed by starch and gluten [

28] which will trigger a lower amount due to flaxseed addition in wheat flour.

Dough stability, which stands for dough strength, significantly decreased (

Figure 1c) from 10.37 to 9.81 min and from 10.25 to 9.40 min when brown flaxseed and golden flaxseed were added in WF F1 at a level from 5% to 20%. A similar decrease in ST was noticed and in the case of F2 (from 10.87 to 9.73 min) when BFs was added and from 10.55 to 9.00 min when GFs was incorporated in WF, at the same levels of addition (5–20%). Similar results were reported by Pourabedin et al. [

14], Meral and Dogan [

15] and Roozegar et al. [

16,

17] for the addition of flaxseed in WF. However, as compared to the control sample, dough stability values gradually increased in mixes with the increase of levels addition from 0 to 10% for BFs and GFs, respectively, in WF F1, whereas for the WF F2 the ST values increased only for the levels of BFs and GFs up to 5% addition in wheat flour. This may likely be due to the interaction between polysaccharides (especially gums) and proteins in flaxseed–wheat composite flour as reported earlier by Rojas et al. [

29]. Also, an increase of dough stability values to a higher level of flaxseed addition for the F1 flour than for the F2 one may be attributed to the WF quality. The F1 flour is of a strong quality for bread-making, which indicates that it can develop stronger and elastic dough than F2 flour which is of a medium quality. This indicates that F1 flour can sustain for a longer period of time higher wheat–flaxseed composite flour dough stability during mixing, compared to F2 flour. By comparing the obtained values for ST one can noticed that stability increased to a greater extent in the case of BFs addition in F1 from 8.02 min for the control sample (C) to 10.37 min for the sample with 5% BFs incorporation and from 8.57 min for the C to 10.87 min for the same level of BFs incorporation in F2. However, for a high level of flaxseed flour addition, a slight decrease in dough stability for both flours in which flaxseeds were incorporated due to gluten dilution was noticed because flaxseed is non-gluten flour.

The effect of incorporation of BFs and GFs flours at varying levels on dough C2 torque represents the protein weakening (C2) as illustrated in

Figure 2a. Its values decreased with the increased level of flaxseed addition more in the case of brown variety than in the case when the golden one was used. The lowest values for C2 torque were recorded for the F2 flour with a decreased of 33.3% to a level of 20% brown flaxseed addition as compared to the control sample.

A similar trend (

Figure 2b) may be seen, and in the case of the difference between the peak C2 and C1 values (C2-1), which measures the speed of protein weakening due to heat, obviously increased with the increased level of flaxseed addition. An increase in the C2-1 values and a decrease in the value of C2 together with the increase in the flaxseed addition are due to the protein network structure. By flaxseed flour addition, proteins become less compact, a fact that favours the enzymatic attaching points, leading to an increase in the speed of protein weakening due to heat (C2-1) and a decrease in C2. Therefore, we may conclude according to the data obtained that by flaxseed addition the protein network becomes weaker under the effect of temperature increase.

When dough is heated above 60 °C the Mixolab begins to record the pasting properties of dough the C3 torque and the difference between the C3 and C2 peak values (C3-2) being associated with the starch gelatinization process. In general, both parameters values decreased (

Figure 3a,b) with the increased level of flaxseed addition in the case of C3 values, this decrease is highly significant (

p < 0.001).

The decrease in C3 values is higher when the GF variety is added in WF dough with 26.2% for F1 and 14.4% for F2 for 20% level addition as compared to the control sample, probably due to starch dilution and the high content of fat and polysaccharides in flaxseed flour [

12,

14,

29]. It is well known that the starch gelatinization process is influenced by the amylase-lipid complex formation, the amount of amylose leaching, the competition for free water between leached amylose and ungelatinised granules remained [

30]. A decrease in C3 might be due to less swelling of the starch granules from WF in the presence of flaxseed flour of whose compounds may interact with amylose. Also, it is possible that some compounds from flaxseed to compete with starch to absorb water during the starch gelatinization process fact that will create difficulties for starch to gelatinize.

The C4 torque values corresponding to the hot starch stability paste decreased with the increased level of flaxseed addition (

Figure 4a); more in the case of F2 with 17.14% when GFs were incorporated and with 13.1% when BFs were added in WF to a level of 20%. This effect may be attributed to the lower amylase activity in the wheat–flaxseed composite flour which slows gelatinization process and due to starch dilution, taking into account that flaxseed flour contains low amount of starch [

12]. The amount of carbohydrates is less in the case of BFs than GFs and therefore the starch dilution of wheat–flaxseed composite flour is higher when GFs were added than in the case when BFs were incorporated in WF. Also, the stability of the starch gel formed is influenced by starch composition. Flaxseed flour addition in WF may have some interactions between starch and some compounds from the flaxseed flour. For example, the polysaccharides from the flaxseed content probably in a higher amount in BFs than in the case of GFs binds through the hydrogen bonds the water from the dough system, leading to a decrease of available water for the starch granules. Also, the high content of fat from the flaxseed flour may form insoluble complex with amylose leading to a decrease of the hot starch stability paste [

31].

The difference between the C4 and C3 peak values (C4-3) did not vary in a significant way with the increased level of flaxseed addition. However, all the C4-3 presented lower values in the samples with flaxseed addition. This fact is explainable since the C4-3 values correspond to the rate of amylases hydrolysis on WF starch. Since the flaxseed flours did not bring amylases in dough system (as we can see from the falling number values) these parameters values decreased as compared to the sample when no flaxseeds were added. The starch retrogradation during the cooling period of the Mixolab device represented by the values of C5 torque and the difference between the C5 and C4 peaks (C5-4) decreased with the increased level of flaxseed addition (

Figure 4b,c). This fact shows an anti-staling effect that flaxseed may have on bread quality more in the case of the golden variety than in the case of the brown one. An extent of bread freshness by flaxseed addition has also been reported by Khorshid et al. [

19].

The decrease in the C5 values was higher when flaxseed was incorporated in F2 with 21.57% when GFs were added and 17.85% when BFs were added at a substitution level of 20% flaxseed in WF. This fact may be due to the high content of fat and other compounds in the flaxseed flour like polysaccharides that interact with gluten and starch in the dough system hindering a less starch retrogradation [

14,

19]. This fact is mainly attributed to the interaction between lipids from flaxseed flour with starch especially with amylose during the baking process. The complex formed between amylose and lipids is insoluble in water. In this form, amylose cannot leach out of starch granules. Thus, it decreased the amount of free amylase capable to leach out of gelatinized starch. As a consequence, it decreased its capacity to form intermolecular association during the cooling stage. On the other hand, the amylose remains inside the starch granules in a higher amount. This is due to the lipids presence, which creates difficulties between the associations of amylopectin molecules. Consequently, the starch retrogradation process is delayed [

32]. Also, the polysaccharides from the flaxseed flours, which are probably in a lower amount in GFs than in BFs, may form intermolecular associations with leached amylose molecules during pasting which prevents starch retrogradation.

3.4. Correlation Analysis of the Evaluated Parameters for the Wheat–Flaxseed Composite Flours

The PCA was performed on wheat–flaxseed composite flours’ characteristics (moisture content (MC), fat content (Fat), protein content (PR), ash content (Ash), carbohydrates content (CHS), falling number (FN)) and dough rheological properties assessed by the Mixolab device (C2, C3, C4 and C5 torques; the difference between the C1 and C2 and peak values (C1-2); the difference between the C3 and C2 and peak values (C3-2); the difference between the C4 and C3 and peak values (C4-3); and the difference between the C5 and C4 and peak values (C5-4)) for the all 18 samples, which were analysed in this study, shown in

Figure 5. The results obtained showed that all the variables used in order to perform PCA can be reduced to two principal components (PCs), 56.03% by PC1 and 26.37% by PC2. In PCA, factors extracted are retained if they have an eigenvalue >1 because they provide a lot more information than the initial variables, the first two components explaining 82.40% of the total variance. The plot of PC1

vs. PC2 plot shows along the PC1 axis, a close relationship between the starch pasting properties (C3, C3-2 and C4-3) and between wheat–flaxseed composite flours characteristics (FN, PR, Ash, Fat and MC and CH). It could be noticed that the Mixolab parameters related to dough rheological properties during heating (C1-2, C2, C3, C3-2, C4 and C4-3) were included in PC2 along with the starch retrogradation values at the cooling stage (C5 and C5-4). The influence of ST values was low, since their loadings for PC1 was close to null. Between wheat–flaxseed composite flours characteristics and Mixolab dough rheological properties a close relationship between MC and DT (

r = 0.838) was noticed, respectively, C5 (

r = 0.919) at a level of

p < 0.01. FN was closely associated with the C1-2 value (

r = 0.903) and inversely correlated to C2 (

r = −0.910), C3-2 (

r = −0.689), C3 (

r = −0.808) at a level of

p < 0.01. The positive correlation between FN and C1-2 may be due to the fact that the flours used in the analysis had a low α amylase activity and probably a low proteolytic activity.

Since C1-2 expresses the speed of protein weakening due to heat, this speed is influenced by the proteolytic activity, and since the flaxseed addition did not improve α amylase activity, it is also probable that it did not to improve the proteolytic activity either. A negative correlation between FN and Mixolab values C3 and C3-2 is also explainable since both parameters are related to starch gelatinization process. The FN is a measure of the α amylase activity, its value being inversely correlated with the α amylase amount in WF and therefore high values of FN show low α amylase activity in dough system [

33,

34] fact that will negatively influence the starch gelatinization process. Protein content of the samples was significantly positively correlated with C1-2 value (r = 0.752) and negatively correlated with C2 (

r = −0.754), C3-2 (

r = −0.751), C3 (

r = −0.812), C4-3 (

r = −0.715) at a level of

p < 0.01. Although flaxseeds have higher protein content, these are non-gluten, and therefore are weaker. Also, the Mixolab values related to dough pasting properties decreased due to the fact that by increasing the level of proteins in dough system the starch content decreased [

35].