Sources of Volatile Aromatic Congeners in Whiskey

Abstract

:1. Introduction

2. Whiskey Origins

Irish Whiskey Regulations

3. Irish Whiskey Types/Styles

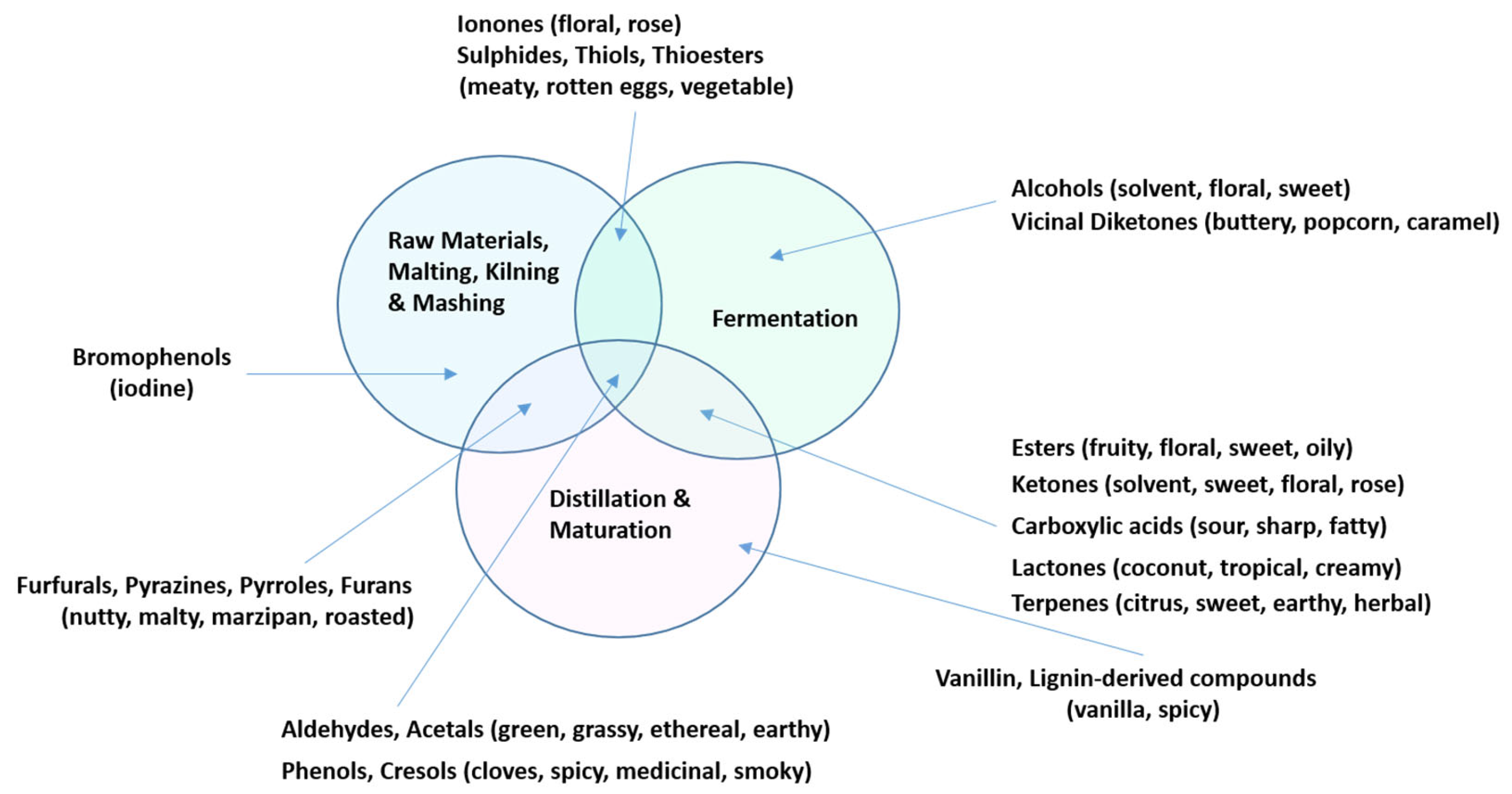

4. Congeners and the Whiskey Process

4.1. Malting Barley

4.2. Fermentation

4.2.1. Yeast and Key Congener Pathways

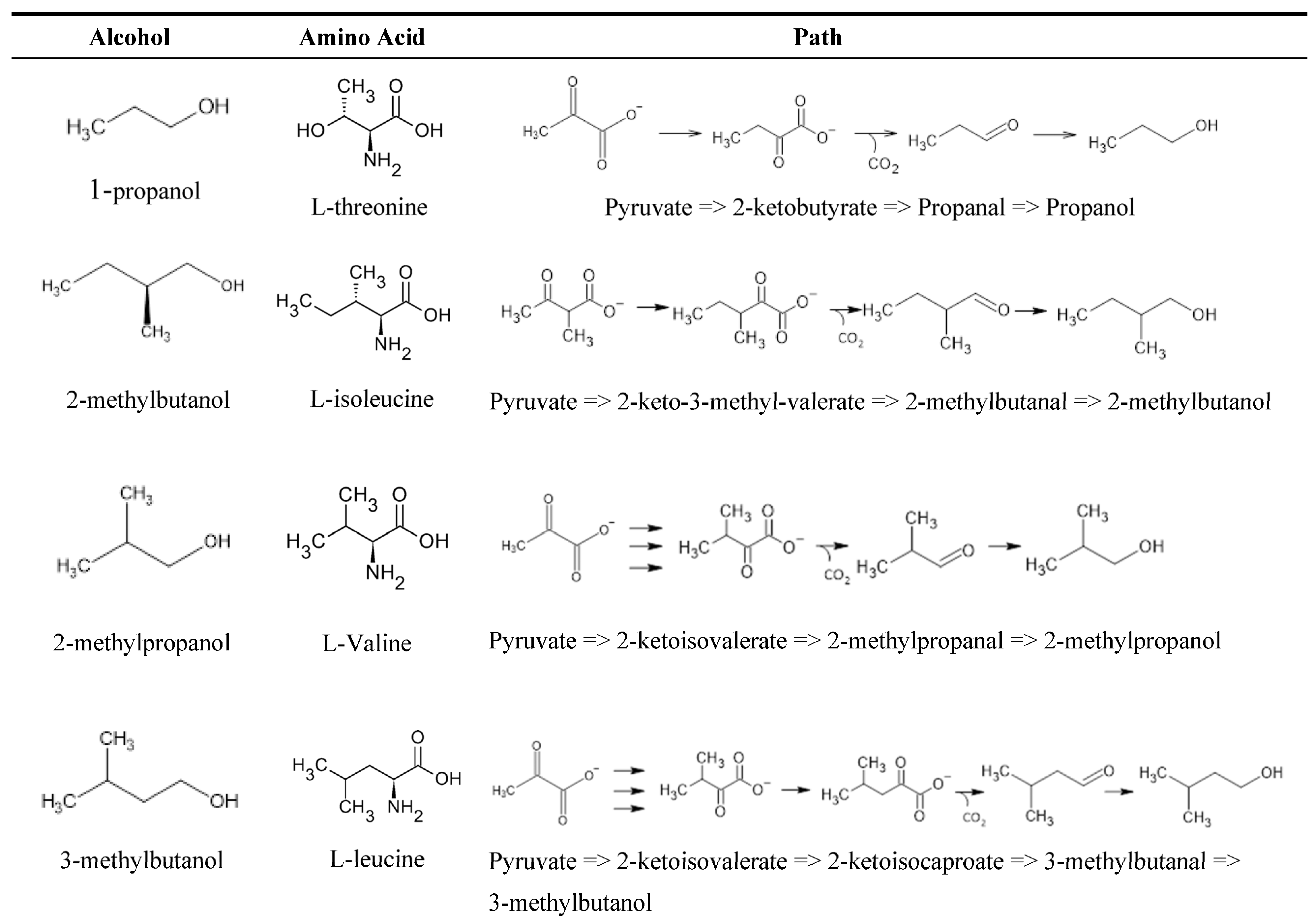

4.2.2. Key Congeners in Fermentation

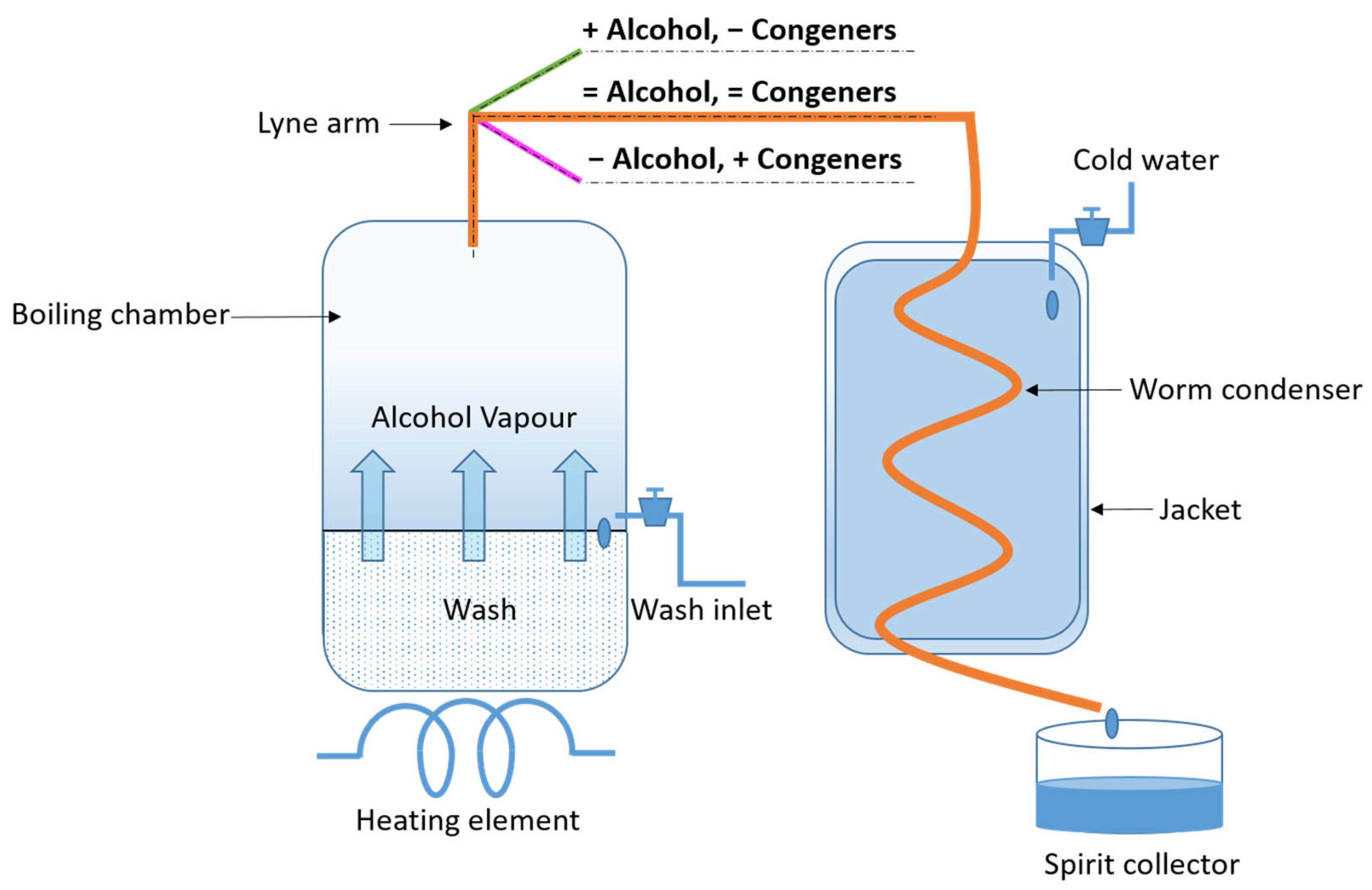

4.3. Distillation

4.3.1. Pot Distillation

4.3.2. Continuous Distillation

4.3.3. Congeners by Volatility

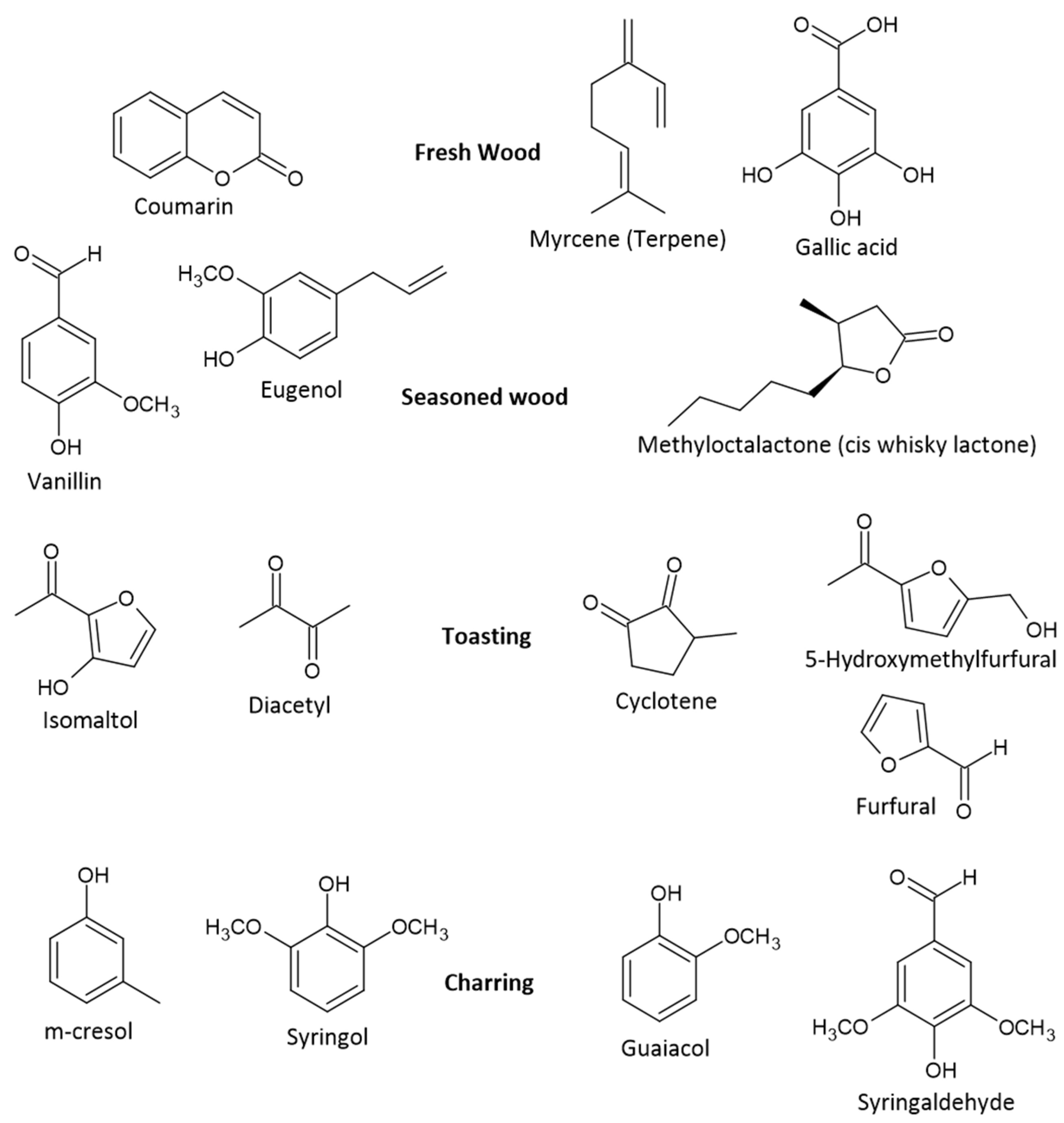

4.4. Cask Maturation

4.4.1. Wood Components

4.4.2. Oak Casks

4.4.3. Cask Toasting and Congeners

4.4.4. Terpenes

5. Congeners as Biomarkers of Fraud and Authentication

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Waymark, C.; Hill, A.E. The influence of Yeast Strain on Whisky New Make Spirit Aroma. Fermentation 2021, 7, 311. [Google Scholar] [CrossRef]

- Smith, B.L.; Hughes, D.M.; Badu-Tawiah, A.K.; Eccles, R.; Goodall, I.; Maher, S. Rapid Scotch Whisky Analysis and Authentication using Desorption Atmospheric Pressure Chemical Ionisation Mass Spectrometry. Sci. Rep. 2019, 9, 7994. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Power, A.C.; Ni Neill, C.; Geoghegan, S.; Currivan, S.; Deasy, M.; Cozzolino, D. A brief history of Whiskey Adulteration and the role of Spectroscopy Combined with Chemometrics in the Detection of Modern Whiskey Fraud. Beverages 2020, 6, 49. [Google Scholar] [CrossRef]

- EUIPO. The Economic Cost of IPR Infringement in Spirits and Wine. 2016. Available online: https://euipo.europa.eu/tunnel-web/secure/webdav.guest/document_library/observatory/resources/research-and-studies/ip_infringement/study8/wines_and_spirtis_en.pdf (accessed on 29 September 2022).

- Drinks Ireland. Irish Whiskey Global Report. Drinks Industry Ireland. Available online: https://www.ibec.ie/drinksireland/news-insights-and-events/news/2022/10/25/irish-whiskey-association-publishes (accessed on 30 November 2022).

- Stupak, M.; Goodall, I.; Tomaniova, M.; Pulkrabova, J.; Hsjslova, J. A novel approach to assess the quality and authenticity of Scotch Whisky based on gas chromatography coupled to high resolution mass spectrometry. Anal. Chim. Acta 2018, 1042, 60–70. [Google Scholar] [CrossRef]

- Aylott, R. Whisky Analysis. In Whisky: Technology, Production and Marketing, 1st ed.; Russell, I., Bamforth, C.W., Stewart, G.G., Eds.; Academic Press: London, UK, 2003; pp. 277–304. [Google Scholar]

- Aylott, R.I.; MacKenzie, W.M. Analytical strategies to confirm the Generic Authenticity of Scotch Whisky. J. Inst. Brew. 2010, 116, 215–229. [Google Scholar] [CrossRef]

- Stead, S.; Jandova, R.; Eccles, R.; Goodall, I. Rapid Determination of Whisky Brands Using the DART QDa with LiveID System for Alcoholic Beverage Quality Control Testing; Waters Corporation: Milford, MA, USA; Scotch Whisky Research Institute: Edinburgh, UK, 2019. [Google Scholar]

- Technical File Setting out the Specifications with Which Irish whiskey/Uisce Beatha Eireannach/Irish Whisky Must Comply. Available online: https://www.gov.ie/pdf/?file=https://assets.gov.ie/91238/e4d51392-dcab-45af-a8e5-39bc0fc4de14.pdf#page=1 (accessed on 17 January 2022).

- Buxton, I.; Hughes, P.S. The Science and Commerce of Whisky, 2nd ed.; Royal Society of Chemistry: London, UK, 2021. [Google Scholar]

- Miller, G.H. The Flavor–Chemistry Association. In Whisky Science: A Condensed Distillation, 1st ed.; Springer: Cham, Switzerland, 2019. [Google Scholar] [CrossRef]

- Magee, M. Irish Whiskey: A 1000 Year Tradition, 2nd ed.; O’Brien Press: Dublin, Ireland, 1991. [Google Scholar]

- Piggott, J. Whisky. In Current Developments in Biotechnology and Bioengineering: Food and Beverages Industry, 1st ed.; Pandey, A., Du, G., Sanroman, M., Soccol, C., Dussap, C.-G., Eds.; Elsevier: Amsterdam, The Netherlands, 2016; pp. 435–450. [Google Scholar]

- Wisniewska, P.; Dymerski, T.; Wardencki, W.; Namiesnik, J. Chemical composition analysis and authentication of whisky. J. Sci. Food Agric. 2015, 95, 2159–2166. [Google Scholar] [CrossRef]

- Pawlaczyk, A.; Gajek, M.; Jozwik, K.; Szynkowska, M.I. Multielemental analysis of various kinds of whisky. Molecules 2019, 24, 1193. [Google Scholar] [CrossRef] [Green Version]

- IBEC IRISH Whiskey Trade Report 2021. Available online: https://www.ibec.ie/drinksireland/news-insights-and-events/news/2021/07/01/irish-whiskey-international-trade-report-2021 (accessed on 19 December 2022).

- Technical File for Scottish Whisky. Available online: https://assets.publishing.service.gov.uk/media/5fd36667e90e07662ed92c85/Scotch_Whisky_Technical_File_-_June_2019.pdf (accessed on 25 January 2022).

- FSAI. Labelling of Irish Whiskey [pdf] Dublin: Food Safety Authority of Ireland. 2019. Available online: https://www.ibec.ie/drinksireland/irish-whiskey/your-association/technical/regulations-governing-irish-whiskey (accessed on 14 January 2022).

- European Parliament and Council. Regulation (EU) 2019/787 of The European Parliament and of The Council of April 2019 on the Definition, Description, Presentation, Labelling and the Protection of Geographical Indications of Spirit Drinks and Repealing Council Regulation (ECC) No 110/2008. Off. J. Eur. Union. 2019, 787, 3. Available online: https://eur-lex.europa.eu/legal-content (accessed on 6 March 2023).

- Appendix Irish Whiskey G.I.-Scheme of Revenue Verification Checks. Irish Tax and Customs. 1–9. Available online: https://www.revenue.ie/en/companies-and-charities/documents/excise/whiskey-verification-checks.pdf (accessed on 14 January 2022).

- Power, A.C.; Jones, J.; NiNeil, C.; Geoghegan, S.; Warren, S.; Currivan, S.; Cozzolino, D. What’s in this drink? Classification and adulterant detection in Irish Whiskey samples using near infrared spectroscopy combined with chemometrics. J. Sci. Food Agric. 2021, 101, 5256–5263. [Google Scholar] [CrossRef]

- Wisniewska, P.; Boque, R.; Borras, E.; Busto, O.; Wardencki, W.; Namiesnik, J.; Dymerski, T. Authentication of whisky due to its botanical origin and way of production by instrumental analysis and multivariate classification methods. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2017, 173, 849–853. [Google Scholar] [CrossRef]

- Lyons, T.P. Production of Scotch and Irish whiskies: Their history and evolution. In The Alcohol Textbook, 4th ed.; Jacques, K.A., Lyons, T.P., Kelsall, D.R., Eds.; Nottingham University Press: Nottingham, UK, 2003; pp. 193–222. [Google Scholar]

- O’Connor, F. A Glass Apart: Irish Single Pot Still Whiskey, 1st ed.; The Images Publishing Group: Mulgrave, Australia, 2017. [Google Scholar]

- Harris, C. The Irish Brewing Industry, c. 1780–1930: An Archaeology. Ph.D. Thesis, University College Cork, Cork, Ireland, 2020. [Google Scholar]

- Morris, S.; Vyrne, J.L.; Murphy, B.; Whelan, S.J.; Carroll, J.P.; Ryan, D. The optimisation of cook parameters to spirit whiskey production from native Irish Wheat: A response surface method approach. Foods 2022, 11, 1199. [Google Scholar] [CrossRef]

- Bathgate, G.N. The influence of malt and wort processing on spirit character: The lost styles of Scotch malt whisky. J. Inst. Brew. 2019, 125, 200–213. [Google Scholar] [CrossRef]

- Piggott, J.R. Whisky, Whiskey and Bourbon: Composition and Analysis of Whisky. In Encyclopedia of Food and Health; Caballero, B., Finglas, P.M., Toldrá, F., Eds.; Academic Press: Oxford, UK, 2016; pp. 514–518. [Google Scholar]

- Bathgate, G.N. A review of malting and malt processing for whisky distillation. J. Inst. Brew. 2016, 122, 197–211. [Google Scholar] [CrossRef] [Green Version]

- Chrispeels, M.J.; Varner, J.E. Gibberellic acid-enhanced synthesis and release of α-amylase and ribonuclease by isolate barley and aleurone layers. Plant Physiol. 1967, 42, 398–406. [Google Scholar] [CrossRef] [Green Version]

- Fox, G. Starch in Brewing Applications. In Food Science, Technology and Nutrition, Starch in Food, 2nd ed.; Sjoo, M., Nilsson, L., Eds.; Woodhead Publishing: Sawston, UK, 2018; pp. 633–659. [Google Scholar]

- Boothroyd, E.; Linforth, R.S.T.; Jack, F.; Cook, D.J. Origins of the perceived nutty character of new-make malt whisky spirit. J. Inst. Brew. 2014, 120, 16–22. [Google Scholar] [CrossRef]

- Tauer, A.; Elss, S.; Frischmann, M.; Tellez, P.; Pischestsrieder, M. Influence of Thermally Processed Carbohydrate/Amino Acid Mixtures on the Fermentation by Saccharomyces cerevisiae. J. Agric. Food Chem. 2004, 52, 2042–2046. [Google Scholar] [CrossRef]

- Cerny, C. The Aroma Side of the Maillard Reaction. Ann. N. Y. Acad. Sci. 2008, 1126, 66–71. [Google Scholar] [CrossRef]

- Marčiulionytė, R.; Johnston, C.; Maskell, D.L.; Mayo, J.; Robertson, D.; Griggs, D.; Holmes, C.P. Roasted Malt for Distilling: Impact on Malt Whisky New Make Spirit Production and Aroma Volatile Development. J. Am. Soc. Brew. Chem. 2022, 80, 329–340. [Google Scholar] [CrossRef]

- Coghe, S.; Gheeraert, B.; Michiels, A.; Delvaux, F.R. Development of Maillard reaction related characteristics during malt roasting. J. Inst. Brew. 2006, 112, 148–156. [Google Scholar] [CrossRef]

- Monica Lee, K.Y.; Paterson, A.; Piggott, J.R.; Richardson, G.D. Origins of Flavour in Whiskies and Revised Flavour Wheel: A Review. J. Inst. Brew. 2001, 107, 287–313. [Google Scholar]

- Stewart, G.S. The Production of Secondary Metabolites with Flavour Potential during Brewing and Distilling Wort Fermentations. Fermentation 2017, 3, 63. [Google Scholar] [CrossRef] [Green Version]

- Daute, M.; Jack, F.; Baxter, I.; Harrison, B.; Grigor, J.; Walker, G. Comparison of three approaches to assess the flavour characteristics of Scotch Whisky Spirit. Appl. Sci. 2021, 11, 1410. [Google Scholar] [CrossRef]

- Liao, S.M.; Liang, G.; Zhu, J.; Lu, B.; Peng, L.-X.; Wang, Q.-Y.; Wei, Y.-T.; Zhou, G.-P.; Huang, R.-B. Influence of Calcium ions on the Thermal characteristics of a-amylase from thermophilic anoxybacillus sp. GXS-BL. Protein Pept. Lett. 2019, 26, 148–157. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Huang, W.; Wang, X.; Tang, T.; Hua, Z.; Yan, G. Improvement of alcoholic fermentation by calcium ions under enological conditions involves the increment of plasma membrane H(+)-ATPase activity. World J. Microbiol. Biotechnol. 2010, 26, 1181–1186. [Google Scholar] [CrossRef] [PubMed]

- Nie, Y.; Kleine-Benne, E. Determining Phenolic Compounds in Whisky using Direct Large Volume Injection and Stir Bar Sorptive Extraction. [pdf] 2012. Gerstel. Available online: https://www.gerstelus.com/applications/determining-phenolic-compounds-in-whiskey-using-direct-large-volume-injection-and-stir-bar-sorptive-extraction/ (accessed on 3 August 2022).

- Furusawa, T. The Formation and Reactions of Sulphur Compounds During Distillation. Ph.D. Thesis, Heriot-Watt University, Edinburgh, UK, 1996. [Google Scholar]

- Fontana, M.; Buiatti, S. 25-Amino Acids in Beer. In Beer in Health and Disease Prevention, 1st ed.; Preedy, V.R., Ed.; Academic Press: Barlington, MA, USA, 2009; pp. 273–284. [Google Scholar]

- Ferreira, I.M.; Guido, L.F. Impact of Wort Amino Acids on Beer Flavour: A Review. Fermentation 2018, 4, 23. [Google Scholar] [CrossRef] [Green Version]

- Nobis, A.; Kwasnicki, M.; Lehnhardt, F.; Hellwig, M.; Henle, T.; Becker, T.; Gastl, M. A Comprehensive Evaluation of Flavor Instability of Beer (Part 2): The Influence of De Novo Formation of Aging Aldehydes. Foods 2021, 10, 2668. [Google Scholar] [CrossRef]

- Buchhaupt, M.; Lahne, F.; Etschmann, M.M.W.; Schrader, J. 37-Biotechnological Production of Fatty Aldehydes. In Flavour Science: Proceedings from XIII Weurman Flavour Research Symposium, 1st ed.; Ferreira, V., Lopez, R., Eds.; Academic Press: San Diego, CA, USA, 2014; pp. 195–199. [Google Scholar]

- Bravi, E.; Marconi, O.; Perretti, G.; Fantozzi, P. Influence of barley variety and malting process on lipid content of malt. Food Chem. 2012, 135, 1112–1117. [Google Scholar] [CrossRef]

- Oliveira, J.M.; Faria, M.; Sá, F.; Barros, F.; Araújo, I.M. C6-alcohols as varietal markers for assessment of wine origin. Anal. Chim. Acta 2006, 563, 300–309. [Google Scholar] [CrossRef] [Green Version]

- Yu, J.; Huang, S.; Dong, J.; Fan, W.; Huang, S.; Liu, J.; Chang, Z.; Tian, Y.; Hao, J.; Hu, S. The influence of LOX-less barley malt on the flavour stability of wort and beer. J. Inst. Brew. 2014, 120, 93–98. [Google Scholar] [CrossRef]

- Christoph, N.; Bauer-Christoph, C. Flavour of Spirit Drinks: Raw Materials, Fermentation, Distillation, and Ageing. In Flavours and Fragrances Chemistry, Bioprocessing and Sustainability; Berger, R.G., Ed.; Springer: Berlin/Heidelberg, Germany, 2007; pp. 219–239. [Google Scholar]

- LaRoe, E.G.; Shipley, P.A. Whiskey composition: Formation of alpha-and beta-ionone by the thermal decomposition of beta-carotene. J. Agric. Food Chem. 1970, 18, 174–175. [Google Scholar] [CrossRef]

- Daute, M.; Jack, F.; Harrison, B.; Walker, G. Experimental whisky fermentations: Influence of wort pre-treatments. Foods 2021, 10, 2755. [Google Scholar] [CrossRef]

- Korhola, M.; Harju, K.; Lehtonen, M. Fermentation. In The Science and Technology of Whiskies; Piggott, J.R., Sharp, R., Duncan, R.E.B., Eds.; Longman Group UK Ltd.: Harlow, UK, 1989; pp. 89–118. [Google Scholar]

- Walker, G.M.; Hill, A.E. Saccharomyces cerevisiae in the Production of Whisk(e)y. Beverages 2016, 2, 38. [Google Scholar] [CrossRef] [Green Version]

- Walker, G.M.; Stewart, G.G. Saccharomyces cerevisiae in the Production of Fermented Beverages. Beverages 2016, 2, 30. [Google Scholar] [CrossRef]

- Rotar, A.M.; Semeniuc, C.A.; Mudura, E.; Coldea, T.; Pop, C.L. Identification of Microbial Contamination Sources in Distilled Spirits. Bull. Univ. Agric. Sci. Vet. Med. Cluj Napoca 2012, 69, 380–385. [Google Scholar] [CrossRef]

- Umego, E.C.; Barry-Ryan, C. Overview of the Irish brewing and distilling sector: Processing inputs supply and quality requirements. Brew. Sci. 2022, 75, 9–16. [Google Scholar]

- Bindon, K.A.; Kassara, S.; Solomon, M.; Bartel, C.; Smith, P.A.; Barker, A.; Curtin, C. Commercial Saccharomyces cerevisiae Yeast Strains Significantly Impact Shiraz Tannin and Polysaccharide Composition with Implications for Wine Colour and Astringency. Biomolecules 2019, 9, 466. [Google Scholar] [CrossRef] [Green Version]

- Wanikawa, A.; Sugimoto, T. A narrative review of sulphur compounds in whisk(e)y. Molecules 2022, 27, 1672. [Google Scholar] [CrossRef]

- Yomo, H.; Noguchi, Y.; Yonezawa, T. Effect on new-make spirit character due to the performance of brewer’s yeast—(I) physiological changes of yeast during propagation and brewing. In Distilled Spirits: Production, Technology and Innovation; Bryce, J.H., Piggott, J.R., Stewart, G.G., Eds.; Nottingham University Press: Nottingham, UK, 2008; pp. 109–116. [Google Scholar]

- He, Y.; Dong, J.; Yin, H.; Zhao, Y.; Chen, R.; Wan, X.; Chen, P.; Hou, X.; Liu, J.; Chen, L. Wort composition and its impact on the flavour-active higher alcohol and ester formation of beer—A review. J. Inst. Brew. 2014, 120, 157–163. [Google Scholar] [CrossRef]

- Younis, O.S.; Stewart, G.G. Effect of malt wort, very-high-gravity malt wort, and very-high-gravity adjunct wort on volatile production in Saccharomyces cerevisiae. J. Am. Soc. Brew. Chem. 1999, 57, 39–45. [Google Scholar]

- Peddie, H.A.B. Ester formation in brewery fermentations. J. Inst. Brew. 1990, 96, 327–331. [Google Scholar] [CrossRef]

- Kucharczyk, K.; Tuszynski, T. The effect of wort aeration on fermentation, maturation and volatile components of beer produced on an industrial scale. J. Inst. Brew. 2017, 123, 31–38. [Google Scholar] [CrossRef] [Green Version]

- Pfeiffer, T.; Morley, A. An evolutionary perspective on the Crabtree effect. Front. Mol. Biosci. 2014, 1, 17. [Google Scholar] [PubMed]

- Dashko, S.; Zhou, N.; Compagno, C.; Piskur, J. Why, when, and how did yeast evolve alcoholic fermentation? FEMS Yeast Res. 2014, 14, 826–832. [Google Scholar] [PubMed] [Green Version]

- Yilmaztekin, M.; Cabaroglu, T.; Erten, H. Effects of Fermentation Temperature and Aeration on Production of Natural Isoamyl Acetate by Williopsis saturnus var. saturnus. Biomed. Res. Int. 2013, 2013, 870802. [Google Scholar]

- Taylor, G.T.; Kirsop, B.H. The origin of the medium fatty acids present in beer. J. Inst. Brew. 1977, 83, 241–243. [Google Scholar]

- Plutowska, B.; Biernacka, P.; Wardencki, W. Identification of Volatile Compounds in Raw Spirits of Different Organoleptic Quality. J. Inst. Brew. 2010, 116, 433–439. [Google Scholar] [CrossRef]

- Saerens, S.M.G.; Delvaux, F.R.; Verstrepen, K.J.; Thevelein, J.M. Production and biological function of volatile esters in Saccharomyces cerevisiae. Microb. Biotechnol. 2010, 3, 165–177. [Google Scholar] [CrossRef] [Green Version]

- Nascimento, E.S.P.; Cardoso, D.R.; Franco, D.W. Quantitative ester analysis in cachaca and distilled spirits by gas chromatography-mass spectrometry (GC-MS). J. Agric. Food Chem. 2008, 56, 5488–5493. [Google Scholar]

- Camara, J.S.; Marques, J.C.; Perestrelo, R.M.; Rodrigues, F.; Oliveira, L.; Andrade, P.; Caldeira, M. Comparative study of the whisky aroma profile based on headspace solid phase microextraction using different fibre coatings. J. Chrom. A 2007, 1150, 198–207. [Google Scholar]

- Kyraleou, M.; Herb, D.; O’Reilly, G.; Conway, N.; Bryan, T.; Kilcawley, K.N. The Impact of Terroir on the Flavour of Single Malt Whisk(e)y New Make Spirit. Foods 2021, 10, 443. [Google Scholar]

- Wisniewska, P.; Sliwinska, M.; Dymerski, T.; Wardencki, W.; Namiesnik, J. Comparison of an Electronic Nose Based on Ultrafast Gas Chromatography, Comprehensive Two-Dimensional Gas Chromatography, and Sensory Evaluation for an Analysis of Type of Whisky. J. Chem. 2017, 2017, 2710104. [Google Scholar] [CrossRef] [Green Version]

- González-Arjona, D.; González-Gallero, V.; Pablos, F.; Gonzalez, A.G. Authentication and differentiation of Irish whiskeys by higher-alcohol congener analysis. Anal. Chim. Acta 1999, 381, 257–264. [Google Scholar] [CrossRef]

- Perestrelo, R.; Caldeira, M.; Rodrigues, F.; Pereira, J.A.M.; Camara, J.S. DLLµE/GC-MS as a Powerful Analytical Approach to Establish the Volatilomic Composition of Different Whiskeys. Beverages 2022, 8, 53. [Google Scholar] [CrossRef]

- Csutoras, C.; Bakos-Barczi, N.; Burkus, B. Medium chain fatty acids and fatty acid esters as potential makers of alcoholic fermentation of white wines. Acta Aliment. 2022, 51, 33–42. [Google Scholar] [CrossRef]

- Patinios, C.; Lanza, L.; Corino, I.; Franssen, M.C.R.; Van Der Oost, J.; Weusthius, R.A.; Kengen, S.W.M. Eat1-Like alcohol acyl transferases from yeasts have high alcoholysis and thiolysis activity. Front. Microbiol. 2020, 11, 579844. [Google Scholar] [CrossRef]

- Rodda, L.N.; Beyer, J.; Gerostamoulos, D.; Drummer, O.H. Alcohol congener analysis and the source of alcohol: A review. Forensic. Sci. Med. Pathol. 2013, 9, 194–207. [Google Scholar] [CrossRef]

- Jones, M.; Pierce, J.S. Absorption of amino acids from wort by yeasts. J. Inst. Brew. 1964, 70, 307–315. [Google Scholar] [CrossRef]

- Krogerus, K.; Gibson, B.R. 125th Anniversary Review: Diacetyl and its control during brewery fermentation. J. Inst. Brew. 2013, 119, 86–97. [Google Scholar]

- Hazelwood, L.A.; Daran, J.-M.; Van Maris, A.J.A.; Pronk, J.T.; Dickinson, J.R. The Ehrlich Pathway for Fusel Alcohol Production: A Century of Research on Saccharomyces cerevisiae Metabolism. Appl. Environ. Microbiol. 2008, 74, 2259–2266. [Google Scholar] [CrossRef] [Green Version]

- Ravasio, D.; Wendland, J.; Walther, A. Major contributor of the Ehrlich pathway for 2-phenylethanol/rose flavor production in Ashbya gossypii. FEMS Yeast Res. 2014, 14, 833–844. [Google Scholar] [CrossRef] [Green Version]

- Klosowski, G.; Mikulski, D.; Macko, D.; Miklaszewska, B.; Kotarska, K.; Czuprynski, B. Influence of various yeast strains and selected starchy raw materials on production of higher alcohols during the alcoholic fermentation process. Eur. Food Res. Technol. 2015, 240, 233–242. [Google Scholar] [CrossRef]

- Gonzalez-Robles, I.W.; Cook, D.J. The impact of maturation on concentrations of key odour active compounds which determine the aroma of tequila. J. Inst. Brew. 2016, 122, 369–380. [Google Scholar] [CrossRef] [Green Version]

- Niu, M.; Huang, J.; Jin, Y.; Wu, C.; Zhou, R. Effect of oak matrix (barrel and toasted chips) on the volatiles in Goji (Lycium Chinese) wine. J. Inst. Brew. 2017, 124, 68–76. [Google Scholar] [CrossRef] [Green Version]

- Chakravarty, J.; Brigham, C. Solvent production by engineered Ralstonia eutropha: Channeling carbon to biofuel. Appl. Microbiol. Biotechnol. 2018, 102, 5012–5031. [Google Scholar] [CrossRef] [PubMed]

- Godillot, J.; Sanchez, I.; Perez, M.; Picou, C.; Galeote, V.; Sablayrolles, J.-M.; Farines, V.; Mouret, J.-R. The Timing of Nitrogen Addition Impacts Yeast Genes Expression and the Production of Aroma Compounds during Wine Fermentation. Front. Microbiol. 2022, 13, 829786. [Google Scholar] [CrossRef]

- Mendes-Ferreira, A.; Barbosa, C.; Falco, V.; Leao, C.; Mendes-Faia, A. The production of hydrogen sulphide and other aroma compounds by wine strains of Saccharomyces cerevisiae in synthetic media with different nitrogen concentrations. J. Ind. Microbiol. Biotechnol. 2009, 36, 571–583. [Google Scholar] [CrossRef]

- Vidal, E.E.; De Billerbeck, G.M.; Simoea, D.A.; Schuler, A.; Francois, J.M.; De Morais Jr, M.A. Influence of nitrogen supply on the production of higher alcohols/esters and expression of flavour-related genes in cachaça fermentation. Food Chem. 2013, 138, 701–708. [Google Scholar] [CrossRef]

- Eram, M.S.; Ma, K. Decarboxylation of Pyruvate to Acetaldehyde for Ethanol Production by Hyperthermophiles. Biomolecules 2013, 3, 578–596. [Google Scholar] [CrossRef] [Green Version]

- Chung, H.; Yoon, M.K.; Han, J.; Kim, Y.-S. Evaluation of volatile organic compounds in alcoholic beverages consumed in Korea. J. Korean Soc. Appl. Biol. Chem. 2015, 58, 423–432. [Google Scholar] [CrossRef]

- Liu, C.; Li, Q.; Niu, C.; Zheng, F.; Zhao, Y. Simultaneous determination of diethylacetal and acetaldehyde during beer fermentation and storage process. J. Sci. Food Agric. 2018, 98, 4733–4741. [Google Scholar] [CrossRef]

- Gordon, R.; Power, A.; Chapman, J.; Chandra, S.; Cozzolino, D. A Review on the Source of Lipids and Their Interactions during Beer Fermentation that Affect Beer Quality. Fermentation 2018, 4, 89. [Google Scholar] [CrossRef] [Green Version]

- Wanikawa, A.; Hosoi, K.; Kato, T.; Nakagawa, K. Identification of green note compounds in malt whisky using multidimensional gas chromatography. Flavour Frag. J. 2002, 17, 207–211. [Google Scholar] [CrossRef]

- Le Bars, D.; Yvon, M. Formation of diacetyl and acetoin by Lactococcus lactis via aspartate catabolism. J. Appl. Microbiol. 2008, 104, 171–177. [Google Scholar] [CrossRef]

- Gibson, B.; Vidgren, V.; Peddinti; Korgerus, K. Diacetyl control during brewery fermentation via adaptive laboratory engineering of the lager yeast Saccharomyces pastorianus. J. Ind. Microbiol. Biotechnol. 2018, 45, 1103–1112. [Google Scholar] [CrossRef] [Green Version]

- Balcerek, M.; Pielech-Przybylska, K.; Dziekonska-Kubczak, U.; Patelski, P.; Strak, E. Fermentation Results and Chemical Composition of Agricultural Distillates Obtained from Rye and Barley Grains and the Corresponding Malts as a Source of Amylolytic Enzymes and Starch. Molecules 2016, 21, 1320. [Google Scholar] [CrossRef] [Green Version]

- Harrison, B.; Fagnen, O.; Jack, F.; Brosnan, J. The Impact of Copper in Different Parts of Malt Whisky Pot Stills on New Make Spirit Composition and Aroma. J. Inst. Brew. 2011, 117, 106–112. [Google Scholar] [CrossRef]

- Owens, B. The Art of Distilling, Revised and Updated: An Enthusiastic Guide to the Artisan Distillers of Whiskey, Vodka, Gin, and Other Potent Potables, 2nd ed.; Owens, B., Dikty, A., Faulkner, A., Eds.; Quarto: Beverley, MA, USA, 2019. [Google Scholar]

- Nicol, D. Batch Distillation. In The Science and Technology of Whiskies; Piggott, J.R., Sharp, R., Duncan, R.E.B., Eds.; Longman Group UK Ltd.: Harlow, UK, 1989; pp. 118–149. [Google Scholar]

- Buttery, R.G.; Ling, L.; Guadagni, D.G. Volatilities of Aldehydes, Ketones, and Esters in Dilute Water Solution. J. Agric. Food Chem. 1969, 17, 385–389. [Google Scholar] [CrossRef]

- Stanzer, D.A.; Cica, K.H.; Blesic, M.; Murtic, M.S.; Mrvcic, J.; Spaho, N. Alcoholic fermentation as a source of congeners in fruit spirits. Foods 2023, 12, 1951. [Google Scholar] [CrossRef]

- Goss, K.A.; Alharethi, R.; Laposata, M. Fatty acid ethyl ester synthesis in the preparation of scotch whiskey. Alcohol 1999, 17, 241–245. [Google Scholar] [CrossRef]

- Boothroyd, E.L.; Linforth, R.S.H.; Cook, D.J. Effects of Ethanol and Long-Chain Ethyl Ester Concentrations on Volatile Partitioning in a Whisky Model System. J. Agric. Food Chem. 2012, 60, 9959–9966. [Google Scholar] [CrossRef]

- Viriot, C.; Scalbert, A.; Lapierre, C.; Moutounet, M. Ellagitannins and Lignins in Aging of Spirits in Oak Barrels. J. Agric. Food Chem. 1993, 41, 1872–1879. [Google Scholar] [CrossRef]

- Prida, A.; Ducousso, A.; Petit, R.J.; Nepveu, G.; Puech, J.-L. Variation in wood volatile compounds in a mixed oak stand: Strong species and spatial differentiation in whisky-lactone content. Ann. For. Sci. 2007, 64, 313–320. [Google Scholar] [CrossRef] [Green Version]

- Owens, J.E.; Zimmerman, L.B.; Gardner, M.A.; Lowe, L.E. Analysis of Whiskey by Dispersive Liquid−Liquid Microextraction Coupled with Gas Chromatography/Mass Spectrometry: An Upper Division Analytical Chemistry Experiment Guided by Green Chemistry. J. Chem. Educ. 2016, 93, 186–192. [Google Scholar] [CrossRef]

- Heinz, H.A.; Elkins, J.T. Comparison of unaged and barrel aged whiskies from the same Mash Bill using gas chromatography/mass spectrometry. J. Brew. Distilling 2019, 8, 1–6. [Google Scholar]

- Gill, V. A Whisky Tour. Chemistry World. 2008, pp. 40–44. Available online: https://www.rsc.org/images/whisky_tcm18-138981.pdf (accessed on 21 October 2022).

- Coldea, T.E.; Mudura, E.; Socaciu, C. Advances in Distilled Beverages Authenticity and Quality Testing. In Ideas and Applications Toward Sample Preparation for Food and Beverage Analysis; Stauffer, M.T., Ed.; IntechOpen: London, UK, 2017. [Google Scholar]

- Mills, D.E.; Baugh, W.D.; Conner, H.A. Studies on the Formation of Acrolein in Distillery Mashes. Appl. Microbiol. 1954, 2, 9–13. [Google Scholar] [CrossRef]

- Cadahia, E.; Fernandez de Simon, B.; Jalocha, J. Volatile Compounds in Spanish, French, and American Oak Woods after Natural Seasoning and Toasting. J. Agric. Food Chem. 2003, 51, 5923–5932. [Google Scholar] [CrossRef]

- Pittari, E.; Moio, L.; Piombino, P. Interactions between Polyphenols and Volatile Compounds in Wine: A Literature Review on Physicochemical and Sensory Insights. Appl. Sci. 2021, 11, 1157. [Google Scholar] [CrossRef]

- Soares, S.; Brandao, E.; Guerreiro, C.; Soares, S.; Mateus, N.; De Freitas, V. Tannins in food: Insights into the molecular perception of astringency and bitter taste. Molecules 2020, 25, 2590. [Google Scholar] [CrossRef]

- Gadrat, M.; Emo, C.; Lavergne, J.; Teissedre, P.-L.; Chira, K. Impact of Barrel Toasting on Ellagitannin Composition of Aged Cognac Eaux-de-Vie. Molecules 2022, 27, 2531. [Google Scholar] [CrossRef]

- Fracassetti, D.; Limbo, S.; Pellegrino, L.; Tirelli, A. Light-induced reactions of methionine and riboflavin in model wine: Effects of hydrolysable tannins and sulfur dioxide. Food Chem. 2019, 298, 124952. [Google Scholar] [CrossRef]

- Picariello, L.; Rinaldi, A.; Forino, M.; Errichiello, F.; Moio, L.; Gambuti, A. Effect of Different Enological Tannins on Oxygen Consumption, Phenolic Compounds, Color and Astringency Evolution of Aglianico Wine. Molecules 2020, 25, 4607. [Google Scholar] [CrossRef]

- Okuda, T.; Yoshida, T.; Hatano, T.; Ito, H. Ellagitannins renewed the concept of tannins. In Chemistry and Biology of Ellagitannins: An Underestimated Class of Bioactive Plant Polyphenols; Quideau, S., Ed.; World Scientific Publishing: Singapore, 2009; pp. 1–54. [Google Scholar]

- Koga, K.; Taguchi, A.; Koshimizu, S.; Suwa, Y.; Yamada, Y.; Shirasaka, N.; Yoshizumi, H. Reactive Oxygen Scavenging Activity of Matured Whiskey and Its Active Polyphenols. J. Food Sci. 2007, 72, 212–217. [Google Scholar] [CrossRef]

- Conner, J.M.; Paterson, A.; Piggott, J.R. Analysis of Lignin from Oak Casks Used for the Maturation of Scotch Whisky. J. Sci. Food Agric. 1992, 60, 349–353. [Google Scholar] [CrossRef]

- Stegarus, D.I.; Calugar, A.; Tanase, C.; Musca, A.; Botoran, O.R.; Manolache, M.; Babes, A.C.; Bunea, C.; Gal, E.; Bunea, A.; et al. Influence of Oak Chips and Oak Barrel Ageing on Volatile Profile in Chardonnay Wine of Romania. Appl. Sci. 2021, 11, 3691. [Google Scholar] [CrossRef]

- Valcárcel-Muñoz, M.J.; Guerrero-Chavinet, M.; Garcia-Moreno, M.V.; Rodriguez-Dodero, M.C.; Guillen-Sanchez, D.A. Comparative Evaluation of Brandy de Jerez Aged in American Oak Barrels with Different Times of Use. Foods 2021, 10, 288. [Google Scholar] [CrossRef]

- Tarko, T.; Frankowski, F.; Duda-Chodak, A. The impact of compounds extracted from wood on the quality of alcoholic beverages. Molecules 2023, 28, 620. [Google Scholar] [CrossRef]

- Gollihue, J.; Pook, V.G.; DeBolt, S. Sources of variation in bourbon whiskey barrels: A review. J. Inst. Brew. 2021, 127, 210–223. [Google Scholar] [CrossRef]

- Jeffrey, J.D.E. Aging of Whiskey Spirits in Barrels of Non-Traditional Volume. Master’s Thesis, Michigan State University, East Lansing, MI, USA, 2012. [Google Scholar]

- Conner, J.M.; Paterson, A.; Piggott, J.R. Changes in wood extractives from oak cask staves through maturation of scotch malt whisky. J. Sci. Food Agric. 1993, 62, 169–174. [Google Scholar] [CrossRef]

- Wanikawa, A.; Hosoi, K.; Takise, I.; Kato, T. Detection of γ -lactones in malt whisky. J. Inst. Brew. 2000, 106, 39–43. [Google Scholar] [CrossRef]

- Feuillat, F.; Keller, R. Variability of oak wood (Quercus robur L., Quercus petraea Liebl.) anatomy relating to cask properties. Am. J. Enol. Vitic. 1997, 48, 502–508. [Google Scholar] [CrossRef]

- Carrau, F.M.; Medina, K.; Boido, E.; Farina, L.; Gaggero, C.; Dellacassa, E.; Versini, G.; Henschke, P.A. De novo synthesis of monoterpenes by Saccharomyces cerevisiae wine yeasts. FEMS Microbiol. Lett. 2005, 243, 107–115. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Karlsson, B.C.G.; Friedman, R. Dilution of whisky—The molecular perspective. Sci. Rep. 2017, 7, 6489. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Arnold, R.J.; Ochoa, A.; Kerth, C.R.; Miller, R.K.; Murray, S.C. Assessing the impact of corn variety and Texas terroir on flavor and alcohol yield in new-make bourbon whiskey. PLoS ONE 2019, 14, e0220787. [Google Scholar] [CrossRef] [Green Version]

- Vivas, N.; Vivas de Gaulejac, N.; Vitry, C.; Mouche, C.; Kahn, N.; Nonier-Bourden, M.F.; Absalon, C. Impact of ethanol content on the scavenging activities of oak wood C-glycosidic ellagitannins. Application to the evaluation of the nutritional status of spirits. J. Inst. Brew. 2013, 119, 116–125. [Google Scholar]

- White, B.; Symth, M.R.; Lunte, C.E. Determination of phenolic acids in a range of Irish whiskies, including single pot stills and aged single malts, using capillary electrophoresis with field amplified sample stacking. Anal. Methods 2017, 9, 1248. [Google Scholar] [CrossRef]

- Gibson, L.T.; Watt, C.M. Acetic and formic acids emitted from wood samples and their effect on selected materials in museum environments. Corros. Sci. 2010, 52, 172–178. [Google Scholar] [CrossRef] [Green Version]

- Cortes-Dieguez, S.; Rodriguez-Solana, R.; Dominguez, J.M.; Diaz, E. Impact odorants and sensory profile of young red wines from four Galician (NW of Spain) traditional cultivars. J. Inst. Brew. 2015, 121, 628–635. [Google Scholar] [CrossRef]

- Ubeda, C.; Kania-Zelada, I.; Del Barrio-Galan, R.; Medel-Maraboli, M.; Gil, M.; Pena-Neira, A. Study of the changes in volatile compounds, aroma and sensory attributes during the production process of sparkling wine by traditional method. Food Res. Int. 2019, 119, 554–563. [Google Scholar] [CrossRef]

- Brizuela, N.S.; Bravo-Ferrada, B.M.; Curilen, Y.; Delfederico, L.; Caballero, A.; Semorile, L.; Angeles Pozo-Bayo, M.; Tymczyszyn, E.E. Advantages of using blend cultures of native L. plantarum and O. oeni strains to induce malolactic fermentation of Patagonian Malbec wine. Front. Microbiol. 2018, 9, 2109. [Google Scholar] [CrossRef] [Green Version]

- Campo, E.; CAcho, J.; Ferreira, V. Solid phase extraction, multidimensional gas chromatography mass spectrometry determination of four novel aroma powerful ethyl esters: Assessment of their occurrence and importance in wine and other alcoholic beverages. J. Chromatogr. A 2007, 1140, 180–188. [Google Scholar] [CrossRef]

- Xiong, A.; Zhao, K.; Hu, Y.; Yang, G.; Kuang, B.; Xiong, X.; Yang, Z.; Zheng, Q. Influence of Electrochemical Oxidation on the Maturation Process of the Distilled Spirit. ACS Omega 2020, 5, 18349–18355. [Google Scholar] [CrossRef] [PubMed]

- Kemsley, E.K.; Defernez, M.; Marini, F. Multivariate statistics: Considerations and confidences in food authenticity problems. Food Control 2019, 105, 102–112. [Google Scholar] [CrossRef]

- Ferracane, A.; Manousi, N.; Tranchida, P.Q.; Zachariadis, G.A.; Mondello, L.; Rosenberg, E. Exploring the volatile profile of whiskey samples using solid-phase microextraction Arrow and comprehensive two-dimensional gas chromatography-mass spectrometry. J. Chromatogr. A 2022, 1676, 463241. [Google Scholar] [CrossRef]

- Jelen, H.H.; Majcher, M.; Szwengiel, A. Key odorants in peated malt whisky and its differentiation from other whisky types using profiling of flavour and volatile compounds. LWT Food Sci. Technol. 2019, 107, 56–63. [Google Scholar] [CrossRef]

- Cody, R.B.; Fukudome, T.; Ubukata, M. Integrated data analysis making use of the total information from gas chromatography and high-resolution time-of-flight mass spectrometry to identify qualitative differences between two whisky samples. Rapid Commun. Mass Spectrom. 2022, 36, e9225. [Google Scholar] [CrossRef]

- Dunkel, A.; Steinhaus, M.; Kotthoff, M.; Nowak, B.; Krautwurst, D.; Schieberle, P.; Hofmann, T. Nature’s Chemical Signatures in Human Olfaction: A Foodborne Perspective for Future Biotechnology. Angew. Chem. Int. Ed. 2014, 53, 7124–7143. [Google Scholar] [CrossRef]

- Zellner, B.d.; Dugo, P.; Dugo, G.; Mondello, L. Gas chromatography–olfactometry in food flavour analysis. J. Chromatogr. A 2008, 1186, 123–143. [Google Scholar] [CrossRef]

- Marques, C.; Correia, E.; Dinis, L.-T.; Vilela, A. An Overview of Sensory Characterization Techniques: From Classical Descriptive Analysis to the Emergence of Novel Profiling Methods. Foods 2022, 11, 255. [Google Scholar]

- Aylott, R.I.; Clyne, A.H.; Fox, A.P.; Walker, D.A. Analytical strategies to confirm Scottish Whisky Authenticity. Analyst 1994, 119, 1741–1746. [Google Scholar] [CrossRef]

- Fitzgerald, G.; James, K.J.; MacNamara, K.; Stack, M.A. Characterisation of whiskeys using solid-phase microextraction with gas chromatography-mass spectrometry. J. Chromatogr. A 2000, 896, 351–359. [Google Scholar] [CrossRef]

- Poisson, L.; Schieberle, P. Characterization of the Most Odor-Active Compounds in an American Bourbon Whisky by Application of the Aroma Extract Dilution Analysis. J. Agric. Food Chem. 2008, 56, 5813–5819. [Google Scholar] [CrossRef] [PubMed]

- Lehtonen, M. Phenols in whisky. Chromatographia 1982, 16, 201–203. [Google Scholar] [CrossRef]

- Heller, M.; Vitali, L.; Oliviera, M.A.L.; Costa, A.C.O.; Micke, G.A. A Rapid Sample Screening Method for Authenticity Control of Whiskey Using Capillary Electrophoresis with Online Preconcentration. J. Agric. Food Chem. 2011, 59, 6882–6888. [Google Scholar] [CrossRef]

- Roullier-Gall, C.; Signoret, J.; Coelho, C.; Hemmler, D.; Kajdan, M.; Lucio, M.; Schafer, B.; Gougeon, R.D.; Schmitt-Kopplin, P. Influence of regionality and maturation time on the chemical fingerprint of whisky. Food Chem. 2020, 323, 126748. [Google Scholar] [CrossRef]

- Roullier-Gall, C.; Signoret, J.; Hemmler, D.; Witting, M.A.; Kanawati, B.; Schafer, B.; Gougeon, R.D.; Schmitt-Kopplin, P. Usage of FT-ICR-MS Metabolomics for Characterizing the Chemical Signatures of Barrel-Aged Whisky. Front Chem. 2018, 6, 29. [Google Scholar] [CrossRef] [Green Version]

- James Reid, S.; Speers, R.A.; Willoughby, N.; Lumsden, W.B.; Maskell, D.L. Pre-fermentation of malt whisky wort using Lactobacillus and its influence on new-make spirit character. Food Chem. 2020, 320, 126605. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kelly, T.J.; O’Connor, C.; Kilcawley, K.N. Sources of Volatile Aromatic Congeners in Whiskey. Beverages 2023, 9, 64. https://doi.org/10.3390/beverages9030064

Kelly TJ, O’Connor C, Kilcawley KN. Sources of Volatile Aromatic Congeners in Whiskey. Beverages. 2023; 9(3):64. https://doi.org/10.3390/beverages9030064

Chicago/Turabian StyleKelly, Thomas J., Christine O’Connor, and Kieran N. Kilcawley. 2023. "Sources of Volatile Aromatic Congeners in Whiskey" Beverages 9, no. 3: 64. https://doi.org/10.3390/beverages9030064