Protein Soft Drinks: A Retail Market Analysis and Selected Product Characterization

Abstract

:1. Introduction

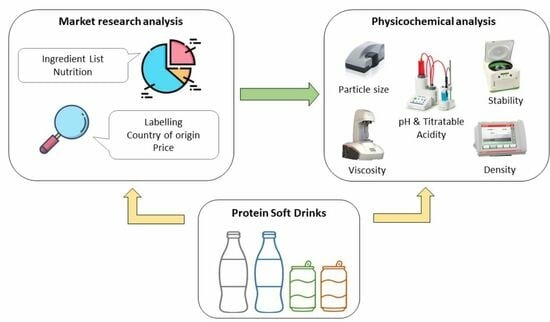

2. Materials and Methods

2.1. Part 1: Retail Market Analysis

2.2. Part 2: Protein Content and Physicochemical Analyses of Selected Protein Soft Drinks

2.2.1. Protein Determination

2.2.2. pH and Total Titratable Acidity

2.2.3. Particle Size Distribution

2.2.4. Density

2.2.5. Apparent Viscosity

2.2.6. Phase Separation

2.2.7. Colour

2.2.8. Statistics

3. Results

3.1. Part 1: Retail Market Analysis

3.1.1. Beverage Descriptions

3.1.2. List of Ingredients

3.1.3. Nutritional Dimension

3.1.4. Economic Dimension

3.2. Part 2: Protein Content and Physicochemical Properties of Selected Protein Soft Drinks

3.2.1. Pictures and Colour

3.2.2. Protein Content

3.2.3. pH and Total Titratable Acidity (TTA)

3.2.4. Apparent Viscosity

3.2.5. Density

3.2.6. Particle Size and Polydispersity Index (PDI)

3.2.7. Stability

3.2.8. PCA Biplot

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| BCAA | Branch chain amino acids |

| BPI | Beef protein isolate |

| CP/H | Collagen protein/hydrolysate |

| EAA | Essential amino acids |

| MPC/I | Milk protein concentrate/isolate |

| PBP | Plant-based protein |

| PPI/H | Pea protein/isolate/hydrolysate |

| SD | Soft drink |

| WPI/H | Whey protein isolate/hydrolysate |

References

- EU Commission. How Often Do You Drink Sugar-Sweetened Soft Drinks? EU Commission: Brussels, Belgium, 2021. [Google Scholar]

- Popkin, B.M.; Hawkes, C. Sweetening of the global diet, particularly beverages: Patterns, trends, and policy responses. Lancet Diabetes Endocrinol. 2016, 4, 174–186. [Google Scholar] [CrossRef]

- Ashurst, P.R. Chemistry and Technology of Soft Drinks and Fruit Juices; Wiley: Hoboken, NJ, USA, 2016. [Google Scholar]

- Prado, M.S.; de Oliveira, D.F.; Tonial, I.B.; Moreira, I.C.; Dias, L.F.; Coelho, A.R. Orange-flavored soft drink with the addition of isolated whey protein. Acta Sci. Technol. 2015, 37, 425–430. [Google Scholar] [CrossRef]

- Goudarzi, M.; Madadlou, A.; E Mousavi, M.; Emam-Djomeh, Z. Formulation of apple juice beverages containing whey protein isolate or whey protein hydrolysate based on sensory and physicochemical analysis. Int. J. Dairy Technol. 2015, 68, 70–78. [Google Scholar] [CrossRef]

- Gupta, A.; Sanwal, N.; Bareen, M.A.; Barua, S.; Sharma, N.; Olatunji, O.J.; Nirmal, N.P.; Sahu, J.K. Trends in functional beverages: Functional ingredients, processing technologies, stability, health benefits, and consumer perspective. Food Res. Int. 2023, 170, 113046. [Google Scholar] [CrossRef]

- Polonini, H.; Dijkers, E.; Ferreira, A.O. Beauty from within: A Review of the Science behind YulivTM Collagen Drink: An Anti-Aging Nutraceutical. J. Cosmet. Dermatol. Sci. Appl. 2021, 11, 263–278. [Google Scholar] [CrossRef]

- Arbach, C.T.; Alves, I.A.; Serafini, M.R.; Stephani, R.; Perrone, T.; Costa, J.d.C.d. Recent patent applications in beverages enriched with plant proteins. NPJ Sci. Food 2021, 5, 1–20. [Google Scholar] [CrossRef]

- Vogelsang-O’Dwyer, M.; Sahin, A.W.; Zannini, E.; Arendt, E.K. Physicochemical and nutritional properties of high protein emulsion-type lupin-based model milk alternatives: Effect of protein source and homogenization pressure. J. Sci. Food Agric. 2021, 102, 5086–5097. [Google Scholar] [CrossRef] [PubMed]

- Jeske, S.; Zannini, E.; Arendt, E.K. Evaluation of Physicochemical and Glycaemic Properties of Commercial Plant-Based Milk Substitutes. Plant Foods Hum. Nutr. 2017, 72, 26–33. [Google Scholar] [CrossRef]

- Mintel Global Food and Drink Trends 2030. Available online: https://www.mintel.com/press-centre/mintel-announces-global-food-and-drink-trends-for-2030/#:~:text=Expect%20to%20see%20consumers%20further,more%20sustainable%20consumption%20and%20innovation (accessed on 9 June 2023).

- AACC. International Method 46—12—Crude Protein—Kjeldahl Method, Boric Acid Modification. In International Approved Methods of Analysis 2011, 11th ed.; Cereals & Grains Association: St. Paul, MN, USA, 2011. [Google Scholar]

- Marchan, S.; Hector, T.; Bascombe, K. The pH and Titratable Acidity of Still and Sparkling Flavored Waters: The Effects of Temperature and Storage Time. Open J. Stomatol. 2021, 11, 148–158. [Google Scholar] [CrossRef]

- Mudalige, T.; Qu, H.; Van Haute, D.; Ansar, S.M.; Paredes, A.; Ingle, T. Characterization of Nanomaterials: Tools and Challenges. In Nanomaterials for Food Applications; Elsevier: Amsterdam, The Netherlands, 2018; pp. 313–353. ISBN 9780128141311. [Google Scholar]

- Nyhan, L.; Sahin, A.W.; Arendt, E.K. Co-fermentation of non-Saccharomyces yeasts with Lactiplantibacillus plantarum FST 1.7 for the production of non-alcoholic beer. Eur. Food Res. Technol. 2023, 249, 167–181. [Google Scholar] [CrossRef]

- Delgado-González, M.J.; Carmona-Jiménez, Y.; Rodríguez-Dodero, M.C.; García-Moreno, M.V. Color Space Mathematical Modeling Using Microsoft Excel. J. Chem. Educ. 2018, 95, 1885–1889. [Google Scholar] [CrossRef]

- European Parliament & Council Regulation (EC). No 1169/2011 of the European Parliament and of the Provision of Food Information to Consumers. EU Commission: Brussels, Belgium, 2011.

- European Parliament & of the Council Regulation (EC). No 1924/2006 of the European Parliament and of the Council on Nutrition and Health Claims Made on Foods. EU Commission: Brussels, Belgium, 2006.

- Herreman, L.; Nommensen, P.; Pennings, B.; Laus, M.C. Comprehensive overview of the quality of plant—And animal-sourced proteins based on the digestible indispensable amino acid score. Food Sci. Nutr. 2020, 8, 5379–5391. [Google Scholar] [CrossRef] [PubMed]

- FAO. Dietary Protein Quality Evaluation in Human Nutrition. FAO Food Nutr. Pap. 2013, 92, 1–66. [Google Scholar]

- Tang, Q.; Roos, Y.H.; Miao, S. Plant Protein versus Dairy Proteins: A pH-Dependency Investigation on Their Structure and Functional Properties. Foods 2023, 12, 368. [Google Scholar] [CrossRef]

- Goulding, D.A.; Fox, P.F.; O’Mahony, J.A. Milk Proteins: An Overview. In Milk Proteins: From Expression to Food; Elsevier: Amsterdam, The Netherlands, 2019; pp. 21–98. ISBN 9780128152515. [Google Scholar]

- León-López, A.; Morales-Peñaloza, A.; Martínez-Juárez, V.M.; Vargas-Torres, A.; Zeugolis, D.I.; Aguirre-Álvarez, G. Hydrolyzed Collagen—Sources and Applications. Molecules 2019, 24, 4031. [Google Scholar] [CrossRef]

- Phillips, S.M. Current Concepts and Unresolved Questions in Dietary Protein Requirements and Supplements in Adults. Front. Nutr. 2017, 4, 13. [Google Scholar] [CrossRef]

- Gauza-Włodarczyk, M.; Kubisz, L.; Włodarczyk, D. Amino acid composition in determination of collagen origin and assessment of physical factors effects. Int. J. Biol. Macromol. 2017, 104, 987–991. [Google Scholar] [CrossRef]

- Bessada, S.M.; Barreira, J.C.; Oliveira, M.B.P. Pulses and food security: Dietary protein, digestibility, bioactive and functional properties. Trends Food Sci. Technol. 2019, 93, 53–68. [Google Scholar] [CrossRef]

- Gorissen, S.H.M.; Crombag, J.J.R.; Senden, J.M.G.; Waterval, W.A.H.; Bierau, J.; Verdijk, L.B.; van Loon, L.J.C. Protein content and amino acid composition of commercially available plant-based protein isolates. Amino Acids 2018, 50, 1685–1695. [Google Scholar] [CrossRef]

- Ma, K.K.; Greis, M.; Lu, J.; Nolden, A.A.; McClements, D.J.; Kinchla, A.J. Functional Performance of Plant Proteins. Foods 2022, 11, 594. [Google Scholar] [CrossRef]

- Henchion, M.; Hayes, M.; Mullen, A.M.; Fenelon, M.; Tiwari, B. Future Protein Supply and Demand: Strategies and Factors Influencing a Sustainable Equilibrium. Foods 2017, 6, 53. [Google Scholar] [CrossRef] [PubMed]

- Schoenfeld, B.J.; Aragon, A.; Wilborn, C.; Urbina, S.L.; Hayward, S.E.; Krieger, J. Pre-versus post-exercise protein intake has similar effects on muscular adaptations. PeerJ 2017, 5, e2825. [Google Scholar] [CrossRef] [PubMed]

- Mellentin, J. 10 Key Trends in Food, Nutrition & Health 2023. New Nutrition Business: London, UK, 2022; ISBN 9781906297657. [Google Scholar]

- Thow, A.M.; Rippin, H.L.; Mulcahy, G.; Duffey, K.; Wickramasinghe, K. Sugar-sweetened beverage taxes in Europe: Learning for the future. Eur. J. Public Health 2022, 32, 273–280. [Google Scholar] [CrossRef] [PubMed]

- Edwards, C.H.; Rossi, M.; Corpe, C.P.; Butterworth, P.J.; Ellis, P.R. The role of sugars and sweeteners in food, diet and health: Alternatives for the future. Trends Food Sci. Technol. 2016, 56, 158–166. [Google Scholar] [CrossRef]

- Abu-Reidah, I.M. Carbonated Beverages. In Trends in Non-Alcoholic Beverages; Elsevier: Amsterdam, The Netherlands, 2019; pp. 1–36. ISBN 9780128169384. [Google Scholar]

- Ashurst, P.R.; Hargitt, R.; Palmer, F. Ingredients in Soft Drinks. In Soft Drink and Fruit Juice Problems Solved; Elsevier: Amsterdam, The Netherlands, 2017; pp. 29–66. [Google Scholar]

- Krul, E.S. Calculation of Nitrogen-to-Protein Conversion Factors: A Review with a Focus on Soy Protein. J. Am. Oil Chem. Soc. 2019, 96, 339–364. [Google Scholar] [CrossRef]

- Watford, M.; Wu, G. Protein. Adv. Nutr. 2018, 9, 651–653. [Google Scholar] [CrossRef]

- Shimomura, Y.; Murakami, T.; Nakai, N.; Nagasaki, M.; Harris, R.A. 3rd Amino Acid Workshop Exercise Promotes BCAA Catabolism: Effects of BCAA Supplementation on Skeletal Muscle during Exercise 1. J. Nutr. 2004, 136, 1583S–1587S. [Google Scholar] [CrossRef]

- Yadav, D.N.; Vishwakarma, R.K.; Borad, S.; Bansal, S.; Jaiswal, A.K.; Sharma, M. Development of protein fortified mango based ready-to-serve beverage. J. Food Sci. Technol. 2016, 53, 3844–3852. [Google Scholar] [CrossRef]

- Steen, D.P.; Ashurst, P.R. Carbonated Soft Drinks Formulation and Manufacture; Blackwell Publishing Ltd.: Hoboken, NJ, USA, 2006. [Google Scholar]

- Dabbas, A.; Al-Dabbas, M.M.; Al-Ismail, K.; Taleb, R.A.; Ibrahim, S. Acid-Base Buffering Properties of Five Legumes and Selected Food in vitro. Am. J. Agric. Biol. Sci. 2010, 5, 154–160. [Google Scholar] [CrossRef]

- Jindal, R.; Singh, S. Evaluating the buffering capacity of various soft drinks, fruit juices and tea. J. Conserv. Dent. 2010, 13, 129–131. [Google Scholar] [CrossRef]

- Jabeen, M.; Razzaq, I.; Aslam, N.; Zafar, N.M. Physico-Chemical Analysis of Some Soft Drinks Available in Pakistan. Pak. J. Anal. Environ. Chem. 2022, 23, 129–140. [Google Scholar] [CrossRef]

- Saniah, K.; Samsiah, M.S.; Sharifah Samsiah, M. The Application of Stevia as Sugar Substitute in Carbonated Drinks Using Response Surface Methodology (Penggunaan Stevia Sebagai Pengganti Gula Di Dalam Minuman Berkarbonat Menggunakan Kaedah Gerak Balas Permukaan). J. Trop. Agric. Fd. Sc. 2012, 40, 23–34. [Google Scholar]

- Al-Dabbas; Maher, M.; Al-Qudsi, J.M. Effect of Partial Replacement of Sucrose with the Artificial Sweetener Sucralose on the Physico-Chemical, Sensory, Microbial Characteristics, and Final Cost Saving of Orange Nectar. Food Res. J. 2012, 19, 679–683. [Google Scholar]

- Saha, B.C.; Hayashi, K. Debittering of Protein Hydrolyzates. Biotechnol. Adv. 2001, 19, 355–370. [Google Scholar] [CrossRef] [PubMed]

- Chu, X.L.; Nikolov, A.D.; Wasan, D.T. Effects of Particle Size and Polydispersity on the Depletion and Structural Forces in Colloidal Dispersions. Langmuir 1996, 12, 5004–5010. [Google Scholar] [CrossRef]

- Cano-Sarmiento, C.; Téllez-Medina, D.I.; Viveros-Contreras, R.; Cornejo-Mazón, M.; Figueroa-Hernández, C.Y.; García-Armenta, E.; Alamilla-Beltrán, L.; García, H.S.; Gutiérrez-López, G.F. Zeta Potential of Food Matrices. Food Eng. Rev. 2018, 10, 113–138. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, Y.; Huang, X.; Jin, Z.; Jiao, A. Stabilization of a collagen peptide-cranberry juice by three functional polysaccharides with different charge characteristics. Food Hydrocoll. 2023, 139, 108518. [Google Scholar] [CrossRef]

- Redondo, N.; Gómez-Martínez, S.; Marcos, A. Sensory attributes of soft drinks and their influence on consumers’ preferences. Food Funct. 2014, 5, 1686–1694. [Google Scholar] [CrossRef]

| Protein | Sweeteners | Acidulants | Preservatives | Stabilisers | |||||

| Carbonated | Uncarbonated | Carbonated | Uncarbonated | Carbonated | Uncarbonated | Carbonated | Uncarbonated | Carbonated | Uncarbonated |

| WPI (10) WPH (3) CH (Bovine) (2) CH (Marine) (5) CH (unknown source) (3) PPH (4) BCAA (8) | BPI (5) WPI (67) CH (Bovine) (13) CH (Marine) (1) CP/H (unknown source) (4) MPI (1) MPC (1) PP (4) PPH (2) PPI (3) BCAA (2) Glutamine (5) | Sucralose (23) Acesulfame-K (5) Steviol glycosides (7) Fructose (2) Inositol (1) | Sucralose (55) Steviol glycosides (45) Acesulfame-K (15) Erythritol (13) Cane sugar (7) Saccharin (1) Fructose (1) | Citric acid (27) Malic acid (8) Phosphoric acid (4) Potassium citrate (4) Sodium citrate (2) Magnesium citrate (1) | Citric acid (54) Phosphoric acid (53) Malic acid (26) Sodium citrate (18) Sodium phosphate (9) Lactic acid (1) | Potassium sorbate (7) Sodium benzoate (6) | Potassium sorbate (20) Sodium benzoate (16) Potassium phosphate (6) Potassium benzoate (3) Calcium citrate (2) | Gum Arabic (1) Glycerol ester of wood rosin (1) Pectin (1) Cellulose gum (1) | Maltodextrin (7) Glycerol ester of wood rosin (4) Modified food starch (4) Inulin (3) Pectin (1) Acacia gum (1) |

| Emulsifiers | Antioxidants | Anti-foaming agents | |||||||

| Carbonated | Uncarbonated | Carbonated | Uncarbonated | Carbonated | Uncarbonated | ||||

| Glycerol (5) | Polysorbate 80 (4) Glycerine (3) Lecithin (2) | Ascorbic acid (2) | Ascorbic acid (8) | Silicone (5) | Dimethylpolysiloxane (1) | ||||

| Soft Drink | Nitrogen (%) | Particle Size (nm) | Polydispersity Index | Separation Rate (%/min) | L* | a* | b* |

|---|---|---|---|---|---|---|---|

| SD 1.a | 0.94 ± 0.01 a | 3359 ± 498 a | 0.26 ± 0.1 ac | 0.198 ± 0.0 a | 69.49 ± 0.11 a | 12.14 ± 0.02 a | 29.67 ± 0.03 a |

| SD 2.a | 0.53 ± 0.0 b | 50 ± 1.37 b | 0.41 ± 0.02 bdef | 0.07 ± 0.0 bcef | 64.88 ± 0.18 b | 40.69 ± 0.11 b | 3.02 ± 0.09 b |

| SD 3.a* | 0.64 ± 0.0 e | 104 ± 2.18 bcd | 0.4 ± 0.04 bdef | 0.064 ± 0.01 cefg | 86.4 ± 0.09 c | 1.26 ± 0.04 c | 17.39 ± 0.0 c |

| SD 3.b* | 0.64 ± 0.0 e | 117 ± 2.44 bcd | 0.36 ± 0.04 bdef | 0.08 ± 0.01 bc | 88.55 ± 0.13 p | 0.85 ± 0.03 d | 15.53 ± 0.03 d |

| SD 3.c* | 0.65 ± 0.01 efg | 104 ± 2.18 bcd | 0.4 ± 0.04 bcd | 0.036 ± 0.01 fgh | 90.11 ± 0.03 r | 0.53 ± 0.01 s | 14.8 ± 0.03 e |

| SD 4.a | 0.6 ± 0.0 c | 54 ± 2.09 b | 0.35 ± 0.05 bcd | 0.102 ± 0.01 bd | 97.12 ± 0.01 d | −0.96 ± 0.03 e | 8.33 ± 0.0 f |

| SD 4.b | 0.59 ± 0.01 c | 65 ± 1.81 bc | 0.42 ± 0.04 bdef | 0.066 ± 0.01 bcef | 89.11 ± 0.02 q | 10.44 ± 0.01 u | 4.24 ± 0.02 v |

| SD 5.a | 0.37 ± 0.0 d | 59 ± 1.08 b | 0.46 ± 0.02 defg | 0.038 ± 0.01 efgh | 88.58 ± 0.02 p | 11.42 ± 0.02 f | 5.96 ± 0.02 w |

| SD 5.b | 0.36 ± 0.01 d | 160 ± 6.07 bcde | 0.63 ± 0.04 h | 0.036 ± 0.02 fgh | 89.79 ± 0.06 r | 2.43 ± 0.02 g | 11.3 ± 0.02 g |

| SD 5.c | 0.36 ± 0.01 d | 68 ± 4.04 bc | 0.56 ± 0.01 gh | 0.026 ± 0.01 h | 98.13 ± 0.02 e | −0.26 ± 0.04 h | 3.27 ± 0.03 h |

| SD 6.a | 0.59 ± 0.01 c | 6 ± 1.14 b | 0.35 ± 0.06 bcd | 0.064 ± 0.0 cefg | 96.69 ± 0.01 s | −2.35 ± 0.01 i | 17.08 ± 0.03 i |

| SD 6.b | 0.64 ± 0.0 ef | 6 ± 0.41 b | 0.35 ± 0.02 bcd | 0.078 ± 0.01 bc | 96.58 ± 0.04 s | −5.88 ± 0.03 j | 24.87 ± 0.05 j |

| SD 6.c | 0.65 ± 0.0 efg | 13 ± 5.74 b | 0.51 ± 0.1 fg | 0.064 ± 0.0 cefg | 89.35 ± 0.01 q | 10.47 ± 0.02 u | 7.79 ± 0.03 k |

| SD 6.d | 0.66 ± 0.0 fg | 11 ± 1.67 b | 0.66 ± 0.09 h | 0.056 ± 0.0 cefgh | 97.59 ± 0.0 f | 0.34 ± 0.0 r | 6.12 ± 0.01 w |

| SD 7.a | 0.66 ± 0.0 g | 791 ± 63.89 h | 0.49 ± 0.16 bde | 0.068 ± 0.01 cefgh | 66.27 ± 0.04 g | 15.88 ± 0.05 k | 31.02 ± 0.02 l |

| SD 7.b | 0.65 ± 0.0 efg | 713 ± 42.5 hi | 0.39 ± 0.06 efg | 0.118 ± 0.01 d | 76.14 ± 0.25 h | 17.4 ± 0.04 l | 10.75 ± 0.04 m |

| SD 8.a | 0.51 ± 0.02 b | 133 ± 2.6 bcd | 0.4 ± 0.05 bcd | 0.028 ± 0.0 gh | 88.27 ± 0.02 p | 0.57 ± 0.04 s | 12.77 ± 0.05 n |

| SD 8.b | 0.52 ± 0.0 b | 185 ± 2.73 bcde | 0.32 ± 0.01 bc | 0.028 ± 0.01 gh | 89.15 ± 0.01 q | 9.12 ± 0.01 t | 15.71 ± 0.01 o |

| SD 9.a* | 0.29 ± 0.0 h | 492 ± 11.2 fg | 0.18 ± 0.03 a | 0.264 ± 0.01 i | 61.08 ± 0.05 i | 3.68 ± 0.02 m | 21.34 ± 0.05 p |

| SD 9.b* | 0.3 ± 0.0 h | 271 ± 4.7 de | 0.2 ± 0.02 a | 0.086 ± 0.01 bcd | 87.1 ± 0.01 j | 9.38 ± 0.02 n | 8.52 ± 0.07 q |

| SD 10.a* | 0.3 ± 0.0 h | 735 ± 74.57 h | 0.47 ± 0.09 efg | 0.156 ± 0.01 j | 85.27 ± 0.08 k | −1.32 ± 0.02 o | 20.29 ± 0.02 r |

| SD 10.b* | 0.3 ± 0.0 h | 950 ± 34.14 i | 0.32 ± 0.07 bc | 0.202 ± 0.0 a | 60.97 ± 0.42 l | 9.23 ± 0.1 t | 26.15 ± 0.2 s |

| SD 11.a* | 0.11 ± 0.0 i | 325 ± 12.6 efg | 0.34 ± 0.05 bc | 0.17 ± 0.01 aj | 85.85 ± 0.08 m | 0.32 ± 0.01 r | 2.54 ± 0.02 t |

| SD 11.b* | 0.1 ± 0.0 i | 400 ± 8.9 fg | 0.2 ± 0.01 a | 0.074 ± 0.01 bce | 78.02 ± 0.03 n | 20.8 ± 0.03 p | 14.09 ± 0.04 u |

| SD 11.c* | 0.11 ± 0.0 i | 245 ± 55.39 cdef | 0.42 ± 0.08 bdef | 0.064 ± 0.01 cefg | 95.62 ± 0.01 o | 4.48 ± 0.04 q | 4.37 ± 0.03 v |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahern, N.; Arendt, E.K.; Sahin, A.W. Protein Soft Drinks: A Retail Market Analysis and Selected Product Characterization. Beverages 2023, 9, 73. https://doi.org/10.3390/beverages9030073

Ahern N, Arendt EK, Sahin AW. Protein Soft Drinks: A Retail Market Analysis and Selected Product Characterization. Beverages. 2023; 9(3):73. https://doi.org/10.3390/beverages9030073

Chicago/Turabian StyleAhern, Niamh, Elke K. Arendt, and Aylin W. Sahin. 2023. "Protein Soft Drinks: A Retail Market Analysis and Selected Product Characterization" Beverages 9, no. 3: 73. https://doi.org/10.3390/beverages9030073