Are Local Heat Transfer Quantities Useful for Predicting the Working Behavior of Different Pulsating Heat Pipe Layouts? A Comparative Study

Abstract

:1. Introduction

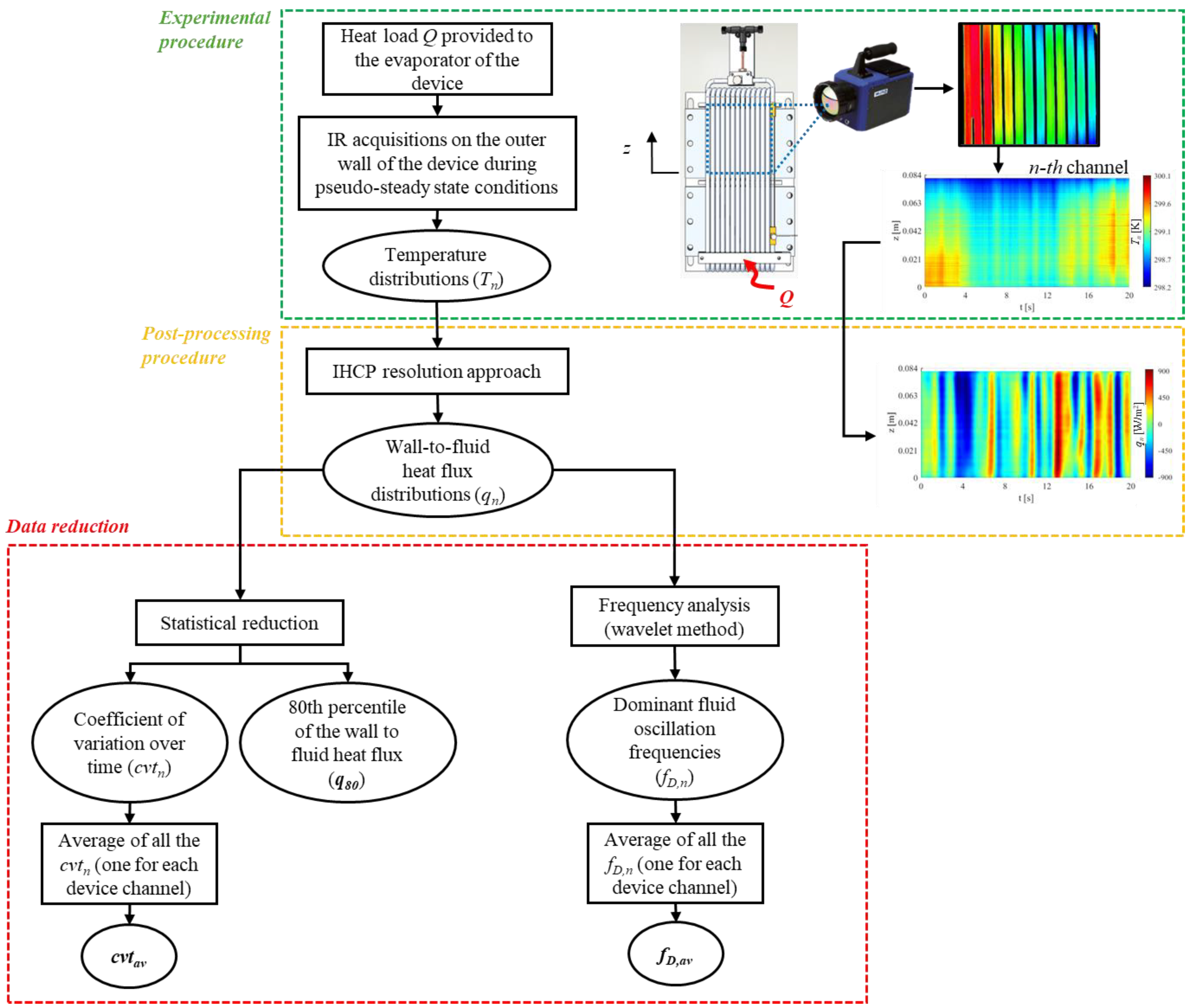

2. Materials and Methods

- Step heat loads are provided to the evaporator, the investigated device under specific working conditions (e.g., specific orientation, condenser temperature, etc.).

- When pseudo-steady-state conditions are reached, IR videos are taken at the outer wall surface of the section of interest (either the adiabatic section or the condenser, depending on the considered device).

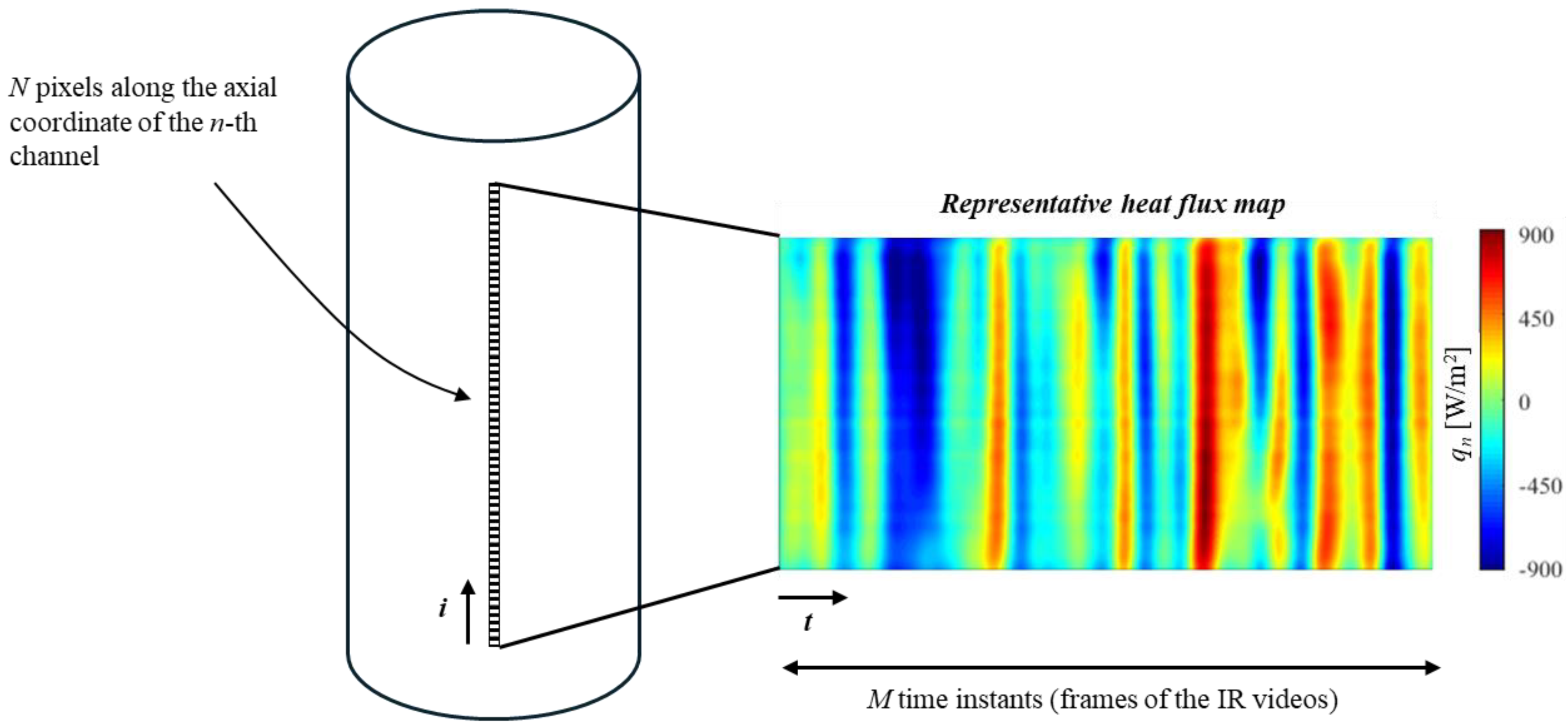

- For every framed channel, temperature distributions are collected by assuming negligible temperature variations along the circumferential direction; this results in N × M temperature distributions, with N being the number of pixels along the axial coordinate of each tube and M the number of time instants (frames).

- The temperature distributions referring to every device channel are therefore processed by means of the IHCP resolution approach, resulting in wall-to-fluid heat flux distributions qn (for the n-th channel). For the sake of brevity and clarity, the theoretical formulations assumed by the IHCP resolution method for the geometries under investigation are left to the reader ([23] for tubular layouts, [26] for FPPHP layouts).

- The wall-to-fluid heat fluxes are processed through different reduction approaches; statistical approaches are used to provide figures of merit for all the collected wall-to-fluid heat flux distributions, while the wavelet method is adopted to assess heat flux oscillation frequencies, which directly reflect fluid oscillation frequencies.

- The above steps are replicated for every heat load step to the evaporator/all-test conditions.

2.1. Statistical Reduction

2.2. Frequency Analysis

3. Results

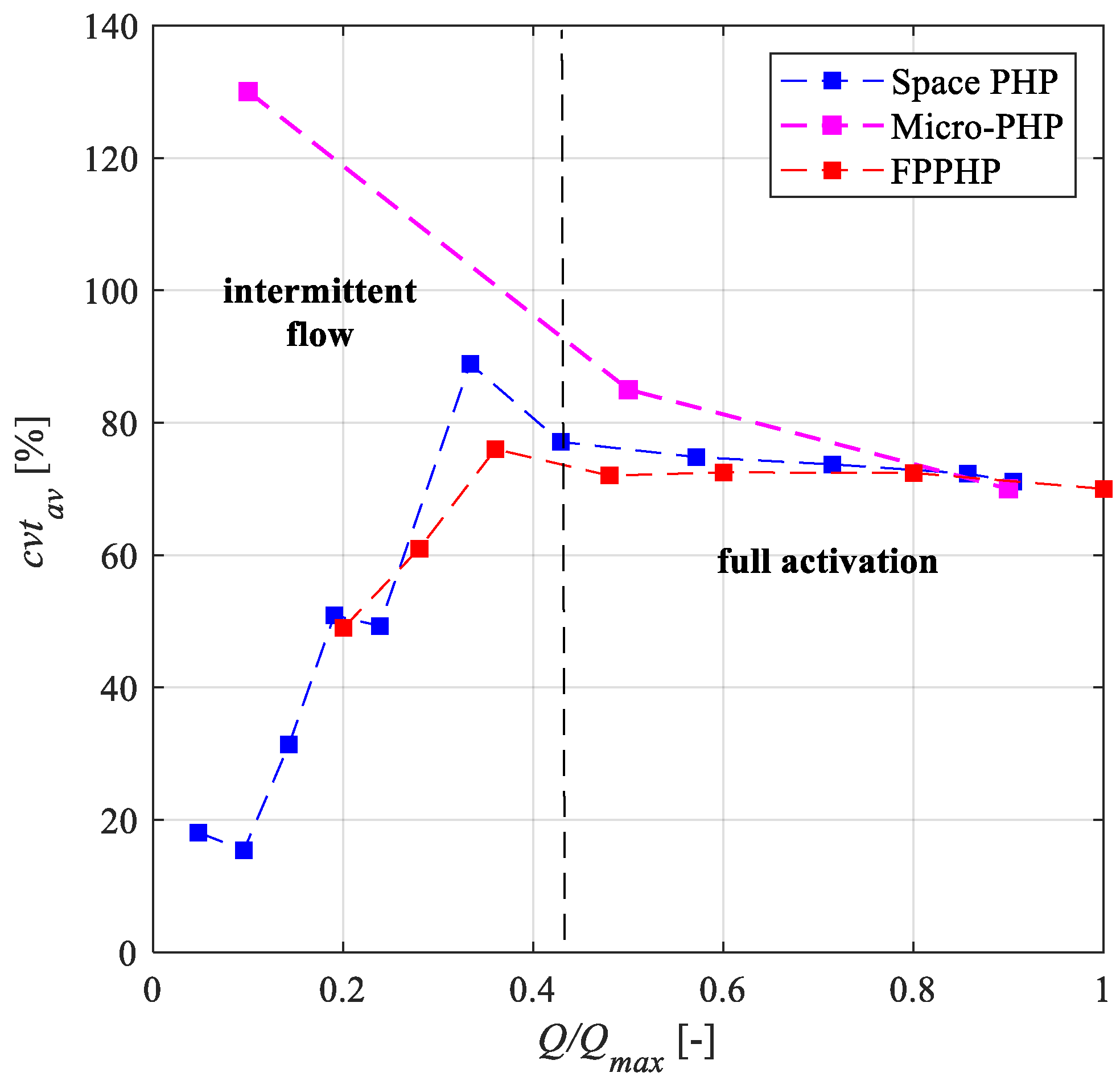

3.1. Repeatable Working Regime Detection

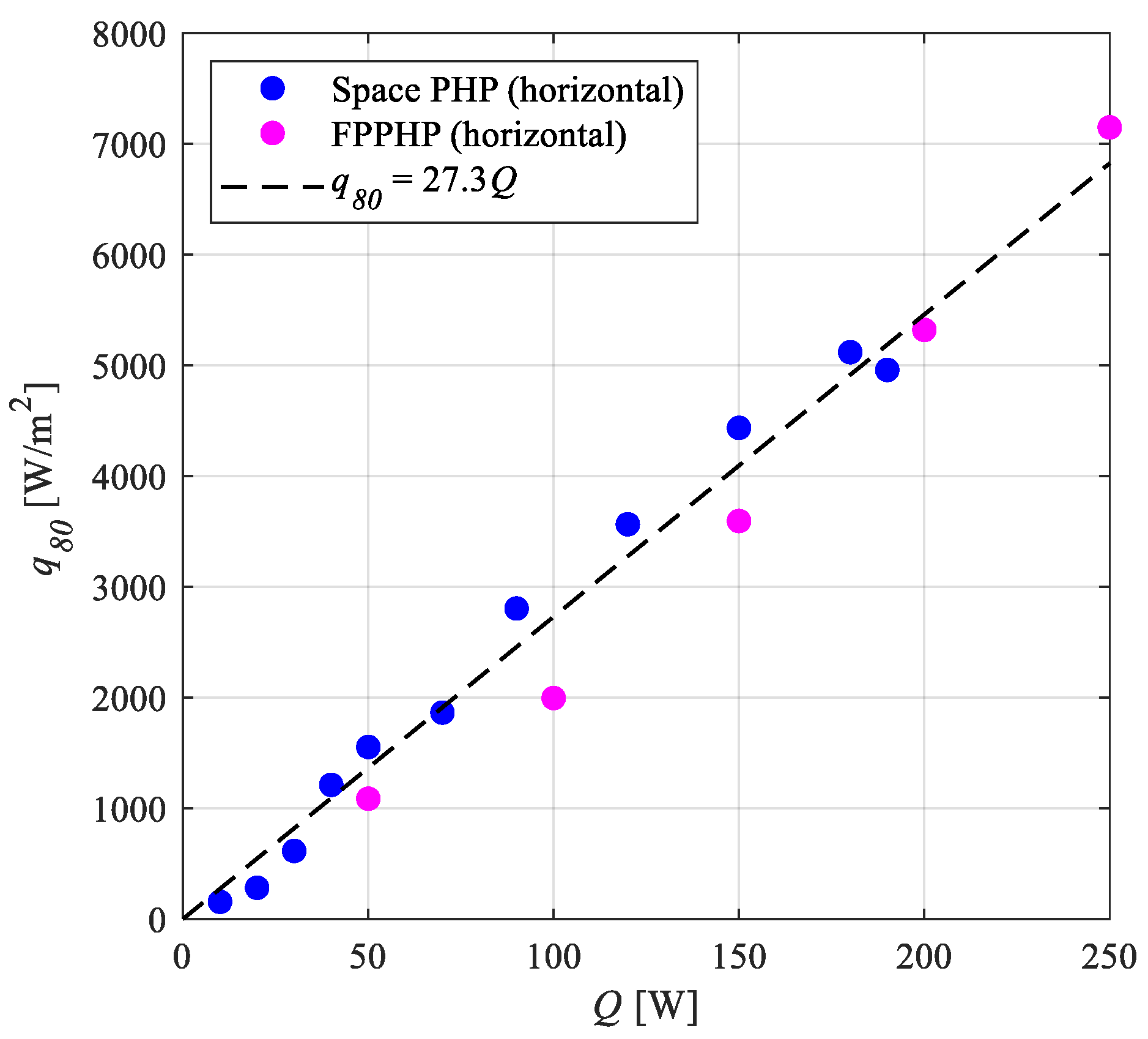

3.2. Trends in the q80 Values

3.3. Stabilization of the Dominant Fluid Oscillation Frequency

4. Conclusions

- The cvtav coefficient succeeds in generalizing the working regime identification in different PHP layouts under the BHM orientation. In fact, it assumes comparable values for all the studied configurations, especially during the full activation phase;

- When different devices (Space PHPs and FPPHPs) tested in the horizontal orientation are compared, the correlation between the 80th percentile of the wall-to-fluid heat fluxes and the heat load provided to the systems follows a linear trend of the form q80 = 27.3 Q;

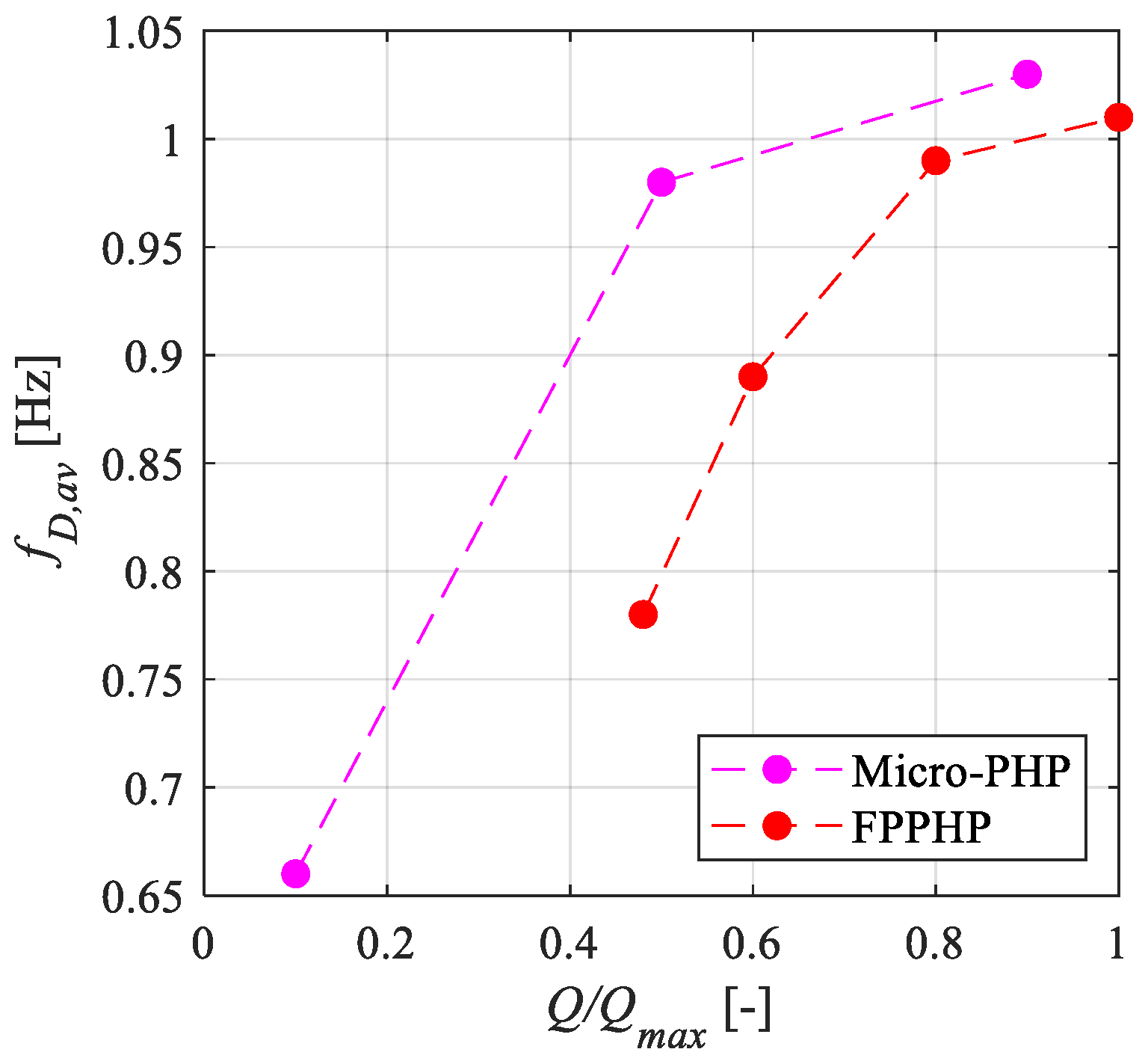

- Regardless of the considered device, the dominant fluid oscillation frequencies tend to stabilize at high heat loads in vertical BHM operation, suggesting that the systems face a saturation of the heat transfer capabilities from the evaporator to the condenser due to intrinsic flow motion limitations. This could lead to the occurrence of local dry-outs at the evaporator section, resulting in the onset of annular flows.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, Y.; Faghri, A. Advances and unsolved issues in pulsating heat pipes. Heat Transf. Eng. 2008, 29, 20–44. [Google Scholar] [CrossRef]

- Marengo, M.; Nikolayev, V.S. Pulsating Heat Pipes: Experimental Analysis, Design and Applications. In Encyclopedia of Two-Phase Heat Transfer and Flow IV: Modeling Methodologies, Boiling of CO₂, and Micro-Two-Phase Cooling Volume 1: Modeling of Two-Phase Flows and Heat Transfer; World Scientific Publishing: Singapore, 2018; pp. 1–62. [Google Scholar] [CrossRef]

- Liu, X.; Chen, Y. Fluid flow and heat transfer in flat-plate oscillating heat pipe. Energy Build 2014, 75, 29–42. [Google Scholar] [CrossRef]

- Ayel, V.; Slobodeniuk, M.; Bertossi, R.; Romestant, C.; Bertin, Y. Flat plate pulsating heat pipes: A review on the thermohydraulic principles, thermal performances and open issues. Appl. Therm. Eng. 2021, 197, 117200. [Google Scholar] [CrossRef]

- Su, Z.; Hu, Y.; Zheng, S.; Wu, T.; Liu, K.; Zhu, M.; Huang, J. Recent advances in visualization of pulsating heat pipes: A review. Appl. Therm. Eng. 2023, 221, 119867. [Google Scholar] [CrossRef]

- Faghri, A. Heat pipes: Review, opportunities and challenges. Front. Heat Pipes FHP 2014, 5, 1–48. [Google Scholar] [CrossRef]

- Barua, H.; Ali, M.; Nuruzzaman, M.; Islam, M.Q.; Feroz, C.M. Effect of Filling Ratio on Heat Transfer Characteristics and Performance of a Closed Loop Pulsating Heat Pipe. Procedia Eng. 2013, 56, 88–95. [Google Scholar] [CrossRef]

- Charoensawan, P.; Terdtoon, P. Thermal performance of horizontal closed-loop oscillating heat pipes. Appl. Therm. Eng. 2008, 28, 460–466. [Google Scholar] [CrossRef]

- Patel, V.M.; Gaurav; Mehta, H.B. Influence of working fluids on startup mechanism and thermal performance of a closed loop pulsating heat pipe. Appl. Therm. Eng. 2017, 110, 1568–1577. [Google Scholar] [CrossRef]

- Rudresha, S.; Babu, E.R.; Thejaraju, R. Experimental investigation and influence of filling ratio on heat transfer performance of a pulsating heat pipe. Therm. Sci. Eng. Prog. 2023, 38, 101649. [Google Scholar] [CrossRef]

- Gu, J.; Kawaji, M.; Futamata, R. Effects of Gravity on the Performance of Pulsating Heat Pipes. J. Thermophys. Heat Trans. 2004, 18, 370–378. [Google Scholar] [CrossRef]

- Lim, J.; Kim, S.J. Fabrication and experimental evaluation of a polymer-based flexible pulsating heat pipe. Energy Convers. Manag. 2018, 156, 358–364. [Google Scholar] [CrossRef]

- Burban, G.; Ayel, V.; Alexandre, A.; Lagonotte, P.; Bertin, Y.; Romestant, C. Experimental investigation of a pulsating heat pipe for hybrid vehicle applications. Appl. Therm. Eng. 2013, 50, 94–103. [Google Scholar] [CrossRef]

- Pietrasanta, L.; Postorino, G.; Perna, R.; Mameli, M.; Filippeschi, S. A pulsating heat pipe embedded radiator: Thermal-vacuum characterisation in the pre-cryogenic temperature range for space applications. Therm. Sci. Eng. Prog. 2020, 19, 100622. [Google Scholar] [CrossRef]

- Rittidech, S.; Terdtoon, P.; Murakami, M.; Kamonpet, P.; Jompakdee, W. Correlation to predict heat transfer characteristics of a closed-end oscillating heat pipe at normal operating condition. Appl. Therm. Eng. 2003, 23, 497–510. [Google Scholar] [CrossRef]

- Khandekar, S.; Charoensawan, P.; Groll, M.; Terdtoon, P. Closed loop pulsating heat pipes Part B: Visualization and semi-empirical modeling. Appl. Therm. Eng. 2003, 23, 2021–2033. [Google Scholar] [CrossRef]

- Qu, J.; Wang, Q. Experimental study on the thermal performance of vertical closed-loop oscillating heat pipes and correlation modeling. Appl. Energy 2013, 112, 1154–1160. [Google Scholar] [CrossRef]

- Wang, X.; Yan, Y.; Meng, X.; Chen, G. A general method to predict the performance of closed pulsating heat pipe by artificial neural network. Appl. Therm. Eng. 2019, 157, 113761. [Google Scholar] [CrossRef]

- Jokar, A.; Godarzi, A.A.; Saber, M.; Shafii, M.B. Simulation and optimization of a pulsating heat pipe using artificial neural network and genetic algorithm. Heat Mass Transf. 2016, 52, 2437–2445. [Google Scholar] [CrossRef]

- Ahmadi, M.H.; Tatar, A.; Nazari, M.A.; Ghasempour, R.; Chamkha, A.J.; Yan, W.-M. Applicability of connectionist methods to predict thermal resistance of pulsating heat pipes with ethanol by using neural networks. Int. J. Heat Mass Transf. 2018, 126, 1079–1086. [Google Scholar] [CrossRef]

- Kholi, F.K.; Park, S.; Yang, J.S.; Ha, M.Y.; Min, J.K. A detailed review of pulsating heat pipe correlations and recent advances using Artificial Neural Network for improved performance prediction. Int. J. Heat Mass Transf. 2023, 207, 124010. [Google Scholar] [CrossRef]

- Jo, J.; Kim, J.; Kim, S.J. Experimental investigations of heat transfer mechanisms of a pulsating heat pipe. Energy Convers. Manag. 2019, 181, 331–341. [Google Scholar] [CrossRef]

- Pagliarini, L.; Cattani, L.; Bozzoli, F.; Mameli, M.; Filippeschi, S.; Rainieri, S.; Marengo, M. Thermal characterization of a multi-turn pulsating heat pipe in microgravity conditions: Statistical approach to the local wall-to-fluid heat flux. Int. J. Heat Mass Transf. 2021, 169, 120930. [Google Scholar] [CrossRef]

- Pagliarini, L.; Cattani, L.; Mameli, M.; Filippeschi, S.; Bozzoli, F.; Rainieri, S. Global and local heat transfer behaviour of a three-dimensional Pulsating Heat Pipe: Combined effect of the heat load, orientation and condenser temperature. Appl. Therm. Eng. 2021, 195, 117144. [Google Scholar] [CrossRef]

- Iwata, N.; Bozzoli, F.; Pagliarini, L.; Cattani, L.; Vocale, P.; Malavasi, M.; Rainieri, S. Characterization of thermal behavior of a micro pulsating heat pipe by local heat transfer investigation. Int. J. Heat Mass Transf. 2022, 196, 123203. [Google Scholar] [CrossRef]

- Pagliarini, L.; Cattani, L.; Slobodeniuk, M.; Ayel, V.; Romestant, C.; Bozzoli, F.; Rainieri, S. Novel Infrared Approach for the Evaluation of Thermofluidic Interactions in a Metallic Flat-Plate Pulsating Heat Pipe. Appl. Sci. 2022, 12, 11682. [Google Scholar] [CrossRef]

- Pagliarini, L.; Cattani, L.; Ayel, V.; Slobodeniuk, M.; Romestant, C.; Bozzoli, F. Thermographic Investigation on Fluid Oscillations and Transverse Interactions in a Fully Metallic Flat-Plate Pulsating Heat Pipe. Appl. Sci. 2023, 13, 6351. [Google Scholar] [CrossRef]

- Cui, X.; Zhu, Y.; Li, Z.; Shun, S. Combination study of operation characteristics and heat transfer mechanism for pulsating heat pipe. Appl. Therm. Eng. 2014, 65, 394–402. [Google Scholar] [CrossRef]

- Khandekar, S.; Gautam, A.P.; Sharma, P.K. Multiple quasi-steady states in a closed loop pulsating heat pipe. Int. J. Therm. Sci. 2009, 48, 535–546. [Google Scholar] [CrossRef]

- Everitt, B.S.; Skrondal, A. The Cambridge Dictionary of Statistics; Cambridge University Press: Cambridge, UK, 2010. [Google Scholar]

- Kim, J.-S.; Bui, N.H.; Jung, H.-S.; Lee, W.-H. The study on pressure oscillation and heat transfer characteristics of oscillating capillary tube heat pipe. KSME Int. J. 2003, 17, 1533–1542. [Google Scholar] [CrossRef]

- Fairley, J.D.; Thompson, S.M.; Anderson, D. Time–frequency analysis of flat-plate oscillating heat pipes. Int. J. Therm. Sci. 2015, 91, 113–124. [Google Scholar] [CrossRef]

- Peng, H.; Pai, P.F.; Ma, H. Nonlinear thermomechanical finite-element modeling, analysis and characterization of multi-turn oscillating heat pipes. Int. J. Heat Mass Transf. 2014, 69, 424–437. [Google Scholar] [CrossRef]

- Spinato, G.; Borhani, N.; Thome, J.R. Understanding the self-sustained oscillating two-phase flow motion in a closed loop pulsating heat pipe. Energy 2015, 90, 889–899. [Google Scholar] [CrossRef]

- Monroe, J.G.; Aspin, Z.S.; Fairley, J.D.; Thompson, S.M. Analysis and comparison of internal and external temperature measurements of a tubular oscillating heat pipe. Exp. Therm. Fluid Sci. 2017, 84, 165–178. [Google Scholar] [CrossRef]

- Chi, R.-G.; Chung, W.-S.; Rhi, S.-H. Thermal Characteristics of an Oscillating Heat Pipe Cooling System for Electric Vehicle Li-Ion Batteries. Energies 2018, 11, 655. [Google Scholar] [CrossRef]

- Karthikeyan, V.K.; Ramachandran, K.; Pillai, B.C.; Brusly Solomon, A. Understanding thermo-fluidic characteristics of a glass tube closed loop pulsating heat pipe: Flow patterns and fluid oscillations. Heat Mass Transf. 2015, 51, 1669–1680. [Google Scholar] [CrossRef]

- Takawale, A.; Abraham, S.; Sielaff, A.; Mahapatra, P.S.; Pattamatta, A.; Stephan, P. A comparative study of flow regimes and thermal performance between flat plate pulsating heat pipe and capillary tube pulsating heat pipe. Appl. Therm. Eng. 2019, 149, 613–624. [Google Scholar] [CrossRef]

- Perna, R.; Abela, M.; Mameli, M.; Mariotti, A.; Pietrasanta, L.; Marengo, M.; Filippeschi, S. Flow characterization of a pulsating heat pipe through the wavelet analysis of pressure signals. Appl. Therm. Eng. 2020, 171, 115128. [Google Scholar] [CrossRef]

- Lilly, J.M. Element analysis: A wavelet-based method for analysing time-localized events in noisy time series. Proc. R. Soc. A 2017, 473, 20160776. [Google Scholar] [CrossRef] [PubMed]

- Mameli, M.; Marengo, M.; Khandekar, S. Local heat transfer measurement and thermo-fluid characterization of a pulsating heat pipe. Int. J. Therm. Sci. 2014, 75, 140–152. [Google Scholar] [CrossRef]

- Ayel, V.; Slobodeniuk, M.; Bertossi, R.; Karmakar, A.; Martineau, F.; Romestant, C.; Bertin, Y.; Khandekar, S. Thermal performances of a flat-plate pulsating heat pipe tested with water, aqueous mixtures and surfactants. Int. J. Therm. Sci. 2022, 178, 107599. [Google Scholar] [CrossRef]

| Studied Device | Manufacturing Material | Working Fluid | Cooling Method | Section of Interest 1 | Quantified Phenomena |

|---|---|---|---|---|---|

| Tubular PHP (Space PHP) [23,24] | Aluminum | Methanol | Prescribed temperature (Peltier cell array) | Adiabatic section |

|

| Micro-PHP [25] | Stainless-steel | R134a | Free convection | Condenser |

|

| FPPHP [26,27] | Copper | Water/ethanol mixture (20% w.) | Prescribed temperature (copper heat exchanger) | Adiabatic section |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pagliarini, L.; Bozzoli, F. Are Local Heat Transfer Quantities Useful for Predicting the Working Behavior of Different Pulsating Heat Pipe Layouts? A Comparative Study. Fluids 2024, 9, 107. https://doi.org/10.3390/fluids9050107

Pagliarini L, Bozzoli F. Are Local Heat Transfer Quantities Useful for Predicting the Working Behavior of Different Pulsating Heat Pipe Layouts? A Comparative Study. Fluids. 2024; 9(5):107. https://doi.org/10.3390/fluids9050107

Chicago/Turabian StylePagliarini, Luca, and Fabio Bozzoli. 2024. "Are Local Heat Transfer Quantities Useful for Predicting the Working Behavior of Different Pulsating Heat Pipe Layouts? A Comparative Study" Fluids 9, no. 5: 107. https://doi.org/10.3390/fluids9050107

APA StylePagliarini, L., & Bozzoli, F. (2024). Are Local Heat Transfer Quantities Useful for Predicting the Working Behavior of Different Pulsating Heat Pipe Layouts? A Comparative Study. Fluids, 9(5), 107. https://doi.org/10.3390/fluids9050107