3.3. Stress Tests

When considering non-

Saccharomyces yeast strains for brewing purposes, several brewing-relevant parameters such as flocculation behavior, POF production and stress responses should be investigated [

33]. The flocculation behavior can give initial indications regarding yeast handling in terms of potential bottom cropping. POF behavior is important because in most beer styles, POF is not desired. Substances like hop-derived iso-α-acids, ethanol content, or the pH value of the wort can have significant influences on yeast activity, manifesting mainly in a prolonged lag time, and even complete growth inhibition [

33,

34,

35]. With the investigated yeast strains, iso-α-acid concentrations of up to 100 IBU had no significant effect on the yeast growth (data not shown), which is in accordance with previous reports on seven different non-

Saccharomyces species [

34,

35]. However, Michel et al. [

33] reported a minor prolongation in the lag time of

Torulaspora delbrueckii strains in concentrations of up to 90 IBU. The results of the investigated characterization attributes are shown in

Table 5.

CBS 1707 exhibited the strongest flocculation behavior, at 85%, followed by 837A and CBS 5763, at 78% and 51%, respectively. NT Cyb, L1 and C6.1 exhibited very low flocculation of below 35%. All strains were negative for POF behavior. NT Cyb and C6.1 exhibited the fastest growth in wort (without a stress factor), overcoming the lag time after only 6 hours, followed by L1 and the CBS strains after 9 hours. Strain 837A exhibited a long lag phase of 18 hours (

Figure 1). Concentrations of 2.5% ABV ethanol in the wort affected the lag time of all investigated strains. 837A was especially susceptible, with a prolonged lag phase of 120 hours. The remainder of the strains showed an extension of the lag phase of 3 to 12 hours. At 5% ABV, growth was fully inhibited for 837A and CBS 5763, while the other strains again exhibited an extension of the lag phase, of up to a maximum of 48 hours in CBS 1707. Complete growth inhibition was observed for L1 and C6.1 at 7.5% ABV, while the lag phase of NT Cyb and CBS 1707 was prolonged to 42 and 126 hours, respectively. All strains except 837A, which showed a significant extension of the lag phase to 66 hours, remained unaffected by a lower pH of 4. Only at pH 3 were lag times affected, while 837A was fully inhibited. Growth at low pH is important when considering the yeast for sour beer production, where the yeast must withstand pH values of below 4 [

36]. However, it has been shown that organic acids like lactic acid can have a stronger inhibitory effect on yeasts and other microorganisms than HCl, which is caused by its chemical properties as a weak acid [

35,

37]. Inhibition by lactic acid could therefore be more pronounced than the HCl inhibition observed in this study.

Figure 1 shows the growth of the investigated yeast strains in wort without the addition of a stressor.

3.4. Screening

To investigate interspecific differences in the fermentation of wort, fermentation trials were performed in a diluted wort extract of 7 °P. Previous studies have shown that extract contents of around 7 °P will yield ethanol concentrations of around 0.5% ABV, a popular legal limit for NAB [

7], in fermentations with maltose-negative yeast strains [

1,

14,

34,

38]. After aerobic propagation for 24 hours, NT Cyb exhibited the highest number of cells, at 2 × 10

9 cells/mL, more than four-fold the amount of cells compared to L1, C6.1, and the CBS strains with counts between 3.4 and 4.9 × 10

8 cells/mL (

Table 6). Due to a delayed growth (compare

Figure 1), 837A had to be propagated for 48 hours, reaching a cell count of 6.1 × 10

8 cells/mL. For the screening in wort, yeast cells were added at a concentration of 3 × 10

7 cells/mL, after a gentle washing step in water to prevent carry-over of propagation wort sugars. The results from the yeast screening are shown in

Table 6. The fermentations were carried out until no change in extract could be measured for two consecutive days.

Strains 837A and CBS 1707 exhibited the lowest attenuation of only 18% and 17%, respectively, owing to their inability to utilize sucrose (

Table 4), which was confirmed by the lack of sucrose consumption. Liu and Quek [

20] also reported the absence of sucrose utilization by CBS 1707. The other strains, which depleted sucrose completely, reached attenuations of 21% to 24%. Consequently, 837A and CBS 1707 also produced, at 0.55% and 0.56% ABV, the lowest amounts of ethanol (

p ≤ 0.05) compared to the remaining strains, where ethanol concentrations ranged from 0.63% to 0.67% ABV. The final pH of the fermented samples ranged from 4.33 (CBS 5763) to 4.51 (NT Cyb). Residual FAN ranged from 78 (CBS 1707) to 88 mg/L (837A). As expected, none of the strains consumed maltotriose. Maltose consumption was also neglectable in all strains, although the species

Cyberlindnera fabianii (like NT Cyb) has been reported to be able to ferment maltose [

31,

39]. The observations also underlined that results from the API substrate utilization test (where NT Cyb, L1 and CBS 1707 were positive for maltose) are not necessarily reflected in practice, especially since sugar utilization during respiration and fermentation can differ [

31,

32,

40]. While glucose was depleted by all strains, fructose was only fully depleted by L1. The remaining strains exhibited glucophilic behavior and consumed only 73% to 83% of fructose during fermentation. Regarding fermentation by-products, glycerol concentrations were low, ranging from 0.18 to 0.36 g/L. The strains 837A and NT Cyb accumulated significantly higher amounts of acetaldehyde, at 9.7 and 8.1 mg/L, respectively, compared to 2.6 to 3.8 mg/L in the remaining samples. The sample fermented with

Cyberlindnera misumaiensis 837A exhibited extremely high values of ethyl acetate, at 65.7 mg/L, twice the flavor threshold concentration in beer [

2,

41]. Ethyl acetate is described to have a fruity, estery character but also solvent-like, especially in high concentrations. The remaining strains exhibited ethyl acetate production between 4.9 (C6.1) and 22.6 mg/L (NT Cyb). Isoamyl acetate, which is predominantly described as having a fruity, banana-like aroma, has a much lower flavor threshold of only 1.4–1.6 mg/L [

2,

41]. The strains C6.1 and CBS 1707 produced the highest amounts of isoamyl acetate, at 1.67 and 1.60 mg/L, followed by CBS 5763, 837A and L1, at 1.03, 0.90 and 0.15 mg/L, respectively. NT Cyb did not produce detectable amounts of isoamyl acetate. Concentrations of ethyl formate and ethyl propionate in the fermented samples were low, ranging from undetectable to 2.7 mg/L. Ethyl butyrate and ethyl caproate were not detected in either of the samples (data not shown). The strain L1 produced a significantly higher amount of higher alcohols, at 35.8 mg/L, followed by NT Cyb, at 27.8 mg/L, and the remaining strains at 20–23 mg/L. During sensory evaluation, the high ethyl acetate concentration in the sample fermented with 837A was indeed perceptible and described as an unpleasant, solvent-like aroma. The sample fermented with NT Cyb was described as having an unpleasant, cabbage-like aroma. The remaining samples were characterized by a pleasant, fruity aroma.

The unpleasant, solvent-like aroma in the sample fermented with 837A was attributed to the very high ethyl acetate concentration, well above the flavor threshold. However, the cabbage-like aroma, which is generally associated with sulfides or thiol compounds [

41], that was detected in the sample fermented with NT Cyb could not be linked to the volatile by-products that were measured. Interestingly, ethyl acetate concentrations in the remaining samples, characterized by a pleasant, fruity aroma, were low, at only 2.6–3.8 mg/L. However, C6.1, CBS 1707 and CBS 5763 exhibited higher amounts of isoamyl acetate, a desired ester in beer (particularly ales) [

42], when compared to the samples with unpleasant aroma. The concentrations of 1.0–1.6 mg/L are within the reported flavor threshold in beer of 0.5–2.0 mg/L [

43]. Additionally, it is well known that synergistic effects between esters occur that can push the concentration of perception below their individual flavor thresholds [

42,

44,

45]. Isoamyl acetate could therefore have been a cause of the fruity aroma in the samples fermented with C6.1, CBS 1707 and CBS 5763. However, the sample fermented with L1, which was also characterized by a fruity aroma, only contained a very low isoamyl acetate concentration of 0.15 mg/L. It is noteworthy, however, that the L1 sample contained a significantly higher amount of isoamyl alcohol, at 23.2 mg/L, which is described as having an alcoholic, fruity and banana-like flavor [

2]. The results have confirmed that not a high amount of esters, but rather a balanced profile will lead to a pleasant, fruity aroma [

5].

Based on the results from the screening,

Cyberlindnera subsufficiens C6.1 was chosen for optimization of fermentation conditions by means of response surface methodology, followed by an up-scaled brewing trial at 60 L to create a fruity, non-alcoholic beer (≤0.5% ABV). Strains 837A and NT Cyb were eliminated because of their poor flavor characteristics. CBS 1707 was eliminated due to its inability to ferment sucrose, which apart from the lower attenuation, would remain in the wort after fermentation, acting as an additional sweetening agent and potential contamination risk.

Cyberlindnera jadinii strain L1 was eliminated due to its very low isoamyl acetate production (

Table 6) and due to its maltose utilization when oxygen was present (

Table 4). The decision between the two similarly performing

Cyberlindnera subsufficiens strains C6.1 and CBS 5763 was made in favor of C6.1 due to a more pleasant fruitiness. In addition, C6.1 showed increased tolerance towards stress caused by ethanol or low pH (

Table 5).

3.5. Response Surface Methodology (RSM)

To find the optimal fermentation conditions for C6.1 for an up-scaled application to produce a fruity, non-alcoholic beer, RSM was performed. Michel et al. [

46] applied RSM to optimize the fermentation conditions of a

Torulaspora delbrueckii strain for brewing purposes. They found that the pitching rate and fermentation temperature were crucial parameters, which influenced the flavor character of the final beer. The optimal fermentation conditions were shown to be at 21 °C with a high pitching rate of 60 × 10

6 cells/mL. Especially for non-

Saccharomyces yeasts, the pitching rate can be crucial since most non-

Saccharomyces species have comparably smaller cell sizes [

46].

Figure 2 shows an example of the differing cell size between

Cyberlindnera subsufficiens strain C6.1 (A) and the brewers’ yeast strain

Saccharomyces cerevisiae WLP001 (B) at identical magnification.

It is also known that temperature and pitching rate have an influence on ester production, though strain-specific differences also play a role [

4,

6]. Previously reported fermentation temperatures of

Cyberlindnera subsufficiens and other

Cyberlindnera spp. range from 20 to 25 °C [

12,

17,

19,

20,

47]. Consequently, a two-factorial, face-centered central composite design was chosen with Factor A: fermentation temperature (17, 22, 27 °C), and Factor B: pitching rate (10, 35, 60 × 10

6 cells/mL). The individual experiment runs are listed in

Table 2. The wort extract applied in the RSM trial was the same as that used for the screening, at an extract content of 7 °P (

Table 1). Fermentation was conducted until no change in extract could be measured for two consecutive days. With the measured response values, significant models could be produced. The significant response models, with their respective minima and maxima and a summary of the model statistics, are shown in

Table 7. Insignificant response models are not shown, and response models with a significant lack of fit will not be discussed in this study but are included in the visualized data for the sake of a complete picture. For a full report on model statistics and response values, refer to the

supplementary Data Sheet S1.

It was possible to create significant models for 12 responses (

Table 7). However, five also exhibited significant lack of fit (LOF), rendering them unusable for predictions. The aim of the RSM was to investigate the optimal fermentation conditions to create a fruity, non-alcoholic beer. The three-dimensional response surface plots of the interactive effects of temperature and pitching rate on the final ethanol content and the fruitiness of the produced NAB are shown in

Figure 3 and

Figure 4.

Ethanol content was lowest at a low temperature of 17 °C and low pitching rate (10

7 cells/mL), and it went up with increasing temperature and pitching rate, but lowered again at a high pitching rate combined with a high fermentation temperature (

Figure 3). The minium and maximum values were 0.41% and 0.60% ABV. Sugar analysis revealed that at 17 °C and 10

7 cells/mL, about 0.5 g/L of glucose was remaining after fermentation, while it was fully depleted in worts fermented at higher pitching rates and higher temperatures (data not shown). The residual sugar explained the lower final ethanol concentration. Fructose was only fully depleted in the samples that were fermented at 27 °C. At 22 °C, fermented samples exhibited residual fructose concentrations between 0.2 and 0.5 g/L, and at 17 °C, fermented samples showed remaining fructose concentrations between 0.2 and 0.7 g/L. Acetaldehyde concentrations were only dependent on the pitching rate, with increasing amounts of acetaldehyde found at lower pitching rates (

Figure A1). This result correlates with other studies that found a decrease in acetaldehyde with increasing pitching rate in wort fermentations with brewers’ yeasts [

48,

49]. However, overdosing yeast (>5 × 10

7 cells/mL) can lead to an increase in acetaldehyde again, as observed by Erten et al. [

50]. The temperature did not have a significant effect on the acetaldehyde concentration and was therefore excluded from the model (

p = 0.39;

supplementary Data Sheet S1). However, regarding higher alcohols, the fermentation temperature had a stronger effect, with increasing amounts of higher alcohols found at higher temperatures (

Figure 5 and

Figure A2), which is consistent with the literature [

4,

5]. Isoamyl acetate concentrations were generally high and ranged from 0.8 to 2.2 mg/L. Although the model was significant (

p < 0.05), it was unsuitable for value prediction due to a significant lack of fit (

p = 0.046).

Interestingly, the production of the esters ethyl acetate and isoamyl acetate did not show a clear correlation to temperature, which underlines that the general rule of thumb, that higher fermentation temperatures lead to increased ester production, is not valid for all yeast strains (

Figure 5) [

4]. Furthermore, the amount of esters that were quantified in this study did not correlate with the perceived fruitiness of the NAB, which tentatively suggests that the fruity flavor profile was caused by yet unidentified compounds (

Figure 5).

In terms of fruitiness, a low fermentation temperature paired with a low pitching rate led to the highest perceived fruitiness. Indeed, the highest fruitiness was recorded at 17 °C and 1 × 10

7 cells/mL and the lowest at 27 °C and 6 × 10

7 cells/mL, following a linear model. General acceptance showed a strong positive correlation with the fruitiness, indicating that the panel preferred fruity samples (

Figure 5 and

Figure A3).

Due to the ideal combination of lowest ethanol content and highest fruitiness and acceptance, the fermentation temperature of 17 °C and pitching rate of 1 × 107 cells/mL were chosen as the optimal fermentation conditions for application to produce a fruity, non-alcoholic beer.

A small-scale fermentation at the optimal conditions (17 °C, 10

7 cells/mL) was conducted to validate the RSM model.

Table 8 shows the predicted mean including 95% prediction intervals (PI) and the measured (“observed”) mean with standard deviation.

Although predicted by a significant model, the observed means for ethanol, acetaldehyde and isobutanol values were not within the 95% prediction interval. Sugar analysis revealed the complete depletion of glucose in the experimental fermentation trial at optimal conditions compared to the RSM model prediction, which explained the increased ethanol production (data not shown). The moderate success in model validation demonstrates the limitations in the application of RSM to optimize fermentations, where small differences in substrate and process conditions can have significant influences on the outcome. Because wort is a very complex substrate, comprising a complex mixture of different sugars, nitrogen sources, minerals and vitamins, among others, any interpretation or the transfer of the RSM results to other substrates (even different wort substrates) should be made with caution. In particular, a different sugar composition will have a significant effect on the responses when applying maltose-negative yeasts. However, the improved fruitiness and therefore higher acceptance of the NAB produced at low temperature and low pitching rate, the main goal from the optimization, was significant and reproducable (

Table 8).

3.6. Pilot-Scale Brewing

Despite the limited model validation, the fermentation parameters were successfully optimized to enhance the fruity character of the NAB. Therefore, the pilot-scale brewing trial was conducted with the optimized conditions of 17 °C fermentation temperature and a pitching rate of 107 cells/mL.

The grain bill of the wort for the pilot-scale brewing trial consisted of 95% pilsner malt and 5% acidulated malt to lower the starting pH of the wort, to account for the reduced pH drop during fermentations with non-

Saccharomyces yeasts compared to brewers’ yeast. A low beer pH is desired to prevent microbial spoilage and to ensure good liveliness of the beer [

51,

52]. The analytical attributes of the wort produced at pilot-scale are shown in

Table 9.

To assess the suitability of

Cyberlindnera subsufficiens C6.1 to produce a fruity NAB, it was compared to two commercial NABs. NAB A was a commercial non-alcoholic beer produced by limited fermentation [

29], and NAB B was a non-alcoholic beer produced by “dialysis technology” [

30]. The NABs were analyzed for their extract, ethanol, FAN and glycerol content as well as their sugar composition and concentration of volatile fermentation by-products. The results are shown in

Table 10.

The C6.1 NAB reached final attenuation after 13 days of fermentation at 17 °C, at an ethanol content of 0.36% ABV. At the end of fermentation, 2.77 g/L glucose was remaining in the wort and sucrose was fully depleted. Compared to the initial sugar concentration of the wort (

Table 9), fructose concentrations in the final beer were significantly higher, at 1.65 g/L, twice as high as the starting concentration in the wort. Since sucrose was fully depleted, it can be assumed that it was converted to glucose and fructose by the yeast’s invertase. The high residual fructose could therefore be attributed to the previously observed glucophilic character of the C6.1 strain in the screening and RSM trial. As a result, fructose was not consumed by the yeast due to the permanent presence of glucose until fermentation came to a halt. As expected, maltose and maltotriose consumption was negligible. Despite the limited fermentation, C6.1 produced a relatively high amount of esters, at 12.8 mg/L, the majority of which was ethyl acetate (12 mg/L). NAB A had an ethanol content of 0.50% ABV. Interestingly, the sugar composition was very similar to that of the C6.1 NAB. Regarding fermentation by-products, however, NAB A exhibited very low concentrations, at about half the amount of higher alcohols and a total lack of the esters ethyl acetate and isoamyl acetate. NAB B had an ethanol content of 0.49% ABV. Owing to its fundamentally different production method, the analyzed attributes were very different from those of the two NABs produced solely by limited fermentation. The low FAN content together with a high glycerol content compared to the other NABs were indicators of a more extensive fermentation, with subsequent removal of ethanol. However, NAB B still exhibited high amounts of monosaccharides, which suggested that the production of the NAB either also entailed a limited fermentation, or the dealcoholized beer was blended with wort (or other means of sugar addition). The increased amounts of higher alcohols in NAB B, at 24.8 mg/L, are uncommon for beers dealcoholized via dialysis, since the process commonly reduces their content in the final NAB by 90%–95% [

7]. Despite the addition of acid malt during the wort production for the C6.1 NAB, the final pH after fermentation was, at 4.45, higher compared to 4.29 in the commercial NABs.

Due to the high amounts of residual sugars, proper pasteurization is essential for non-alcoholic beers produced by limited fermentation to avoid microbial spoilage [

1,

38,

53]. After bottling, C6.1 NAB was therefore pasteurized with approximately 23 PU, and the successful pasteurization was confirmed by plating the pasteurized NAB on agar to check for microorganism growth, which was found to be negative.

3.7. Sensory Evaluation

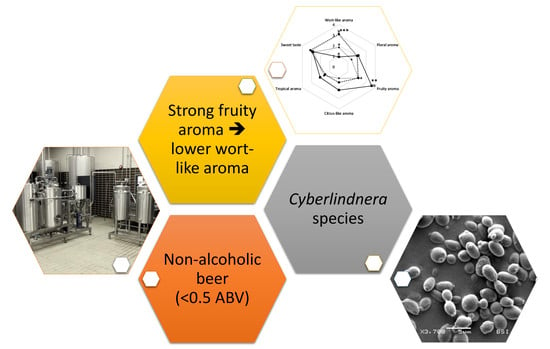

For a holistic evaluation of the C6.1 NAB compared to the two commercial NABs, a sensory trial was conducted with 10 trained and experienced panelists. The panel was asked to describe the flavor of the beer in their own words, followed by an assessment of several intensity attributes. The mean score values of the parameters wort-like, floral, fruity, citrus-like and tropical aroma, as well as sweet taste, of the NABs are shown in

Figure 6.

The NAB produced with C6.1 was described as very fruity with aromas of pear, banana, mango and maracuja together with a slightly wort-like character. NAB A was described as malty, wort-like and hoppy, while NAB B was described as wort-like and caramel-like. The C6.1 NAB was indeed evaluated as being significantly more fruity than the commercial NABs (

p ≤ 0.01), at an average of 3.6 out of 5 compared to 2.1 and 2.2 out of 5, scoring also higher in citrus-like and tropical aromas. Consequently, the wort-like aroma, one of the most criticized flaws of NABs produced by limited fermentation [

1,

2,

52], was least pronounced in the NAB produced with C6.1 with an average of 1 out of 5, followed by NAB B with 1.8 out of 5. NAB A exhibited, at an average of 3.2, a significantly more pronounced wort-like aroma (

p ≤ 0.001). A sweet taste, caused by a high amount of residual sugars, is another major point of criticism for NABs produced by limited fermentation [

1,

2,

52]. All NABs scored similarly in sweet taste without significant differences. NAB B scored lower for “floral” compared to the other NABs. However, the difference was not statistically significant. When the panelists were asked for their favorite sample, 40% chose C6.1 NAB, 40% chose NAB A, and 20% chose NAB B. Similarly, Strejc et al. [

3] investigated the production of a non-alcoholic beer (0.5% ABV) by a cold contact process (characterized by a low temperature and high pitching rate) with a mutated lager yeast strain (

Saccharomyces pastorianus). The strain’s targeted mutation resulted in an overproduction of isoamyl acetate and isoamyl alcohols. The authors reported that the fruity flavour of the NAB produced with the mutated strain was “partially able to disguise” the typical wort-like off-flavor [

21]. However, the isoamyl acetate concentration of the resulting NAB was, at 0.5 mg/L, lower than the concentration in the C6.1 NAB in this study (

Table 10). Furthermore, the complex mutation and isolation procedure paired with a potentially limited stability of the mutation limits its applicability in practice. Saerens and Swiegers [

22] reported the successful production of a NAB at 1000 L scale with a

Pichia kluyveri strain, owing to its high production of isoamyl acetate (2–5 mg/L), which reportedly gave the NAB a fruity flavor that was more like that of a regular beer than commercial NABs. In accordance, the results of the sensory indicated that a strong fruity aroma can mask the wort-like off flavor, and that the non-

Saccharomyces yeasts, which produce a pronounced fruity character, can therefore be a means to produce NAB with improved flavor characteristics.