Single-Cell Protein Production from Industrial Off-Gas through Acetate: Techno-Economic Analysis for a Coupled Fermentation Approach

Abstract

:1. Introduction

2. Methodology

2.1. Modeling and Simulation Software

2.2. Process Design

2.2.1. Medium Preparation

2.2.2. Gas Pretreatment

2.2.3. Anaerobic Gas-to-Acetate Fermentation

2.2.4. Aerobic Acetate-to-SCP Fermentation

2.2.5. DSP of SCP

2.2.6. NH3 Recovery

2.2.7. Anaerobic Digestion and Gas Combustion

2.2.8. Wastewater Treatment

2.3. Economic Assessment

3. Results and Discussion

3.1. Process Simulation and Conversion Yield

- A total of 55% is emitted through the off-gas of the gas-to-acetate fermentation. More specifically, 10% accounts for the amount of CO that remains unconverted, whereas the remaining 45% is emitted as CO2 during the conversion of CO to M. thermoacetica biomass and acetate (Equations (1) and (2));

- A total of 18% is emitted as CO2 through the off-gas of the acetate-to-SCP fermentation when converting ammonium acetate (Equation (5));

- Totals of 5% and 1% are fixed in the discarded biomass of M. thermoacetica (removed in the bleed stream during the gas-to-acetate fermentation) and C. necator (lost in the two-step microfiltration during the DSP of SCP), respectively, which are treated by anaerobic digestion.

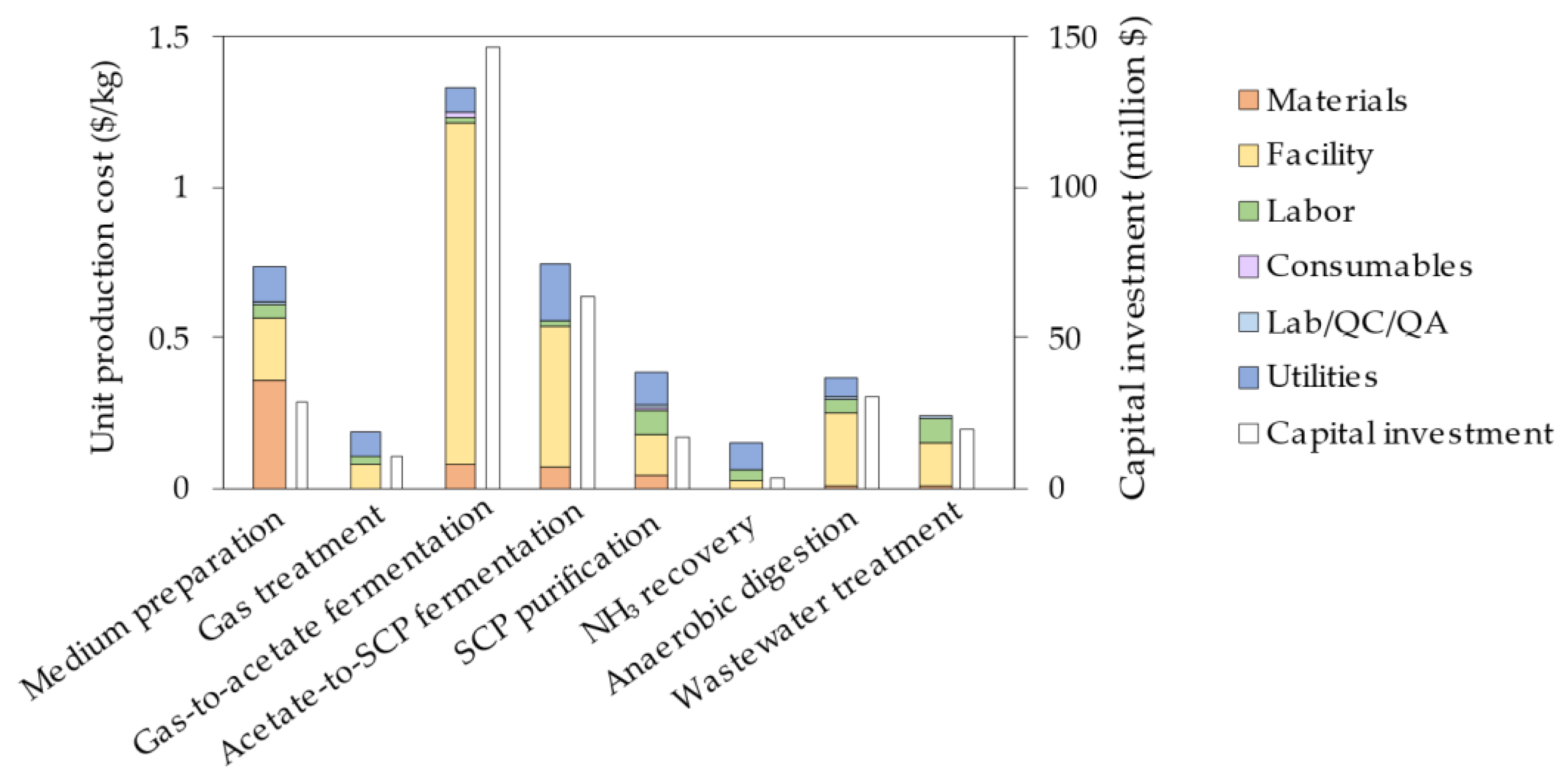

3.2. Capital Investment and Breakdown of the Unit Production Cost

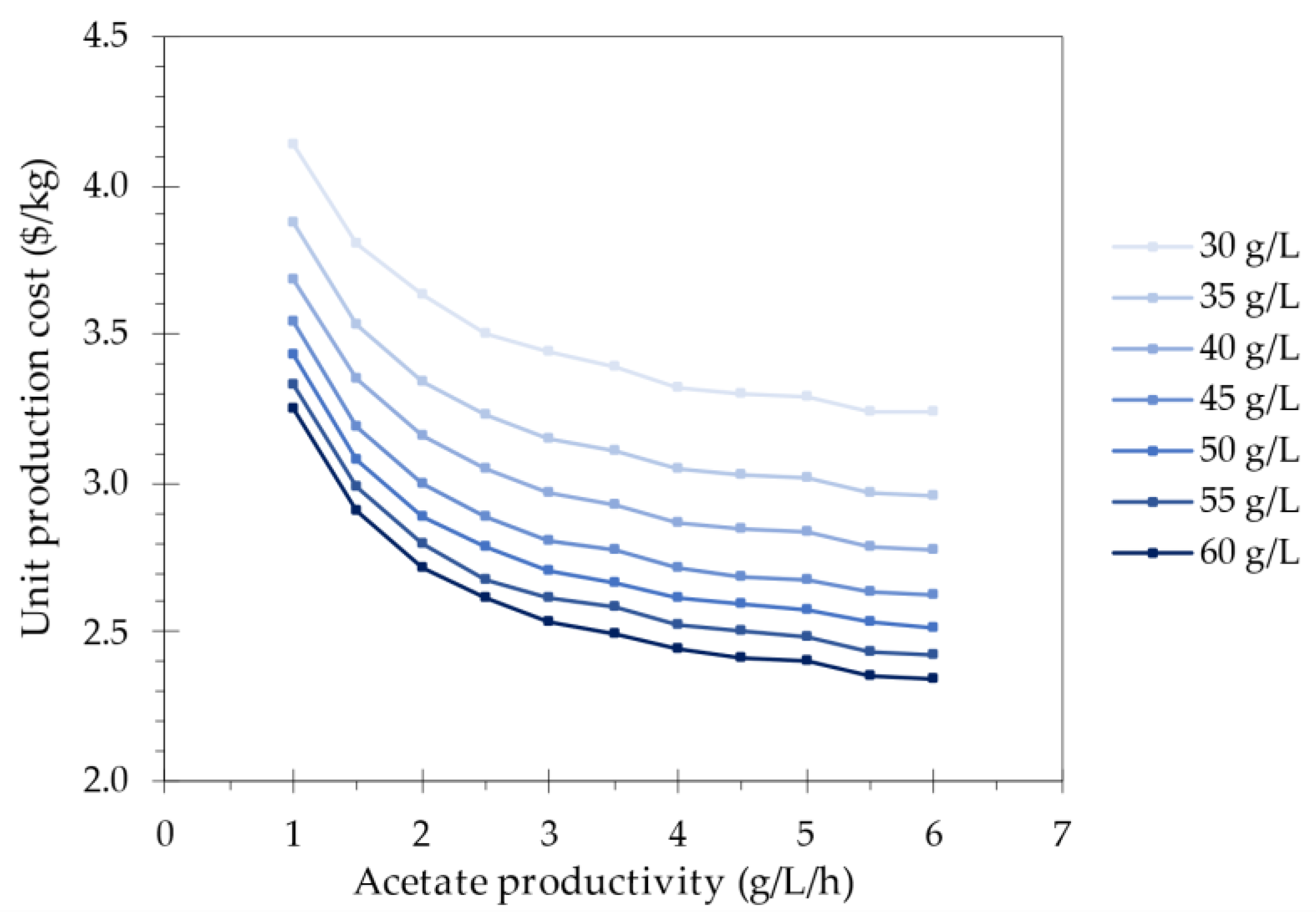

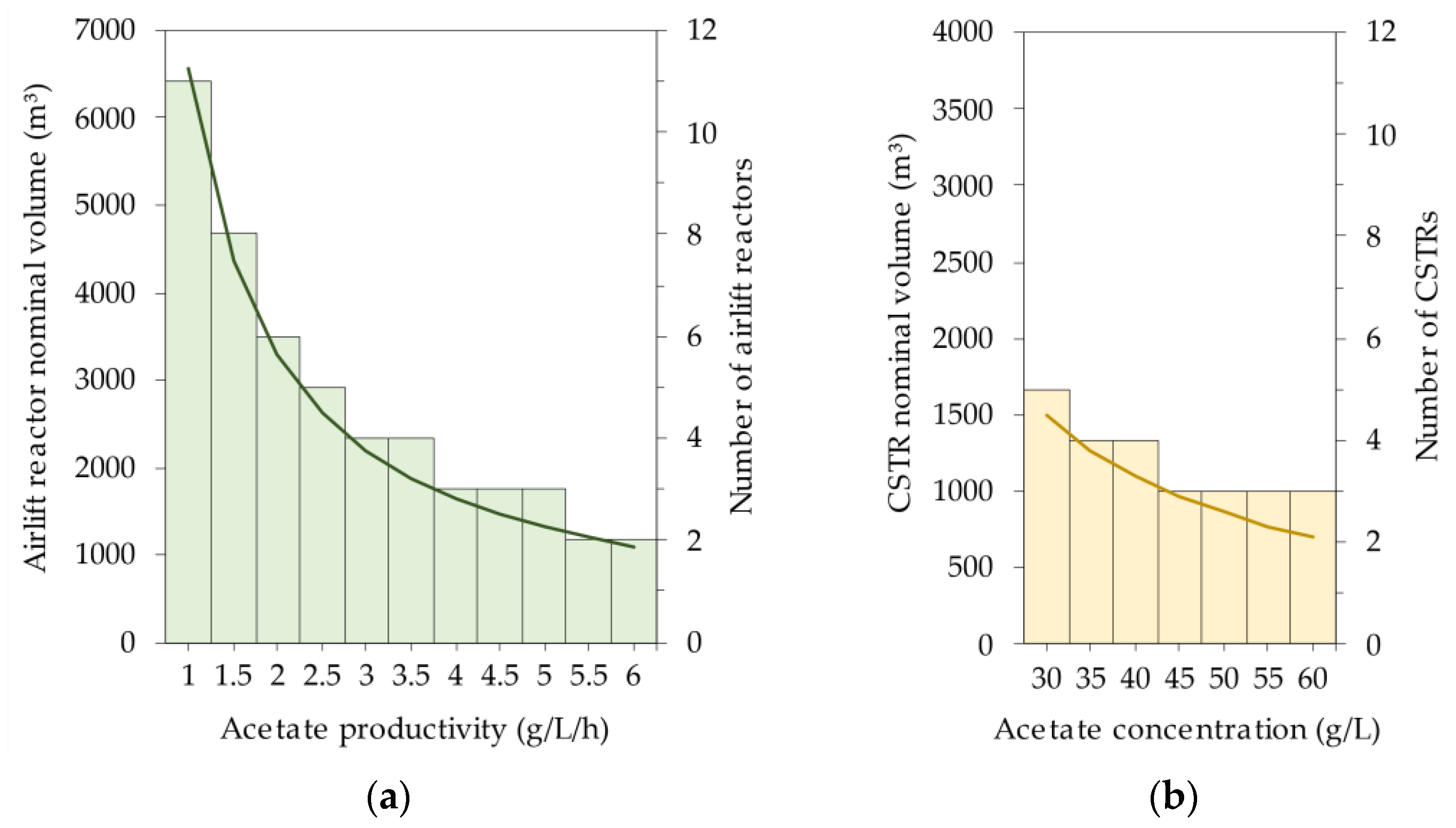

3.3. Impact of Process Intensification on the Production Costs

3.4. Towards Commercialization

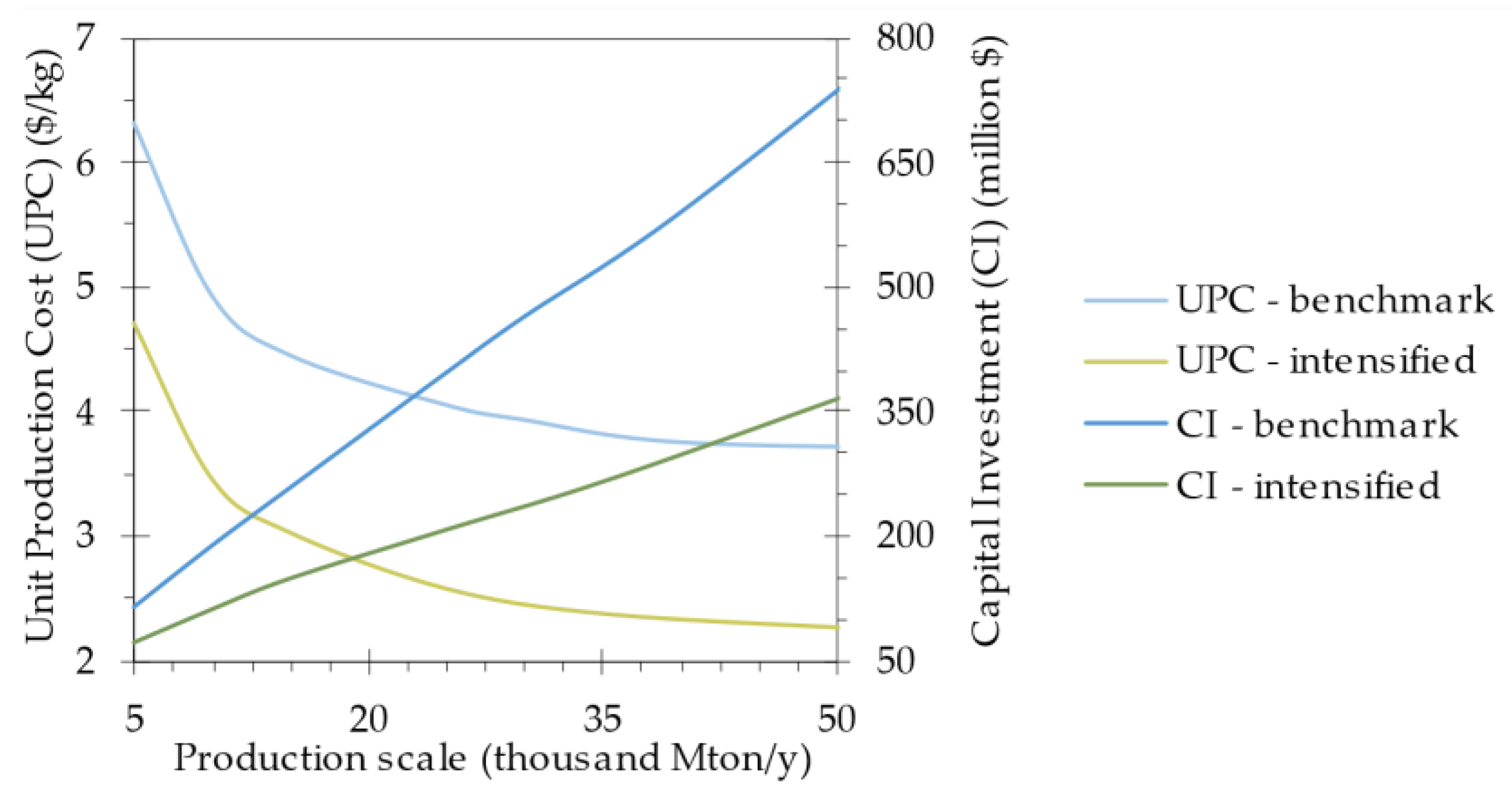

3.4.1. (Dis)Economy of Scale for a 3G Biorefinery

3.4.2. Introducing Off-Gas-Derived SCP Feed to the Market

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Azapagic, A. Sustainability Considerations for Integrated Biorefineries. Trends Biotechnol. 2014, 32, 1–4. [Google Scholar] [CrossRef] [PubMed]

- Pfleger, B.F.; Takors, R. Recent Progress in the Synthesis of Advanced Biofuel and Bioproducts. Curr. Opin. Biotechnol. 2023, 80, 102913. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, K.; Chen, Y.; Tan, T.; Nielsen, J. Third-Generation Biorefineries as the Means to Produce Fuels and Chemicals from CO2. Nat. Catal. 2020, 3, 274–288. [Google Scholar] [CrossRef]

- Phillips, J.R.; Huhnke, R.L.; Atiyeh, H.K. Syngas Fermentation: A Microbial Conversion Process of Gaseous Substrates to Various Products. Fermentation 2017, 3, 28. [Google Scholar] [CrossRef]

- Molitor, B.; Richter, H.; Martin, M.E.; Jensen, R.O.; Juminaga, A.; Mihalcea, C.; Angenent, L.T. Carbon Recovery by Fermentation of CO-Rich off Gases—Turning Steel Mills into Biorefineries. Bioresour. Technol. 2016, 215, 386–396. [Google Scholar] [CrossRef]

- Collis, J.; Strunge, T.; Steubing, B.; Zimmermann, A.; Schomäcker, R. Deriving Economic Potential and GHG Emissions of Steel Mill Gas for Chemical Industry. Front. Energy Res. 2021, 9, 642162. [Google Scholar] [CrossRef]

- Drake, H.L.; Gößner, A.S.; Daniel, S.L. Old Acetogens, New Light. Ann. N. Y. Acad. Sci. 2008, 1125, 100–128. [Google Scholar] [CrossRef]

- Kantzow, C.; Mayer, A.; Weuster-Botz, D. Continuous Gas Fermentation by Acetobacterium Woodii in a Submerged Membrane Reactor with Full Cell Retention. J. Biotechnol. 2015, 212, 11–18. [Google Scholar] [CrossRef]

- Rosenbaum, F.P.; Müller, V. Moorella Thermoacetica: A Promising Cytochrome- and Quinone-Containing Acetogenic Bacterium as Platform for a CO2-Based Bioeconomy. Green Carbon 2023. [Google Scholar] [CrossRef]

- Kiefer, D.; Merkel, M.; Lilge, L.; Henkel, M.; Hausmann, R. From Acetate to Bio-Based Products: Underexploited Potential for Industrial Biotechnology. Trends Biotechnol. 2020, 39, 397–411. [Google Scholar] [CrossRef]

- Vlaeminck, E.; Quataert, K.; Uitterhaegen, E.; De Winter, K.; Soetaert, W.K. Advanced PHB Fermentation Strategies with CO2-Derived Organic Acids. J. Biotechnol. 2022, 343, 102–109. [Google Scholar] [CrossRef] [PubMed]

- Molitor, B.; Mishra, A.; Angenent, L.T. Power-to-Protein: Converting Renewable Electric Power and Carbon Dioxide into Single Cell Protein with a Two-Stage Bioprocess. Energy Environ. Sci. 2019, 12, 3515–3521. [Google Scholar] [CrossRef]

- Hu, P.; Chakraborty, S.; Kumar, A.; Woolston, B.; Liu, H.; Emerson, D.; Stephanopoulos, G. Integrated Bioprocess for Conversion of Gaseous Substrates to Liquids. Proc. Natl. Acad. Sci. USA 2016, 113, 3773–3778. [Google Scholar] [CrossRef] [PubMed]

- Ma, X.; Liang, H.; Panda, S.; Fung, V.K.Y.; Zhou, J.F.J.; Zhou, K. C2 Feedstock-Based Biomanufacturing of Value-Added Chemicals. Curr. Opin. Biotechnol. 2022, 73, 240–245. [Google Scholar] [CrossRef]

- Van Peteghem, L.; Sakarika, M.; Matassa, S.; Pikaar, I.; Ganigué, R.; Rabaey, K. Towards New Carbon–Neutral Food Systems: Combining Carbon Capture and Utilization with Microbial Protein Production. Bioresour. Technol. 2022, 349, 126853. [Google Scholar] [CrossRef]

- Angenent, S.C.; Schuttinga, J.H.; van Efferen, M.F.H.; Kuizenga, B.; van Bree, B.; van der Krieken, R.O.; Verhoeven, T.J.; Wijffels, R.H. Hydrogen Oxidizing Bacteria as Novel Protein Source for Human Consumption: An Overview. Open Microbiol. J. 2022, 16, e187428582207270. [Google Scholar] [CrossRef]

- Claassens, N.J.; Cotton, C.A.R.; Kopljar, D.; Bar-Even, A. Making Quantitative Sense of Electromicrobial Production. Nat. Catal. 2019, 2, 437–447. [Google Scholar] [CrossRef]

- Vaghari, H.; Anarjan, N.; Najian, Y.; Jafarizadeh-Malmiri, H. Sterilization Process. In Essentials in Fermentation Technology; Berenjian, A., Ed.; Springer: Cham, Switzerland, 2019; pp. 85–103. ISBN 9783030162306. [Google Scholar]

- Uribe-Soto, W.; Portha, J.F.; Commenge, J.M.; Falk, L. A Review of Thermochemical Processes and Technologies to Use Steelworks Off-Gases. Renew. Sustain. Energy Rev. 2017, 74, 809–823. [Google Scholar] [CrossRef]

- Yan, Q.; Wan, C.; Street, J.; Yan, D.W.; Han, J.; Yu, F. Catalytic Removal of Oxygen from Biomass-Derived Syngas. Bioresour. Technol. 2013, 147, 117–123. [Google Scholar] [CrossRef]

- Sandlöbes, S.; Senk, D.; Sancho, L.; Diaz, A. In-Situ Measurement of CO- and CO2-Concentrations in BOF Off-Gas. Steel Res. Int. 2011, 82, 632–637. [Google Scholar] [CrossRef]

- Hu, P.; Rismani-Yazdi, H.; Stephanopoulos, G. Anaerobic CO2 Fixation by the Acetogenic Bacterium Moorella thermoacetica. AIChE J. 2013, 59, 3176–3183. [Google Scholar] [CrossRef]

- Puiman, L.; Abrahamson, B.; Van Der Lans, R.G.J.M.; Haringa, C.; Noorman, H.J.; Picioreanu, C. Alleviating Mass Transfer Limitations in Industrial External-Loop Syngas-to-Ethanol Fermentation. Chem. Eng. Sci. 2022, 259, 117770. [Google Scholar] [CrossRef]

- Simpson, S.D.; Collet, C.; Forster, R.L.S.; Cockrem, M.C.M.; Oakley, S.D.; Kopke, M. Carbon Capture in Fermentation. U.S. Patent US20100323417A1, 23 December 2010. [Google Scholar]

- Tracy, B.P.; Jones, S.W.; Fast, A.G.; Indurthi, D.C.; Papoutsakis, E.T. Clostridia: The Importance of Their Exceptional Substrate and Metabolite Diversity for Biofuel and Biorefinery Applications. Curr. Opin. Biotechnol. 2012, 23, 364–381. [Google Scholar] [CrossRef] [PubMed]

- Nasseri, A.T.; Rasoul-Amini, S.; Morowvat, M.H.; Ghasemi, Y. Single Cell Protein: Production and Process. Am. J. Food Technol. 2011, 6, 103–116. [Google Scholar] [CrossRef]

- Byeon, S.H.; Lee, B.K.; Raj Mohan, B. Removal of Ammonia and Particulate Matter Using a Modified Turbulent Wet Scrubbing System. Sep. Purif. Technol. 2012, 98, 221–229. [Google Scholar] [CrossRef]

- Gallert, C.; Winter, J. Bacterial Metabolism in Wastewater Treatment Systems. In Environmental Biotechnology: Concepts and Applications; Jördening, H.-J., Winter, J., Eds.; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2005; pp. 1–48. ISBN 3527305858. [Google Scholar]

- Misailidis, N.; Petrides, D. Food Industry Wastewater Treatment Plant—Process Modeling and Techno-Economic Assessment (TEA) Using SuperPro Designer; Intelligen, Inc.: Scotch Plains, NJ, USA, 2021. [Google Scholar] [CrossRef]

- Scarlat, N.; Dallemand, J.F.; Fahl, F. Biogas: Developments and Perspectives in Europe. Renew Energy 2018, 129, 457–472. [Google Scholar] [CrossRef]

- Amann, A.; Weber, N.; Krampe, J.; Rechberger, H.; Zoboli, O.; Zessner, M. Operation and Performance of Austrian Wastewater and Sewage Sludge Treatment as a Basis for Resource Optimization. Water 2021, 13, 2998. [Google Scholar] [CrossRef]

- Ho, M.T.; Bustamante, A.; Wiley, D.E. Comparison of CO2 Capture Economics for Iron and Steel Mills. Int. J. Greenh. Gas Control 2013, 19, 145–159. [Google Scholar] [CrossRef]

- Ciliberti, C.; Biundo, A.; Albergo, R.; Agrimi, G.; Braccio, G.; de Bari, I.; Pisano, I. Syngas Derived from Lignocellulosic Biomass Gasification as an Alternative Resource for Innovative Bioprocesses. Processes 2020, 8, 1567. [Google Scholar] [CrossRef]

- Lambauer, V.; Kratzer, R. Lab-Scale Cultivation of Cupriavidus necator on Explosive Gas Mixtures: Carbon Dioxide Fixation into Polyhydroxybutyrate. Bioengineering 2022, 9, 204. [Google Scholar] [CrossRef] [PubMed]

- Valgepea, K.; De Souza Pinto Lemgruber, R.; Abdalla, T.; Binos, S.; Takemori, N.; Takemori, A.; Tanaka, Y.; Tappel, R.; Köpke, M.; Simpson, S.D.; et al. H2 Drives Metabolic Rearrangements in Gas-Fermenting Clostridium autoethanogenum. Biotechnol. Biofuels 2018, 11, 55. [Google Scholar] [CrossRef] [PubMed]

- Claassens, N.J.; Bordanaba-Florit, G.; Cotton, C.A.R.; De Maria, A.; Finger-Bou, M.; Friedeheim, L.; Giner-Laguarda, N.; Munar-Palmer, M.; Newell, W.; Scarinci, G.; et al. Replacing the Calvin Cycle with the Reductive Glycine Pathway in Cupriavidus necator. Metab. Eng. 2020, 62, 30–41. [Google Scholar] [CrossRef] [PubMed]

- Heffernan, J.K.; Valgepea, K.; de Souza Pinto Lemgruber, R.; Casini, I.; Plan, M.; Tappel, R.; Simpson, S.D.; Köpke, M.; Nielsen, L.K.; Marcellin, E. Enhancing CO2-Valorization Using Clostridium autoethanogenum for Sustainable Fuel and Chemicals Production. Front. Bioeng. Biotechnol. 2020, 8, 204. [Google Scholar] [CrossRef]

- Stiglitz, J.E.; Stern, N.; Duan, M.; Edenhofer, O.; Giraud, G.; Heal, G.; Lèbre la Rovere, E.; Moyer, E.; Pangestu, M.; Shukla, P.R.; et al. Report of the High-Level Commission on Carbon Prices; World Bank: Washington, DC, USA, 2019. [Google Scholar] [CrossRef]

- Trček, J.; Mira, N.P.; Jarboe, L.R. Adaptation and Tolerance of Bacteria against Acetic Acid. Appl. Microbiol. Biotechnol. 2015, 99, 6215–6229. [Google Scholar] [CrossRef] [PubMed]

- Van Hecke, W.; Bockrath, R.; De Wever, H. Effects of Moderately Elevated Pressure on Gas Fermentation Processes. Bioresour. Technol. 2019, 293, 122129. [Google Scholar] [CrossRef]

- Gaddy, J.L.; Arora, D.K.; Ko, C.W.; Phillips, J.R.; Basu, R.; Wikstrom, C.V.; Clausen, E.C. Methods for Increasing the Production of Ethanol from Microbial Fermentation. U.S. Patent US20030211585A1, 23 October 2007. [Google Scholar]

- Lee, U.; R Hawkins, T.; Yoo, E.; Wang, M.; Huang, Z.; Tao, L. Using Waste CO2 from Corn Ethanol Biorefineries for Additional Ethanol Production: Life-Cycle Analysis. Biofuels Bioprod. Biorefining 2021, 15, 468–480. [Google Scholar] [CrossRef]

- Linder, T. Making the Case for Edible Microorganisms as an Integral Part of a More Sustainable and Resilient Food Production System. ACS Food Sci. Technol. 2023, 11, 1144–1152. [Google Scholar] [CrossRef]

- Thielges, S.; Olfe-Kräutlein, B.; Rees, A.; Jahn, J.; Sick, V.; Quitzow, R. Committed to Implementing CCU? A Comparison of the Policy Mix in the US and the EU. Front. Clim. 2022, 4, 943387. [Google Scholar] [CrossRef]

- Jones, S.W.; Karpol, A.; Friedman, S.; Maru, B.T.; Tracy, B.P. Recent Advances in Single Cell Protein Use as a Feed Ingredient in Aquaculture. Curr. Opin. Biotechnol. 2020, 61, 189–197. [Google Scholar] [CrossRef]

- Single Cell Protein Market Share|Industry Statistics 2030. Available online: https://www.gminsights.com/industry-analysis/single-cell-protein-market (accessed on 12 July 2023).

- Aidoo, R.; Kwofie, E.M.; Adewale, P.; Lam, E.; Ngadi, M. Overview of Single Cell Protein: Production Pathway, Sustainability Outlook, and Digital Twin Potentials. Trends Food Sci. Technol. 2023, 138, 577–598. [Google Scholar] [CrossRef]

| Fermentation Parameter | Benchmark Process Value |

|---|---|

| Biomass concentration | 10.0 g/L |

| Biomass productivity | 0.1 g/L/h |

| Acetate concentration | 30.0 g/L |

| Acetate productivity | 1.0 g/L/h |

| Residence time | 30.0 h |

| Fermentation Parameter | Benchmark Process Value |

|---|---|

| Biomass concentration | 14.0 g/L |

| Biomass productivity | 2.0 g/L/h |

| Residence time | 7.0 h |

| Process section | Fermentation Parameter | Intensified Process Value |

|---|---|---|

| Biomass concentration | 14.6 g/L | |

| Biomass productivity | 1.3 g/L/h | |

| Gas-to-acetate fermentation | Acetate concentration | 45.0 g/L |

| Acetate productivity | 4.0 g/L/h | |

| Residence time | 11.3 h | |

| Biomass concentration | 21.3 g/L | |

| Acetate-to-SCP fermentation | Biomass productivity | 3.0 g/L/h |

| Residence time | 7.0 h |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vlaeminck, E.; Uitterhaegen, E.; Quataert, K.; Delmulle, T.; Kontovas, S.-S.; Misailidis, N.; Ferreira, R.G.; Petrides, D.; De Winter, K.; Soetaert, W.K. Single-Cell Protein Production from Industrial Off-Gas through Acetate: Techno-Economic Analysis for a Coupled Fermentation Approach. Fermentation 2023, 9, 771. https://doi.org/10.3390/fermentation9080771

Vlaeminck E, Uitterhaegen E, Quataert K, Delmulle T, Kontovas S-S, Misailidis N, Ferreira RG, Petrides D, De Winter K, Soetaert WK. Single-Cell Protein Production from Industrial Off-Gas through Acetate: Techno-Economic Analysis for a Coupled Fermentation Approach. Fermentation. 2023; 9(8):771. https://doi.org/10.3390/fermentation9080771

Chicago/Turabian StyleVlaeminck, Elodie, Evelien Uitterhaegen, Koen Quataert, Tom Delmulle, Stoilas-Stylianos Kontovas, Nikiforos Misailidis, Rafael G. Ferreira, Demetri Petrides, Karel De Winter, and Wim K. Soetaert. 2023. "Single-Cell Protein Production from Industrial Off-Gas through Acetate: Techno-Economic Analysis for a Coupled Fermentation Approach" Fermentation 9, no. 8: 771. https://doi.org/10.3390/fermentation9080771