1. Introduction

As an important part of modern power systems, lithium-ion batteries have undergone rapid development in electric vehicles, renewable energy, and other fields. Currently, there is a growing demand for lithium batteries in various industries. However, the performance and remaining life of the battery decrease as its usage time increases. Additionally, environmental factors such as temperature and humidity can harm the components in the battery, affecting its capacity. Therefore, it is particularly important to conduct in-depth research and effectively evaluate the health of lithium-ion batteries.

Several evaluation models for health status evaluation have been developed by researchers, and four common types of modeling approaches have been summarized. The data-driven approach involves the collection of large amounts of data, which are analyzed and modeled to discover patterns, relationships, and regularities. This approach typically uses data to guide decisions, predict future events, and optimize systems [

1]. The advantage of data-driven modeling is that the patterns and laws of the system can be learned from the data to support more accurate predictions and decisions. However, in real systems, models based on data-driven approaches may be inconsistent or unfair across different datasets due to external factors, such as data limitations and system complexity. The knowledge-driven approach is a modeling methodology based on a priori knowledge and the experience of domain experts, which is aimed at better understanding and describing the behavior and relationships of complex systems [

2,

3,

4]. The knowledge-driven modeling approach aims to enhance the performance and explanatory power of the model by leveraging the knowledge and experience of domain experts in the modeling process. However, this approach typically relies on a set of physical assumptions and a priori knowledge that may not hold in real systems. Model failure or loss of accuracy may be caused by these assumptions. The model-driven approach focuses on the use of formal models to guide the different phases of system development. The reliability and consistency of system development are improved by this approach, errors are reduced, and the system is made easier to maintain and evolve [

5,

6]. However, it also requires an investment of time and resources to learn and use modeling tools and techniques. For the hybrid-driven approach, the different modeling approaches mentioned above are combined with this modeling approach to overcome the limitations of a single approach and provide a more comprehensive and flexible solution to accommodate complex and diverse problems.

A modeling approach based on a hybrid-driven method was proposed by Yang et al. [

7]. The traditional fuzzy rules are extended by integrating the belief rule framework, resulting in the construction of a belief rule base (BRB) model. This model uses the transparently interpretable evidential reasoning (ER) approach as its inference engine. BRB models are widely used in equipment health evaluation due to their strong interpretability. The health state evaluation of lithium batteries is a challenging field due to the large amount of uncertainty and ambiguous data that need to be dealt with. The BRB model can effectively integrate and process complex and inconsistent information, including data from multiple sensors and expert knowledge, and it can provide more accurate and reliable evaluation results through its belief assignment mechanism. This not only enhances the accuracy of the evaluation but also improves the ability to predict the health of the battery. Finally, the BRB model provides a more flexible and dynamic evaluation framework than traditional evaluation methods, allowing it to adapt to rapidly changing data environments and evolving battery technologies.

However, in real operating environments, Li-ion batteries are often affected by a variety of external disturbances, such as temperature variations, charge/discharge cycles, and changes in usage conditions. Fluctuations and changes in battery performance and health can be caused by these disturbances. Without considering the disturbance factors, the changes and fluctuations in the real environment may not be captured by the evaluation model, leading to biased evaluation results. In addition, the performance of the battery may be affected by the condition and operation of other components in the system. For example, the dynamic characteristics of the vehicle while driving may affect the onboard battery of an electric vehicle, and the performance of the battery may also be affected by the operational status of devices such as charge controllers and inverters in a solar energy storage system. There are certain variations and uncertainties in the manufacturing process of lithium-ion batteries, such as material selection and process parameters, which may result in different performance characteristics for the same battery model. In summary, the consideration of disturbance factors is critical to an accurate evaluation of the state of health of lithium-ion batteries, as it allows for a more comprehensive consideration of the true operating conditions of the battery under different environmental conditions, operating conditions, and system configurations, thus improving the accuracy and reliability of the evaluation.

Disturbances in lithium-ion batteries are typically small changes in input parameters or fluctuations caused by uncertainties in the model structure or parameters. Various BRB models were developed by Han et al. [

8,

9] to evaluate lithium-ion battery health. Among the existing models, a complex system evaluation model considering disturbed ER rules was constructed by Tang et al. [

10], a sensor-disturbed complex system based on the BRB model was constructed by Lian et al. [

11], and a new multi-source uncertainty-informed BRB expert system was constructed by Feng et al. [

12] to solve the problem of stochastic environmental disturbances. However, in the existing research, there is little in the literature on the robustness of the model to disturbances, and a model that is robust to disturbances should maintain a good performance state when disturbances occur. Therefore, a method is needed to measure the disturbance resistance of the model. The robustness of the BRB model was defined by Cao et al. [

13], and the robustness of the BRB model was analyzed from four aspects. However, a reasonable method to solve the problem of weak robustness in the input conversion part was not provided. In this paper, based on the study by Cao, a modeling approach that takes into account the disturbance of lithium-ion batteries is proposed, which aims to be able to analyze the decisions made by the model when it encounters a disturbance and to measure the disturbance-resistant capability of the model. In addition, since existing optimization approaches do not consider robust optimization, this paper proposes an improved optimization algorithm that aims to improve the disturbance resistance of the model. In summary, the modeling approaches proposed in this paper help to improve battery management systems and provide a new way of thinking for researchers in battery health evaluation. The specific contributions are as follows:

- (1)

The operating environment of lithium-ion batteries is complex, so disturbances are introduced, and the battery health state evaluation model of the BRB model considering disturbances is established, which is capable of measuring its disturbance-resistant capability.

- (2)

An improved optimization algorithm is proposed that embeds robustness and interpretability constraints to effectively improve the robustness of the model and maintain the interpretability of the BRB model itself.

The problem description of the BRB model is presented in

Section 2, the construction of the disturbance BRB model is presented in

Section 3, the optimization algorithm is presented in

Section 4, the case study is presented in

Section 5, and, finally, the conclusion is given in

Section 6.

3. Modeling of the Disturbance BRB

A robustness analysis of a model is conducted to determine the maximum capacity of the model to resist disturbances, and the concept of Lipschitz stabilization has been introduced to the model by many studies to explore its resistance to disturbances [

15,

16,

17,

18,

19].

Mathematically, Lipschitz stability is a property of continuous functions or mappings where there exists an upper bound on the difference between the values of the function

f(

x) when the inputs to the function are slightly changed. Specifically, a function is Lipschitz-stable over its domain of definition if there exists a constant

L(

L > 0) for which the following inequality holds for all

and

.

This means that the difference between the function values is controlled for small changes in the input, so the Lipschitz stability can be used to describe the smoothness and robustness of the function. In the BRB model, the training and output of the model can be regarded as a process of function processing, and the robustness corresponds to the ability of the model to resist disturbances. Therefore, the Lipschitz stability of a BRB model can be defined as follows:

For

, the condition of Lipschitz stability on

is that there exists a minimum constant

, such that:

where, for all

,

is the input value

corresponding to the generated disturbance value.

denotes the result produced by the disturbance value

.

is the Manhattan distance.

In lithium batteries, disturbances often involve small changes in the inputs or parameters of the model, so the disturbance data in this paper are simulated by adding a disturbance factor to the data. The function for generating the disturbed data is as follows:

where

denotes the disturbance factor, and

random(−1,1) denotes a random value between −1 and 1. Since the size of the disturbance factor directly affects the prediction results of the model, the disturbance factor should be set according to the actual system.

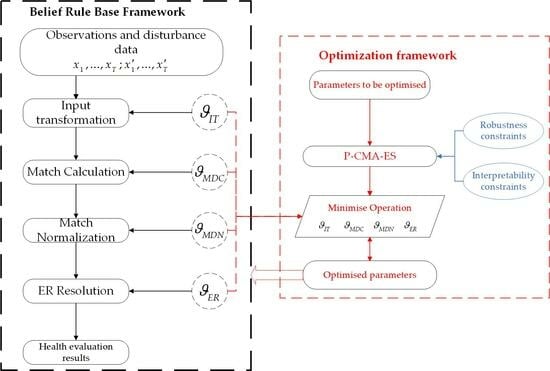

The BRB disturbance analysis process is divided into four specific steps, and the analysis framework is shown in

Figure 1, which includes (1) input transformation, (2) matching degree calculation, (3) matching degree normalization, and (4) rule aggregation. The Lipschitz constants of these parts are denoted by

, respectively [

13]. The framework of the disturbance analysis for the whole model is given in

Figure 1.

Step 1: In the actual operation of lithium-ion batteries, the collected data may fluctuate due to disturbances, and

represents the maximum fluctuation that can be generated by the BRB model during input transformation. The

ith input message

and the corresponding disturbance input message

,

is calculated as follows:

where

are the membership degrees of the

jth attribute reference value

corresponding to

, respectively.

Step 2: The Lipschitz constant is calculated for the individual degree of matching

. The input data of the lithium-ion battery are transformed to obtain the belief degree, and the corresponding rule is activated based on the belief degree. The matching degree between the activation rule and the belief degree is denoted by

. Taking the kth rule as an example, the distance between the belief degree and the corresponding activation rule in the rule space is measured, and the closer the distance is, the greater the matching degree.

where

is the normalized weight of the

ith attribute, and

is the vector of matching degrees produced by the reference values in the

kth rule.

Step 3: The normalization calculation of the matching degree is conducted next. The matching degrees are normalized to better measure the match between attributes and rules.

Step 4: The Lipschitz constant calculation of the inferred result

is next conducted for the activation weight

. The relationship between the degree of belief obtained after the ER inference and the

L rule is denoted by

. The degree of fluctuation of the degree of belief, calculated by combining the reference value given by the expert, is denoted by

. The smaller the value of

, the more limited the response to small disturbances in the belief degree space, resulting in a relatively small change in belief degree.

Step 5: The overall resistance to disturbance of the model built based on the health assessment of lithium-ion batteries is described as follows.

The overall disturbance resistance of the model is denoted by .

To facilitate the understanding of the decision processing made by the disturbance BRB model when encountering a disturbance in practical applications, this paper simulates that the lithium-ion battery is disturbed by the data

collected at the moment of

T, where the disturbed data is denoted as

, and the overall operation process of the model is shown in

Figure 2.

The input data at the Tth moment and the disturbed data are calculated by the membership degree corresponding to the attribute reference value through the membership degree function, and the model calculates the Lipschitz constant for the input transformation according to Equation (17), and combined with the definition of Lipschitz stabilization, the membership degree calculated from the input after the disturbance is limited by and thus does not deviate too much.

The membership degree is calculated from the membership function, which further activates the corresponding rule and generates the corresponding matching degree, , is used to limit the matching degree generated from the disturbance data from deviating excessively, where denotes the matching degree calculation. The calculated degree of matching corresponds to the activation weights of the rules activated by the degree of membership after performing the normalization of Equation (6) on L rules. denotes the maximum value of the activation weights after the disturbance that differs from the activation weights generated by the original data at the time of normalization.

After activating the corresponding rule by the membership degree, the final belief degree is calculated iteratively using the ER of Equations (7)–(11), and calculated by Equations (20)–(21) represents the maximum degree of deviation from the value of the belief degree obtained from the disturbance data after the ER calculation.

Remark 1. The maximum value of the Lipschitz constants for each part of the model is determined by the model itself and has no relation to the disturbance itself, and indicate that in the calculation of each of the four parts, the disturbed data will fluctuate due to the effect of Lipschitz stabilization and thus be limited to fluctuate within a certain range.denotes the Lipschitz constant of the model, i.e., the input disturbed data produce the maximum value of the final output of the maximum value of the deviation from the belief degree. Therefore, the smaller the Lipschitz constant, the smaller the range of fluctuations that can be produced by the disturbance data, and the more resistant the model is to disturbances.

4. Model Optimization Strategy

In this paper, the P-CMA-ES (projection covariance matrix adaptive evolution strategy) [

20,

21,

22,

23] is used as the global optimization algorithm. Real-time performance is usually required to evaluate the health of lithium-ion batteries, especially under dynamic operating conditions. The fast convergence capability of the P-CMA-ES means that a near-optimal solution can be found in a relatively short period, providing timely information about the health of the battery and enabling timely action to be taken.

For accurate prediction of battery health by the model, accuracy is chosen as the global optimization objective of the model in this paper. The effectiveness of the BRB model in matching the predicted Li-ion battery values to the actual system values is quantified using the mean square error (MSE). The optimization objectives are described as follows:

where

y is the predicted value of the model output,

is the true value of the system, and

is the set of parameters to be optimized.

According to Equation (18), the Lipschitz constant can reach a maximum value of when . This value is not affected by the disturbance but is determined solely by the reference value of the input attribute, which is typically derived from the experience accumulated by experts in the field over an extended period. To address this problem, an improved P-CMA-ES optimization algorithm is proposed in this paper to construct a constraint that considers the disturbance resistance of the model. The optimization steps are as follows.

Step 1 (Initialize the optimization target parameters): The specific optimization parameters are the input attribute reference values, belief degree, rule weight, and attribute weight. The set of target parameters can be expressed as:

Step 2 (Sampling): The data of each generation are obtained by sampling, denoted as follows:

where

is the

ith solution in the

s + 1th generation optimization.

is the step size.

is the mean of the search distribution for generation

s.

is the covariance matrix.

denote the normal distribution function, where

h is the number of offspring.

Step 3 (Robustness and interpretability constraints): After analyzing the disturbance of the model, a disturbance metric of the model, denoted as

, is calculated. Due to undesirable disturbances in the operation of lithium-ion batteries, the data may fluctuate when collected by a researcher. Input transformation is considered the most important process in the calculation of membership degrees within a BRB expert system. It directly affects the calculated membership degree, which in turn affects the activation of rules and ER inference. Cao [

13] noted that the Lipschitz constant of the input transformation is too large, resulting in a decrease in the disturbance resistance of the model. Therefore, it is necessary to design an optimization method to improve the disturbance resistance of the model during the input transformation process.

where

and

are the lower and upper limits of

, respectively, as determined by experts in connection with the actual operating state of the lithium-ion battery, and

is the optimization result of the reference value.

In addition, the knowledge and logical relationships in the data or problem domain are described by the BRB model through a set of rules. Compared to other machine learning models, BRB models are highly interpretable [

24,

25,

26]. However, existing research has shown that the interpretability of the model is disrupted by the optimization process. For instance, if there are three outcomes with semantic values of poor, medium, and good, the belief degree obtained by the BRB model after ER parsing may assign belief degrees of 0.45 to good and bad and a belief degree of 0.1 to medium. Assigning a high degree of belief to two conflicting semantic values is impractical. Therefore, constraints are imposed to ensure the interpretability of the model, and these are expressed as follows:

where

denotes the belief degree of the nth result in the kth rule under constraints.

Step 4 (Projection operation): The candidate data are projected onto a feasible hyperplane as follows:

where

is an all-unity

N-dimensional row vector, and

denotes the number of constrained variables.

is the number of equality constraints.

Step 5 (Update the mean iteratively):

where

is the offspring population size, and

is the weight coefficient.

is the

ith solution among the

h solutions of generation

s + 1.

Step 6 (Update the covariance matrix):

where

represents the step size of generation

s.

is the evolutionary path for the

s + 1th generation.

are the learning rates.

is the number of offspring at generation

s.

denotes the

ith solution vector among the

h solution vectors under generation

s + 1.

Finally, the above six-step process is recursively executed until the optimization is complete.