Concepts for Reusing Composite Materials from Decommissioned Wind Turbine Blades in Affordable Housing

Abstract

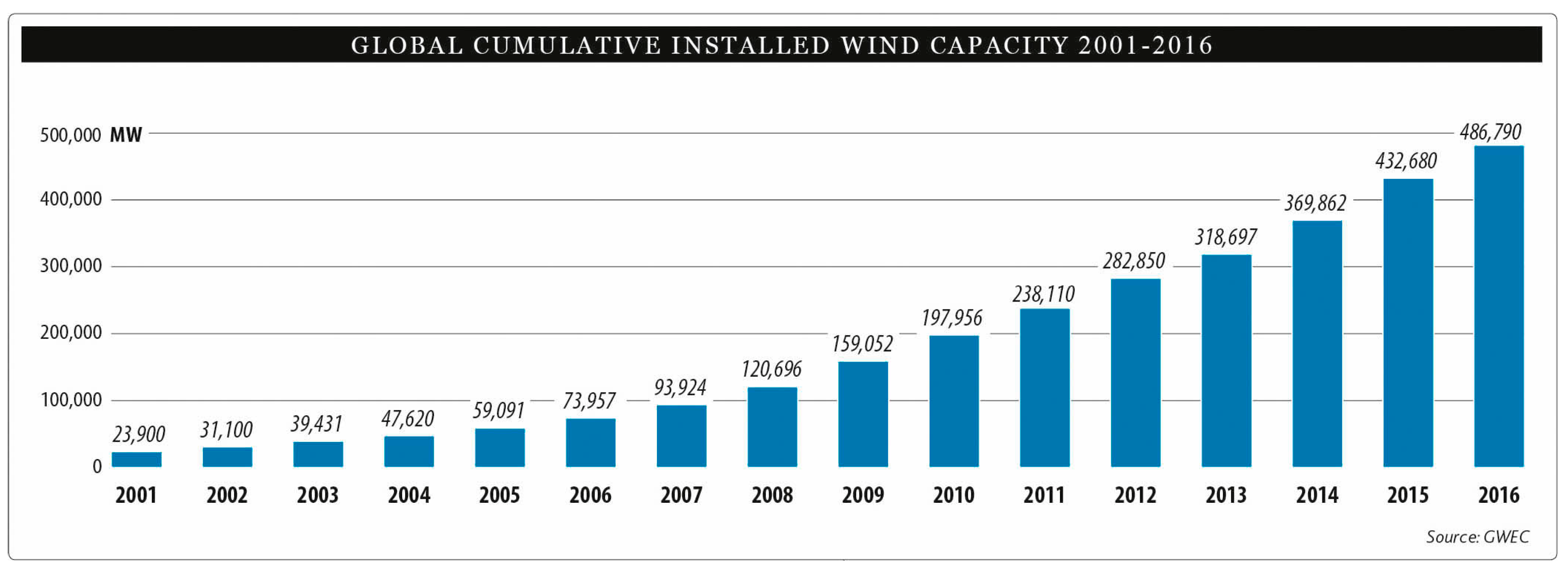

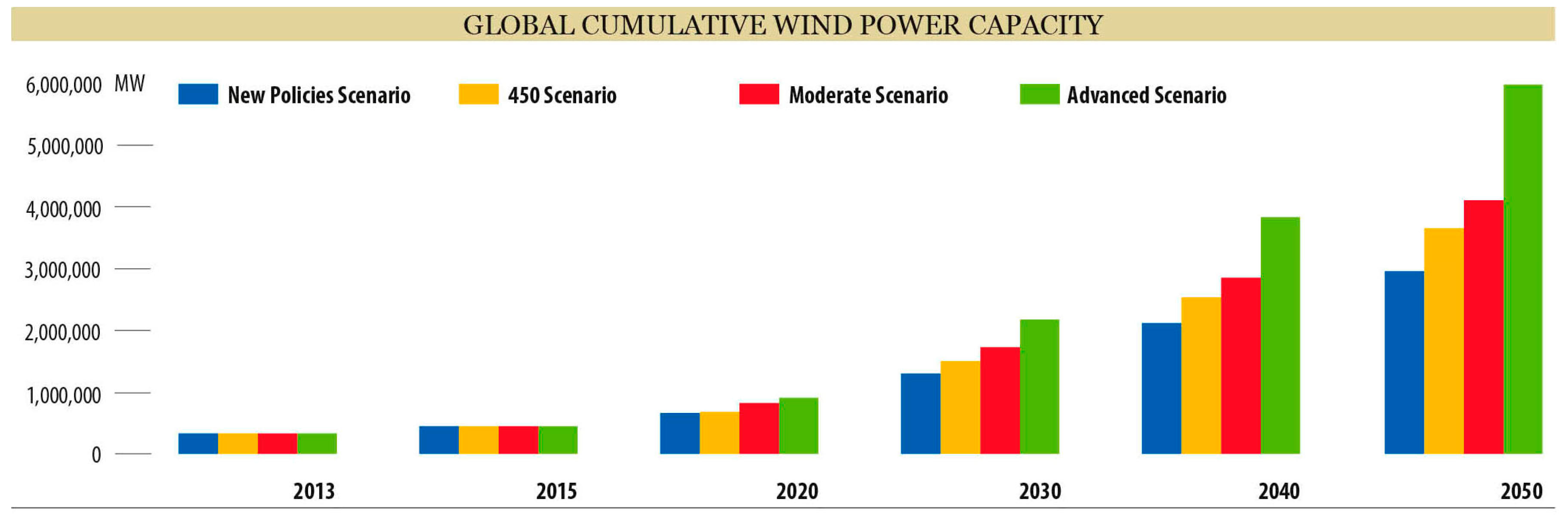

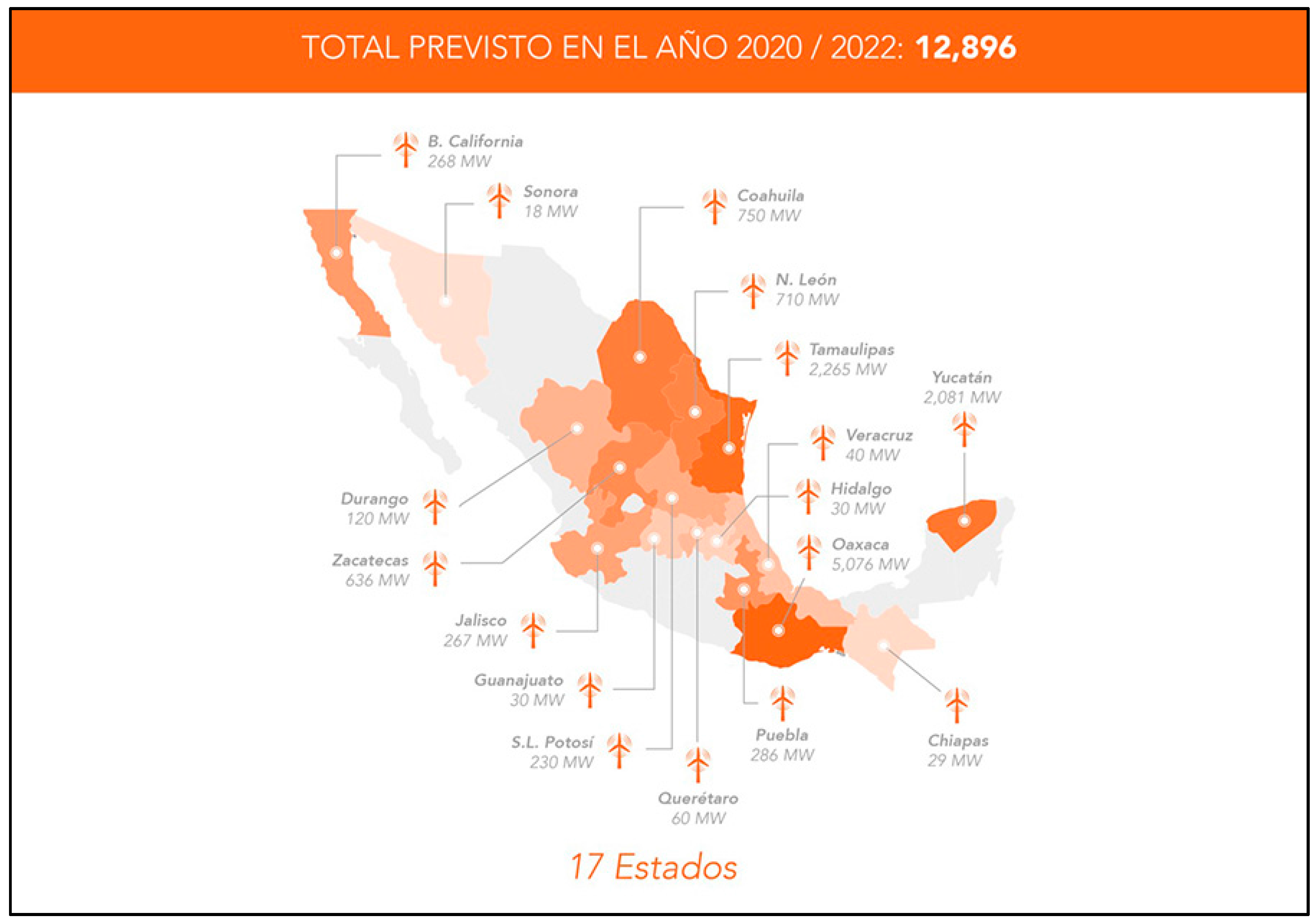

:1. Introduction

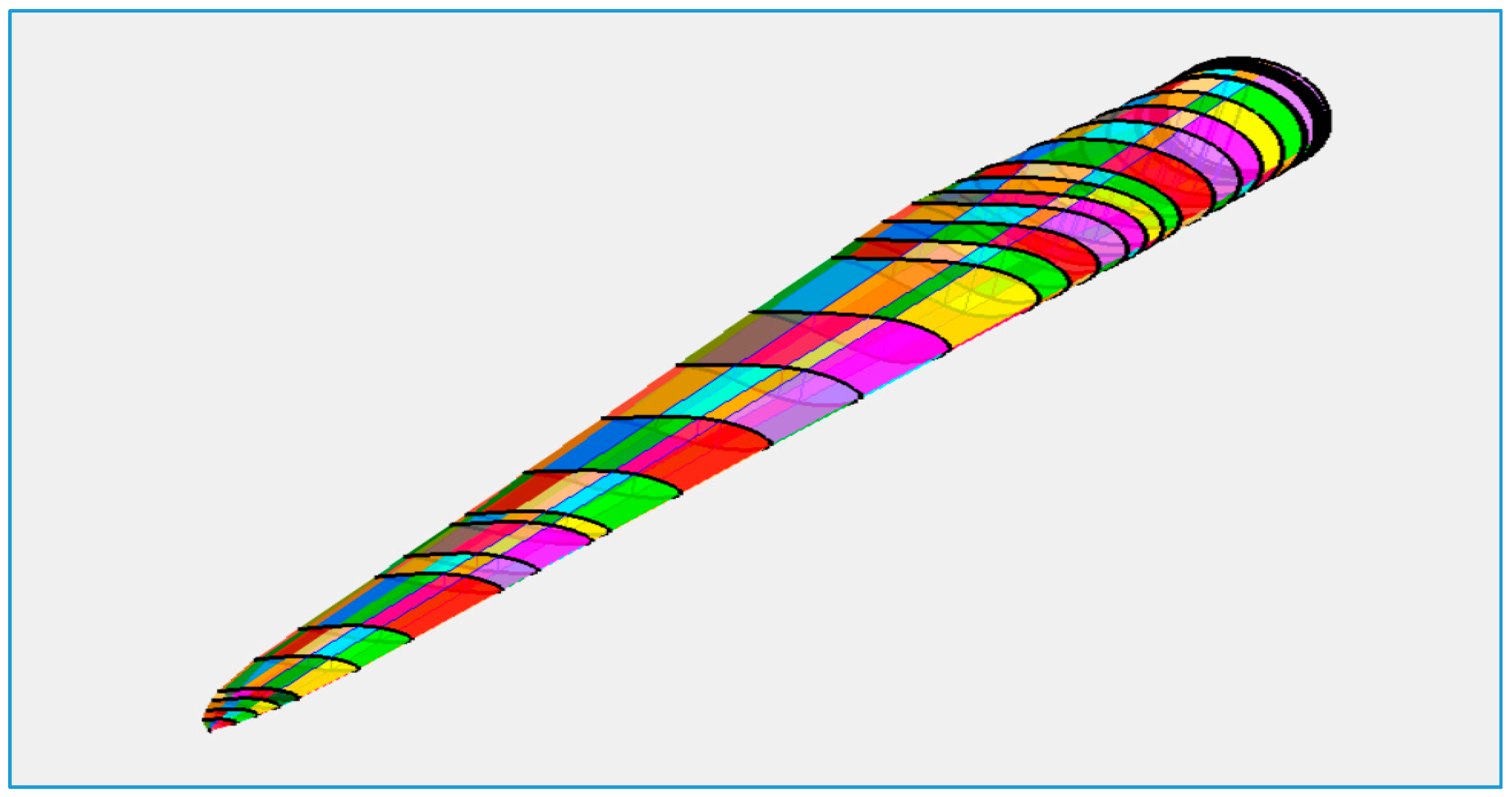

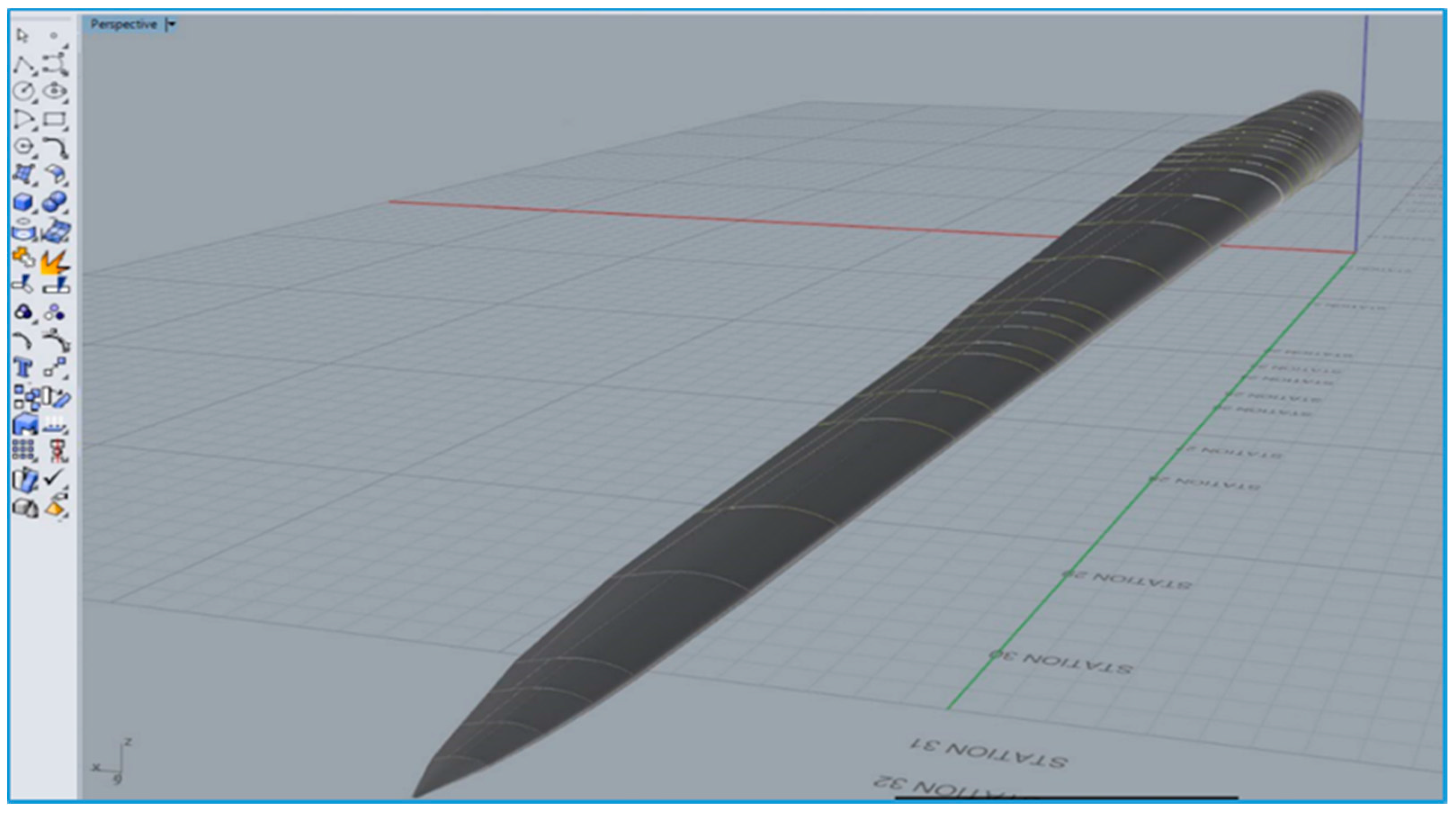

2. Wind Blade Computational Models

3. Architectural Concepts for Decommissioned 100 m Long Wind Blade Segments

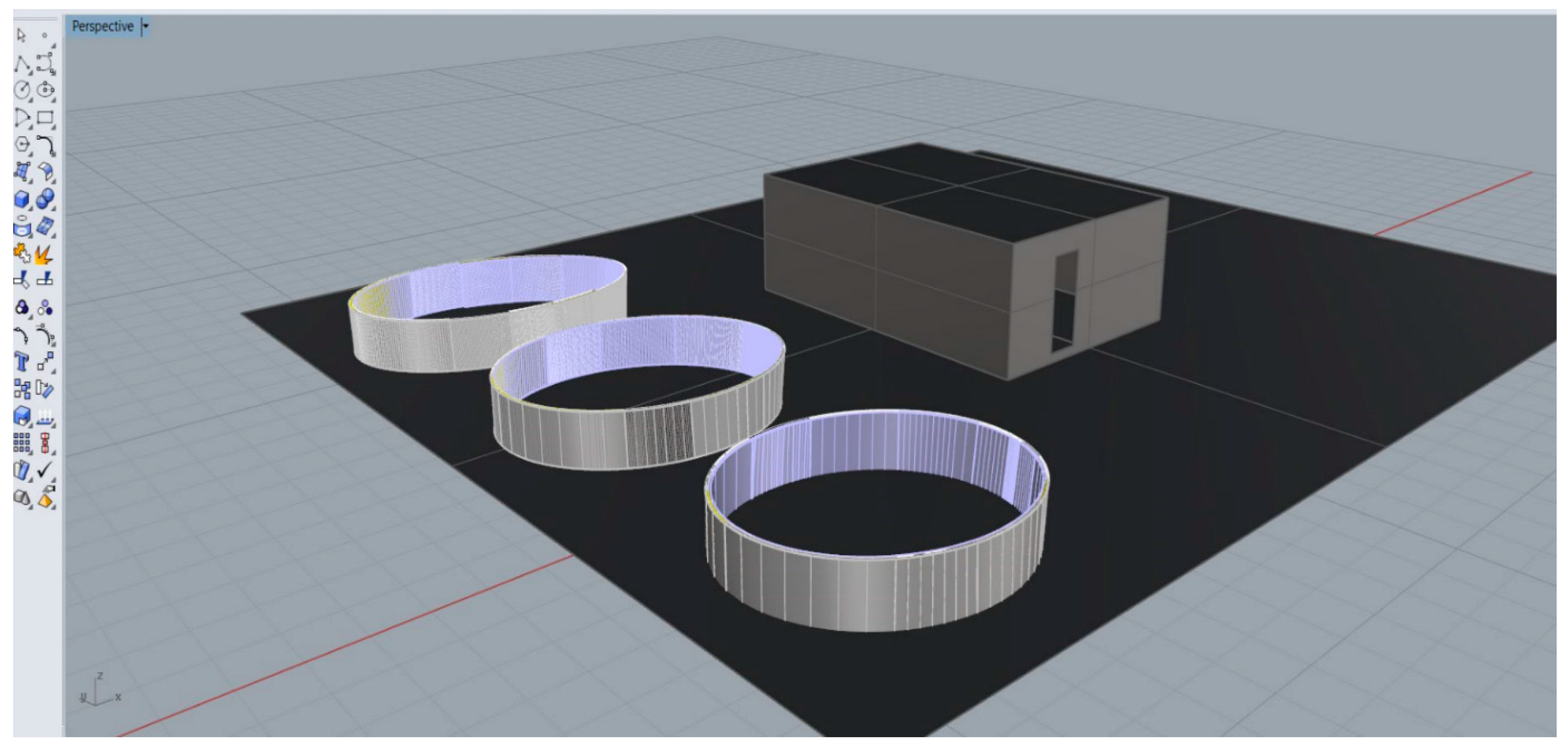

3.1. Root-Foundation System

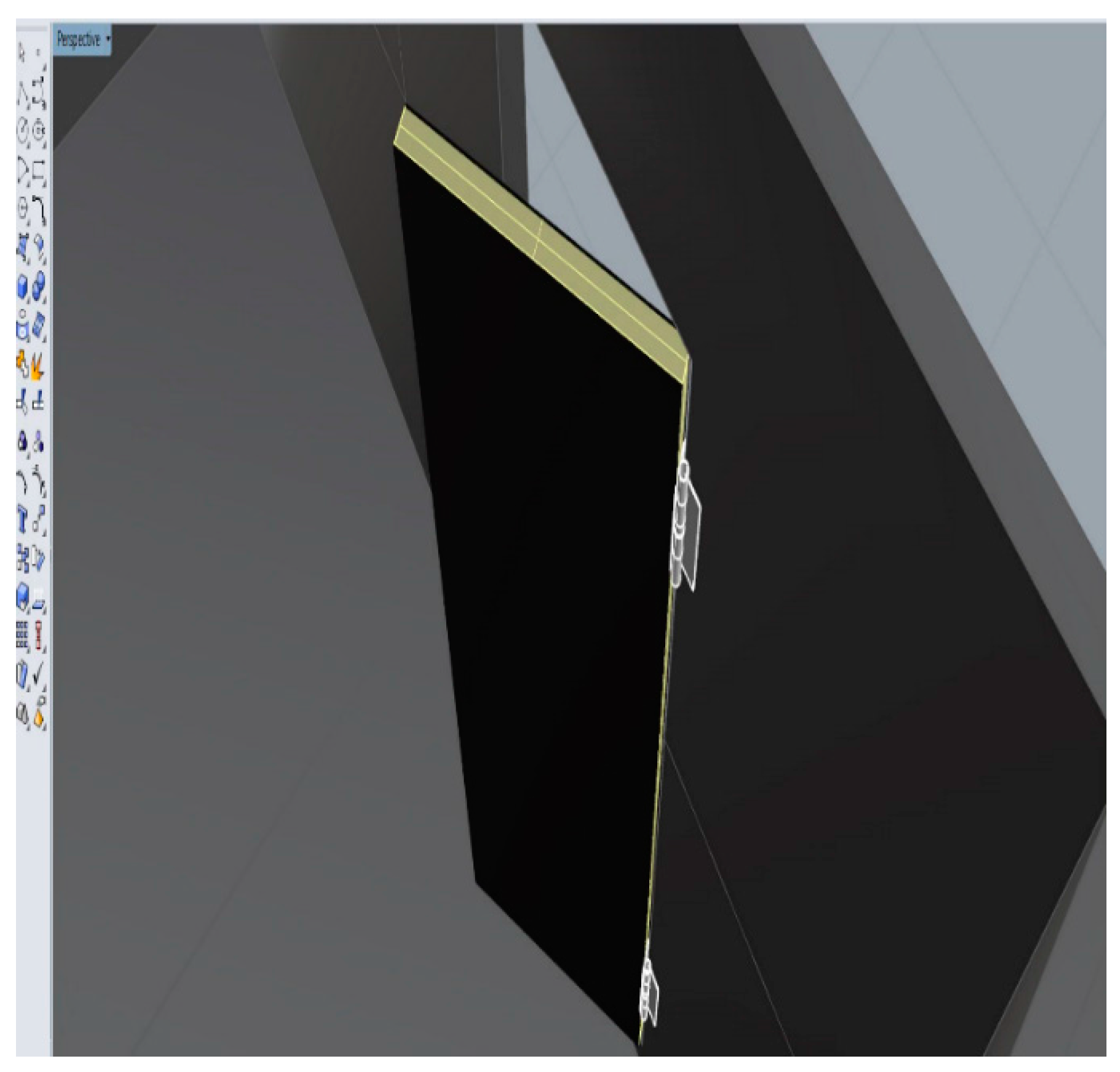

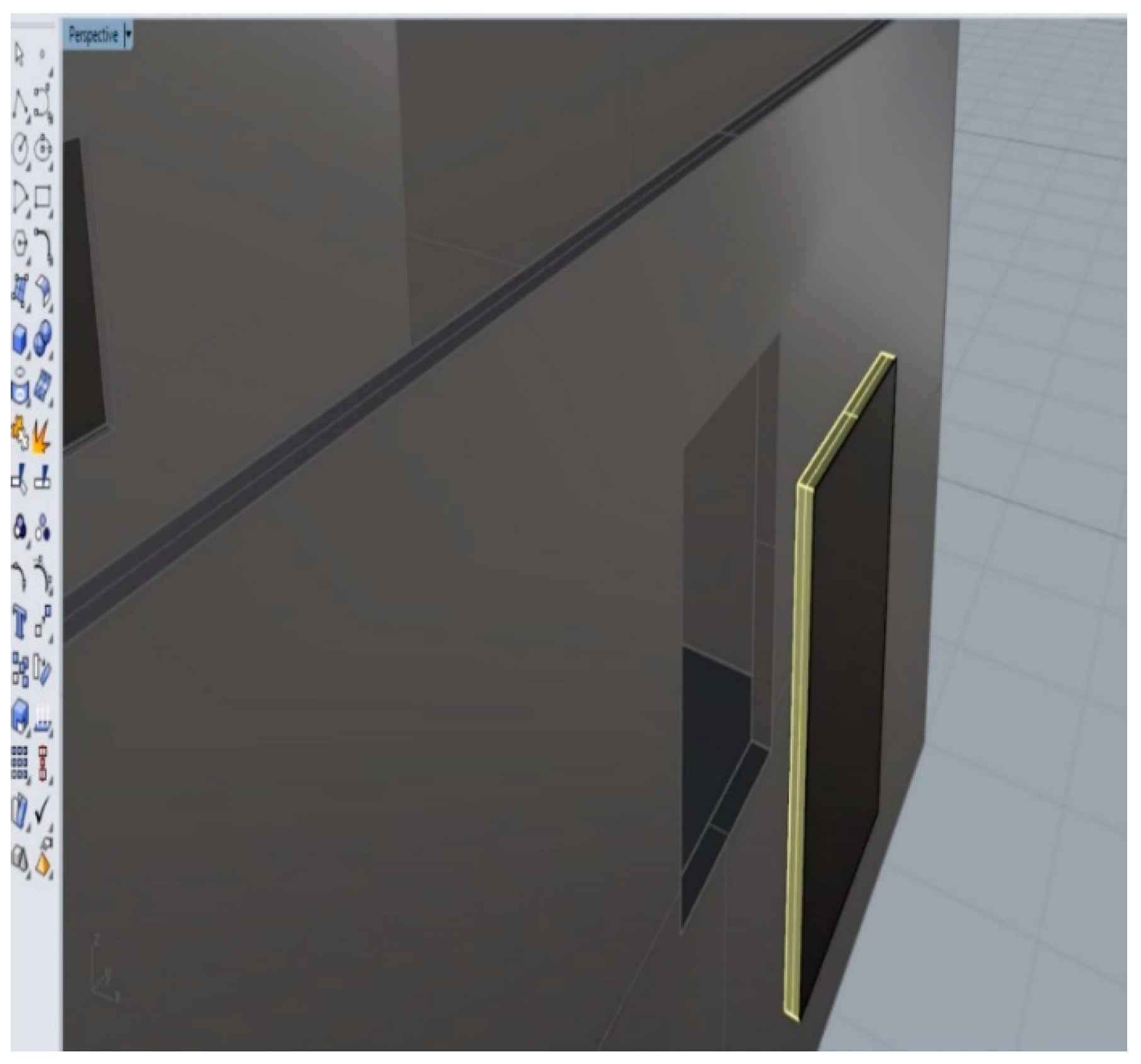

3.2. Doors and Window Covers

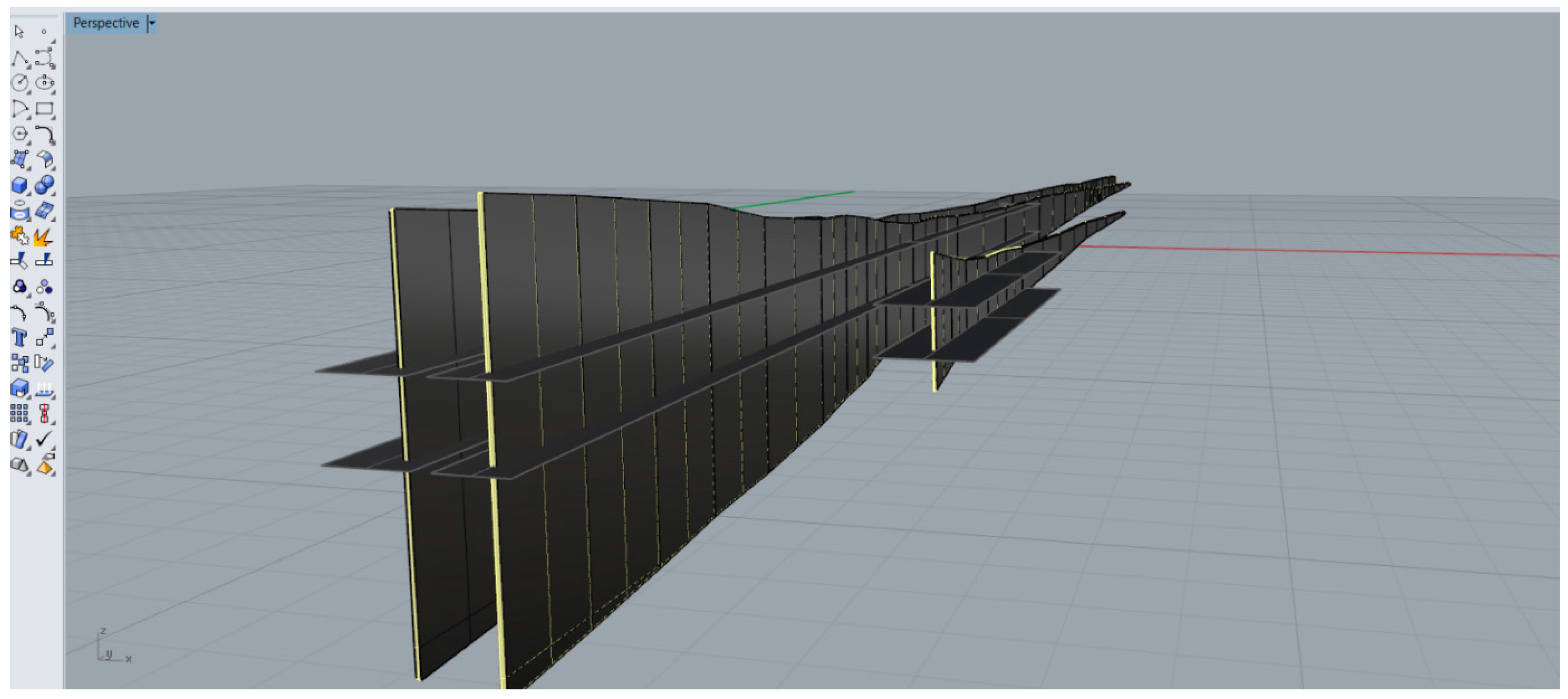

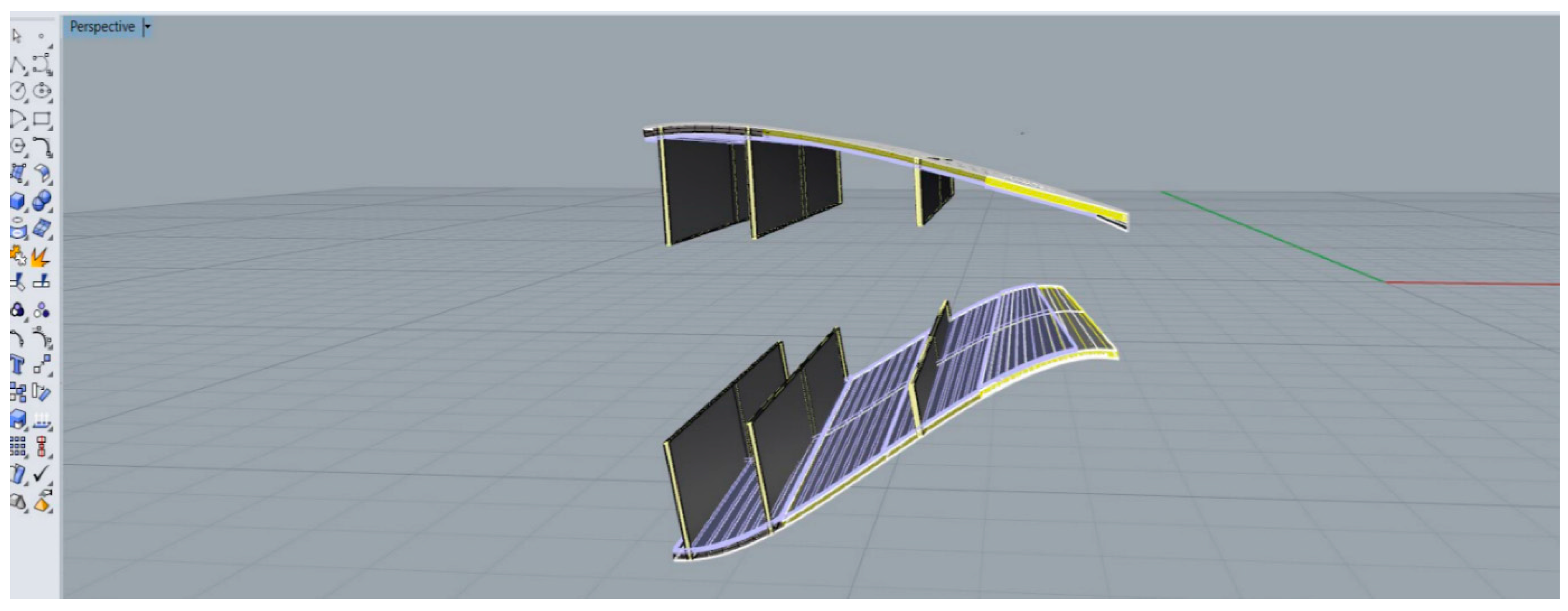

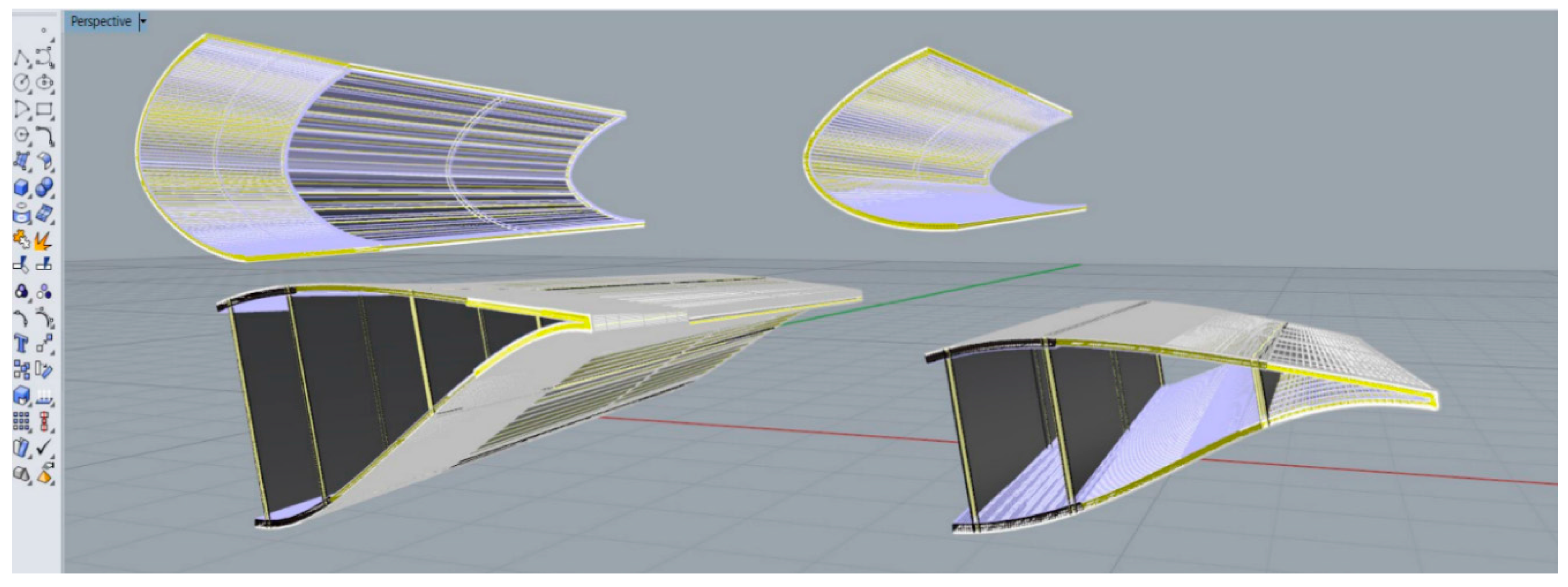

3.3. Roof Frames

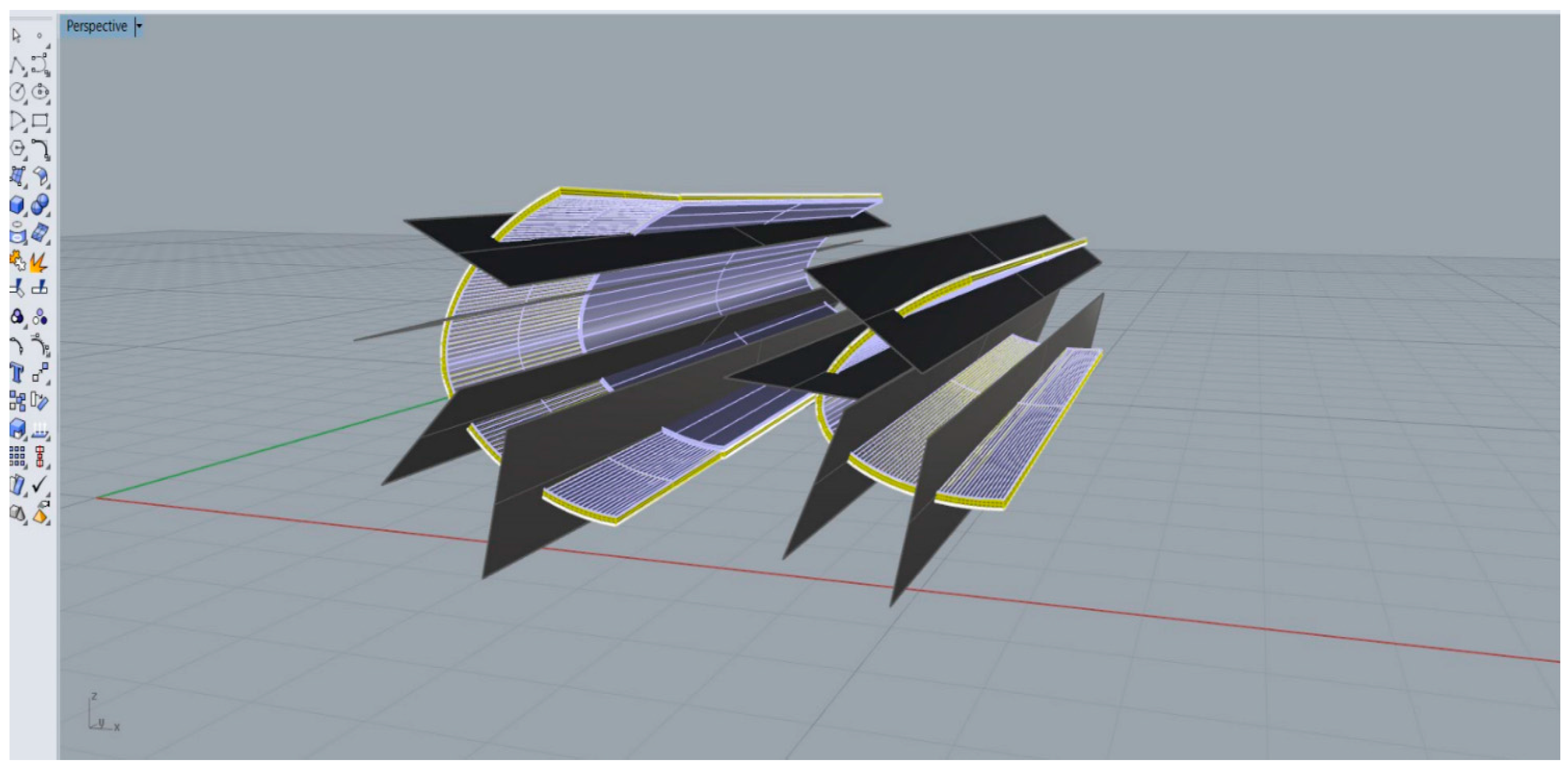

3.4. Interlocking Roof System

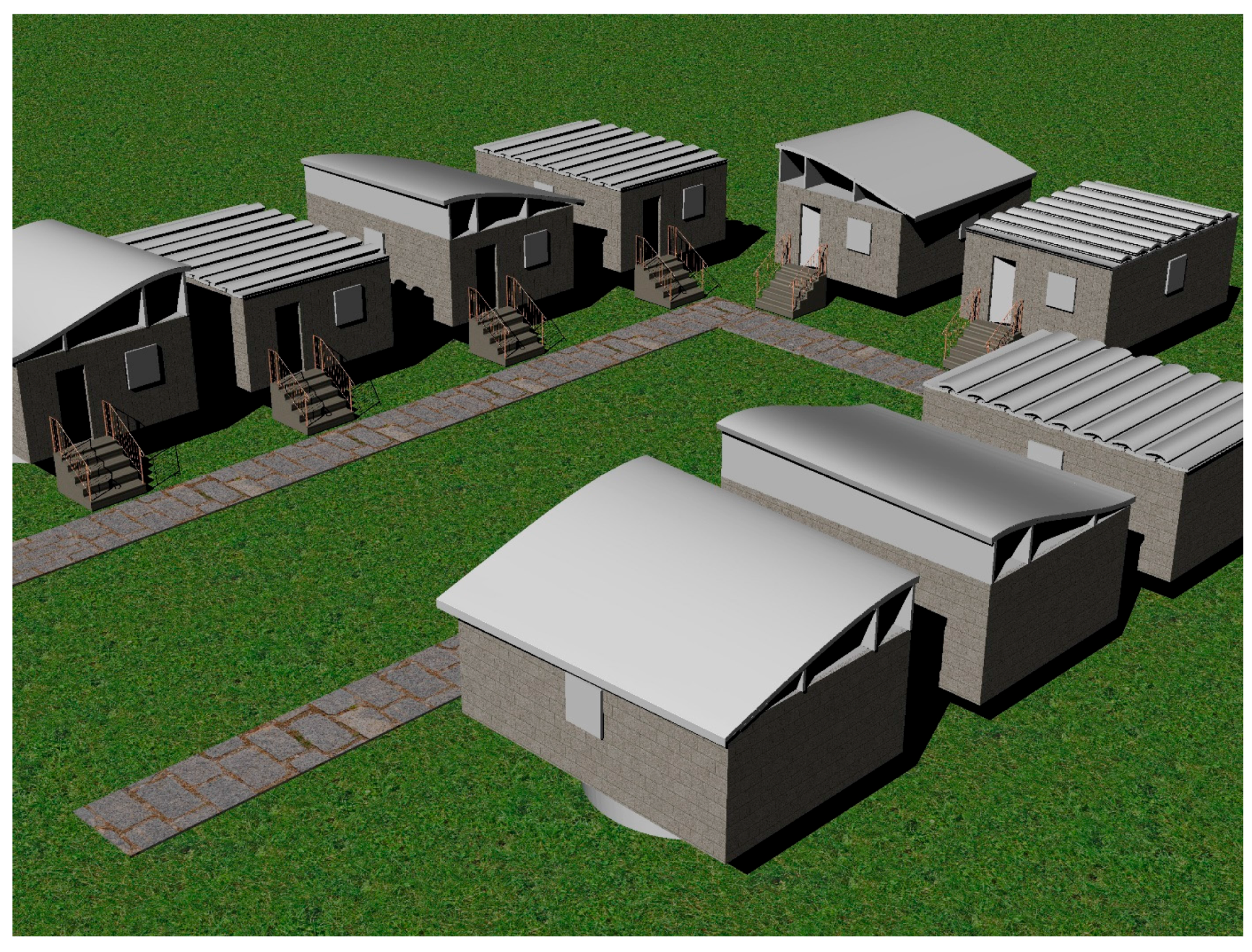

4. A Conceptual Housing Community

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Arias, F.R. Assessment of Present/Future Decommissioned Wind Blade Fiber-Reinforced Composite Material in the United States; Internal Research Report; Department of Civil Engineering, City College of New York: New York, NY, USA, 2016. [Google Scholar] [CrossRef]

- Albers, H.; Greiner, S.; Seifert, H.; Kühne, U. Recycling of Wind Turbine Rotor Blades—Fact or Fiction? (Recycling von Rotorblättern aus Windenergieanlagen—Fakt oder Fiktion?). DEWI Mag. 2009, 34, 32–41. [Google Scholar]

- Welstead, J.; Hirst, R.; Keogh, D.; Robb, G.; Bainsfair, R. Research and Guidance on Restoration and Decommissioning of Onshore Wind Farms. Scottish Natural Heritage Commissioned Report No. 591. 2013. Available online: http://www.snh.org.uk/pdfs/publications/commissioned_reports/591.pdf (accessed on 16 January 2018).

- Liu, P.; Barlow, C.Y. Wind turbine blade waste in 2050. Waste Manag. 2017, 62, 229–240. [Google Scholar] [CrossRef] [PubMed]

- GWEC (Global Wind Energy Council). Global Wind Report—Annual Market Update 2016; Global Wind Energy Council: Brussels, Belgium, 2016; Available online: http://gwec.net/publications/global-wind-report-2/global-wind-report-2016/ (accessed on 16 January 2018).

- GWEC (Global Wind Energy Council). Global Wind Energy Outlook 2016; Global Wind Energy Council: Brussels, Belgium, 2017; Available online: http://gwec.net/publications/global-wind-energy-outlook/global-wind-energy-outlook-2016/ (accessed on 16 January 2018).

- AMDEE, Asociación Mexicana de Energía Eólica (Mexican Wind Power Association). Estimated Wind Energy Capacity in Mexico 2020; Mexican Wind Power Association (AMDEE): Mexico City, Mexico, 2017; Available online: http://www.amdee.org/mapas/parques-eolicos-mexico-2020 (accessed on 16 January 2018).

- Bresko, M.; Cuéllar-Azcárate, M.; Matta, F.; Bank, L.C.; Biles, J.J.; Johnson, A. Overcoming Barriers to Diffusion and Adoption of Sustainable and Resilient Building Materials in Coastal Areas of Southern Mexico—Analysis of 2014 Household Survey Data; Internal Research Report; University of South Carolina: Columbia, SC, USA, 2017. [Google Scholar] [CrossRef]

- Ortegon, K.; Nies, L.; Sutherland, J. Preparing for end of service life of wind turbines. J. Clean. Prod. 2013, 39, 191–199. [Google Scholar] [CrossRef]

- Oliveux, G.; Dandy, L.; Leeke, G. Current status of recycling of fibre reinforced polymers: Review of technologies, reuse and resulting properties. Prog. Mater. Sci. 2015, 72, 61–99. [Google Scholar] [CrossRef]

- Job, S.; Leeke, G.; Mativenga, P.T.; Oliveux, G.; Pickering, S.; Shuaib, N.A. Composites Recycling: Where Are We Now? Composites UK Ltd.: Berkhamsted, UK, 2016. Available online: https://compositesuk.co.uk/system/files/documents/Recycling%20Report%202016.pdf (accessed on 16 January 2018).

- Griffith, T. The SNL100-01 Blade: Carbon Design Studies for the Sandia 100-Meter Blade; SAND2013-1178; Sandia National Laboratories: Albuquerque, NM, USA, 2013. Available online: http://prod.sandia.gov/techlib/access-control.cgi/2013/131178.pdf (accessed on 16 January 2018).

- Berg, J.C.; Resor, B.R. Numerical Manufacturing and Design Tool (NuMAD v2.0) for Wind Turbine Blades: User’s Guide; SAND2012-7028; Sandia National Laboratories: Albuquerque, NM, USA, 2012. Available online: http://energy.sandia.gov/energy/renewable-energy/wind-power/rotor-innovation/numerical-manufacturing-and-design-tool-numad/ (accessed on 16 January 2018).

- Robert McNeel & Associates. Rhino 3D. Rhinoceros 3D; Robert McNeel & Associates: Seattle, WA, USA, 2017; Available online: www.rhino3d.com (accessed on 16 January 2018).

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bank, L.C.; Arias, F.R.; Yazdanbakhsh, A.; Gentry, T.R.; Al-Haddad, T.; Chen, J.-F.; Morrow, R. Concepts for Reusing Composite Materials from Decommissioned Wind Turbine Blades in Affordable Housing. Recycling 2018, 3, 3. https://doi.org/10.3390/recycling3010003

Bank LC, Arias FR, Yazdanbakhsh A, Gentry TR, Al-Haddad T, Chen J-F, Morrow R. Concepts for Reusing Composite Materials from Decommissioned Wind Turbine Blades in Affordable Housing. Recycling. 2018; 3(1):3. https://doi.org/10.3390/recycling3010003

Chicago/Turabian StyleBank, Lawrence C., Franco R. Arias, Ardavan Yazdanbakhsh, T. Russell Gentry, Tristan Al-Haddad, Jian-Fei Chen, and Ruth Morrow. 2018. "Concepts for Reusing Composite Materials from Decommissioned Wind Turbine Blades in Affordable Housing" Recycling 3, no. 1: 3. https://doi.org/10.3390/recycling3010003