Cross-Characterization for Imaging Parasitic Resistive Losses in Thin-Film Photovoltaic Modules

Abstract

:1. Introduction

2. Experimental Details

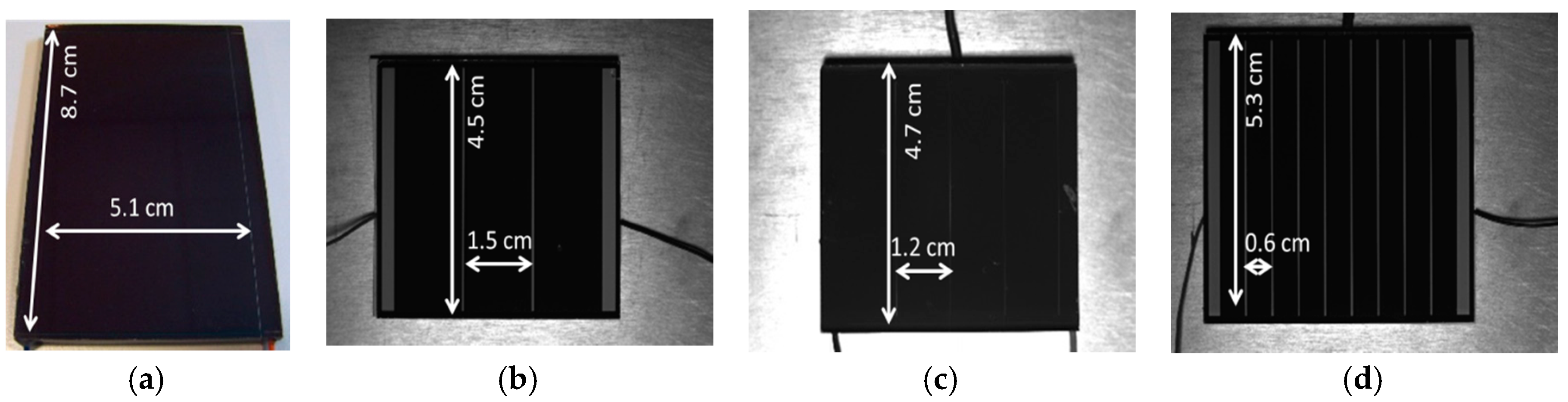

2.1. Samples

2.2. Spatially-Resolved Characterization Techniques

2.2.1. Current Dependent Electroluminescence Imaging

2.2.2. Dark and Illuminated Lock-In Thermography

2.2.3. Limited-Light Beam Induced Current

3. Results and Discussion

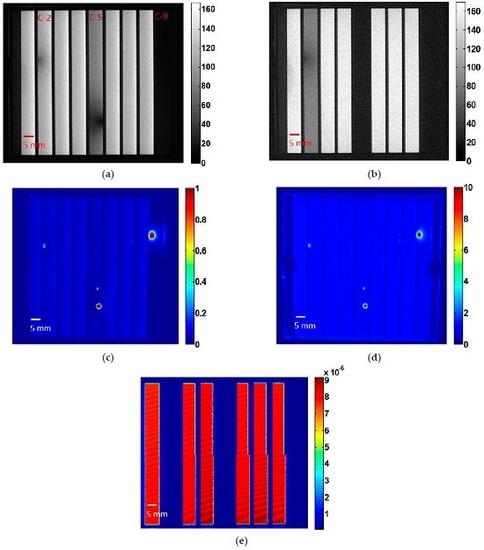

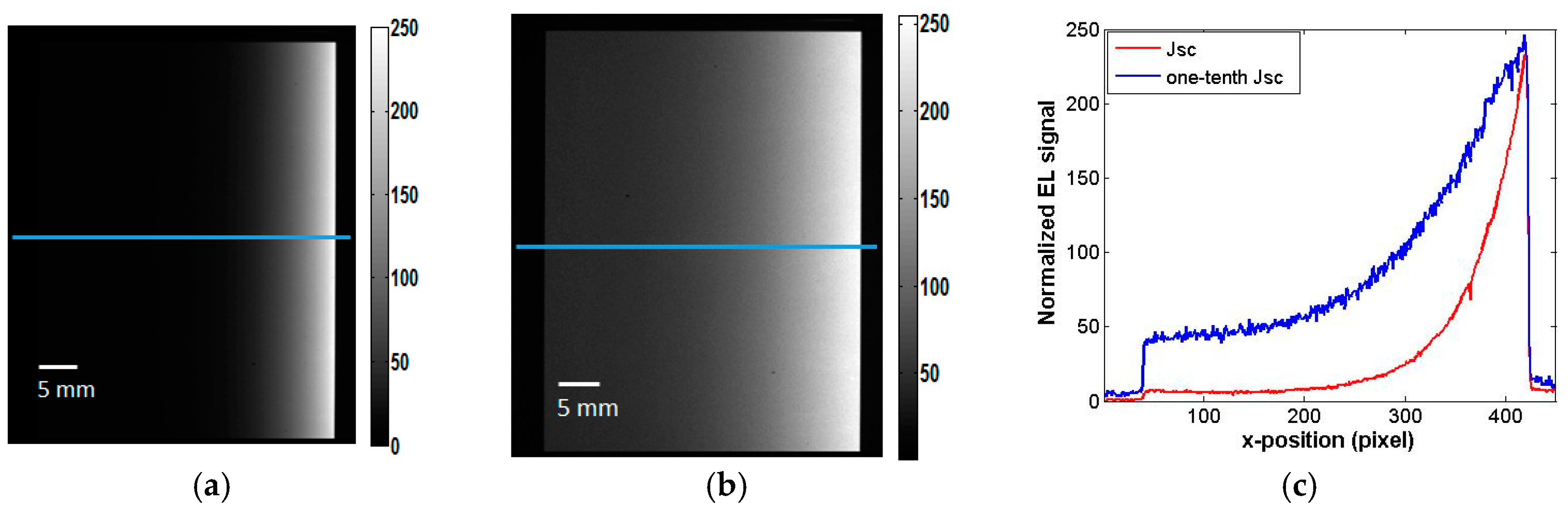

3.1. TCO Lateral Resistance Imaging

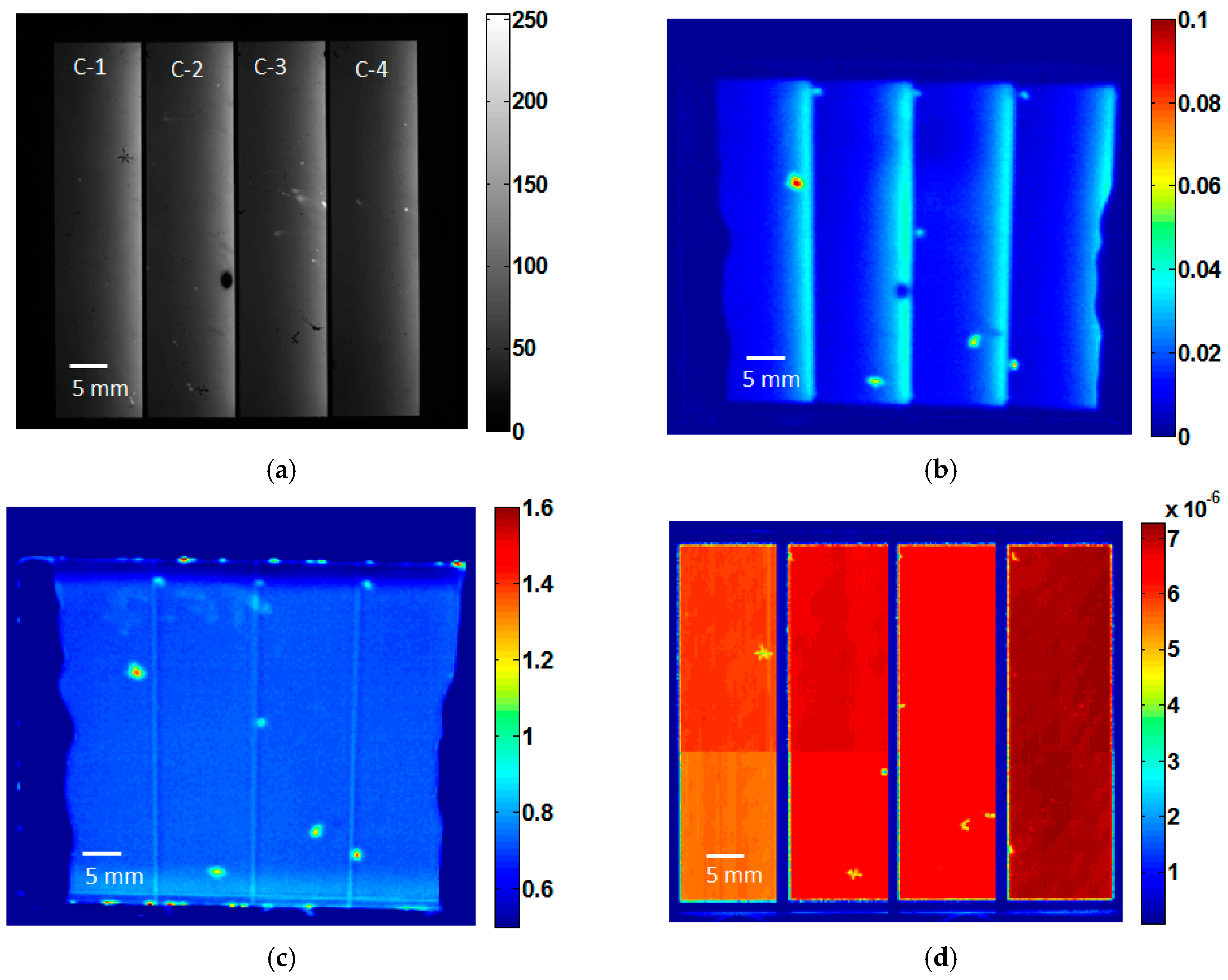

3.2. Shunts Imaging

3.3. Scratches Imaging

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| PV | Photovoltaic |

| TCO | Transparent Conductive Oxide |

| EL | Electroluminescence |

| LIT | Lock-in thermography |

| LBIC | Light beam induced current |

References

- Brecl, K.; Topič, M.; Smole, F. A detailed study of monolithic contacts and electrical losses in a large-area thin-film module. Prog. Photovolt. Res. Appl. 2005, 13, 297–310. [Google Scholar] [CrossRef]

- Lee, S.S.; Kim, Y.N.; Shin, H.G. Thermal Degradation Behavior of Aluminum-Doped Zinc-Oxide Thin Films Prepared by Using a Sol-Gel Process. J. Korean Phys. Soc. 2008, 53, 188–191. [Google Scholar]

- Lemire, H.M.; Peterson, K.A.; Sprawls, S.; Singer, K.; Martin, I.T.; French, R.H. Degradation of transparent conductive oxides: Mechanistic insights across configurations and exposures. In Proceedings of the SPIE 8825, Reliability of Photovoltaic Cells, Modules, Components and Systems VI, San Diego, CA, USA, 25 August 2013.

- Mirletz, H.M.; Peterson, K.A.; Martin, I.T.; French, R.H. Degradation of transparent conductive oxides: Interfacial engineering and mechanistic insights. Sol. Energy Mater. Sol. Cells 2015, 143, 529–538. [Google Scholar] [CrossRef]

- Dongaonkar, S.; Servaites, J.D.; Ford, G.M. Universality of non-ohmic shunt leakage in thin-film solar cells. J. Appl. Phys. 2010, 108, 124509. [Google Scholar] [CrossRef]

- Fortes, M.; Comesaña, E.; Rodriguez, J.A.; Otero, P.; Garcia-Loureiro, A.J. Impact of series and shunt resistances in amorphous silicon thin film solar cells. Sol. Energy 2014, 100, 114–123. [Google Scholar] [CrossRef]

- Lapinski, M.; Domaradzki, J.; Prociow, E.L.; Sieradzka, K.; Gornicka, B. Electrical and optical characterization of ITO thin films. In International Students and Young Scientists Workshop “Photonics and Microsystems”; IEEE: Wernigerode, Germany, 2009; pp. 52–55. [Google Scholar]

- Szitasi, G.; Korsos, F.; Selmeczi, D. Integrated Electrical and Optical Characterization of Large Area Thin Film Photovoltaic Materials. In Proceedings of the 38th IEEE Photovoltaic Specialists Conference, Austin, TX, USA, 3–8 June 2012; pp. 474–478.

- Fuyuki, T.; Kondo, H.; Yamazaki, T.; Takahashi, Y.; Uraoka, Y. Photographic surveying of minority carrier diffusion length in polycrystalline silicon solar cells by electroluminescence. Appl. Phys. Lett. 2005, 86, 262108. [Google Scholar] [CrossRef]

- Fuyuki, T.; Kondo, H.; Kaji, Y.; Ogane, A.; Takahashi, Y. Analytic findings in the electroluminescence characterization of crystalline silicon solar cells. J. Appl. Phys. 2007, 10, 023711. [Google Scholar] [CrossRef]

- Breitenstein, O.; Rakotoniaina, J.P.; Al Rifai, M.H. Quantitative Evaluation of Shunts in Solar Cells by Lock-in Thermography. Prog. Photovolt. Res. Appl. 2003, 11, 515–526. [Google Scholar] [CrossRef]

- Breitenstein, O.; Gupta, R.; Schneider, J. Surface potential mapping on crystalline silicon on glass solar modules. J. Appl. Phys. 2007, 102, 024511. [Google Scholar] [CrossRef]

- Filipič, M.; Holman, Z.C.; Smole, F.; De Wolf, S.; Ballif, C.; Topič, M. Analysis of lateral transport through the inversion layer in amorphous silicon/crystalline silicon heterojunction solar cells. J. Appl. Phys. 2013, 114, 074504. [Google Scholar] [CrossRef]

- Fecher, F.W.; Adams, J.; Vetter, A.; Buerhop-Lutz, C.; Brabec, C.J. Loss analysis on CIGS-modules by using contactless, imaging illuminated lock-in thermography and 2D electrical simulations. In Proceedings of the 40th IEEE Photovoltaic Specialist Conference, Denver, CO, USA, 8–13 June 2014; pp. 3331–3334.

- Bachmann, J.; Buerhop-Lutz, C.; Steim, R. Highly sensitive non-contact shunt detection of organic photovoltaic modules. Sol. Energy Mater. Sol. Cells 2012, 101, 176–179. [Google Scholar] [CrossRef]

- Seeland, M.; Rösch, R.; Muhsin, B.; Gobsch, G.; Hoppe, H. Electroluminescence as characterization tool for polymer solar cells and modules. Energy Procedia 2011, 31, 167–172. [Google Scholar] [CrossRef]

- Rösch, R.; Krebs, F.C.; Tanenbaum, D.M.; Hoppe, H. Quality control of roll-to-roll processed polymer solar modules by complementary imaging methods. Sol. Energy Mater. Sol. Cells 2012, 97, 176–180. [Google Scholar] [CrossRef]

- Runai, F.R.; Schwäble, F.; Walter, T. Imaging and performance of CIGS thin film modules. In Proceedings of the 37th IEEE Photovoltaic Specialist Conference, Seattle, WA, USA, 19–24 June 2011; pp. 3399–3403.

- Zaunbrecher, K.; Johnston, S.; Sites, J.R. Analysis of thin-film inhomogeneities using electroluminescence and LBIC measurements. In Proceedings of the 39th IEEE Photovoltaic Specialists Conference, Tampa, FL, USA, 16–21 June 2013; pp. 166–169.

- Feron, K.; Nagle, T.J.; Rozanski, L.J.; Gong, B.B.; Fell, C.J. Spatially resolved photocurrent measurements of organic solar cells: Tracking water ingress at edges and pinholes. Sol. Energy Mater. Sol. Cells 2013, 109, 169–177. [Google Scholar] [CrossRef]

- Besold, S.; Hoyer, U.; Bachmann, J.; Swonke, T.; Schilinsky, P.; Steim, R.; Brabec, C.J. Quantitative imaging of shunts in organic photovoltaic modules using lock-in thermography. Sol. Energy Mater. Sol. Cells 2014, 124, 133–137. [Google Scholar] [CrossRef]

- Bliss, M.; Wu, X.; Bedrich, K.G.; Bowers, J.W.; Betts, T.R.; Gottschalg, R. Spatially and spectrally resolved electroluminescence measurement system for photovoltaic characterisation. IET Renew. Power Gener. 2015, 9, 446–452. [Google Scholar] [CrossRef] [Green Version]

- Helbig, A.; Kirchartz, T.; Schaeffler, R.; Werner, J.H.; Rau, U.H. Quantitative electroluminescence analysis of resistive losses in Cu(In,Ga)Se2 thin-film modules. Sol. Energy Mater. Sol. Cells 2010, 94, 979–984. [Google Scholar] [CrossRef]

- Seeland, M.; Rösch, R.; Hoppe, H. Quantitative analysis of electroluminescence images from polymer solar cells. J. Appl. Phys. 2012, 111, 024505. [Google Scholar] [CrossRef]

- Wu, X.; Bliss, M.; Sinha, A.; Betts, T.; Gupta, R.; Gottschalg, R. Distributed electrical network modelling approach for spatially resolved characterisation of photovoltaic modules. IET Renew. Power Gener. 2014, 8, 459–466. [Google Scholar] [CrossRef] [Green Version]

- Courtois, G.; Fuyuki, T.; Tani, A.; Salomon, A.; Cabarrocas, P.R. Quantitative assessment of TCO sheet resistance in thin-film silicon devices from electroluminescence images. In Proceedings of the 28th European Photovoltaic Solar Energy Conference and Exhibition, Paris, France, 30 September–4 October 2013; pp. 2484–2488.

- Paire, M.; Lombez, L.; Guillemoles, J.F.; Lincot, D. Measuring sheet resistance of CIGS solar cell's window layer by spatially resolved electroluminescence imaging. Thin Solid Films 2011, 519, 7493–7496. [Google Scholar] [CrossRef]

- Shvydka, D.; Rakotoniaina, J.P.; Breitenstein, O. Lock-in thermography and nonuniformity modeling of thin-film CdTe solar cells. Appl. Phys. Lett. 2004, 84, 729–731. [Google Scholar] [CrossRef]

- Breitenstein, O.; Langenkamp, M.; Lang, O.; Schirrmacher, A. Shunts due to laser scribing of solar cells evaluated by highly sensitive lock-in thermography. Sol. Energy Mater. Sol. Cells 2001, 65, 55–62. [Google Scholar] [CrossRef]

- Zhang, L.; Xu, X.; Yang, Z.; Sun, X.; Xu, H.; Liu, H.; Shen, H. An efficient method for monitoring the shunts in silicon solar cells during fabrication processes with infrared imaging. J. Semicond. 2009, 30, 1–4. [Google Scholar]

- Chung, T.; Wang, C.H.; Chang, K.J.; Chen, S.Y.; Hsieh, H.H.; Huang, C.P.; Cheng, C.H.A. Evaluation of the spatial distribution of series and shunt resistance of a solar cell using dark lock-in thermography. J. Appl. Phys. 2014, 115, 034901. [Google Scholar] [CrossRef]

- Kasemann, M.; Schubert, M.C.; The, M.; Köber, M.; Hermle, M.; Warta, W. Comparison of luminescence imaging and illuminated lock-in thermography on silicon solar cells. Appl. Phys. Lett. 2006, 89, 224102. [Google Scholar] [CrossRef]

- Colvin, J. Comparative Failure Analysis of Photovoltaic Devices. In Proceedings of the 35th International Symposium for Testing and Failure Analysis, San Jose, CA, USA, 14–19 November 2009; pp. 149–156.

- Wehrmann, A.; Puttnins, S.; Hartmann, L.; Ehrhardt, M.; Lorenz, P.; Zimmer, K. Analysis of laser scribes at CIGS thin-film solar cells by localized electrical and optical measurements. Opt. Laser Technol. 2012, 44, 1753–1757. [Google Scholar] [CrossRef]

- Brooks, W.S.M.; Irvine, S.J.C.; Barrioz, V.; Clayton, A.J. Laser beam induced current measurements of Cd1−xZnxS/CdTe solar cells. Sol. Energy Mater. Sol. Cells 2012, 101, 26–31. [Google Scholar] [CrossRef]

- Würfel, P.; Trupke, T.; Puzzer, T.; Schäffer, E.; Warta, W.; Glunz, S.W. Diffusion lengths of silicon solar cells from luminescence images. J. Appl. Phys. 2007, 101, 123110. [Google Scholar] [CrossRef]

- Hinken, D.; Ramspeck, K.; Bothe, K.; Fischer, B.; Brendel, R. Series resistance imaging of solar cells by voltage dependent electroluminescence. Appl. Phys. Lett. 2007, 91, 182104. [Google Scholar] [CrossRef]

- Kajari-Schröder, S.; Kunze, I.; Köntges, M. Criticality of cracks in PV modules. Energy Procedia 2012, 27, 658–663. [Google Scholar] [CrossRef]

- Pankove, J.I. Radiative Recombination in Hydrogenated Amorphous Silicon. Czechoslov. J. Phys. B 1980, 30, 355–364. [Google Scholar] [CrossRef]

- Wang, K.; Han, D.; Silver, M.; Branz, H.M. Electroluminescence studies of recombination in hydrogenated amorphous silicon p-i-n devices. Sol. Energy 1991, 30, 219–225. [Google Scholar] [CrossRef]

- Fuyuki, T.; Kitiyanan, A. Photographic diagnosis of crystalline silicon solar cells utilizing electroluminescence. Appl. Phys. A Mater. Sci. Process. 2009, 96, 189–196. [Google Scholar] [CrossRef]

- Fuyuki, T.; Tani, A.; Tsujii, S.; Sugimura, E. Photographic distinction of defects in polycrystalline Si by spectroscopic electroluminescence. In Proceedings of the 35th IEEE Photovoltaic Specialists Conference, Honolulu, HI, USA, 20–25 June 2010; pp. 1380–1382.

- Predatsch, H.; Heinzmann, U.; Stiebig, H. Thin-film silicon solar cell and module analysis by electroluminescence. Energy Procedia 2014, 60, 71–75. [Google Scholar] [CrossRef]

- Breitenstein, O.; Warta, W.; Langenkamp, M. Lock-in Thermography—Basics and Use for Evaluating Electronic Devices and Materials, 2nd ed.; Springer: Heidelberg, Germany, 2010; pp. 213–214. [Google Scholar]

- Vorasayan, P.; Betts, T.R.; Gottschalg, R. Spatially distributed model for the analysis of laser beam induced current (LBIC) measurements of thin film silicon solar modules. Sol. Energy Mater. Sol. Cells 2011, 95, 111–114. [Google Scholar] [CrossRef]

- Roschier, S.; Agostinelli, G.; Dunlop, E.D. Laser scanning of amorphous silicon photovoltaic modules with different bias conditions. Opto-Electron. Rev. 2000, 8, 328–332. [Google Scholar]

- Gerber, A.; Huhn, V.; Tran, T.M.H. Advanced large area characterization of thin- film solar modules by electroluminescence and thermography imaging techniques. Sol. Energy Mater. Sol. Cells 2015, 135, 35–42. [Google Scholar] [CrossRef]

| Module Name | No. of Cells | Maximum Power, Pm (W) | Current Density, Jsc (mA/cm2) | Voc per Unit Cell, (V) | Fill Factor, FF (%) | Efficiency, η (%) | Cell Rs (Ω cm2) | Cell Rsh (Ω cm2) |

|---|---|---|---|---|---|---|---|---|

| TF-1 | 1 | 0.14 | 10.4 | 0.90 | 33.4 | 3.4 | 33.7 | 92 |

| TF-3 | 3 | 0.12 | 13.5 | 0.88 | 49.9 | 6.8 | 22.1 | 567 |

| TF-4 | 4 | 0.15 | 12.9 | 0.91 | 57.6 | 6.7 | 15.8 | 753 |

| TF-9 | 9 | 0.14 | 10.7 | 0.87 | 53.9 | 6.0 | 19.0 | 769 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sinha, A.; Bliss, M.; Wu, X.; Roy, S.; Gottschalg, R.; Gupta, R. Cross-Characterization for Imaging Parasitic Resistive Losses in Thin-Film Photovoltaic Modules. J. Imaging 2016, 2, 23. https://doi.org/10.3390/jimaging2030023

Sinha A, Bliss M, Wu X, Roy S, Gottschalg R, Gupta R. Cross-Characterization for Imaging Parasitic Resistive Losses in Thin-Film Photovoltaic Modules. Journal of Imaging. 2016; 2(3):23. https://doi.org/10.3390/jimaging2030023

Chicago/Turabian StyleSinha, Archana, Martin Bliss, Xiaofeng Wu, Subinoy Roy, Ralph Gottschalg, and Rajesh Gupta. 2016. "Cross-Characterization for Imaging Parasitic Resistive Losses in Thin-Film Photovoltaic Modules" Journal of Imaging 2, no. 3: 23. https://doi.org/10.3390/jimaging2030023

APA StyleSinha, A., Bliss, M., Wu, X., Roy, S., Gottschalg, R., & Gupta, R. (2016). Cross-Characterization for Imaging Parasitic Resistive Losses in Thin-Film Photovoltaic Modules. Journal of Imaging, 2(3), 23. https://doi.org/10.3390/jimaging2030023