The Influence of Temperature on Anisotropic Wettability Revealed by Friction Force Measurement

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Preparation

2.2. Characterization

3. Results and Discussion

3.1. Geometry of the GP-MA

3.2. Interfacial Interaction of a Water Droplet on the GP-MA at Room Temperature

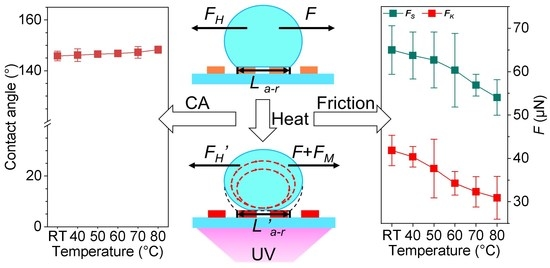

3.3. Liquid-Solid Friction Measurement on the GP-MA at Elevated Temperatures

3.4. Liquid-Solid Friction on the GP-MA under Various Elongations

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, H.; Zhang, P.; Zhang, L.; Liu, H.; Jiang, Y.; Zhang, D.; Han, Z.; Jiang, L. Continuous Directional Water Transport on the Peristome Surface of Nepenthes alata. Nature 2016, 532, 85–89. [Google Scholar] [CrossRef]

- Zheng, Y.; Gao, X.; Jiang, L. Directional Adhesion of Superhydrophobic Butterfly Wings. Soft Matter 2007, 3, 178–182. [Google Scholar] [CrossRef]

- Feng, L.; Li, S.; Li, Y.; Li, H.; Zhang, L.; Zhai, J.; Song, Y.; Liu, B.; Jiang, L.; Zhu, D. Super-Hydrophobic Surfaces: From Natural to Artificial. Adv. Mater. 2002, 14, 1857–1860. [Google Scholar] [CrossRef]

- Qian, Z.; Zhang, S.; Xue, L. Numerical Study of Mitigating Cloud Cavitation Shedding Using Biomimetic Protuberant Stripes. J. Fluids Eng. 2022, 144, 091201. [Google Scholar] [CrossRef]

- Xu, P.; Zhang, Y.; Li, L.; Lin, Z.; Zhu, B.; Chen, W.; Li, G.; Liu, H.; Xiao, K.; Xiong, Y.; et al. Adhesion Behaviors of Water Droplets on Bioinspired Superhydrophobic Surfaces. Bioinspir. Biomim. 2022, 17, 041003. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Han, X.; Li, W.; Yang, L.; Li, X.; Wang, L. Nature-Inspired Reentrant Surfaces. Prog. Mater. Sci. 2023, 133, 101064. [Google Scholar] [CrossRef]

- Yu, C.; Liu, M.; Zhang, C.; Yan, H.; Zhang, M.; Wu, Q.; Liu, M.; Jiang, L. Bio-Inspired Drag Reduction: From Nature Organisms to Artificial Functional Surfaces. Giant 2020, 2, 100017. [Google Scholar] [CrossRef]

- Si, Y.; Dong, Z.; Jiang, L. Bioinspired Designs of Superhydrophobic and Superhydrophilic Materials. ACS Cent. Sci. 2018, 4, 1102–1112. [Google Scholar] [CrossRef]

- Parker, A.; Lawrence, C. Water Capture by a Desert Beetle. Nature 2001, 414, 33–34. [Google Scholar] [CrossRef]

- Jiang, M.; Wang, Y.; Liu, F.; Du, H.; Li, Y.; Zhang, H.; To, S.; Wang, S.; Pan, C.; Yu, J.; et al. Inhibiting the Leidenfrost Effect above 1000 °C for Sustained Thermal Cooling. Nature 2022, 601, 568–572. [Google Scholar] [CrossRef]

- Liu, C.; Lu, C.; Yuan, Z.; Lv, C.; Liu, Y. Steerable Drops on Heated Concentric Microgroove Arrays. Nat. Commun. 2022, 13, 3141. [Google Scholar] [CrossRef] [PubMed]

- Zhao, W.; Jiang, Y.; Yu, W.; Yu, Z.; Liu, X. Wettability Controlled Surface for Energy Conversion. Small 2022, 18, 2202906. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Hou, Y.; Liu, Y.; Hao, C.; Li, M.; Chaudhury, M.; Yao, S.; Wang, Z. Directional Transport of High-Temperature Janus Droplets Mediated by Structural Topography. Nat. Phys. 2016, 12, 606–612. [Google Scholar] [CrossRef]

- Vakarelski, I.; Marston, J.; Chan, D.; Thoroddsen, S. Drag Reduction by Leidenfrost Vapor Layers. Phys. Rev. Lett. 2011, 106, 214501. [Google Scholar] [CrossRef]

- Song, M.; Hu, D.; Zheng, X.; Wang, L.; Yu, Z.; An, W.; Na, R.; Li, C.; Li, N.; Lu, Z.; et al. Enhancing Droplet Deposition on Wired and Curved Superhydrophobic Leaves. ACS Nano 2019, 13, 7966–7974. [Google Scholar] [CrossRef]

- Linke, H.; Alemán, B.; Melling, L.; Taormina, M.; Francis, M.; Dow-Hygelund, C.; Narayanan, V.; Taylor, R.; Stout, A. Self-Propelled Leidenfrost Droplets. Phys. Rev. Lett. 2006, 96, 154502. [Google Scholar] [CrossRef]

- Lagubeau, G.; Le Merrer, M.; Clanet, C.; Quéré, D. Leidenfrost on a Ratchet. Nat. Phys. 2011, 7, 395–398. [Google Scholar] [CrossRef]

- Li, Q.; Li, L.; Shi, K.; Yang, B.; Wang, X.; Shi, Z.; Tan, D.; Meng, F.; Liu, Q.; Hu, S.; et al. Reversible Structure Engineering of Bioinspired Anisotropic Surface for Droplet Recognition and Transportation. Adv. Sci. 2020, 7, 2001650. [Google Scholar] [CrossRef]

- Zhang, J.; Li, L.; Xu, P.; Lei, Y.; Song, Q.; Liu, J.; Xiong, Y.; Yang, S.; Zhang, Y.; Xue, L. Anisotropic Wettability of Bioinspired Surface Characterized by Friction Force. Biomimetics 2022, 7, 108. [Google Scholar] [CrossRef]

- Shi, K.; Li, Q.; Zhang, J.; Li, L.; Yang, B.; Hu, S.; Lei, Y.; Liu, Z.; Liu, S.; Xue, L. Quantitative Characterization of Surface Wettability by Friction Force. Appl. Surf. Sci. 2021, 536, 147788. [Google Scholar] [CrossRef]

- Zhang, J.; Shi, K.; Xu, P.; Li, Q.; Xue, L. The dynamic regulation of friction force of a water droplet on goose bumps-inspired surfaces. Surf. Tech. 2021, 50, 66–73. [Google Scholar] [CrossRef]

- Luo, X.; Lai, H.; Cheng, Z.; Liu, P.; Li, Y.; Yu, X.; Liu, Y. Slippery Shape Memory Polymer Arrays with Switchable Isotropy/Anisotropy and Its Application as a Reprogrammable Platform for Controllable Droplet Motion. Chem. Eng. J. 2021, 403, 126356. [Google Scholar] [CrossRef]

- Wang, Y.; Lai, H.; Cheng, Z.; Zhang, H.; Liu, Y.; Jiang, L. Smart Superhydrophobic Shape Memory Adhesive Surface toward Selective Capture/Release of Microdroplets. ACS Appl. Mater. Interfaces 2019, 11, 10988–10997. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Jiao, Y.; Zhang, Y.; Jiang, S.; Lv, X.; Wu, S.; Li, J.; Hu, Y.; Ye, J.; Liu, K.; et al. Noncontact All-In-Situ Reversible Reconfiguration of Femtosecond Laser-Induced Shape Memory Magnetic Microcones for Multifunctional Liquid Droplet Manipulation and Information Encryption. Adv. Funct. Mater. 2021, 31, 2100543. [Google Scholar] [CrossRef]

- Hwang, H.; Papadopoulos, P.; Fujii, S.; Wooh, S. Driving Droplets on Liquid Repellent Surfaces via Light-Driven Marangoni Propulsion. Adv. Funct. Mater. 2022, 32, 2111311. [Google Scholar] [CrossRef]

- Gao, C.; Wang, L.; Lin, Y.; Li, J.; Liu, Y.; Li, X.; Feng, S.; Zheng, Y. Droplets Manipulated on Photothermal Organogel Surfaces. Adv. Funct. Mater. 2018, 28, 1803072. [Google Scholar] [CrossRef]

- Manabe, K.; Saito, K.; Nakano, M.; Ohzono, T.; Norikane, Y. Light-Driven Liquid Conveyors: Manipulating Liquid Mobility and Transporting Solids on Demand. ACS Nano 2022, 16, 16353–16362. [Google Scholar] [CrossRef]

- Wang, F.; Liu, M.; Liu, C.; Zhao, Q.; Wang, T.; Wang, Z.; Du, X. Light-Induced Charged Slippery Surfaces. Sci. Adv. 2022, 8, eabp9369. [Google Scholar] [CrossRef]

- Han, K.; Wang, Z.; Heng, L.; Jiang, L. Photothermal Slippery Surfaces towards Spatial Droplet Manipulation. J. Mater. Chem. A 2021, 9, 16974–16981. [Google Scholar] [CrossRef]

- Zhao, D.; Sun, Y.; Liu, C.; Zhan, H.; Wang, M.; Liu, J.; Liu, Y. Temperature-Regulated Directional Bounce of Impacting Droplets on Gradient Grooves. Surf. Coat. Technol. 2018, 356, 132–137. [Google Scholar] [CrossRef]

- Wang, X.; Tan, D.; Hu, S.; Li, Q.; Yang, B.; Shi, Z.; Das, R.; Xu, X.; Wu, Z.; Xue, L. Reversible Adhesion via Light-Regulated Conformations of Rubber Chains. ACS Appl. Mater. Interfaces 2019, 11, 46337–46343. [Google Scholar] [CrossRef] [PubMed]

- Malard, L.; Pimenta, M.; Dresselhaus, G.; Dresselhaus, M. Raman Spectroscopy in Graphene. Phys. Rep. 2009, 473, 51–87. [Google Scholar] [CrossRef]

- Khan, U.; O’Neill, A.; Lotya, M.; De, S.; Coleman, J. High-Concentration Solvent Exfoliation of Graphene. Small 2010, 6, 864–871. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Ren, W.; Gao, L.; Liu, B.; Jiang, C.; Cheng, H. Synthesis of High-Quality Graphene with a Pre-Determined Number of Layers. Carbon 2009, 47, 493–499. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, R.; Shi, Z.; Zhang, L.; Shi, D.; Wang, E.; Zhang, G. Super-Elastic Graphene Ripples for Flexible Strain Sensors. ACS Nano 2011, 5, 3645–3650. [Google Scholar] [CrossRef]

- Wang, X.; Shi, Z.; Meng, F.; Zhao, Y.; Wu, Z.; Lei, Y.; Xue, L. Interfacial Interaction-Induced Temperature-Dependent Mechanical Property of Graphene-PDMS Nanocomposite. J. Mater. Sci. 2020, 55, 1553–1561. [Google Scholar] [CrossRef]

- Wang, X.; Yang, B.; Tan, D.; Li, Q.; Song, B.; Wu, Z.; del Campo, A.; Kappl, M.; Wang, Z.; Gorb, S.; et al. Bioinspired Footed Soft Robot with Unidirectional All-Terrain Mobility. Mater. Today 2020, 35, 42–49. [Google Scholar] [CrossRef]

- Liu, K.; Vuckovac, M.; Latikka, M.; Huhtamäki, T.; Ras, R. Improving Surface-Wetting Characterization. Science 2019, 363, 1147–1148. [Google Scholar] [CrossRef]

- Gao, N.; Geyer, F.; Pilat, D.; Wooh, S.; Vollmer, D.; Butt, H.; Berger, R. How Drops Start Sliding over Solid Surfaces. Nat. Phys. 2018, 14, 191–196. [Google Scholar] [CrossRef]

- Liu, C.; Chang, Y.; Norris, T.; Zhong, Z. Graphene Photodetectors with Ultra-Broadband and High Responsivity at Room Temperature. Nat. Nanotechnol. 2014, 9, 273–278. [Google Scholar] [CrossRef]

- Novoselov, K.; Fal′ko, V.; Colombo, L.; Gellert, P.; Schwab, M.; Kim, K. A Roadmap for Graphene. Nature 2012, 490, 192–200. [Google Scholar] [CrossRef] [PubMed]

- Smith, J.; Dhiman, R.; Anand, S.; Reza-Garduno, E.; Cohen, R.; McKinley, G.; Varanasi, K. Droplet Mobility on Lubricant-Impregnated Surfaces. Soft Matter 2013, 9, 1772–1780. [Google Scholar] [CrossRef]

- Brzoska, J.; Brochard-Wyart, F.; Rondelez, F. Motions of Droplets on Hydrophobic Model Surfaces Induced by Thermal Gradients. Langmuir 1993, 9, 2220–2224. [Google Scholar] [CrossRef]

- Bjelobrk, N.; Girard, H.; Bengaluru Subramanyam, S.; Kwon, H.; Quéré, D.; Varanasi, K. Thermocapillary Motion on Lubricant-Impregnated Surfaces. Phys. Rev. Fluids 2016, 1, 063902. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, Z.; Xiao, K.; Li, L.; Zhang, Y.; Zhang, X.; Chen, D.; Xue, L. The Influence of Temperature on Anisotropic Wettability Revealed by Friction Force Measurement. Biomimetics 2023, 8, 180. https://doi.org/10.3390/biomimetics8020180

Lin Z, Xiao K, Li L, Zhang Y, Zhang X, Chen D, Xue L. The Influence of Temperature on Anisotropic Wettability Revealed by Friction Force Measurement. Biomimetics. 2023; 8(2):180. https://doi.org/10.3390/biomimetics8020180

Chicago/Turabian StyleLin, Zhen, Kangjian Xiao, Lijun Li, Yurong Zhang, Xiaolong Zhang, Daobing Chen, and Longjian Xue. 2023. "The Influence of Temperature on Anisotropic Wettability Revealed by Friction Force Measurement" Biomimetics 8, no. 2: 180. https://doi.org/10.3390/biomimetics8020180