Creation of a 3D Goethite–Spongin Composite Using an Extreme Biomimetics Approach

Abstract

:1. Introduction

- • “Finding corresponding natural sources and examples for inspiration;

- • Understanding the principles and mechanisms of biological phenomena occurring under natural extremes;

- • Application of already proven technologies related to the use of biological materials;

- • Making scientifically based but daring experimental decisions including the development of a new generation of composite materials” [4].

2. Materials and Methods

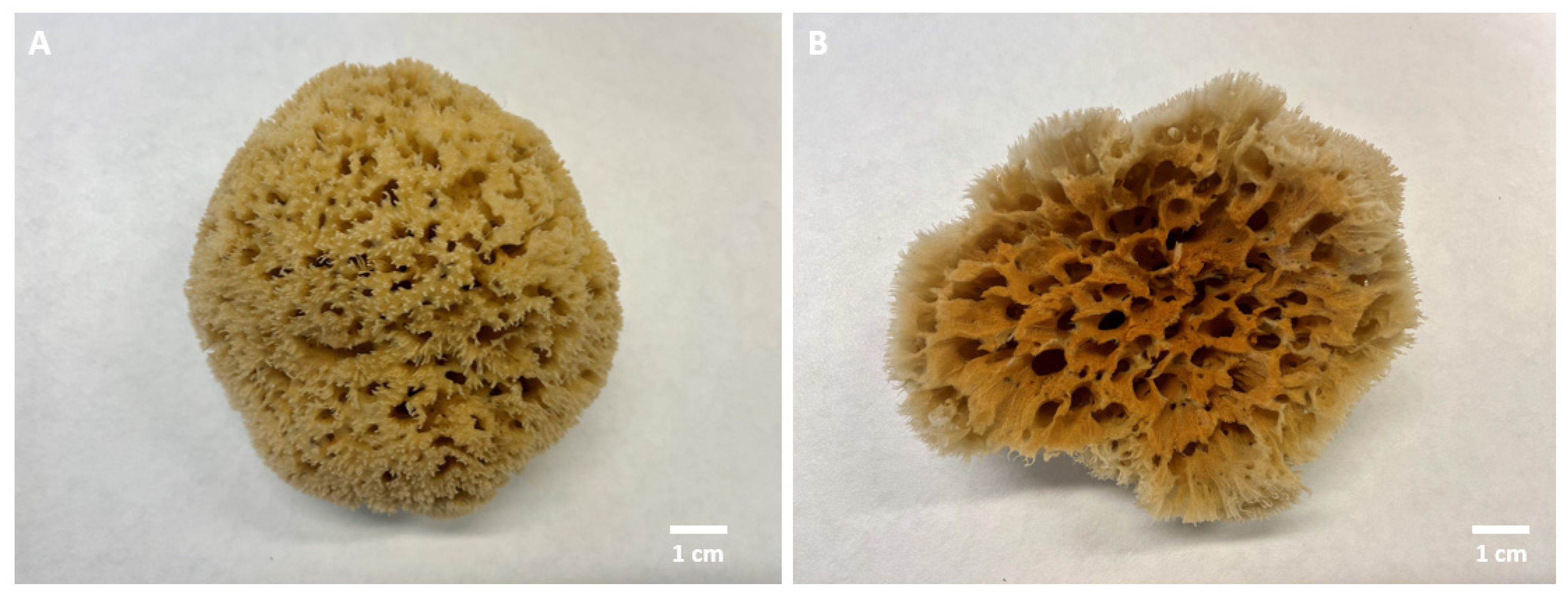

2.1. Materials

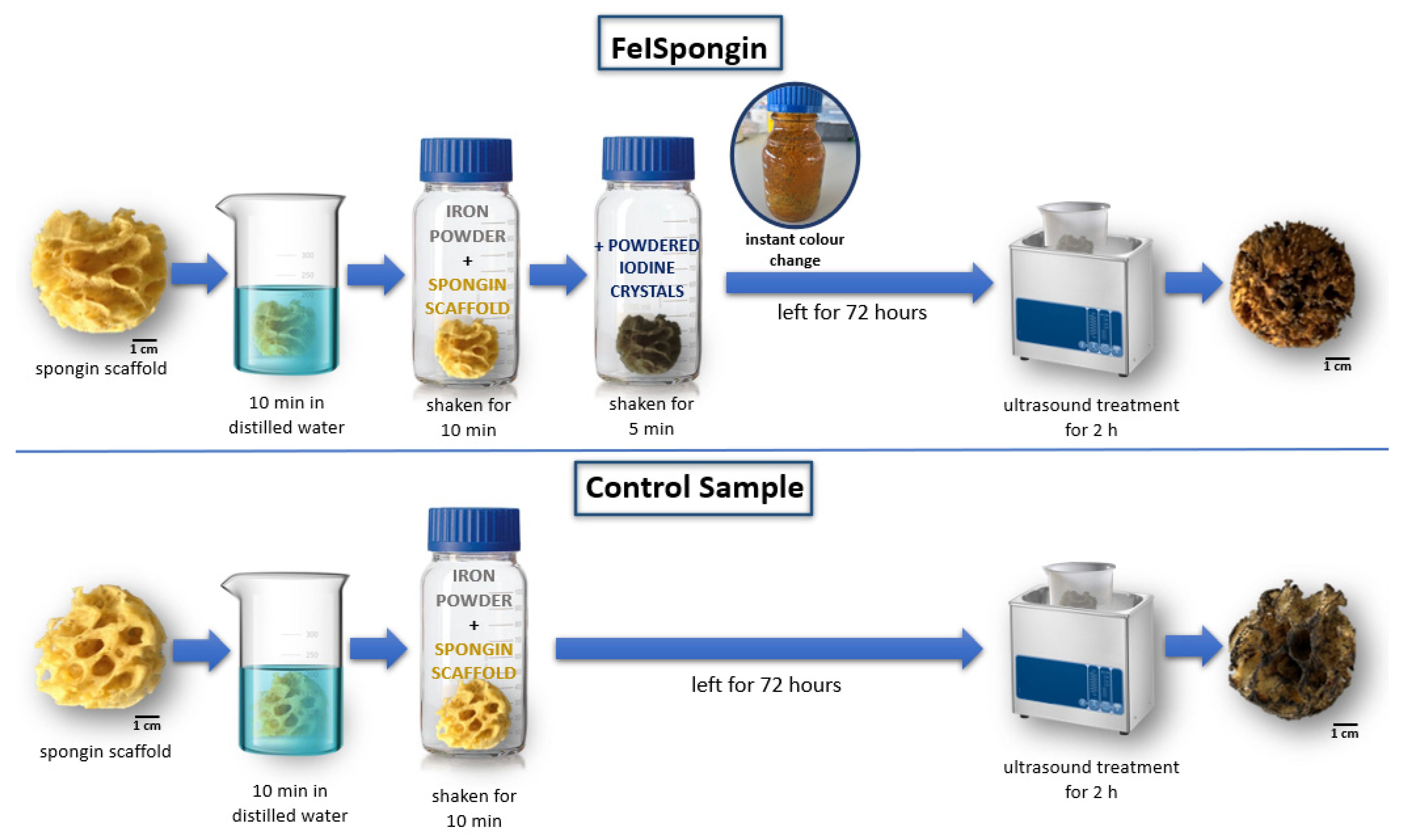

2.2. Sample Preparation

Preparation of Materials

2.3. Characterization Techniques

2.3.1. Digital Microscopy

2.3.2. Scanning Electron Microscopy (SEM) with Energy Dispersive X-ray Analysis (EDX)

2.3.3. Fourier Transform Infrared Spectroscopy

2.3.4. Raman Spectroscopy

2.3.5. X-ray Diffraction

2.3.6. Thermogravimetric Analysis

2.3.7. Magnetic Properties

2.3.8. Confocal Micro X-ray Fluorescence Spectroscopy (CMXRF)

2.4. Dopamine Detection

3. Results

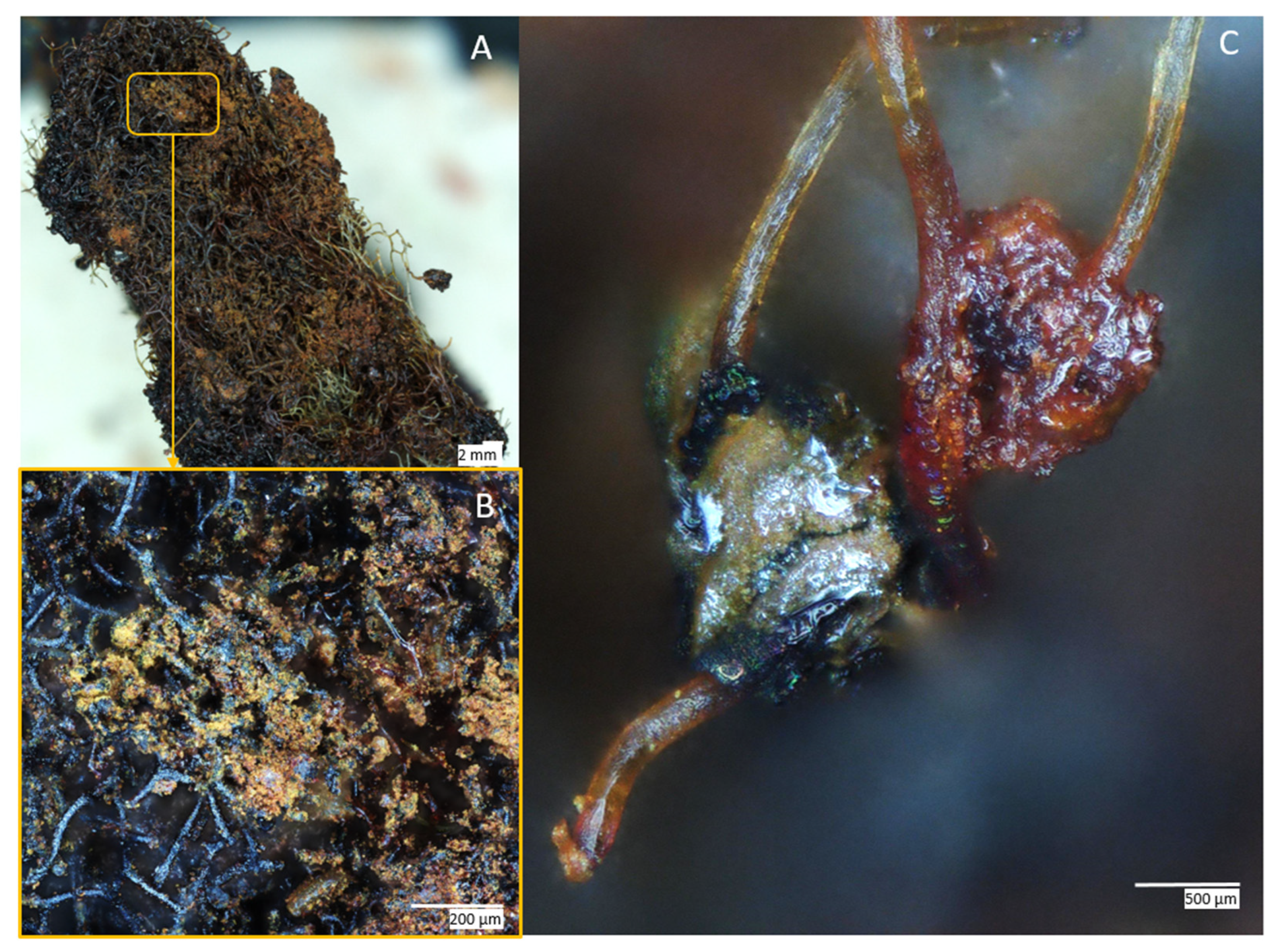

3.1. Digital Microscopy

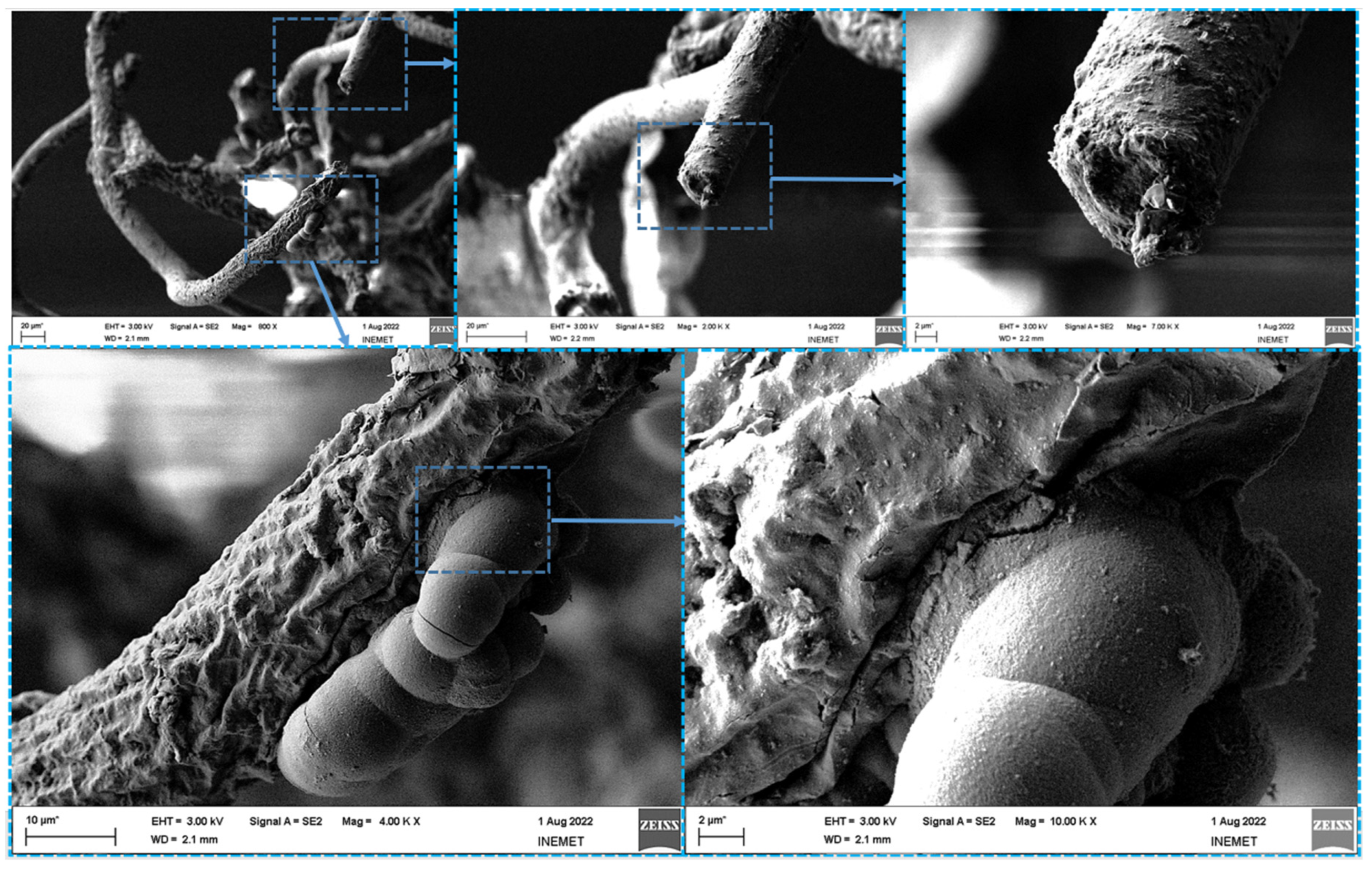

3.2. Scanning Electron Microscopy (SEM) with Energy Dispersive X-ray Analysis (EDX)

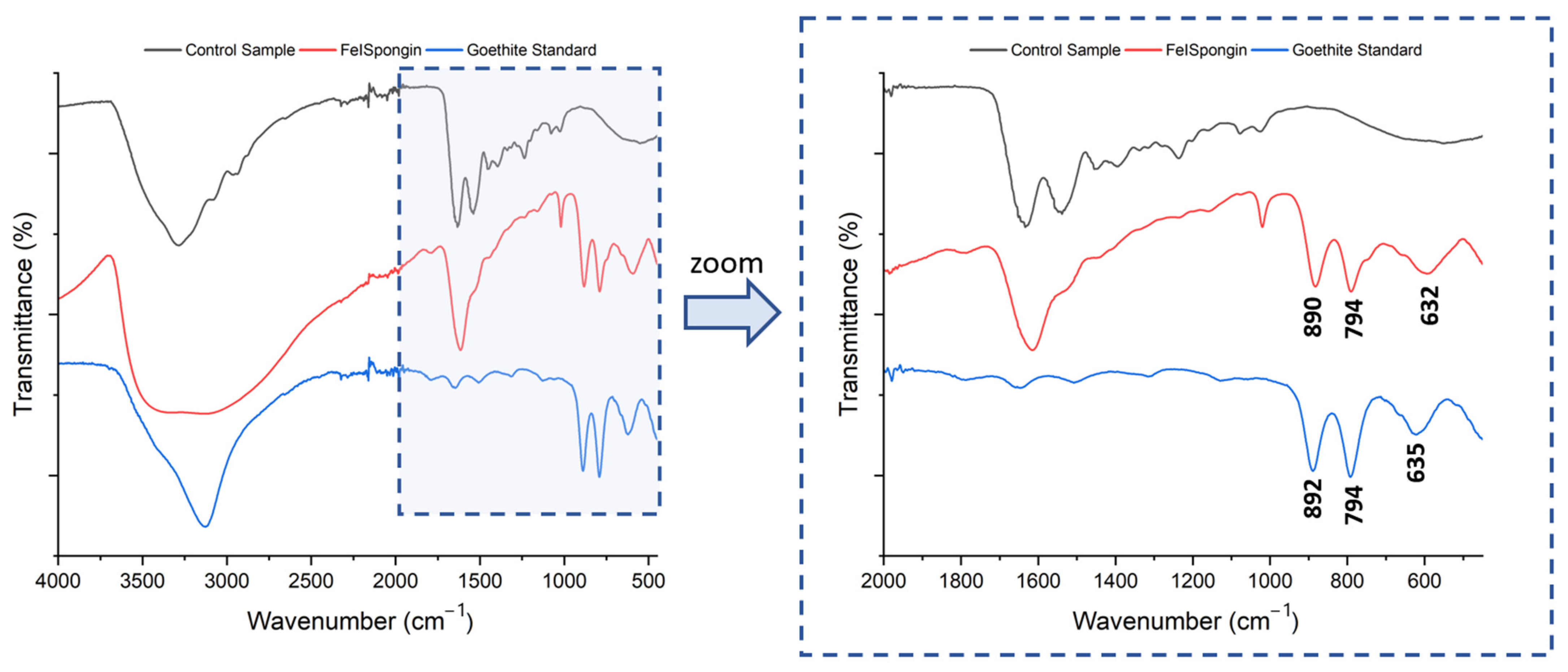

3.3. Fourier Transform Infrared Spectroscopy (FTIR)

3.4. Raman Spectroscopy

3.5. X-ray Diffraction

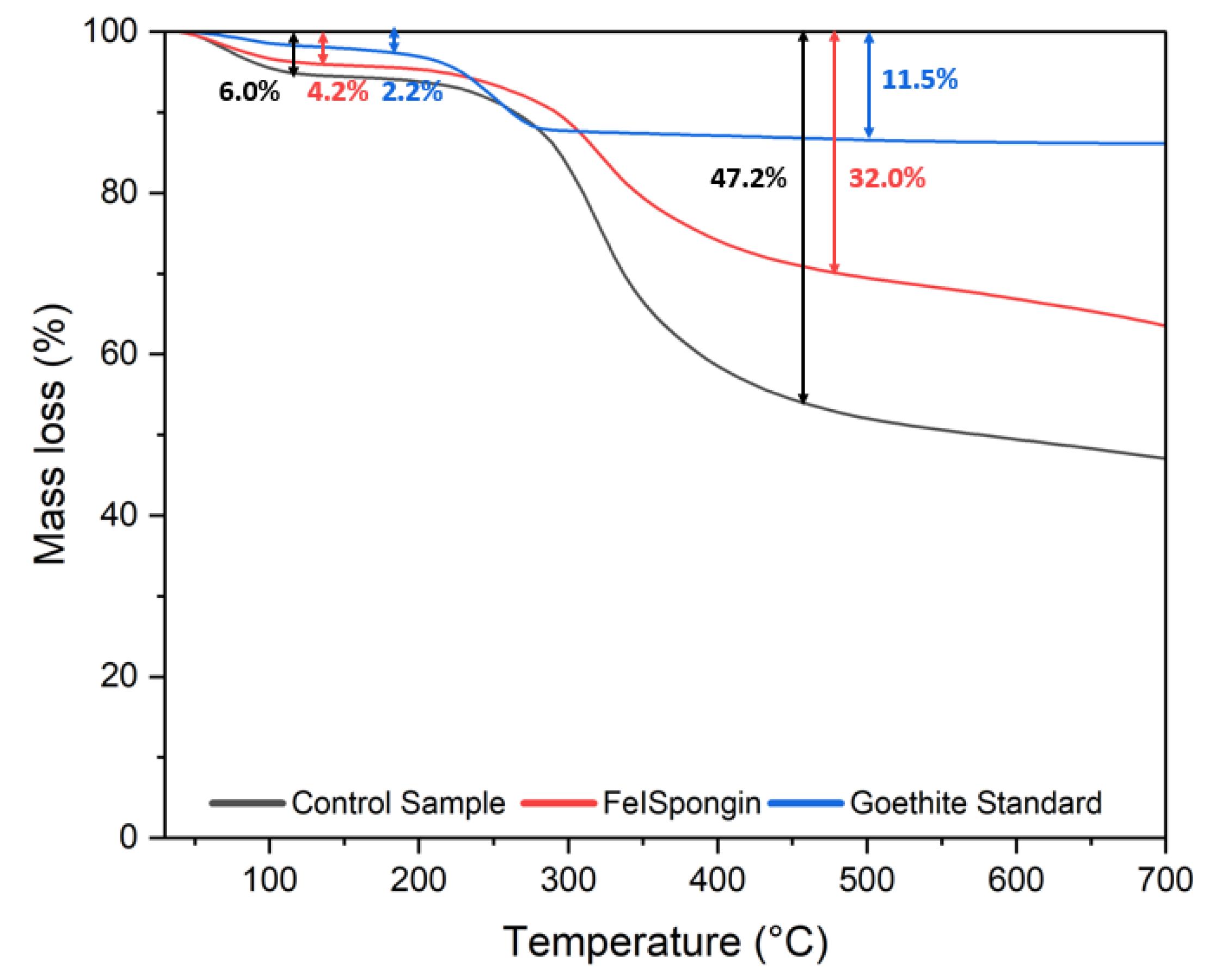

3.6. Thermogravimetric Analysis

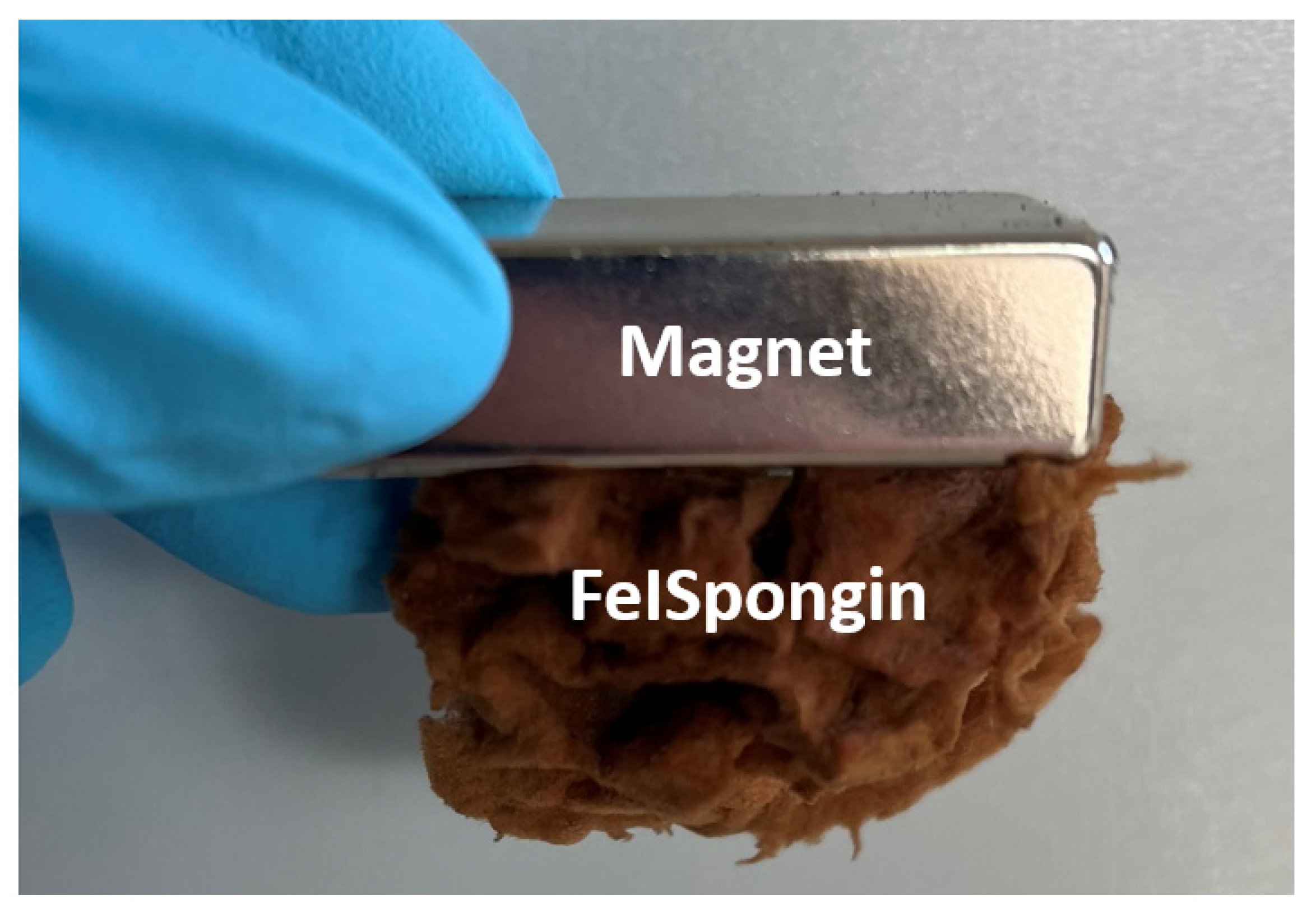

3.7. Magnetic Properties

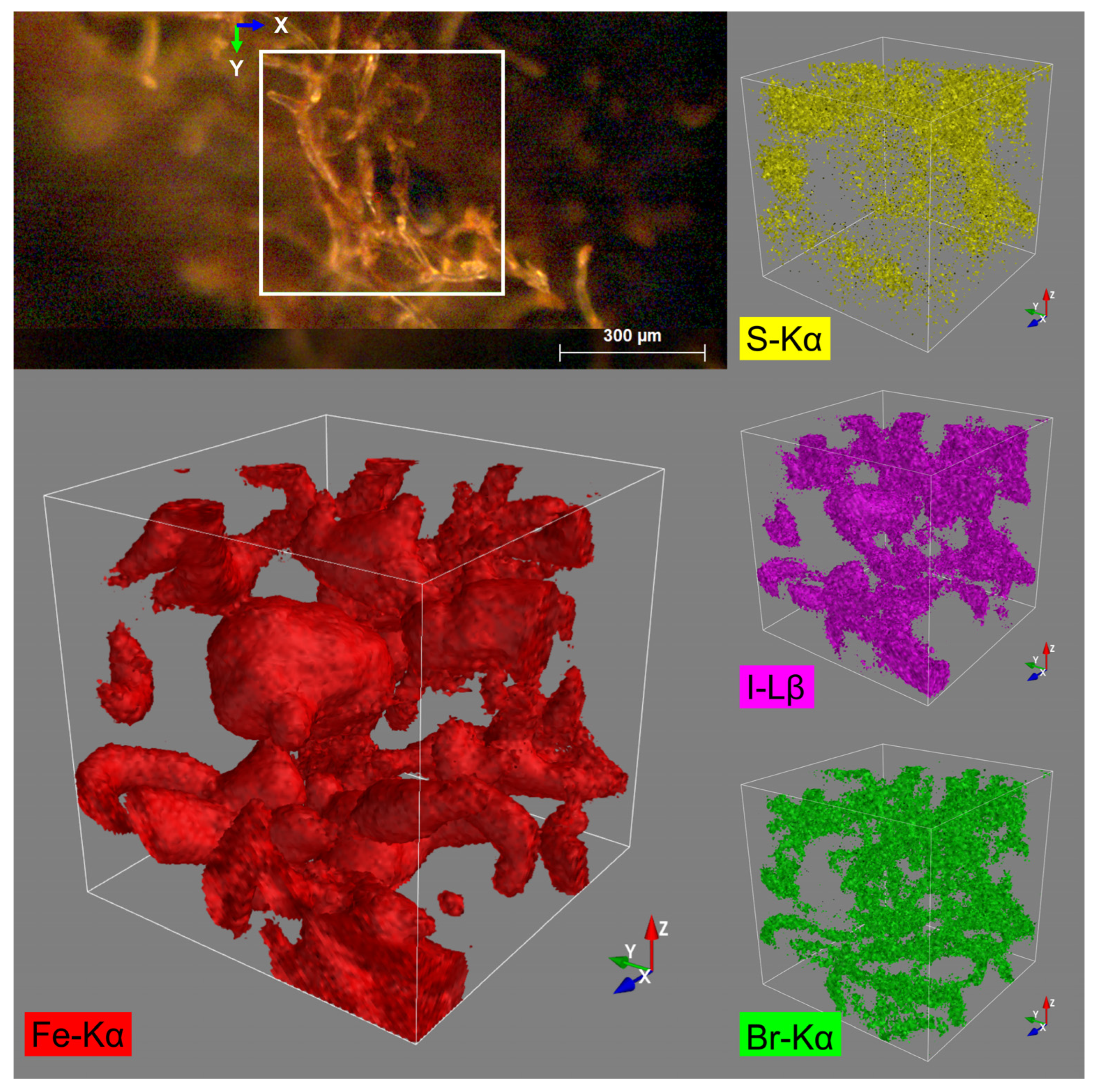

3.8. Confocal Micro X-ray Fluorescence Spectroscopy (CMXRF)

3.9. Dopamine Detection

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vincent, J.F.V.; Bogatyreva, O.A.; Bogatyrev, N.R.; Bowyer, A.; Pahl, A.-K. Biomimetics: Its Practice and Theory. J. R. Soc. Interface 2006, 3, 471–482. [Google Scholar] [CrossRef] [PubMed]

- Gorb, S.N.; Carbone, G.; Speck, T.; Taubert, A. Advances in Biomimetics: Combination of Various Effects at Different Scales. Biomimetics 2023, 8, 329. [Google Scholar] [CrossRef] [PubMed]

- Mail, M.; Koch, K.; Speck, T.; Megill, W.M.; Gorb, S.N. Biomimetics on the Micro- and Nanoscale—The 25th Anniversary of the Lotus Effect. Beilstein J. Nanotechnol. 2023, 14, 850–856. [Google Scholar] [CrossRef] [PubMed]

- Ehrlich, H.; Wysokowski, M.; Jesionowski, T. The Philosophy of Extreme Biomimetics. Sustain. Mater. Technol. 2022, 32, e00447. [Google Scholar] [CrossRef]

- Ehrlich, H.; Bailey, E.; Wysokowski, M.; Jesionowski, T. Forced Biomineralization: A Review. Biomimetics 2021, 6, 46. [Google Scholar] [CrossRef]

- Wysokowski, M.; Zaslansky, P.; Ehrlich, H. Macrobiomineralogy: Insights and Enigmas in Giant Whale Bones and Perspectives for Bioinspired Materials Science. ACS Biomater. Sci. Eng. 2020, 6, 5357–5367. [Google Scholar] [CrossRef]

- Ehrlich, H.; Wysokowski, M.; Zółtowska-Aksamitowska, S.; Petrenko, I.; Jesionowski, T. Collagens of Poriferan Origin. Mar. Drugs 2018, 16, 79. [Google Scholar] [CrossRef]

- Żółtowska, S.; Koltsov, I.; Alejski, K.; Ehrlich, H.; Ciałkowski, M.; Jesionowski, T. Thermal Decomposition Behaviour and Numerical Fitting for the Pyrolysis Kinetics of 3D Spongin-Based Scaffolds. The Classic Approach. Polym. Test. 2021, 97, 107148. [Google Scholar] [CrossRef]

- Jesionowski, T.; Norman, M.; Zółtowska-Aksamitowska, S.; Petrenko, I.; Joseph, Y.; Ehrlich, H. Marine Spongin: Naturally Prefabricated 3D Scaffold-Based Biomaterial. Mar. Drugs 2018, 16, 88. [Google Scholar] [CrossRef]

- Kubiak, A.; Kotula, M.; Leśniewski, B.; Pajewska-Szmyt, M. Iron-Sponges Interrelations: From Biocorrosion to Nanostructured Biocomposites. Lett. Appl. NanoBioSci. 2022, 12, 64. [Google Scholar]

- Petrenko, I.; Summers, A.P.; Simon, P.; Zółtowska-Aksamitowska, S.; Motylenko, M.; Schimpf, C.; Rafaja, D.; Roth, F.; Kummer, K.; Brendler, E.; et al. Extreme Biomimetics: Preservation of Molecular Detail in Centimeter-Scale Samples of Biological Meshes Laid down by Sponges. Sci. Adv. 2019, 5, eaax2805. [Google Scholar] [CrossRef]

- Kotula, M.; Kubiak, A.; Leśniewski, B.; Pajewska-Szmyt, M. Carbonization of Selected Biological Materials, Trends, and Perspectives. Lett. Appl. NanoBioSci. 2022, 12, 68. [Google Scholar]

- Kubiak, A.; Pajewska-Szmyt, M.; Kotula, M.; Leśniewski, B.; Voronkina, A.; Rahimi, P.; Falahi, S.; Heimler, K.; Rogoll, A.; Vogt, C.; et al. Spongin as a Unique 3D Template for the Development of Functional Iron-Based Composites Using Biomimetic Approach In Vitro. Mar. Drugs 2023, 21, 460. [Google Scholar] [CrossRef]

- Falahi, S.; Jaafar, A.; Petrenko, I.; Zarejousheghani, M.; Ehrlich, H.; Rahimi, P.; Joseph, Y. High-Performance Three-Dimensional Spongin–Atacamite Biocomposite for Electrochemical Nonenzymatic Glucose Sensing. ACS Appl. Bio Mater. 2022, 5, 873–880. [Google Scholar] [CrossRef] [PubMed]

- Shahdost-Fard, F.; Faridfar, S.; Keihan, A.H.; Aghaei, M.; Petrenko, I.; Ahmadi, F.; Ehrlich, H.; Rahimi-Nasrabadi, M. Applicability of a Green Nanocomposite Consisted of Spongin Decorated Cu2WO4(OH)2 and AgNPs as a High-Performance Aptasensing Platform in Staphylococcus aureus Detection. Biosensors 2023, 13, 271. [Google Scholar] [CrossRef] [PubMed]

- Falahi, S.; Falahi, S.; Zarejousheghani, M.; Ehrlich, H.; Joseph, Y.; Rahimi, P. Electrochemical Sensing of Gallic Acid in Beverages Using a 3D Bio-Nanocomposite Based on Carbon Nanotubes/Spongin-Atacamite. Biosensors 2023, 13, 262. [Google Scholar] [CrossRef] [PubMed]

- Abrefah, J.; de Abreu, H.F.G.; Tehranian, F.; Kim, Y.S.; Olander, D.R. Interaction of Iodine with Preoxidized Stainless Steel. Nucl. Technol. 1994, 105, 137–144. [Google Scholar] [CrossRef]

- Beck, C.L.; Smith, N.P.; Riley, B.J.; Clark, S.B. Adsorption of Iodine on Metal Coupons in Humid and Dry Environments. J. Nucl. Mater. 2021, 556, 153204. [Google Scholar] [CrossRef]

- Beck, C.L.; Riley, B.J.; Chong, S.; Smith, N.; Seiner, D.R.; Seiner, B.N.; Engelhard, M.H.; Clark, S.B. Molecular Iodine Interactions with Fe, Ni, Cr, and Stainless Steel Alloys. Ind. Eng. Chem. Res. 2021, 60, 2447–2454. [Google Scholar] [CrossRef]

- Wren, J.C.; Glowa, G.A.; Merritt, J. Corrosion of Stainless Steel by Gaseous I2. J. Nucl. Mater. 1999, 265, 161–177. [Google Scholar] [CrossRef]

- Funke, F.; Greger, G.-U.; Hellmann, S.; Bleier, A.; Morell, W. Iodine-Steel Reactions under Severe Accident Conditions in Light-Water Reactors. Nucl. Eng. Des. 1996, 166, 357–365. [Google Scholar] [CrossRef]

- Förste, F.; Bauer, L.; Heimler, K.; Hansel, B.; Vogt, C.; Kanngießer, B.; Mantouvalou, I. Quantification Routines for Full 3D Elemental Distributions of Homogeneous and Layered Samples Obtained with Laboratory Confocal Micro XRF Spectrometers. J. Anal. Spectrom. 2022, 37, 1687–1695. [Google Scholar] [CrossRef]

- Voronkina, A.; Romanczuk-Ruszuk, E.; Przekop, R.E.; Lipowicz, P.; Gabriel, E.; Heimler, K.; Rogoll, A.; Vogt, C.; Frydrych, M.; Wienclaw, P.; et al. Honeycomb Biosilica in Sponges: From Understanding Principles of Unique Hierarchical Organization to Assessing Biomimetic Potential. Biomimetics 2023, 8, 234. [Google Scholar] [CrossRef] [PubMed]

- Mayavi: 3D Visualization of Scientific Data in Python. Available online: https://github.com/enthought/mayavi (accessed on 31 March 2020).

- Akbari, M.; Jafari, H.; Rostami, M.; Mahdavinia, G.R.; Nasab, A.S.; Tsurkan, D.; Petrenko, I.; Ganjali, M.R.; Rahimi-Nasrabadi, M.; Ehrlich, H. Adsorption of Cationic Dyes on a Magnetic 3d Spongin Scaffold with Nano-Sized Fe3O4 Cores. Mar. Drugs 2021, 19, 512. [Google Scholar] [CrossRef] [PubMed]

- Norman, M.; Bartczak, P.; Zdarta, J.; Tylus, W.; Szatkowski, T.; Stelling, A.; Ehrlich, H.; Jesionowski, T. Adsorption of C.I. Natural Red 4 onto Spongin Skeleton of Marine Demosponge. Materials 2014, 8, 96–116. [Google Scholar] [CrossRef]

- Veneranda, M.; Aramendia, J.; Bellot-Gurlet, L.; Colomban, P.; Castro, K.; Madariaga, J.M. FTIR Spectroscopic Semi-Quantification of Iron Phases: A New Method to Evaluate the Protection Ability Index (PAI) of Archaeological Artefacts Corrosion Systems. Corros. Sci. 2018, 133, 68–77. [Google Scholar] [CrossRef]

- Liu, Z.; Chen, G.; Xu, L.; Hu, F.; Duan, X. Removal of Cr(VI) from Wastewater by a Novel Adsorbent of Magnetic Goethite: Adsorption Performance and Adsorbent Characterisation. ChemistrySelect 2019, 4, 13817–13827. [Google Scholar] [CrossRef]

- Betancur, A.F. Quantitative Approach in Iron Oxides and Oxyhydroxides by Vibrational Analysis. Opt. Pura Apl. 2012, 45, 269–275. [Google Scholar] [CrossRef]

- Prasad, P.S.R.; Shiva Prasad, K.; Krishna Chaitanya, V.; Babu, E.V.S.S.K.; Sreedhar, B.; Ramana Murthy, S. In Situ FTIR Study on the Dehydration of Natural Goethite. J. Asian Earth Sci. 2006, 27, 503–511. [Google Scholar] [CrossRef]

- Zhu, M.; Hu, X.; Tu, C.; Zhang, H.; Song, F.; Luo, Y.; Christie, P. Sorption Mechanisms of Diphenylarsinic Acid on Ferrihydrite, Goethite and Hematite Using Sequential Extraction, FTIR Measurement and XAFS Spectroscopy. Sci. Total Environ. 2019, 669, 991–1000. [Google Scholar] [CrossRef]

- Ma, H.; Wang, P.; Thompson, A.; Xie, Q.; Zhu, M.; Teng, H.H.; Fu, P.; Liu, C.; Chen, C. Secondary Mineral Formation and Carbon Dynamics during FeS Oxidation in the Presence of Dissolved Organic Matter. Environ. Sci. Technol. 2022, 56, 14120–14132. [Google Scholar] [CrossRef]

- de Faria, D.L.A.; Lopes, F.N. Heated Goethite and Natural Hematite: Can Raman Spectroscopy Be Used to Differentiate Them? Vib. Spectrosc. 2007, 45, 117–121. [Google Scholar] [CrossRef]

- Li, S.; Hihara, L.H. A Micro-Raman Spectroscopic Study of Marine Atmospheric Corrosion of Carbon Steel: The Effect of Akaganeite. J. Electrochem. Soc. 2015, 162, C495–C502. [Google Scholar] [CrossRef]

- Hanesch, M. Raman Spectroscopy of Iron Oxides and (Oxy)Hydroxides at Low Laser Power and Possible Applications in Environmental Magnetic Studies. Geophys. J. Int. 2009, 177, 941–948. [Google Scholar] [CrossRef]

- Abrashev, M.V.; Ivanov, V.G.; Stefanov, B.S.; Todorov, N.D.; Rosell, J.; Skumryev, V. Raman Spectroscopy of Alpha-FeOOH (Goethite) near Antiferromagnetic to Paramagnetic Phase Transition. J. Appl. Phys. 2020, 127, 205108. [Google Scholar] [CrossRef]

- Shao, Y.; Hu, G.; Liu, Z.; Xu, X.; Zhang, M.; Ding, C.; Li, Y. Determination of Band Structure of Naturally Occurring Goethite with Al Substitution: A Case Study of Zhushan Iron Zone. Materials 2022, 15, 1465. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, M.K.; Poinern, G.E.J.; Issa, T.B.; Singh, P. Arsenic Adsorption on Goethite Nanoparticles Produced through Hydrazine Sulfate Assisted Synthesis Method. Korean J. Chem. Eng. 2012, 29, 95–102. [Google Scholar] [CrossRef]

- Gupta, H.; Kumar, R.; Park, H.-S.; Jeon, B.-H. Photocatalytic Efficiency of Iron Oxide Nanoparticles for the Degradation of Priority Pollutant Anthracene. Geosystem Eng. 2017, 20, 21–27. [Google Scholar] [CrossRef]

- Ristić, M.; Krehula, S.; Reissner, M.; Musić, S. 57Fe Mössbauer, XRD, FT-IR, FE SEM Analyses of Natural Goethite, Hematite and Siderite. Croat. Chem. Acta 2017, 90, 499–507. [Google Scholar] [CrossRef]

- Szatkowski, T.; Wysokowski, M.; Lota, G.; Pęziak, D.; Bazhenov, V.V.; Nowaczyk, G.; Walter, J.; Molodtsov, S.L.; Stöcker, H.; Himcinschi, C.; et al. Novel Nanostructured Hematite-Spongin Composite Developed Using an Extreme Biomimetic Approach. RSC Adv. 2015, 5, 79031–79040. [Google Scholar] [CrossRef]

- Walter, D.; Buxbaum, G.; Laqua, W. The Mechanism of the Thermal Transformation from Goethite to Hematite. J. Therm. Anal. Calorim. 2001, 63, 733–748. [Google Scholar] [CrossRef]

- Norman, M.; Żółtowska-Aksamitowska, S.; Zgoła-Grześkowiak, A.; Ehrlich, H.; Jesionowski, T. Iron(III) Phthalocyanine Supported on a Spongin Scaffold as an Advanced Photocatalyst in a Highly Efficient Removal Process of Halophenols and Bisphenol A. J. Hazard. Mater. 2018, 347, 78–88. [Google Scholar] [CrossRef]

- Wetzel, R.; Perry, L.J.; Baase, W.A.; Becktel, W.J. Disulfide Bonds and Thermal Stability in T4 Lysozyme. Proc. Natl. Acad. Sci. USA 1988, 85, 401–405. [Google Scholar] [CrossRef] [PubMed]

- Pavese, A.; Artioli, G.; Hull, S. In Situ Study of the Goethite-Hematite Phase Transformation by Real Time Synchrotron Powder Diffraction. Am. Min. 1999, 84, 905–912. [Google Scholar] [CrossRef]

- Morales, M.P.; Pereda, C.J.S.; Pozas, R.; Ocaña, M. Acicular Iron Nanoparticles Protected against Sintering with Aluminium Oxide. Bol. Soc. Esp. Cerám. Vidr. 2004, 43, 796–800. [Google Scholar]

- Valezi, D.F.; Maeda, J.T.; Vicentin, B.L.S.; Mantovani, A.C.G.; Spadotto, J.C.; Urbano, A.; Ivashita, F.F.; Paesano, A.; Magon, C.J.; di Mauro, E. Magnetic Fluctuations of Goethite (α-FeOOH) Analyzed through Al Substituted Samples. Phys. B Condens. Matter. 2023, 650, 414537. [Google Scholar] [CrossRef]

- Valezi, D.F.; Piccinato, M.T.; Sarvezuk, P.W.C.; Ivashita, F.F.; Paesano, A.; Varalda, J.; Mosca, D.H.; Urbano, A.; Guedes, C.L.B.; di Mauro, E. Goethite (α-FeOOH) Magnetic Transition by ESR, Magnetometry and Mössbauer. Mater. Chem. Phys. 2016, 173, 179–185. [Google Scholar] [CrossRef]

- Pankhurst, Q.A.; Barquín, L.F.; Lord, J.S.; Amato, A.; Zimmermann, U. Intrinsic Magnetic Relaxation in Goethite. Phys. Rev. B 2012, 85, 174437. [Google Scholar] [CrossRef]

- Barrero, C.A.; Betancur, J.D.; Greneche, J.M.; Goya, G.F.; Berquó, T.S. Magnetism in Non-Stoichiometric Goethite of Varying Total Water Content and Surface Area. Geophys. J. Int. 2006, 164, 331–339. [Google Scholar] [CrossRef]

- Rochette, P.; Fillion, G. Field and Temperature Behavior of Remanence in Synthetic Goethite: Paleomagnetic Implications. Geophys. Res. Lett. 1989, 16, 851–854. [Google Scholar] [CrossRef]

- Banerjee, S.K. Origin of Thermoremanence in Goethite. Earth Planet Sci. Lett. 1970, 8, 197–201. [Google Scholar] [CrossRef]

- Valezi, D.F.; Carneiro, C.E.A.; Costa, A.C.S.; Paesano, A.; Spadotto, J.C.; Solórzano, I.G.; Londoño, O.M.; di Mauro, E. Weak Ferromagnetic Component in Goethite (α-FeOOH) and Its Relation with Microstructural Characteristics. Mater. Chem. Phys. 2020, 246, 122851. [Google Scholar] [CrossRef]

- Strangway, D.W.; Honea, R.M.; McMahon, B.E.; Larson, E.E. The Magnetic Properties of Naturally Occurring Goethite. Geophys. J. Int. 1968, 15, 345–359. [Google Scholar] [CrossRef]

- Gnahore, G.T.; Velasco-Torrijos, T.; Colleran, J. The Selective Electrochemical Detection of Dopamine Using a Sulfated β-Cyclodextrin Carbon Paste Electrode. Electrocatalysis 2017, 8, 459–471. [Google Scholar] [CrossRef]

- Channer, B.; Matt, S.M.; Nickoloff-Bybel, E.A.; Pappa, V.; Agarwal, Y.; Wickman, J.; Gaskill, P.J. Dopamine, Immunity, and Disease. Pharmacol. Rev. 2023, 75, 62–158. [Google Scholar] [CrossRef]

- Adekunle, A.S.; Agboola, B.O.; Pillay, J.; Ozoemena, K.I. Electrocatalytic Detection of Dopamine at Single-Walled Carbon Nanotubes–Iron (III) Oxide Nanoparticles Platform. Sens. Actuators B Chem. 2010, 148, 93–102. [Google Scholar] [CrossRef]

- Kokulnathan, T.; Joseph Anthuvan, A.; Chen, S.-M.; Chinnuswamy, V.; Kadirvelu, K. Trace Level Electrochemical Determination of the Neurotransmitter Dopamine in Biological Samples Based on Iron Oxide Nanoparticle Decorated Graphene Sheets. Inorg. Chem. Front. 2018, 5, 705–718. [Google Scholar] [CrossRef]

- Anantha, M.S.; Kiran Kumar, S.R.; Anarghya, D.; Venkatesh, K.; Santosh, M.S.; Yogesh Kumar, K.; Muralidhara, H.B. ZnO@MnO2 Nanocomposite Modified Carbon Paste Electrode for Electrochemical Detection of Dopamine. Sens. Int. 2021, 2, 100087. [Google Scholar] [CrossRef]

- Fyfe, A. Account of Some Experiments, Made with the View of Ascertaining the Different Substances from Which Iodine Can Be Procured. Edinb. Phil. J. 1819, 1, 254–258. [Google Scholar]

- Hundeshagen, F. Über jodhaltige Spongien and Jodospongin. Angew. Chem. Int. Ed. 1895, 8, 473–476. [Google Scholar] [CrossRef]

- Harnack, E. Ueber Das Jodospongin, Die Jodhaltige Eiweissartige Substanz Aus Dem Badeschwamm. Hoppe Seylers Z Physiol. Chem. 1898, 24, 412–424. [Google Scholar] [CrossRef]

- Vacelet, J.; Verdenal, B.; Perinet, G. The Iron Mineralization of Spongia officinalis L. (Porifera, Dictyoceratida) and Its Relationships with the Collagen Skeleton. Biol. Cell 1988, 62, 189–198. [Google Scholar] [CrossRef]

- Yan, W.; Zhou, J.; Liu, H.; Chen, R.; Zhang, Y.; Wei, Y. Formation of Goethite and Magnetite Rust via Reaction with Fe(II). J. Electrochem. Soc. 2016, 163, C289–C295. [Google Scholar] [CrossRef]

- Wren, J.C.; Glowa, G.A. Kinetics of Gaseous Iodine Uptake onto Stainless Steel during Iodine-Assisted Corrosion. Nucl. Technol. 2001, 133, 33–49. [Google Scholar] [CrossRef]

- Zschätzsch, D.; Benz, S.L.; Holste, K.; Vaupel, M.; Hey, F.G.; Kern, C.; Janek, J.; Klar, P.J. Corrosion of Metal Parts on Satellites by Iodine Exposure in Space. J. Propuls. Power 2022, 1, 14. [Google Scholar] [CrossRef]

- Das, S.; Hendry, M.J.; Essilfie-Dughan, J. Transformation of Two-Line Ferrihydrite to Goethite and Hematite as a Function of PH and Temperature. Environ. Sci. Technol. 2011, 45, 268–275. [Google Scholar] [CrossRef]

- Notini, L.; Thomasarrigo, L.K.; Kaegi, R.; Kretzschmar, R. Coexisting Goethite Promotes Fe(II)-Catalyzed Transformation of Ferrihydrite to Goethite. Environ. Sci. Technol. 2022, 56, 12723–12733. [Google Scholar] [CrossRef]

- Cornell, R.M.; Schwertmann, U. The Iron Oxides; Wiley: Hoboken, NJ, USA, 2003; ISBN 9783527302741. [Google Scholar]

- Liu, H.; Chen, T.; Frost, R.L. An Overview of the Role of Goethite Surfaces in the Environment. Chemosphere 2014, 103, 1–11. [Google Scholar] [CrossRef]

- Atkinson, R.J.; Posner, A.M.; Quirk, J.P. Kinetics of Isotopic Exchange of Phosphate at the α-FeOOH-Aqueous Solution Interface. J. Inorg. Nucl. Chem. 1972, 34, 2201–2211. [Google Scholar] [CrossRef]

- Strauss, R.; Brümmer, G.W.; Barrow, N.J. Effects of Crystallinity of Goethite: II. Rates of Sorption and Desorption of Phosphate. Eur. J. Soil. Sci. 1997, 48, 101–114. [Google Scholar] [CrossRef]

- Hinrichs, S.; Grossmann, L.; Clasen, E.; Klages, H.G.G.; Skroblin, D.; Gollwitzer, C.; Meyer, A.; Hankiewicz, B. Goethite Nanorods: Synthesis and Investigation of the Size Effect on Their Orientation within a Magnetic Field by SAXS. Nanomaterials 2020, 10, 2526. [Google Scholar] [CrossRef]

- Durães, L.; Costa, B.F.O.; Vasques, J.; Campos, J.; Portugal, A. Phase Investigation of As-Prepared Iron Oxide/Hydroxide Produced by Sol–Gel Synthesis. Mater. Lett. 2005, 59, 859–863. [Google Scholar] [CrossRef]

- Thies-Weesie, D.M.E.; de Hoog, J.P.; Hernandez Mendiola, M.H.; Petukhov, A.V.; Vroege, G.J. Synthesis of Goethite as a Model Colloid for Mineral Liquid Crystals. Chem. Mater. 2007, 19, 5538–5546. [Google Scholar] [CrossRef]

- Ristić, M.; Opačak, I.; Musić, S. The Synthesis and Microstructure of Goethite Particles Precipitated in Highly Alkaline Media. J. Alloys Compd. 2013, 559, 49–56. [Google Scholar] [CrossRef]

- Wu, Y.; Hu, W.; Xie, R.; Liu, X.; Yang, D.; Chen, P.; Zhang, J.; Zhang, F. Composite of Nano-Goethite and Natural Organic Luffa Sponge as Template: Synergy of High Efficiency Adsorption and Visible-Light Photocatalysis. Inorg. Chem. Commun. 2018, 98, 115–119. [Google Scholar] [CrossRef]

- Ratnam, K.V.; Manjunatha, H.; Janardan, S.; Babu Naidu, K.C.; Ramesh, S. Nonenzymatic Electrochemical Sensor Based on Metal Oxide, MO (M = Cu, Ni, Zn, and Fe) Nanomaterials for Neurotransmitters: An Abridged Review. Sens. Int. 2020, 1, 100047. [Google Scholar] [CrossRef]

- Tavakolian-Ardakani, Z.; Hosu, O.; Cristea, C.; Mazloum-Ardakani, M.; Marrazza, G. Latest Trends in Electrochemical Sensors for Neurotransmitters: A Review. Sensors 2019, 19, 2037. [Google Scholar] [CrossRef]

- Campbell, F.W.; Compton, R.G. The Use of Nanoparticles in Electroanalysis: An Updated Review. Anal. Bioanal. Chem. 2010, 396, 241–259. [Google Scholar] [CrossRef] [PubMed]

- Jackowska, K.; Krysinski, P. New Trends in the Electrochemical Sensing of Dopamine. Anal. Bioanal. Chem. 2013, 405, 3753–3771. [Google Scholar] [CrossRef]

- Lakard, S.; Pavel, I.-A.; Lakard, B. Electrochemical Biosensing of Dopamine Neurotransmitter: A Review. Biosensors 2021, 11, 179. [Google Scholar] [CrossRef]

- Mugiraneza, S.; Hallas, A.M. Tutorial: A beginner’s guide to interpreting magnetic susceptibility data with the Curie-Weiss law. Commun. Phys. 2022, 5, 95. [Google Scholar] [CrossRef]

- Mohamed, A.-M.O.; Paleologos, E.K. Magnetic Properties of Soils. In Fundamentals of Geoenvironmental Engineering; Elsevier: Amsterdam, The Netherlands, 2018; pp. 535–580. [Google Scholar]

- Murad, E. The characterization of goethite by Mössbauer spectroscopy. Am. Mineral. 1982, 67, 1007–1011. [Google Scholar]

- Shehzad, M.A.; Yasmin, A.; Ge, X.; Ge, Z.; Zhang, K.; Liang, X.; Zhang, J.; Li, G.; Xiao, X.; Jiang, B.; et al. Shielded goethite catalyst that enables fast water dissociation in bipolar membranes. Nat. Commun 2021, 12, 9. [Google Scholar] [CrossRef]

- Fernández-Marchante, C.M.; Raschitor, A.; Mena, I.F.; Rodrigo, M.A.; Lobato, J. Evaluation of Goethite as a Catalyst for the Thermal Stage of the Westinghouse Process for Hydrogen Production. Catalysts 2021, 11, 1145. [Google Scholar] [CrossRef]

- Ohemeng-Boahen, G.; Tran, H.N.; Sewu, D.D.; Woo, S.H. Multi-Membrane Formation in Chitosan Hydrogel Shell by the Addition of Goethite Nanoparticles. Carbohydr. Polym. 2020, 229, 115543. [Google Scholar] [CrossRef] [PubMed]

- Munagapati, V.S.; Yarramuthi, V.; Kim, D.S. Methyl Orange Removal from Aqueous Solution Using Goethite, Chitosan Beads and Goethite Impregnated with Chitosan Beads. J. Mol. Liq. 2017, 240, 329–339. [Google Scholar] [CrossRef]

- Sirijaree, T.; Praipipat, P. Adsorption of Lead (II) Ions onto Goethite Chitosan Beads: Isotherms, Kinetics, and Mechanism Studies. ChemEngineering 2023, 7, 52. [Google Scholar] [CrossRef]

- Wang, S.; Yin, W.; Bu, H.; Zeng, W.; Li, P.; Zheng, X.; Chiang, P.; Wu, J. A Facile Modification of Cation Exchange Resin by Nano-Sized Goethite for Enhanced Cr(VI) Removal from Water. Environ. Technol. 2022, 43, 1833–1842. [Google Scholar] [CrossRef]

- Liu, Z.; Mukherjee, M.; Wu, Y.; Huang, Q.; Cai, P. Increased Particle Size of Goethite Enhances the Antibacterial Effect on Human Pathogen Escherichia coli O157:H7: A Raman Spectroscopic Study. J. Hazard. Mater. 2021, 405, 124174. [Google Scholar] [CrossRef]

- Olagoke, F.K.; Kaiser, K.; Mikutta, R.; Kalbitz, K.; Vogel, C. Persistent Activities of Extracellular Enzymes Adsorbed to Soil Minerals. Microorganisms 2020, 8, 1796. [Google Scholar] [CrossRef]

- Kitadai, N.; Nishiuchi, K. Thermodynamic Impact of Mineral Surfaces on Amino Acid Polymerization: Aspartate Dimerization on Goethite. Astrobiology 2019, 19, 1363–1376. [Google Scholar] [CrossRef] [PubMed]

- Elahi, N.; Rizwan, M. Progress and Prospects of Magnetic Iron Oxide Nanoparticles in Biomedical Applications: A Review. Artif. Organs 2021, 45, 1272–1299. [Google Scholar] [CrossRef] [PubMed]

- Sihivahanan, D.; Nandini, V.; Rajesh, E.; Anitha, N. Goethite Nanofibers as Bio-Fillers in Dental Composite Resin. Indian J. Med. Forensic Med. Toxicol. 2020, 14, 1488–1491. [Google Scholar]

| Control Sample | FeISpongin | Goethite Standard | Vibrational Assignment |

|---|---|---|---|

| 3300 | 3300 | - | –NH stretching |

| - | 3140 | 3140 | –OH stretching |

| 1633 | 1633 | - | C=O stretching |

| 1536 | 1536 | - | –NH deformational |

| 1244 | 1244 | - | C–N stretching |

| - | 1021 | - | Fe–OH |

| - | 892 | 890 | –OH bending |

| - | 794 | 794 | –OH bending |

| 635 | 632 | Fe–O stretching |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kubiak, A.; Voronkina, A.; Pajewska-Szmyt, M.; Kotula, M.; Leśniewski, B.; Ereskovsky, A.; Heimler, K.; Rogoll, A.; Vogt, C.; Rahimi, P.; et al. Creation of a 3D Goethite–Spongin Composite Using an Extreme Biomimetics Approach. Biomimetics 2023, 8, 533. https://doi.org/10.3390/biomimetics8070533

Kubiak A, Voronkina A, Pajewska-Szmyt M, Kotula M, Leśniewski B, Ereskovsky A, Heimler K, Rogoll A, Vogt C, Rahimi P, et al. Creation of a 3D Goethite–Spongin Composite Using an Extreme Biomimetics Approach. Biomimetics. 2023; 8(7):533. https://doi.org/10.3390/biomimetics8070533

Chicago/Turabian StyleKubiak, Anita, Alona Voronkina, Martyna Pajewska-Szmyt, Martyna Kotula, Bartosz Leśniewski, Alexander Ereskovsky, Korbinian Heimler, Anika Rogoll, Carla Vogt, Parvaneh Rahimi, and et al. 2023. "Creation of a 3D Goethite–Spongin Composite Using an Extreme Biomimetics Approach" Biomimetics 8, no. 7: 533. https://doi.org/10.3390/biomimetics8070533