Effects of Load Forecast Deviation on the Specification of Energy Storage Systems

Abstract

:1. Introduction

1.1. Motivation and Problem Formulation

1.2. Objective

1.3. Scope

2. State of the Art

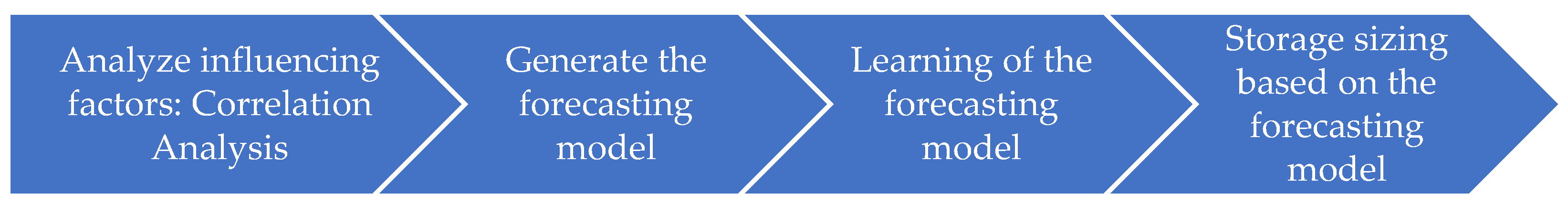

3. Methodology

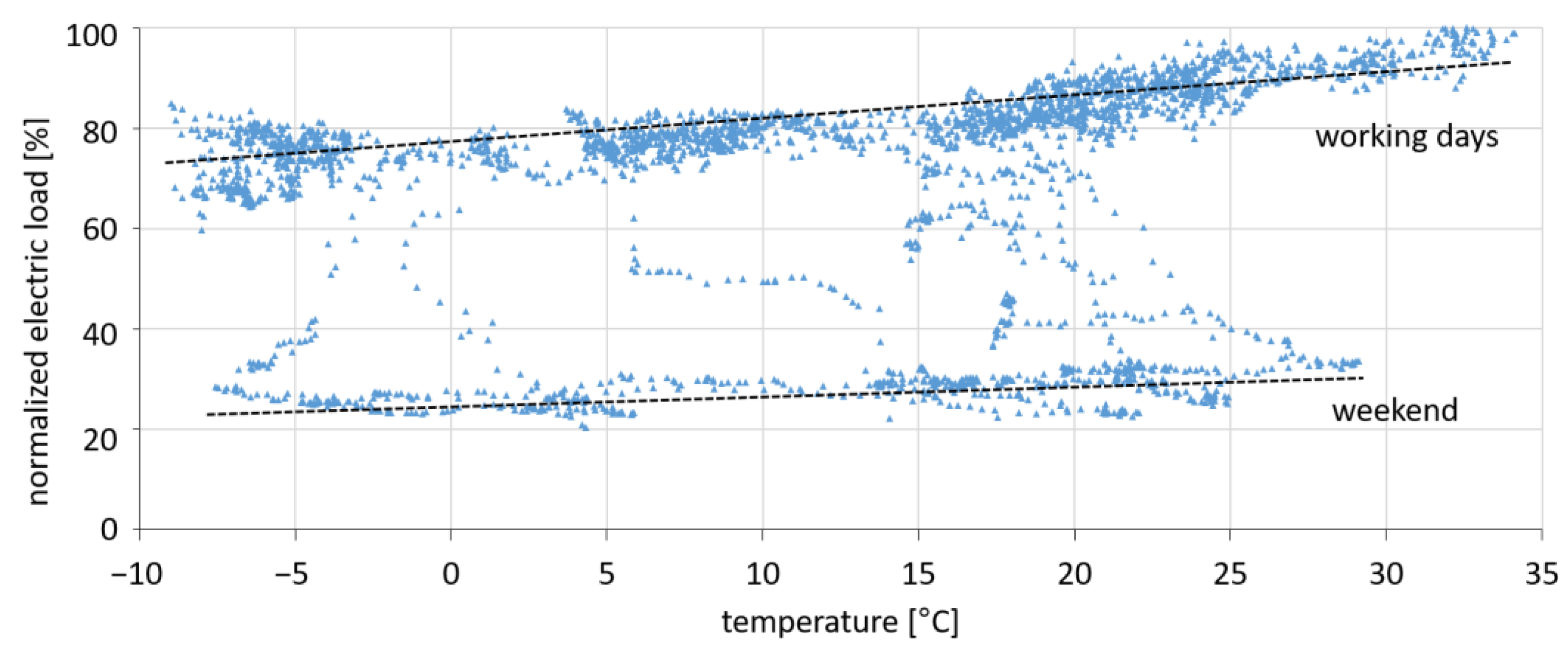

3.1. Correlation Analysis

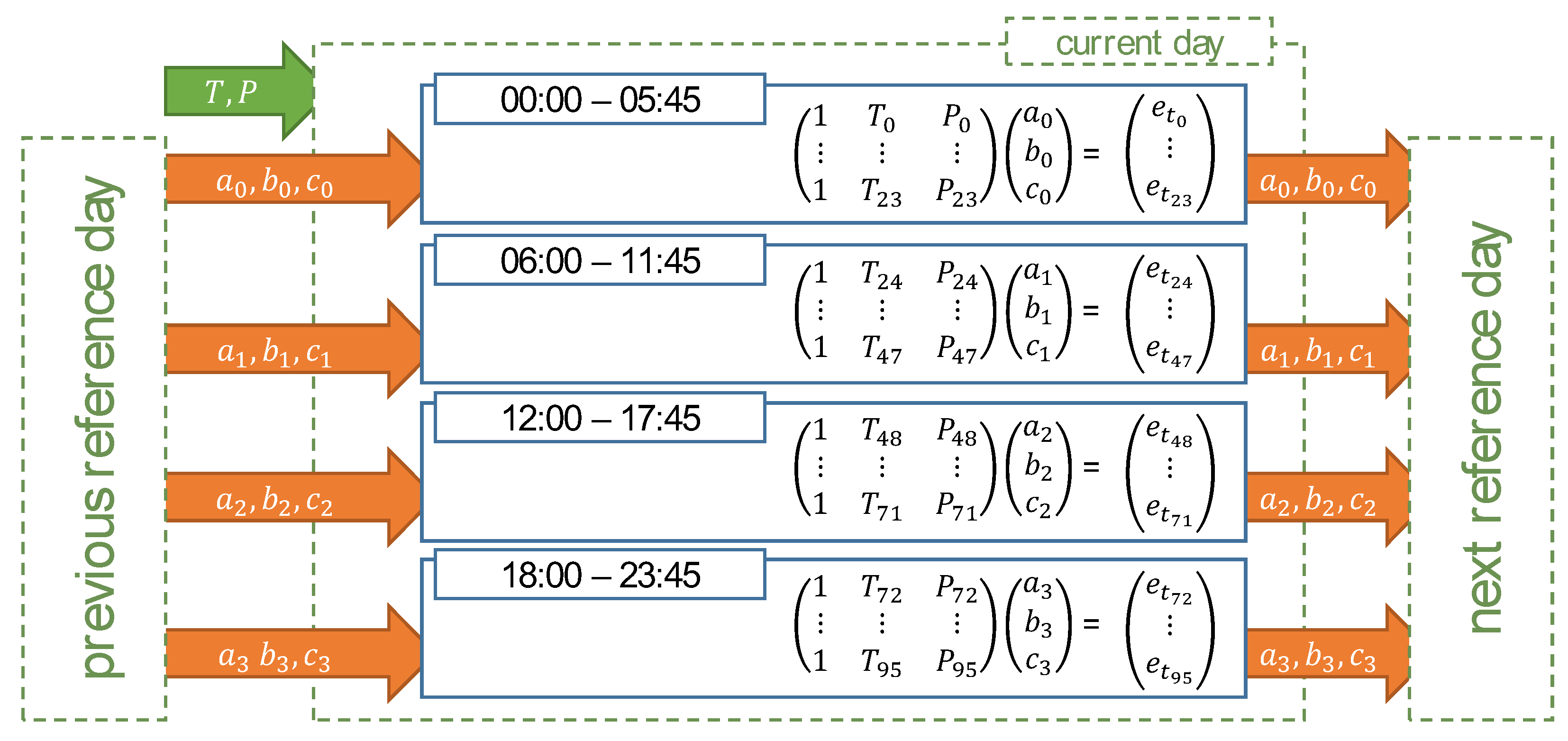

3.2. Forecasting Model Based on the Correlation Analysis

3.3. Use Cases: Energy Storage Sizing and Operation Planning

4. Results and Discussion

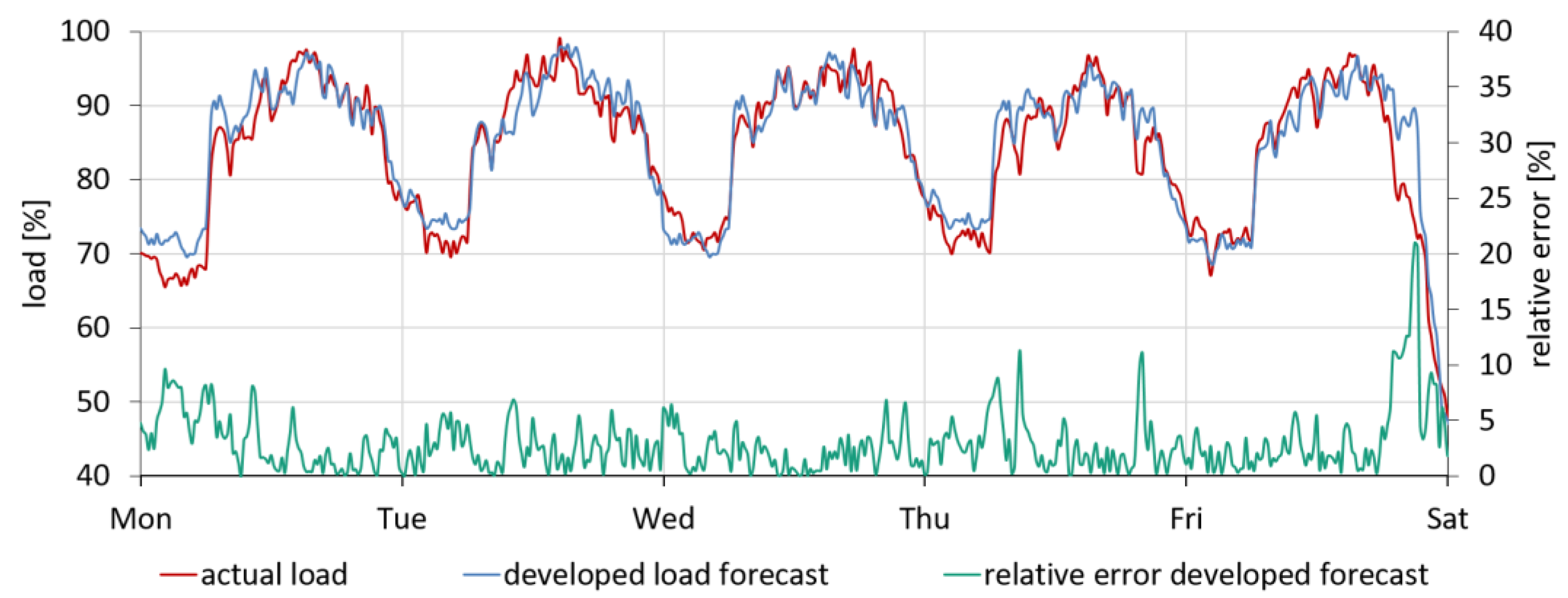

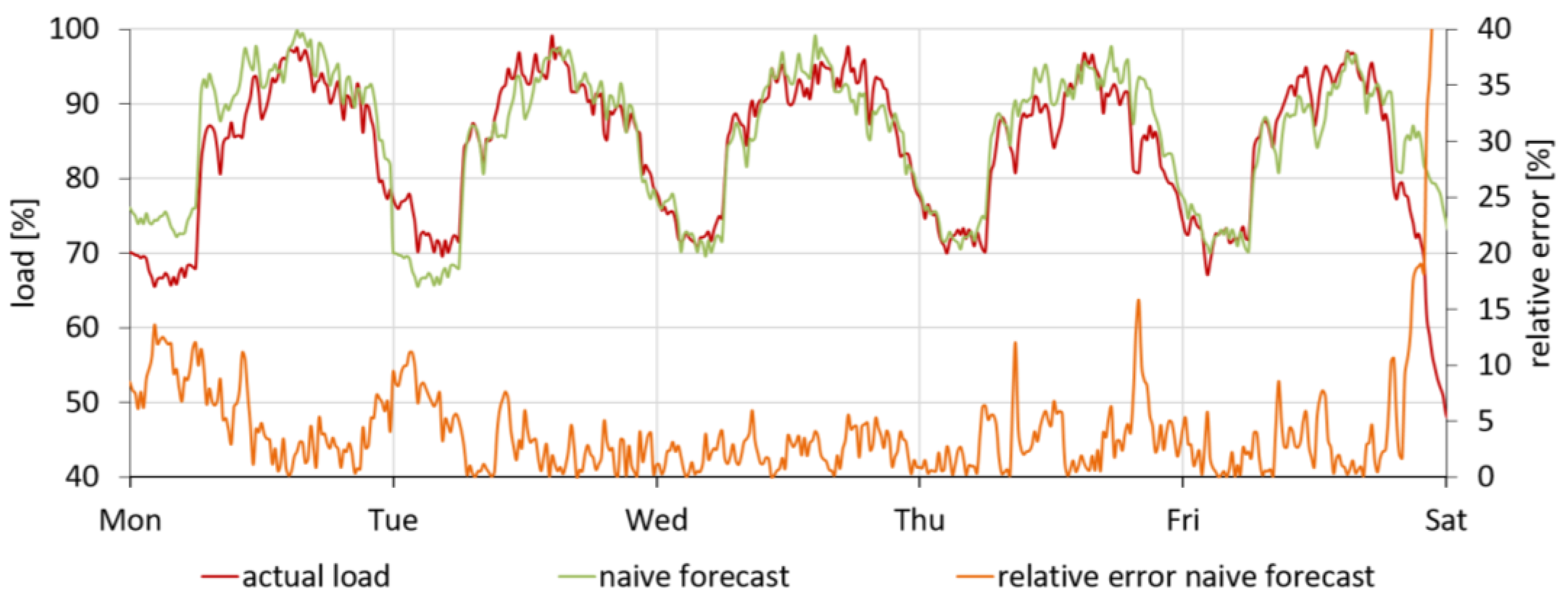

4.1. Forecast Analysis

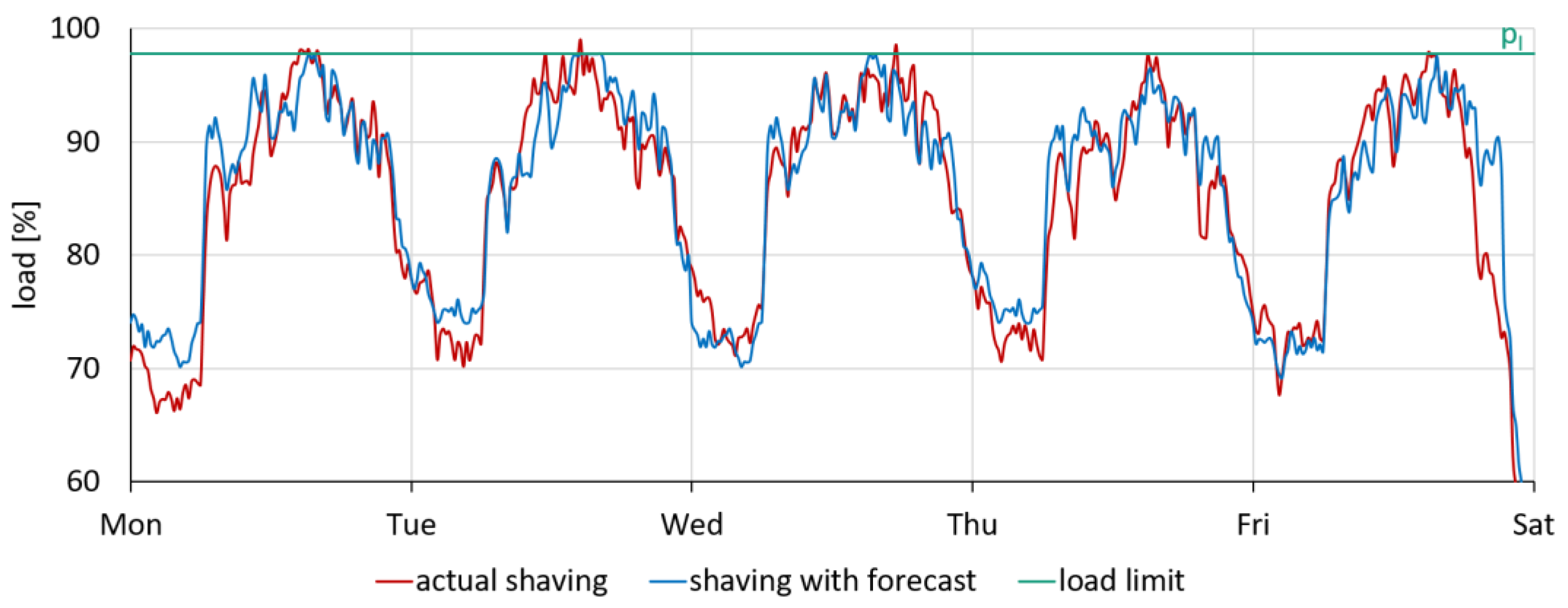

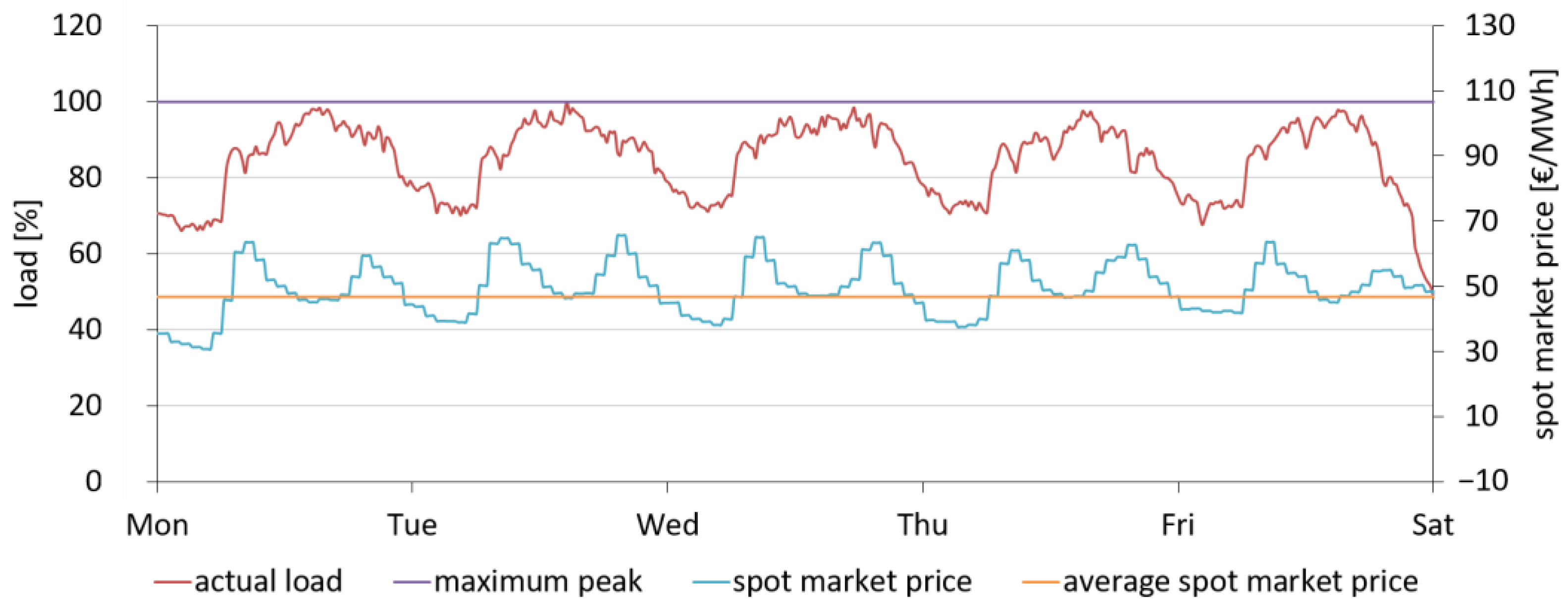

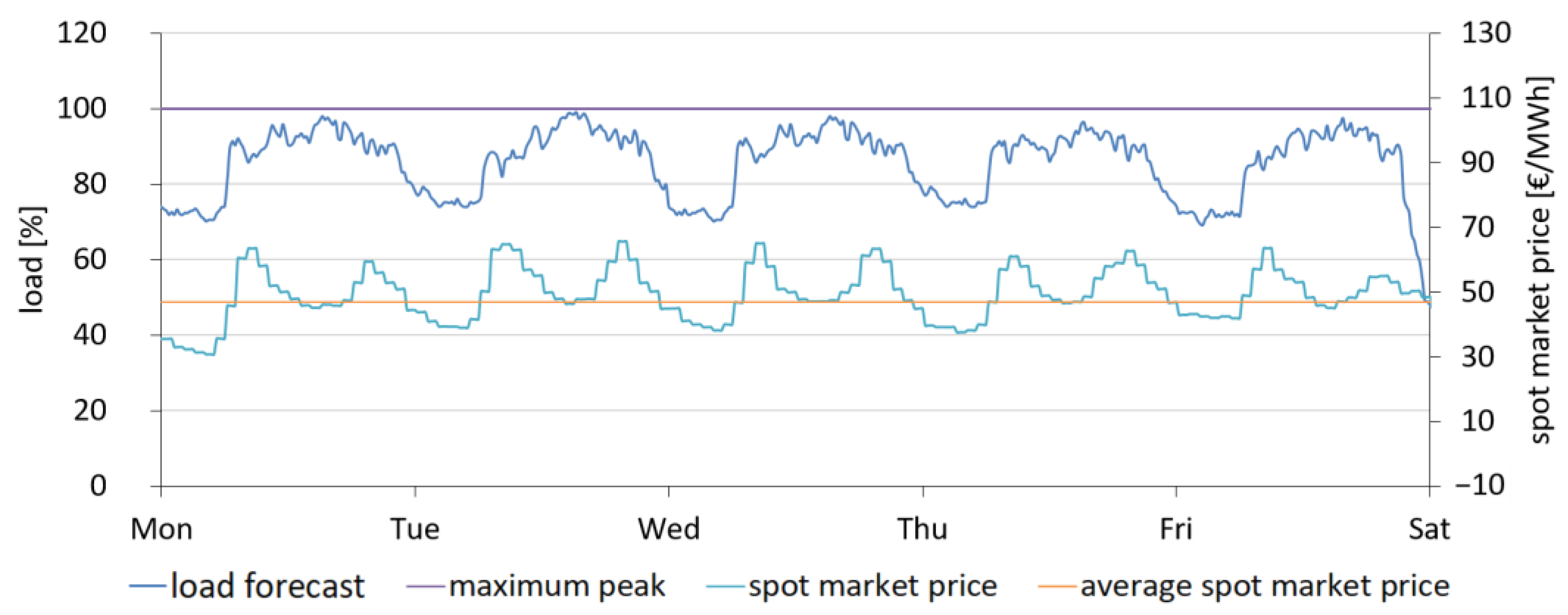

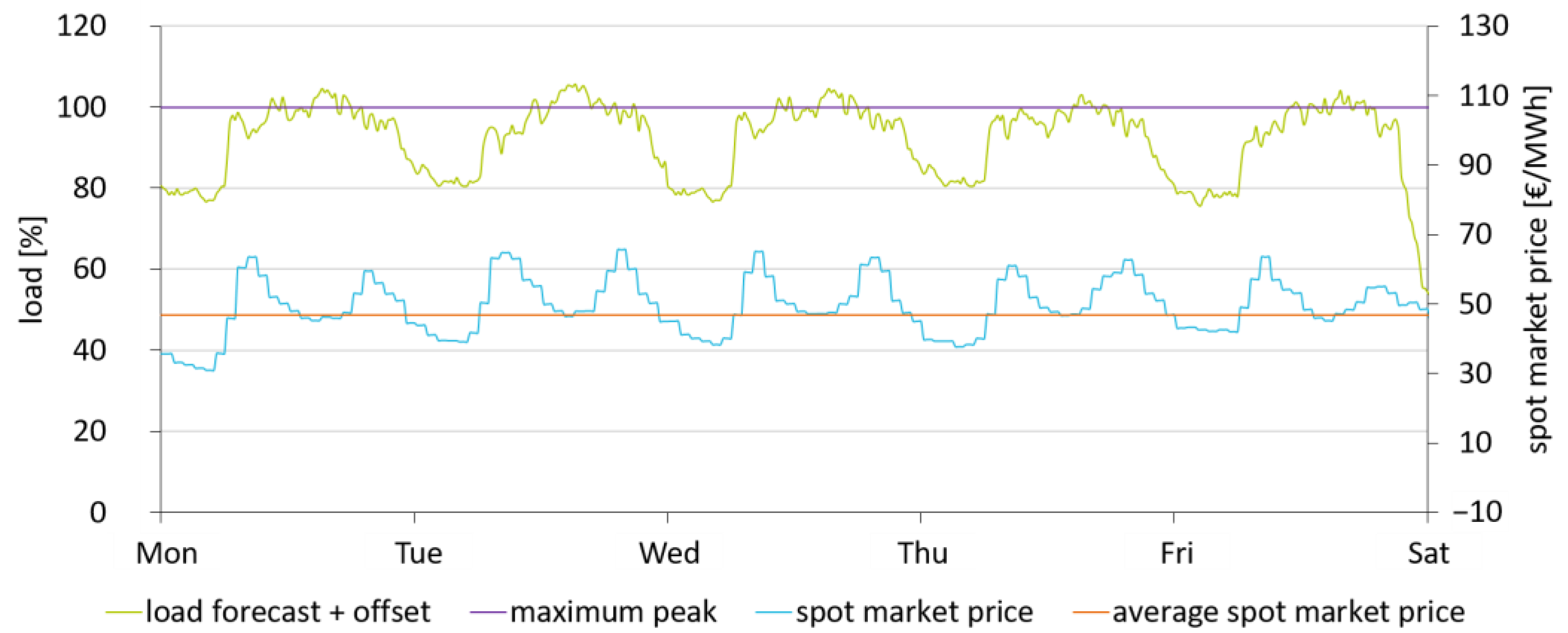

4.2. Impact on Peak Load Reduction

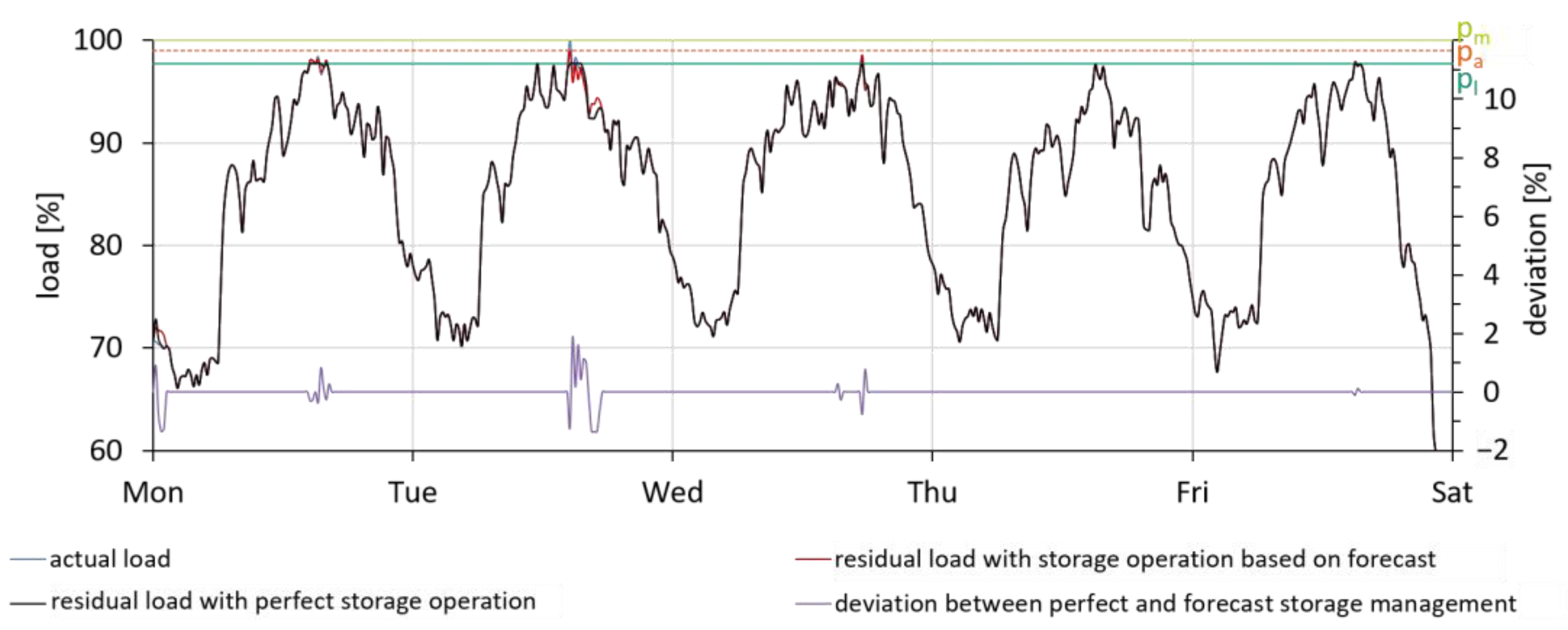

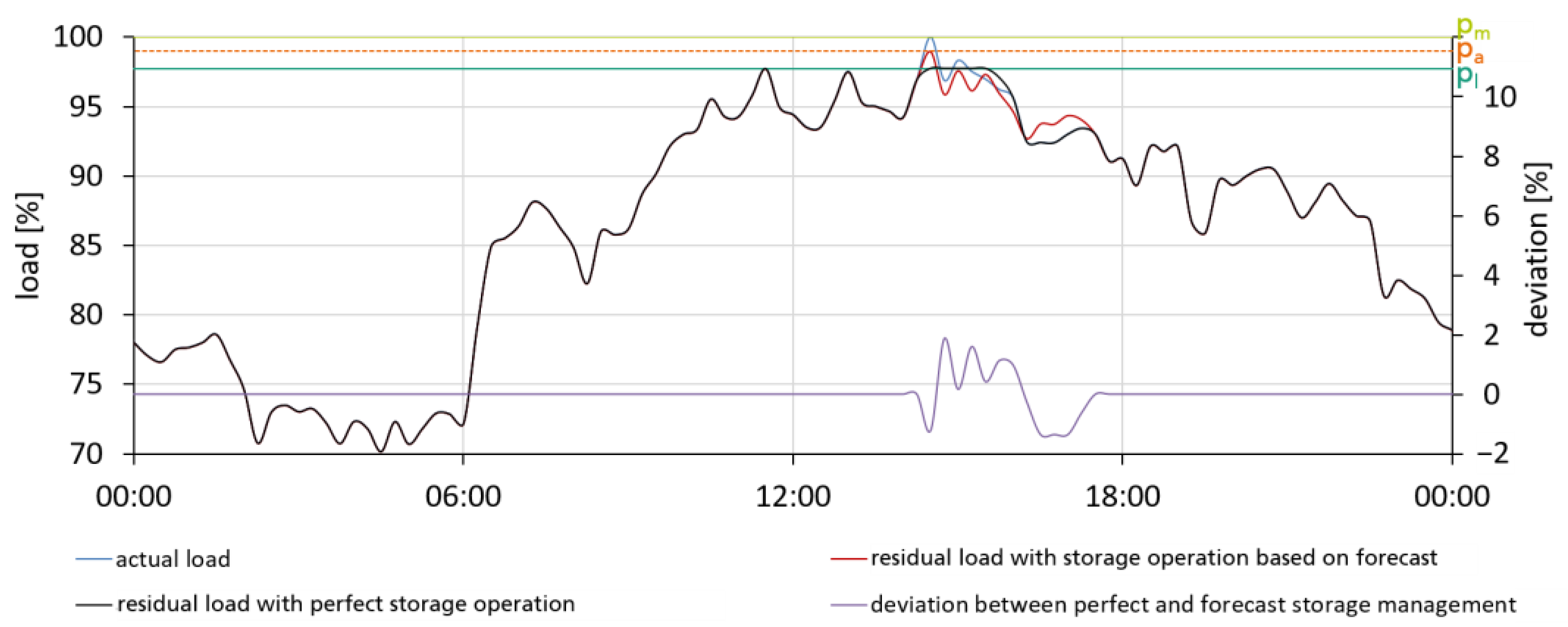

4.3. Impact on Spot Market Revenue

5. Conclusions and Outlook

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zimmermann, F.; Emde, A.; Laribi, R.; Wang, D.; Sauer, A. Energiespeicher in Produktionssystemen—ESIP Studie. Herausforderungen und Chancen; University of Stuttgart: Stuttgart, Germany, 2019. [Google Scholar] [CrossRef]

- Elio, J.; Peinado-Guerrero, M.; Villalobos, R.; Milcarek, R.J. An energy storage dispatch optimization for demand-side management in industrial facilities. J. Energy Storage 2022, 53, 105063. [Google Scholar] [CrossRef]

- Carpinelli, G.; Di Fazio, A.; Khormali, S.; Mottola, F. Optimal Sizing of Battery Storage Systems for Industrial Applications when Uncertainties Exist. Energies 2014, 7, 130–149. [Google Scholar] [CrossRef]

- Hannan, M.A.; Faisal, M.; Jern Ker, P.; Begum, R.A.; Dong, Z.Y.; Zhang, C. Review of optimal methods and algorithms for sizing energy storage systems to achieve decarbonization in microgrid applications. Renew. Sustain. Energy Rev. 2020, 131, 110022. [Google Scholar] [CrossRef]

- Bitterer, R.; Schieferdecker, B. Repräsentative VDEW-Lastprofile; Technical Report; Verband der Elektrizitätswirtschaft e. V. (VDEW): Frankfurt, Germany, 1999. [Google Scholar]

- Zimmermann, F.; Pottmeier, D.; Emde, A.; Sauer, A. A Comparison of Peak Shaving and Atypical Grid Usage Application for Energy Storage Systems in the German Industrial Sector. In Proceedings of the EnInnov2020: 16, Symposium Energieinnovation Energy for Future—Wege zur Klimaneutralität, Graz, Austria, 12–14 February 2020; Technische Universität Graz: Graz, Austria, 2020; pp. 303–304. [Google Scholar]

- Yesilyurt, O.; Bauer, D.; Emde, A.; Sauer, A. Why should the automated guided vehicles’ batteries be used in the manufacturing plants as an energy storage? E3S Web Conf. 2021, 231, 01004. [Google Scholar] [CrossRef]

- Viehmann, J. State of the German Short-Term Power Market. Z. Energiewirtschaft 2017, 41, 87–103. [Google Scholar] [CrossRef]

- Kim, Y.; Son, H.; Kim, S. Short term electricity load forecasting for institutional buildings. Energy Rep. 2019, 5, 1270–1280. [Google Scholar] [CrossRef]

- Ryu, S.; Noh, J.; Kim, H. Deep Neural Network Based Demand Side Short Term Load Forecasting. Energies 2017, 10, 3. [Google Scholar] [CrossRef]

- Khan, A.R.; Mahmood, A.; Safdar, A.; Khan, Z.A.; Khan, N.A. Load forecasting, dynamic pricing and DSM in smart grid: A review. Renew. Sustain. Energy Rev. 2016, 54, 1311–1322. [Google Scholar] [CrossRef]

- Ghasemi, A.; Shayeghi, H.; Moradzadeh, M.; Nooshyar, M. A novel hybrid algorithm for electricity price and load forecasting in smart grids with demand-side management. Appl. Energy 2016, 177, 40–59. [Google Scholar] [CrossRef]

- Zheng, J.; Xu, C.; Zhang, Z.; Li, X. Electric load forecasting in smart grids using Long-Short-Term-Memory based Recurrent Neural Network. In Proceedings of the 2017 51st Annual Conference on Information Sciences and Systems (CISS), Baltimore, MD, USA, 22–24 March 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 1–6, ISBN 978-1-5090-4780-2. [Google Scholar]

- Hippert, H.S.; Pedreira, C.E.; Souza, R.C. Neural networks for short-term load forecasting: A review and evaluation. IEEE Trans. Power Syst. 2001, 16, 44–55. [Google Scholar] [CrossRef]

- Dewangan, F.; Abdelaziz, A.Y.; Biswal, M. Load Forecasting Models in Smart Grid Using Smart Meter Information: A Review. Energies 2023, 16, 1404. [Google Scholar] [CrossRef]

- Habbak, H.; Mahmoud, M.; Metwally, K.; Fouda, M.M.; Ibrahem, M.I. Load Forecasting Techniques and Their Applications in Smart Grids. Energies 2023, 16, 1480. [Google Scholar] [CrossRef]

- Wang, H.; Alattas, K.A.; Mohammadzadeh, A.; Sabzalian, M.H.; Aly, A.A.; Mosavi, A. Comprehensive review of load forecasting with emphasis on intelligent computing approaches. Energy Rep. 2022, 8, 13189–13198. [Google Scholar] [CrossRef]

- Zhu, J.; Dong, H.; Zheng, W.; Li, S.; Huang, Y.; Xi, L. Review and prospect of data-driven techniques for load forecasting in integrated energy systems. Appl. Energy 2022, 321, 119269. [Google Scholar] [CrossRef]

- Bartolucci, L.; Cordiner, S.; Mulone, V.; Santarelli, M. Hybrid renewable energy systems: Influence of short term forecasting on model predictive control performance. Energy 2019, 172, 997–1004. [Google Scholar] [CrossRef]

- Jia, C.; Zhou, J.; He, H.; Li, J.; Wei, Z.; Li, K.; Shi, M. A novel energy management strategy for hybrid electric bus with fuel cell health and battery thermal- and health-constrained awareness. Energy 2023, 271, 127105. [Google Scholar] [CrossRef]

- Schellong, W. Analyse und Optimierung von Energieverbundsystemen, 1. Auflage; Springer: Berlin/Heidelberg, Germany, 2016; ISBN 978-3-662-49463-9. [Google Scholar]

- Hirsch, C. Fahrplanbasiertes Energiemanagementsystem in Smart Grids; KIT: Karlsruhe, Germany, 2017. [Google Scholar]

- Chow, J.H.; Wu, F.F.; Momoh, J. Applied Mathematics for Restructured Electric Power Systems: Optimization, Control, and Computational Intelligence; Springer: Boston, MA, USA, 2005; ISBN 978-0-387-23471-7. [Google Scholar]

- Chen, K. Trends in Neural Computation; Springer: Berlin/Heidelberg, Germany, 2007; ISBN 978-3-540-36122-0. [Google Scholar]

- Almeshaiei, E.; Soltan, H. A methodology for Electric Power Load Forecasting. Alex. Eng. J. 2011, 50, 137–144. [Google Scholar] [CrossRef]

- Nti, I.K.; Teimeh, M.; Nyarko-Boateng, O.; Adekoya, A.F. Electricity load forecasting: A systematic review. J. Electr. Syst. Inf. Technol. 2020, 7, 13. [Google Scholar] [CrossRef]

- Hahn, H.; Meyer-Nieberg, S.; Pickl, S. Electric load forecasting methods: Tools for decision making. Eur. J. Oper. Res. 2009, 199, 902–907. [Google Scholar] [CrossRef]

- Chen, C.; Duan, S.; Cai, T.; Liu, B.; Hu, G. Optimal Allocation and Economic Analysis of Energy Storage System in Microgrids. IEEE Trans. Power Electron. 2011, 26, 2762–2773. [Google Scholar] [CrossRef]

- Soroudi, A.; Siano, P.; Keane, A. Optimal DR and ESS Scheduling for Distribution Losses Payments Minimization under Electricity Price Uncertainty. IEEE Trans. Smart Grid 2016, 7, 261–272. [Google Scholar] [CrossRef]

- Mukhopadhyay, P.; Mitra, G.; Banerjee, S.; Mukherjee, G. Electricity load forecasting using fuzzy logic: Short term load forecasting factoring weather parameter. In Proceedings of the 2017 7th International Conference on Power Systems (ICPS), Pune, India, 21–23 December 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 812–819, ISBN 978-1-5386-1789-2. [Google Scholar]

- Afrasiabi, M.; Mohammadi, M.; Rastegar, M.; Kargarian, A. Multi-agent microgrid energy management based on deep learning forecaster. Energy 2019, 186, 115873. [Google Scholar] [CrossRef]

- Zor, K.; Timur, O.; Teke, A. A state-of-the-art review of artificial intelligence techniques for short-term electric load forecasting. In Proceedings of the 6th International Youth Conference on Energy (IYCE), Budapest, Hungary, 21–24 June 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 1–7, ISBN 978-1-5090-6409-0. [Google Scholar]

- Emde, A.; Zimmermann, F.; Feil, M.; Sauer, A. Erstellung und Validierung von Lastprofilen für die energieintensive Industrie. Z. Wirtsch. Fabr. 2018, 113, 545–549. [Google Scholar] [CrossRef]

- Dutta, S.; Sharma, R. Optimal storage sizing for integrating wind and load forecast uncertainties. In Proceedings of the 2012 IEEE PES Innovative Smart Grid Technologies (ISGT), Washington, DC, USA, 16–20 January 2012; pp. 1–7, ISBN 978-1-4577-2159-5. [Google Scholar]

- Senchilo, N.D.; Ustinov, D.A. Method for Determining the Optimal Capacity of Energy Storage Systems with a Long-Term Forecast of Power Consumption. Energies 2021, 14, 7098. [Google Scholar] [CrossRef]

- Soman, A.; Trivedi, A.; Irwin, D.; Kosanovic, B.; McDaniel, B.; Shenoy, P. Peak Forecasting for Battery-based Energy Optimizations in Campus Microgrids. In Proceedings of the Eleventh ACM International Conference on Future Energy Systems, Virtual Event, Australia, 22–26 June 2020; ACM: New York, NY, USA, 2020; pp. 237–241, ISBN 9781450380096. [Google Scholar]

- Hwang, J.S.; Rosyiana Fitri, I.; Kim, J.-S.; Song, H. Optimal ESS Scheduling for Peak Shaving of Building Energy Using Accuracy-Enhanced Load Forecast. Energies 2020, 13, 5633. [Google Scholar] [CrossRef]

- Chapaloglou, S.; Nesiadis, A.; Iliadis, P.; Atsonios, K.; Nikolopoulos, N.; Grammelis, P.; Yiakopoulos, C.; Antoniadis, I.; Kakaras, E. Smart energy management algorithm for load smoothing and peak shaving based on load forecasting of an island’s power system. Appl. Energy 2019, 238, 627–642. [Google Scholar] [CrossRef]

- Collath, N.; Englberger, S.; Jossen, A.; Hesse, H. Reduction of Battery Energy Storage Degradation in Peak Shaving Operation through Load Forecast Dependent Energy Management. In Proceedings of the NEIS 2020: Conference on Sustainable Energy Supply and Energy Storage Systems, Hamburg, Germany, 14–15 September 2020; Schulz, D., Ed.; VDE VERLAG: Berlin, Germany, 2020; pp. 1–6, ISBN 978-3-8007-5359-8. [Google Scholar]

- Ilic, D.; Karnouskos, S.; Goncalves Da Silva, P. Improving Load Forecast in Prosumer Clusters by Varying Energy Storage Size. In Proceedings of the IEEE Grenoble PowerTech, Grenoble, France, 16–20 June 2013. [Google Scholar]

- Quinino, R.C.; Reis, E.A.; Bessegato, L.F. Using the coefficient of determination R2 to test the significance of multiple linear regression. Teach. Stat. 2013, 35, 84–88. [Google Scholar] [CrossRef]

- Asuero, A.G.; Sayago, A.; González, A.G. The Correlation Coefficient: An Overview. Crit. Rev. Anal. Chem. 2006, 36, 41–59. [Google Scholar] [CrossRef]

- Hyndman, R.J.; Athanasopoulos, G. Forecasting: Principles and Practice, 2nd ed.; Otexts Online Open-Access Textbook; Otexts: Lexington, KY, USA, 2018; ISBN 978-0-9875071-1-2. [Google Scholar]

- Elektrizitätswerk Hammermühle. Preisblatt für die Netznutzung des Stromnetzes der EWH Versorgungs GmbH; Elektrizitätswerk Hammermühle: Selters, Germany, 2017. [Google Scholar]

| Parameters | Thermal Load | Electrical Load |

|---|---|---|

| Geographical location | +++ | +++ |

| Season | +++ | ++ |

| Vacation | + | ++ |

| Weekday | ++ | +++ |

| Outdoor temperature | +++ | ++ |

| Public holidays | ++ | +++ |

| Production plan | ++ | +++ |

| Peak Shaving [kW] | Actual Shave with Forecast [kW] | Actual Shave [%] |

|---|---|---|

| 500 | 455 | 91 |

| 1000 | 663 | 66 |

| 1500 | 551 | 37 |

| 2000 | 819 | 41 |

| 2500 | 178 | 7 |

| 3000 | 547 | 18 |

| Type of Offset | kW |

|---|---|

| maximum deviation | 3180 |

| average deviation | 1108 |

| average deviation (load > forecast) | 910 |

| Scenarios | Shave [kW] | Power [kW] | Capacity [kWh] |

|---|---|---|---|

| Actual load | 500 | 500 | 125 |

| Forecast | 455 | 500 | 437 |

| Forecast + offset | 500 | 3680 | 437 |

| Actual load | 1000 | 1000 | 312 |

| Forecast | 663 | 1000 | 1521 |

| Forecast + offset | 1000 | 4180 | 1521 |

| Actual load | 1500 | 1500 | 947 |

| Forecast | 551 | 1500 | 2896 |

| Forecast + offset | 1500 | 4680 | 2896 |

| Actual load | 2000 | 2000 | 2302 |

| Forecast | 819 | 2000 | 4602 |

| Forecast + offset | 2000 | 5180 | 4602 |

| Actual load | 2500 | 2500 | 3980 |

| Forecast | 178 | 2500 | 7050 |

| Forecast + offset | 2500 | 5680 | 7050 |

| Scenario | Potential Annual Revenue [€] |

|---|---|

| Only charge at night | 201,292 |

| Charge based on forecast + Offset | 251,420 |

| Charge based on actual load | 266,656 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Emde, A.; Märkle, L.; Kratzer, B.; Schnell, F.; Baur, L.; Sauer, A. Effects of Load Forecast Deviation on the Specification of Energy Storage Systems. Designs 2023, 7, 107. https://doi.org/10.3390/designs7050107

Emde A, Märkle L, Kratzer B, Schnell F, Baur L, Sauer A. Effects of Load Forecast Deviation on the Specification of Energy Storage Systems. Designs. 2023; 7(5):107. https://doi.org/10.3390/designs7050107

Chicago/Turabian StyleEmde, Alexander, Lisa Märkle, Benedikt Kratzer, Felix Schnell, Lukas Baur, and Alexander Sauer. 2023. "Effects of Load Forecast Deviation on the Specification of Energy Storage Systems" Designs 7, no. 5: 107. https://doi.org/10.3390/designs7050107