Effect of Process Parameters on Laser Powder Bed Fusion of Al-Sn Miscibility Gap Alloy

Abstract

:1. Introduction

2. Materials and Methods

- Equivalent diameter (∅eq), i.e., calculated diameter of a circle with the same area as the pore;

- Circularity, i.e., 4·π·area/perimeter2, which tends to 1 if the particle is round and smooth, and tends to 0 if it has irregular surface and/or elongated shape;

- Solidity, i.e., ratio between pore area and the minimum convex area that can cover the pore, which tends towards 1 if the pore has a convex shape, and tends towards zero if the boundary is irregular.

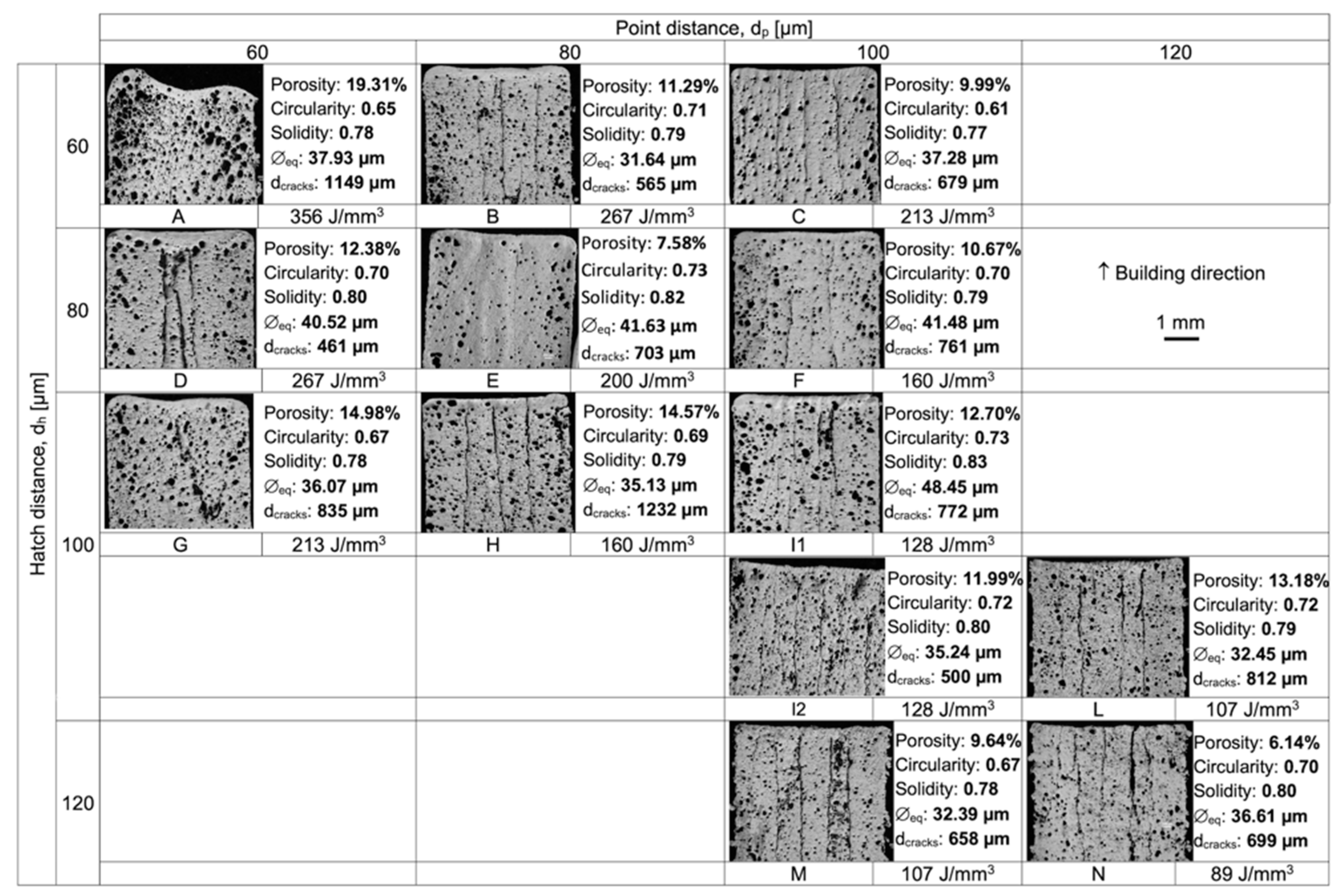

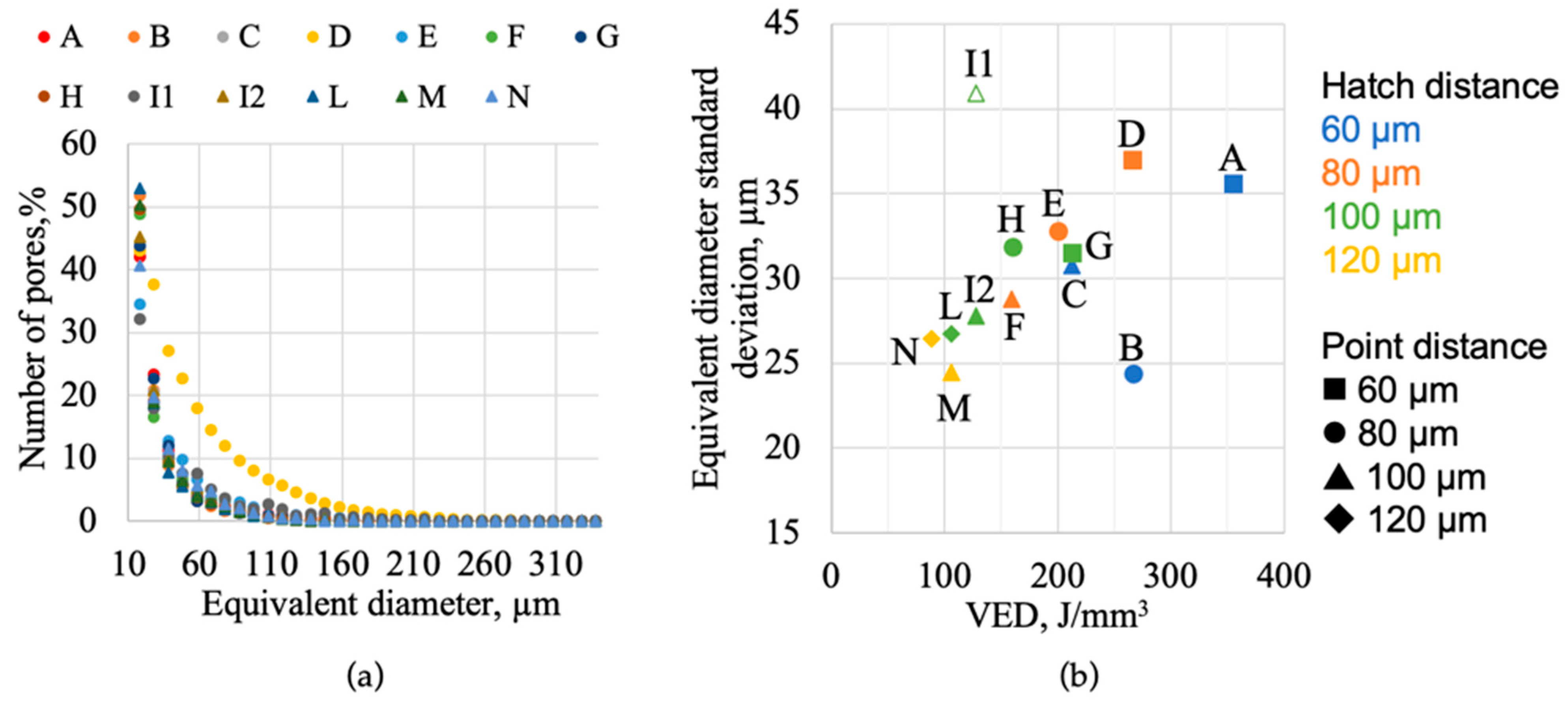

3. Results

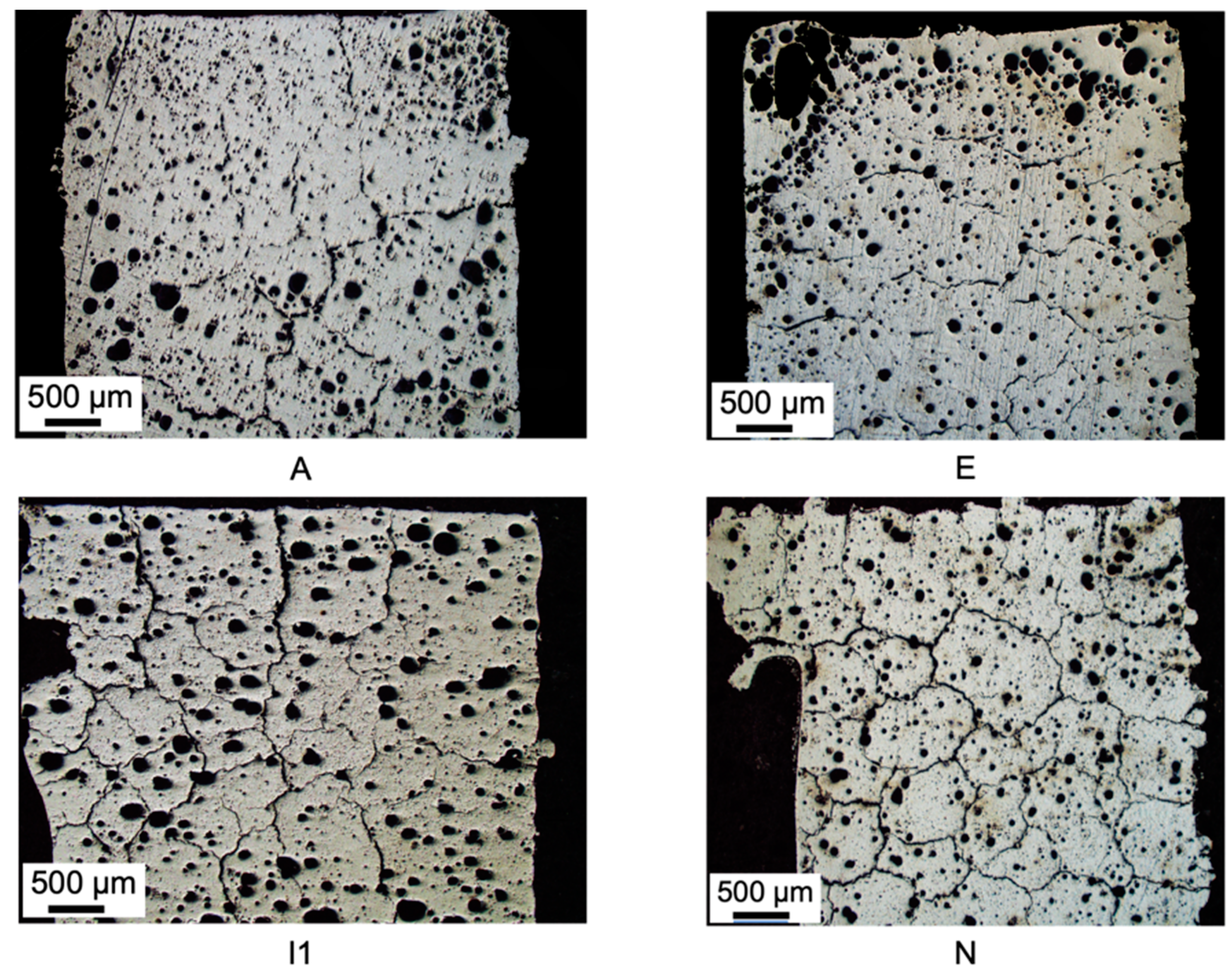

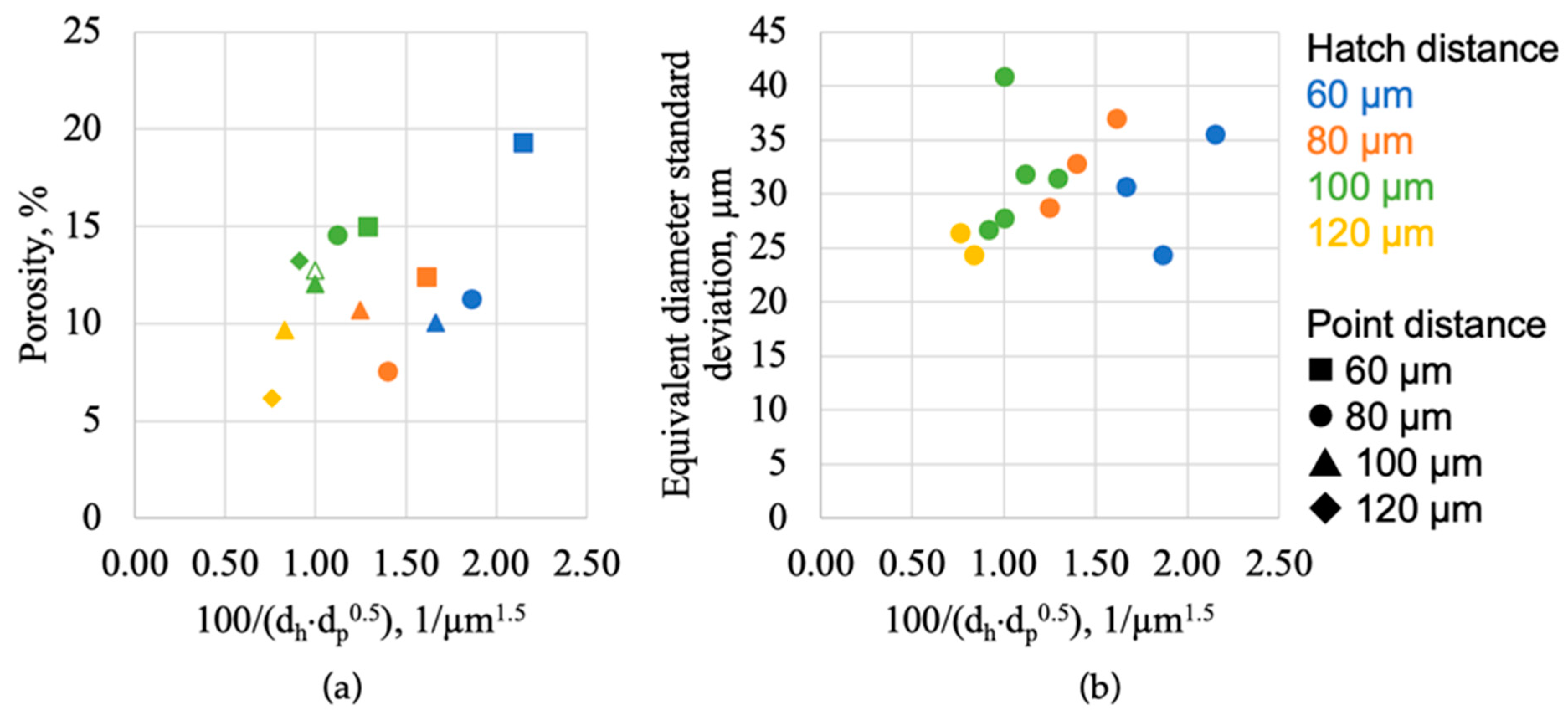

3.1. Low Magnification Analysis

3.2. SEM Analysis

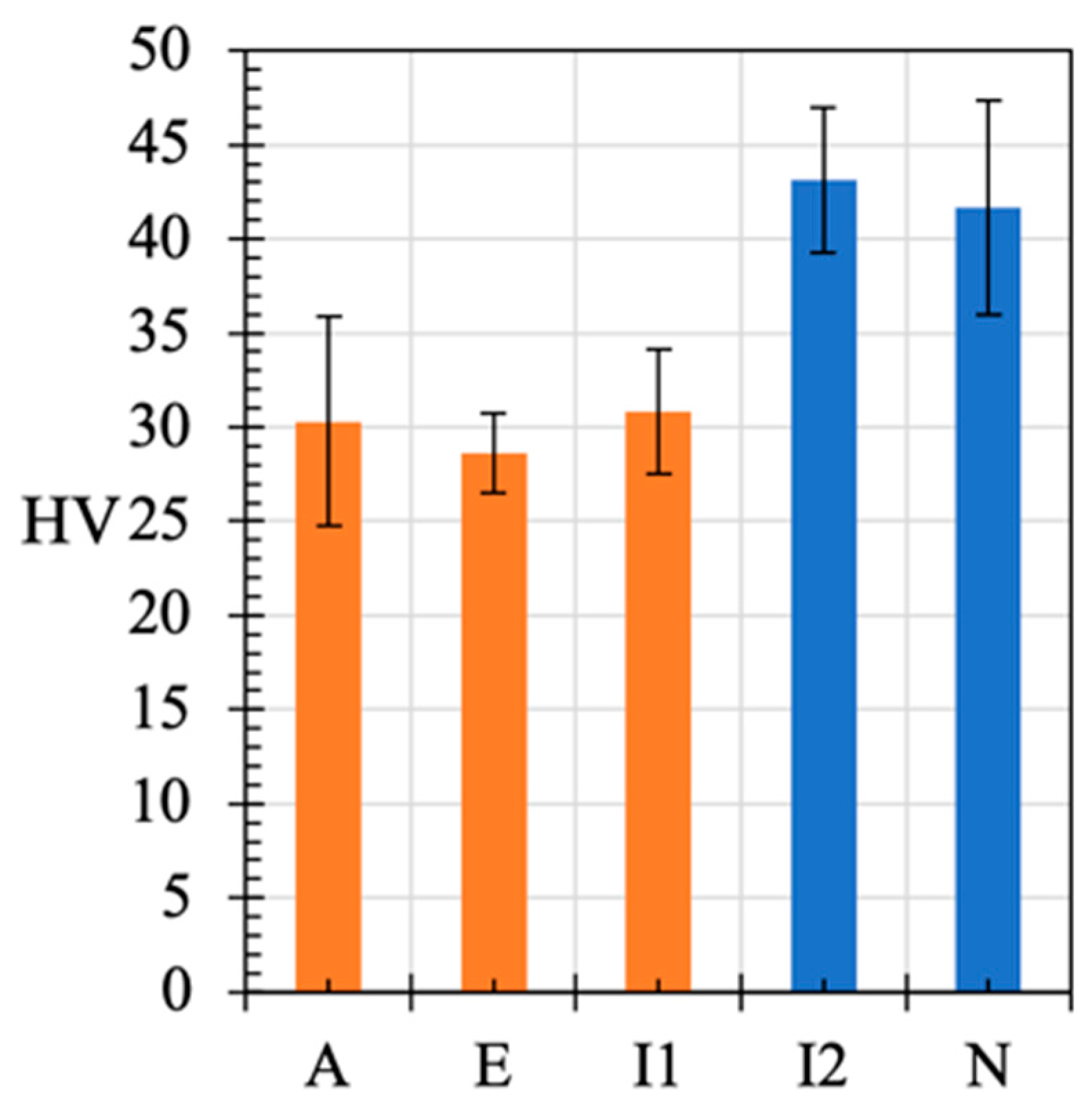

3.3. Vickers Microhardness

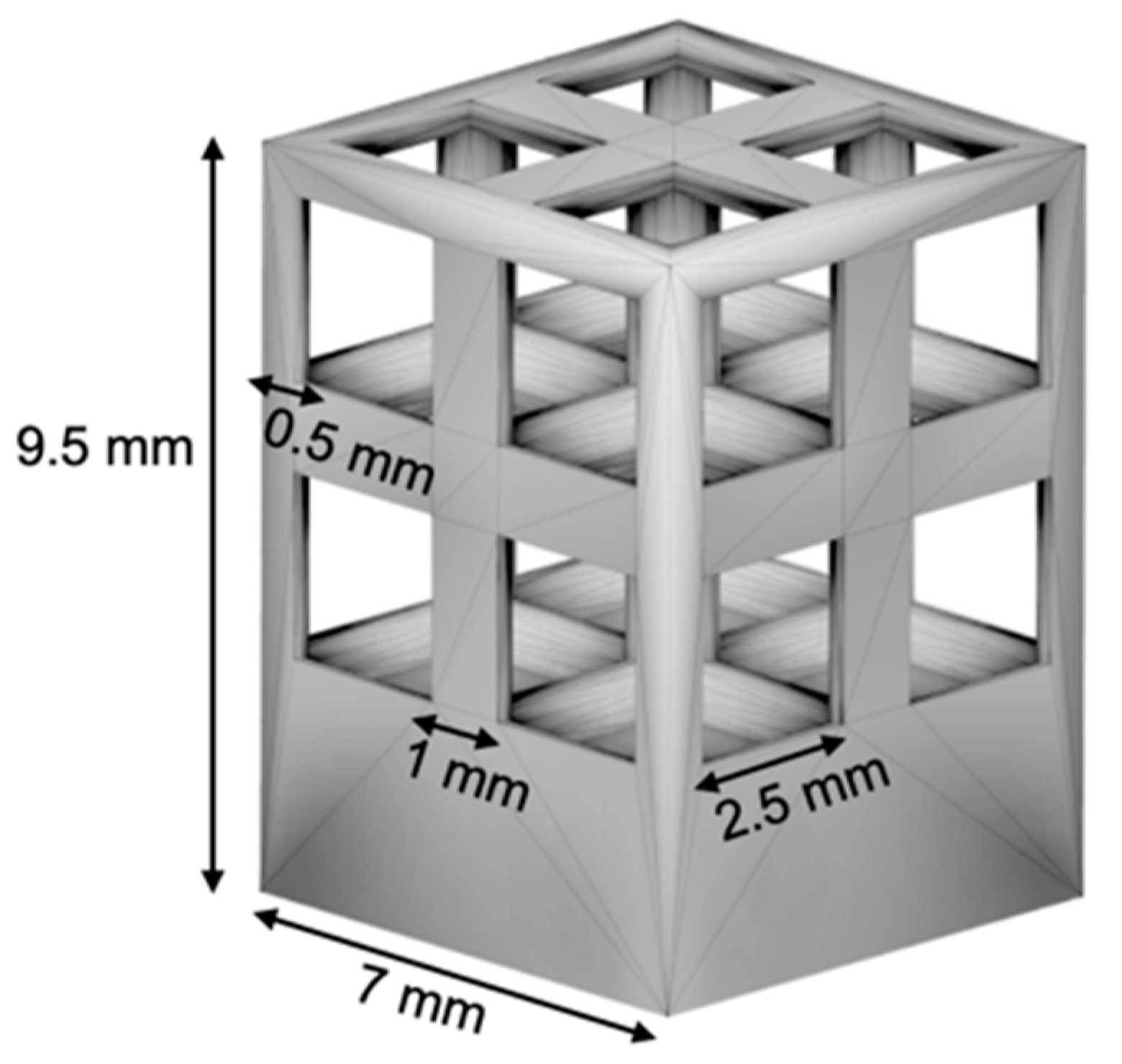

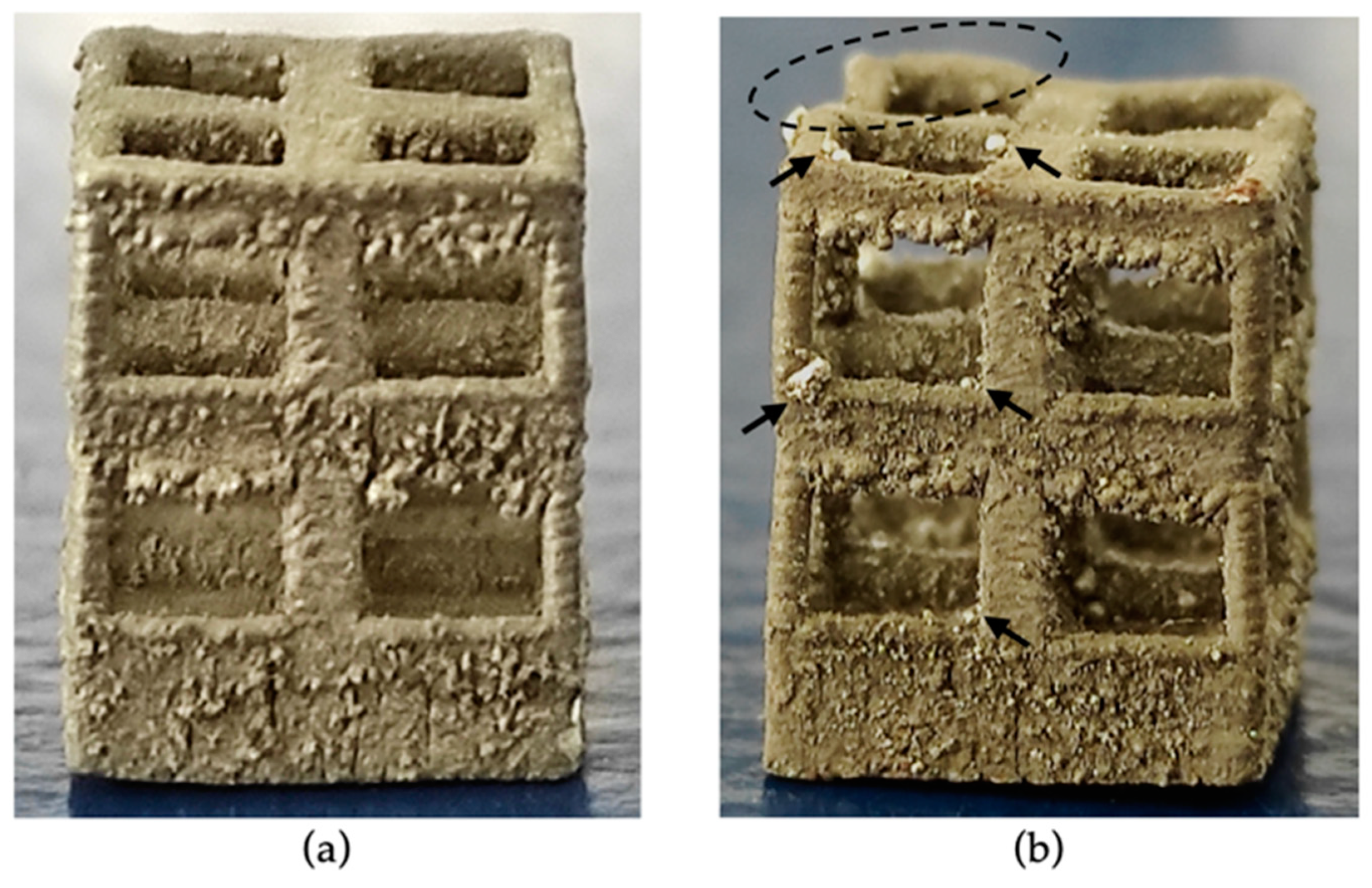

3.4. Lattice Structures

4. Discussion

4.1. Effect of Process Parameters on Microstructure

- Excessively high energy density increases pore size and results in accumulation of materials on the top surface corners;

- Most of the parameter sets lead to coarse porosity located at the outer surface, especially in high VED conditions. As energy decreases porosity is more homogeneously distributed in the sample;

- High energy results in coarse and homogeneous phase distribution;

- Low VED samples are more affected by hot-cracking.

4.2. Lattice Structures

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, X.; Zeng, M.; Ma, Y.; Zhu, M. Promoting the high load-carrying capability of Al–20wt%Sn bearing alloys through creating nanocomposite structure by mechanical alloying. Wear 2012, 294–295, 387–394. [Google Scholar] [CrossRef]

- Sugo, H.; Kisi, E.; Cuskelly, D. Miscibility gap alloys with inverse microstructures and high thermal conductivity for high energy density thermal storage applications. Appl. Therm. Eng. 2013, 51, 1345–1350. [Google Scholar] [CrossRef]

- Confalonieri, C.; Perrin, M.; Gariboldi, E. Combined powder metallurgy routes to improve thermal and mechanical response of Al−Sn composite phase change materials. Trans. Nonferrous Met. Soc. China 2020, 30, 3226–3239. [Google Scholar] [CrossRef]

- Zhai, W.; Hu, L.; Geng, D.; Wei, B. Thermodynamic properties and microstructure evolution of ternary Al–10%Cu–x%Sn immiscible alloys. J. Alloys Compd. 2015, 627, 402–409. [Google Scholar] [CrossRef]

- Liu, X.; Zeng, M.; Ma, Y.; Zhu, M. Wear behavior of Al–Sn alloys with different distribution of Sn dispersoids manipulated by mechanical alloying and sintering. Wear 2008, 265, 1857–1863. [Google Scholar] [CrossRef]

- Lu, Z.; Zeng, M.; Gao, Y.; Zhu, M. Significant improvement of wear properties by creating micro/nano dual-scale structure in Al–Sn alloys. Wear 2012, 296, 469–478. [Google Scholar] [CrossRef]

- Liu, X.; Zeng, M.; Ma, Y.; Zhu, M. Melting behavior and the correlation of Sn distribution on hardness in a nanostructured Al–Sn alloy. Mater. Sci. Eng. A 2009, 506, 1–7. [Google Scholar] [CrossRef]

- Confalonieri, C.; Grimaldi, A.T.; Gariboldi, E. Ball-milled Al–Sn alloy as composite Phase Change Material. Mater. Today Energy 2020, 17, 100456. [Google Scholar] [CrossRef]

- Confalonieri, C.; Bassani, P.; Gariboldi, E. Microstructural and thermal response evolution of metallic form-stable phase change materials produced from ball-milled powders. J. Therm. Anal. 2020, 142, 85–96. [Google Scholar] [CrossRef]

- Makhatha, M.E.; Fatoba, O.S.; Akinlabi, E.T. Effects of rapid solidification on the microstructure and surface analyses of laser-deposited Al-Sn coatings on AISI 1015 steel. Int. J. Adv. Manuf. Technol. 2018, 94, 773–787. [Google Scholar] [CrossRef]

- Marrocco, T.; Driver, L.C.; Harris, S.J.; McCartney, D.G.; Mc Cartney, G. Microstructure and Properties of Thermally Sprayed Al-Sn-Based Alloys for Plain Bearing Applications. J. Therm. Spray Technol. 2006, 15, 634–639. [Google Scholar] [CrossRef]

- Lucchetta, M.C.; Saporiti, F.; Audebert, F. Improvement of surface properties of an Al–Sn–Cu plain bearing alloy produced by rapid solidification. J. Alloys Compd. 2019, 805, 709–717. [Google Scholar] [CrossRef]

- Kim, W.T.; Cantor, B. Solidification of tin droplets embedded in an aluminium matrix. J. Mater. Sci. 1991, 26, 2868–2878. [Google Scholar] [CrossRef]

- Zhang, W.; Zhao, B.; Zhai, Q.; Gao, Y. Application of Fast Scanning Calorimetry in the Rapid Solidification of Tin Particles Embedded in Al Matrix. In TMS2013 Supplemental Proceedings; Wiley: Hoboken, NJ, USA, 2013; pp. 477–484. [Google Scholar]

- Zhang, Z.; Wang, Y.; Bian, X.; Wang, W. Orientation of nanocrystals in rapidly solidified Al-based alloys and its correlation to the compound-forming tendency of alloys. J. Cryst. Growth 2005, 281, 646–653. [Google Scholar] [CrossRef]

- Confalonieri, C.; Gariboldi, E. Al-Sn Miscibility Gap Alloy produced by Power Bed Laser Melting for application as Phase Change Material. J. Alloys Compd. 2021, 881, 160596. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.; Zuback, J.; Mukherjee, T.; Elmer, J.; Milewski, J.; Beese, A.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components – Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Kim, W.R.; Bang, G.B.; Park, J.H.; Lee, T.W.; Lee, B.-S.; Yang, S.-M.; Kim, G.-H.; Lee, K.; Kim, H.G. Microstructural study on a Fe-10Cu alloy fabricated by selective laser melting for defect-free process optimization based on the energy density. J. Mater. Res. Technol. 2020, 9, 12834–12839. [Google Scholar] [CrossRef]

- Zafari, A.; Xia, K. Nano/ultrafine grained immiscible Fe-Cu alloy with ultrahigh strength produced by selective laser melting. Mater. Res. Lett. 2021, 9, 247–254. [Google Scholar] [CrossRef]

- Hubert, R.; Matar, O.B.; Foncin, J.; Coquet, P.; Tan, D.; Li, H.; Teo, E.H.T.; Merlet, T.; Pernod, P. An effective thermal conductivity model for architected phase change material enhancer: Theoretical and experimental investigations. Int. J. Heat Mass Transf. 2021, 176, 121364. [Google Scholar] [CrossRef]

- Li, Z.; Gariboldi, E. On the use of effective thermophysical properties to predict the melting process of composite phase change materials with coarse structures. Int. J. Heat Mass Transf. 2021, 180, 121765. [Google Scholar] [CrossRef]

- Vakhshouri, A.R. Paraffin as Phase Change Material. In Paraffin—An Overview; IntechOpen: London, UK, 2020. [Google Scholar]

- Li, Z.; Gariboldi, E. Modelling the conditions for natural convection onset in open-cell porous Al/paraffin composite phase change materials: Effects of temperature, paraffin type and metallic structure geometry. Int. J. Heat Mass Transf. 2021, 173, 121279. [Google Scholar] [CrossRef]

- Casati, R.; Vedani, M. Aging Response of an A357 Al Alloy Processed by Selective Laser Melting. Adv. Eng. Mater. 2019, 21, 1800406. [Google Scholar] [CrossRef]

- Rasband, W.S. ImageJ. 2018. Available online: https://imagej.net/Welcome (accessed on 20 March 2022).

- Ferreira, T.; Rasband, W. ImageJ User Guide. 2012. Available online: https://imagej.nih.gov/ij/docs/guide/146.html (accessed on 25 November 2019).

- Takashimizu, Y.; Iiyoshi, M. New parameter of roundness R: Circularity corrected by aspect ratio. Prog. Earth Planet. Sci. 2016, 3, 2. [Google Scholar] [CrossRef] [Green Version]

- Russ, J.C. The Image Processing Handbook; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Ferro, P.; Meneghello, R.; Savio, G.; Berto, F. A modified volumetric energy density–based approach for porosity assessment in additive manufacturing process design. Int. J. Adv. Manuf. Technol. 2020, 110, 1–11. [Google Scholar] [CrossRef]

- Zhang, J.; Song, B.; Wei, Q.; Bourell, D.; Shi, Y. A review of selective laser melting of aluminum alloys: Processing, microstructure, property and developing trends. J. Mater. Sci. Technol. 2019, 35, 270–284. [Google Scholar] [CrossRef]

- Weingarten, C.; Buchbinder, D.; Pirch, N.; Meiners, W.; Wissenbach, K.; Poprawe, R. Formation and reduction of hydrogen porosity during selective laser melting of AlSi10Mg. J. Mater. Process. Technol. 2015, 221, 112–120. [Google Scholar] [CrossRef]

- Wang, Z.; Ummethala, R.; Singh, N.; Tang, S.; Suryanarayana, C.; Eckert, J.; Prashanth, K.G. Selective Laser Melting of Aluminum and Its Alloys. Materials 2020, 13, 4564. [Google Scholar] [CrossRef]

- Yap, C.Y.; Chua, C.K.; Dong, Z.L. Preliminary investigation on selective laser melting of pure tin. Proc. Int. Conf. Prog. Addit. Manuf. 2016, 1290, 409–414. [Google Scholar]

- Gariboldi, E.; Perrin, M. Metallic Composites as Form-Stable Phase Change Alloys. Mater. Sci. Forum 2018, 941, 1966–1971. [Google Scholar] [CrossRef]

| Point Distance, dp [µm] | |||||

|---|---|---|---|---|---|

| 60 | 80 | 100 | 120 | ||

| Hatch distance, dh [µm] | 60 | A 356 J/mm3 | B 267 J/mm3 | C 213 J/mm3 | |

| 80 | D 267 J/mm3 | E 200 J/mm3 | F 160 J/mm3 | ||

| 100 | G 213 J/mm3 | H 160 J/mm3 | I 128 J/mm3 | L 107 J/mm3 | |

| 120 | M 107 J/mm3 | N 89 J/mm3 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Confalonieri, C.; Casati, R.; Gariboldi, E. Effect of Process Parameters on Laser Powder Bed Fusion of Al-Sn Miscibility Gap Alloy. Quantum Beam Sci. 2022, 6, 17. https://doi.org/10.3390/qubs6020017

Confalonieri C, Casati R, Gariboldi E. Effect of Process Parameters on Laser Powder Bed Fusion of Al-Sn Miscibility Gap Alloy. Quantum Beam Science. 2022; 6(2):17. https://doi.org/10.3390/qubs6020017

Chicago/Turabian StyleConfalonieri, Chiara, Riccardo Casati, and Elisabetta Gariboldi. 2022. "Effect of Process Parameters on Laser Powder Bed Fusion of Al-Sn Miscibility Gap Alloy" Quantum Beam Science 6, no. 2: 17. https://doi.org/10.3390/qubs6020017