How Lack of Knowledge and Tools Hinders the Eco-Design of Buildings—A Systematic Review

Abstract

:1. Introduction

- What are the barriers to implement eco-design of buildings in the building sector?

- Which tools and methods exist for eco-designing buildings?

2. Method

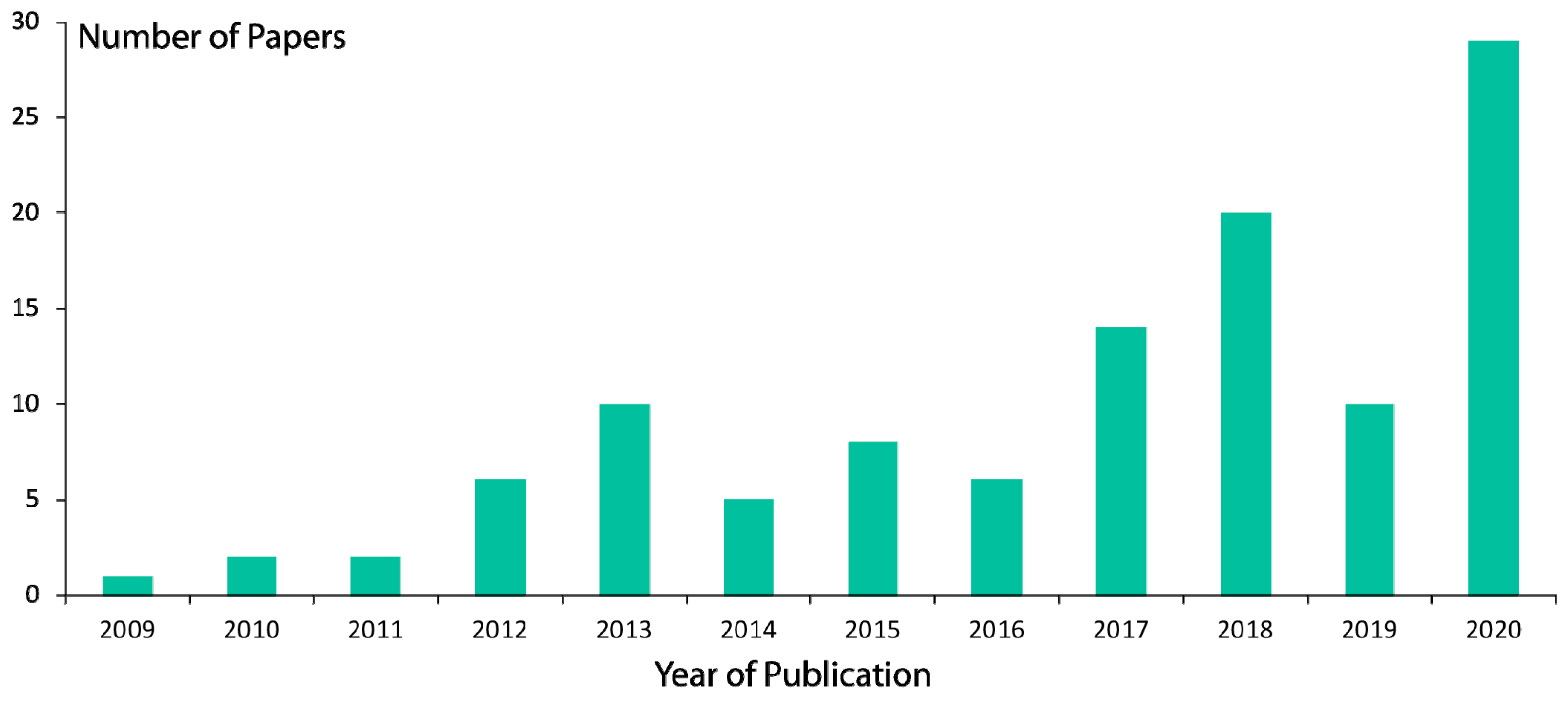

3. Analysis of Publications

4. Barriers to Implementation

4.1. Barriers Related to Clients

4.2. Barriers Related to Government/Policy-Makers

4.3. Barriers Related to Building Designers

4.4. Barriers Related to the Building Sector

4.5. Means to Overcome the Barriers

5. Existing Tools and Strategies

5.1. Tools For Eco-Design of Buildings

5.1.1. Life-Cycle Assessment in the Building Design Process

5.1.2. Green Building Certifications Schemes

5.2. Strategies for Eco-Design of Buildings

5.2.1. Material Selection/Substitution

5.2.2. Design for Manufacture and Assembly

5.2.3. Energy-Efficient Design

5.2.4. Design for Maintainability

5.2.5. Design for Adaptability

5.2.6. Design for Disassembly

5.2.7. Material Efficient Design

5.2.8. Design for Waste Minimization

5.2.9. Design for Circular Economy

6. Discussion

7. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Krausmann, F.; Gingrich, S.; Eisenmenger, N.; Erb, K.N.; Haberl, H.; Fischer-Kowalski, M. Growth in global materials use, GDP and population during the 20th century. Ecol. Econ. 2009, 68, 2696–2705. [Google Scholar] [CrossRef]

- IEA. 2018 Global Status Report: Towards a Zero-Emission, Efficient and Resilient Buildings and Construction Sector; United Nations Environment Programme: Nairobi, Kenya, 2018. [Google Scholar]

- Jeswiet, J.; Hauschild, M. EcoDesign and future environmental impacts. Mater. Des. 2005, 26, 629–634. [Google Scholar] [CrossRef]

- Debref, R. Environmental Innovation and Ecodesign: Certainties and Controversies; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2018. [Google Scholar]

- ISO. ISO 14006:2020 (en) Environmental Management Systems—Guidelines for Incorporating Ecodesign. 2020. Available online: https://www.iso.org/obp/ui/#iso:std:iso:14006:ed-2:v1:en (accessed on 17 September 2020).

- Baumann, H.; Boons, F.; Bragd, A. Mapping the green product development field: Engineering, policy and business perspectives. J. Clean. Prod. 2002, 10, 409–425. [Google Scholar] [CrossRef]

- Vallet, F.; Eynard, B.; Millet, D.; Mahut, S.G.; Tyl, B.; Bertoluci, G. Using eco-design tools: An overview of experts’ practices. Des. Stud. 2013, 34, 345–377. [Google Scholar] [CrossRef]

- Pigosso, D.C.A.; McAloone, T.C.; Rozenfeld, H. Characterization of the State-of-the-art and Identification of Main Trends for Ecodesign Tools and Methods: Classifying Three Decades of Research and Implementation. J. Indian Inst. Sci. 2015, 95, 405–427. [Google Scholar]

- Knight, P.; Jenkins, J.O. Adopting and applying eco-design techniques: A practitioners perspective. J. Clean. Prod. 2009, 17, 549–558. [Google Scholar] [CrossRef] [Green Version]

- Hernandez, P.R.J.; Brissaud, D.; Mathieux, F.; Zwolinski, P. Contribution to the characterization of eco-design projects. Int. J. Sustain. Eng. 2011, 4, 301–312. [Google Scholar] [CrossRef]

- Bovea, M.D.; Pérez-Belis, V. A taxonomy of ecodesign tools for integrating environmental requirements into the product design process. J. Clean. Prod. 2012, 20, 61–71. [Google Scholar] [CrossRef]

- Rousseaux, P.; Gremy-Gros, C.; Bonnin, M.; Henriel-Ricordel, C.; Bernard, P.; Floury, L.; Staigre, G.; Vincent, P. “Eco-tool-seeker”: A new and unique business guide for choosing ecodesign tool. J. Clean. Prod. 2017, 151, 546–577. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.; Cluzel, F.; Leroy, Y.; Yannou, B.; Yannou-Le Bris, G. Research perspectives in ecodesign. Des. Sci. 2020, 6. [Google Scholar] [CrossRef] [Green Version]

- Rossi, M.; Germani, M.; Zamagni, A. Review of ecodesign methods and tools. Barriers and strategies for an effective implementation in industrial companies. J. Clean. Prod. 2016, 129, 361–373. [Google Scholar] [CrossRef]

- Dekoninck, E.A.; Domingo, L.; O’Hare, J.A.; Pigosso, D.C.A.; Reyes, T.; Troussier, N. Defining the challenges for ecodesign implementation in companies: Development and consolidation of a framework. J. Clean. Prod. 2016, 135, 410–425. [Google Scholar] [CrossRef] [Green Version]

- Lamé, G.; Leroy, Y.; Yannou, B. Ecodesign tools in the construction sector: Analyzing usage inadequacies with designers’ needs. J. Clean. Prod. 2017, 148, 60–72. [Google Scholar] [CrossRef]

- Denac, M.; Obrecht, M.; Radonjič, G. Current and potential ecodesign integration in small and medium enterprises: Construction and related industries. Bus. Strateg. Environ. 2018, 27, 825–837. [Google Scholar] [CrossRef]

- Annunziata, E.; Testa, F.; Iraldo, F.; Frey, M. Environmental responsibility in building design: An Italian regional study. J. Clean. Prod. 2016, 112, 639–648. [Google Scholar] [CrossRef]

- Fox, S.; Marsh, L.; Cockerham, G. Design for manufacture: A strategy for successful application to buildings. Constr. Manag. Econ. 2001, 19, 493–502. [Google Scholar] [CrossRef]

- Okoli, C.; Schabram, K. A Guide to Conducting a Systematic Literature Review of Information Systems Research. Sprouts Work. Pap. Inf. Syst. 2010, 10. [Google Scholar] [CrossRef] [Green Version]

- Agyekum, K.; Adinyira, E.; Baiden, B.; Ampratwum, G.; Duah, D. Barriers to the adoption of green certification of buildings: A thematic analysis of verbatim comments from built environment professionals. J. Eng. Des. Technol. 2019, 17, 1035–1055. [Google Scholar] [CrossRef]

- Nduka, D.O.; Ogunmakinde, O.E. Stakeholders Perception of Factors Determining the Adoptability of Green Building Practices in Construction Projects in Nigeria. J. Environ. Earth. Sci. 2015, 5, 188–197. [Google Scholar]

- Olanrewaju, S.D.; Ogunmakinde, O.E. Waste minimisation strategies at the design phase: Architects’ response. Waste Manag. 2020, 118, 323–330. [Google Scholar] [CrossRef]

- Bilal, M.; Khan, K.I.A.; Thaheem, M.J.; Nasir, A.R. Current state and barriers to the circular economy in the building sector: Towards a mitigation framework. J. Clean. Prod. 2020, 276, 123250. [Google Scholar] [CrossRef]

- Giesekam, J.; Barrett, J.; Taylor, P.; Owen, A. The greenhouse gas emissions and mitigation options for materials used in UK construction. Energy Build. 2014, 78, 202–214. [Google Scholar] [CrossRef]

- Akadiri, P.O. Understanding barriers affecting the selection of sustainable materials in building projects. J. Build. Eng. 2015, 4, 86–93. [Google Scholar] [CrossRef]

- Kanters, J. Circular building design: An analysis of barriers and drivers for a circular building sector. Buildings 2020, 10, 77. [Google Scholar] [CrossRef]

- Adams, K.T.; Osmani, M.; Thorpe, T.; Thornback, J. Circular economy in construction: Current awareness, challenges and enablers. Waste Resour. Manag. 2017, 170, 15–24. [Google Scholar] [CrossRef] [Green Version]

- Juan, Y.; Cheng, Y.C. Improving Building Longevity, Adaptability, and Sustainability: Examination of Multi-Unit Residential Building Regulations in Taiwan. Civ. Eng. J. 2018, 4, 394. [Google Scholar] [CrossRef]

- Jusselme, T.; Rey, E.; Andersen, M. Surveying the environmental life-cycle performance assessments: Practice and context at early building design stages. Sustain. Cities Soc. 2020, 52, 101879. [Google Scholar] [CrossRef]

- Kanniyapan, G.; Mohammad, I.S.; Nesan, L.J.; Mohammed, A.H.; Andullah, M.N.; Asmoni, M.; Ganisen, S. Implementing Maintainability in Building Material Selection: A Preliminary Survey. J. Teknol. 2015, 30, 145–154. [Google Scholar] [CrossRef] [Green Version]

- Pinder, J.; Schmidt, R., III; Saker, J. Stakeholder perspectives on developing more adaptable buildings. Constr. Manag. Econ. 2013, 31, 440–459. [Google Scholar] [CrossRef]

- Marques, B.; Tadeu, A.; De Brito, J.; Almeida, J. A perspective on the development of sustainable construction products: An eco-design approach. Int. J. Sustain. Dev. Plan. 2017, 12, 304–314. [Google Scholar] [CrossRef] [Green Version]

- Maslesa, E.; Jensen, P.A.; Birkved, M. Indicators for quantifying environmental building performance: A systematic literature review. J. Build. Eng. 2018, 19, 552–560. [Google Scholar] [CrossRef]

- Zuo, J.; Zhao, Z.Y. Green building research-current status and future agenda: A review. Renew. Sustain. Energy Rev. 2014, 30, 271–281. [Google Scholar] [CrossRef]

- Buyle, M.; Braet, J.; Audenaert, A. Life cycle assessment in the construction sector: A review. Renew. Sustain. Energy Rev. 2013, 26, 379–388. [Google Scholar] [CrossRef]

- Malmqvist, T.; Glaumann, M.; Scarpellimi, S.; Zabalza, I.; Aranda, A.; Llaera, E.; Díaz, S. Life cycle assessment in buildings: The ENSLIC simplified method and guidelines. Energy 2011, 36, 1900–1907. [Google Scholar] [CrossRef]

- Häkkinen, T.; Kuittinen, M.; Ruuska, A.; Jung, N. Reducing embodied carbon during the design process of buildings. J. Build. Eng. 2015, 4, 1–13. [Google Scholar] [CrossRef]

- Roberts, M.; Allen, S.; Coley, D. Life cycle assessment in the building design process—A systematic literature review. Build. Environ. 2020, 185, 107274. [Google Scholar] [CrossRef]

- Budig, M.; Heckmann, O.; Hudert, M.; Ng, A.Q.B.; Conti, Z.X.; Lork, C.J.H. Computational screening-LCA tools for early design stages. Int. J. Archit. Comput. 2020, 1–17. [Google Scholar] [CrossRef]

- Soust-Verdaguer, B.; Llatas, C.; García-Martínez, A. Simplification in life cycle assessment of single-family houses: A review of recent developments. Build. Environ. 2016, 103, 215–227. [Google Scholar] [CrossRef] [Green Version]

- Sauer, A.S.; Calmon, J.L. Life-cycle assessment applied to buildings: Gaps in knowledge. Int. J. Environ. Stud. 2019, 77, 767–785. [Google Scholar] [CrossRef]

- Bahramian, M.; Yetilmezsoy, K. Life cycle assessment of the building industry: An overview of two decades of research (1995–2018). Energy Build. 2020, 219, 109917. [Google Scholar] [CrossRef]

- Pomponi, F.; Moncaster, A. Scrutinising embodied carbon in buildings: The next performance gap made manifest. Renew. Sustain. Energy Rev. 2018, 81, 2431–2442. [Google Scholar] [CrossRef] [Green Version]

- Al-Ghamdi, S.G.; Bilec, M.M. Green Building Rating Systems and Whole-Building Life Cycle Assessment: Comparative Study of the Existing Assessment Tools. J. Archit. Eng. 2017, 23, 1–9. [Google Scholar] [CrossRef]

- Hossain, M.U.; Ng, S.T. Critical consideration of buildings’ environmental impact assessment towards adoption of circular economy: An analytical review. J. Clean. Prod. 2018, 205, 763–780. [Google Scholar] [CrossRef]

- Moncaster, A.M.; Rasmussen, F.N.; Malmqvist, T.; Wiberg, A.H.; Birgisdottir, H. Widening understanding of low embodied impact buildings: Results and recommendations from 80 multi-national quantitative and qualitative case studies. J. Clean. Prod. 2019, 235, 378–393. [Google Scholar] [CrossRef]

- Röck, M.; Saade, M.R.M.; Balouktsi, M.; Rasmussen, F.N.; Birgisdottir, H.; Frischknecht, R.; Habert, G.; Lützkendorf, T.; Passer, A. Embodied GHG emissions of buildings—The hidden challenge for effective climate change mitigation. Appl. Energy 2020, 258, 114107. [Google Scholar] [CrossRef]

- Anand, C.K.; Amor, B. Recent developments, future challenges and new research directions in LCA of buildings: A critical review. Renew. Sustain. Energy Rev. 2017, 67, 408–416. [Google Scholar] [CrossRef]

- Llatas, C.; Soust-Verdaguer, B.; Passer, A. Implementing Life Cycle Sustainability Assessment during design stages in Building Information Modelling: From systematic literature review to a methodological approach. Build. Environ. 2020, 182, 107164. [Google Scholar] [CrossRef]

- Jrade, A.; Jalaei, F. Integrating building information modelling with sustainability to design building projects at the conceptual stage. Build. Simul. 2013, 6, 429–444. [Google Scholar] [CrossRef]

- Basbagill, J.; Flager, F.; Lepech, M.; Fischer, M. Application of life-cycle assessment to early stage building design for reduced embodied environmental impacts. Build. Environ. 2013, 60, 81–92. [Google Scholar] [CrossRef]

- Röck, M.; Hollberg, A.; Habert, C.; Passer, A. LCA and BIM: Visualization of environmental potentials in building construction at early design stages. Build. Environ. 2018, 140, 153–161. [Google Scholar] [CrossRef]

- Rezaei, F.; Bulle, C.; Lesage, P. Integrating building information modeling and life cycle assessment in the early and detailed building design stages. Build. Environ. 2019, 153, 158–167. [Google Scholar] [CrossRef] [Green Version]

- Belucio, M.; Rodrigues, C.; Antunes, C.H.; Freire, F.; Dias, L.C. Eco-efficiency in early design decisions: A multimethodology approach. J. Clean. Prod. 2020, 283, 124630. [Google Scholar] [CrossRef]

- Bribián, I.Z.; Usón, A.A.; Scarpellini, S. Life cycle assessment in buildings: State-of-the-art and simplified LCA methodology as a complement for building certification. Build. Environ. 2009, 44, 2510–2520. [Google Scholar] [CrossRef]

- Božiček, D.; Kunič, R.; Košir, M. Interpreting environmental impacts in building design: Application of a comparative assertion method in the context of the EPD scheme for building products. J. Clean. Prod. 2020, 279, 123399. [Google Scholar] [CrossRef]

- Hollberg, A.; Lützkendorf, T.; Habert, G. Top-down or bottom-up?—How environmental benchmarks can support the design process. Build. Environ. 2019, 153, 148–157. [Google Scholar] [CrossRef]

- Russell-Smith, S.V.; Lepech, M.D.; Fruchter, R.; Meyer, Y.B. Sustainable target value design: Integrating life cycle assessment and target value design to improve building energy and environmental performance. J. Clean. Prod. 2015, 88, 43–51. [Google Scholar] [CrossRef]

- Ade, R.; Rehm, M. The unwritten history of green building rating tools: A personal view from some of the ‘founding fathers’. Build. Res. Inf. 2020, 48, 1–17. [Google Scholar] [CrossRef]

- Doan, D.T.; Ghaffarianhoseini, A.; Naismith, N.; Zhang, T.; Ghaffarianhoseini, A.; Tookey, J. A critical comparison of green building rating systems. Build. Environ. 2017, 123, 243–260. [Google Scholar] [CrossRef]

- Pongiglione, M.; Calderini, C. Sustainable Structural Design: Comprehensive Literature Review. J. Struct. Eng. 2016, 142, 1–15. [Google Scholar] [CrossRef]

- Shan, M.; Hwang, B. Green building rating systems: Global reviews of practices and research efforts. Sustain. Cities Soc. 2018, 39, 172–180. [Google Scholar] [CrossRef]

- Mahdavinejad, M.; Zia, A.; Larki, A.N.; Ghanavati, S.; Elmi, N. Dilemma of green and pseudo green architecture based on LEED norms in case of developing countries. Int. J. Sustain. Built Environ. 2014, 3, 235–246. [Google Scholar] [CrossRef] [Green Version]

- He, Y.; Kvan, T.; Liu, M.; Li, B. How green building rating systems affect designing green. Build. Environ. 2018, 133, 19–31. [Google Scholar] [CrossRef]

- Chen, X.; Yang, H.; Lu, L. A comprehensive review on passive design approaches in green building rating tools. Renew. Sustain. Energy Rev. 2015, 50, 1425–1436. [Google Scholar] [CrossRef]

- Mattoni, B.; Guattari, C.; Evangelisti, L.; Bisegna, F.; Gori, P.; Asdrubali, F. Critical review and methodological approach to evaluate the differences among international green building rating tools. Renew. Sustain. Energy Rev. 2018, 82, 950–960. [Google Scholar] [CrossRef]

- Ismaeel, W.S.E. Drawing the operating mechanisms of green building rating systems. J. Clean. Prod. 2019, 213, 599–609. [Google Scholar] [CrossRef]

- Aye, L.; Hes, D. Green building rating system scores for building reuse. J. Green Build. 2012, 7, 105–112. [Google Scholar] [CrossRef]

- Wen, B.; Musa, N.; Onn, C.C.; Ramesh, S.; Liang, L.; Wang, W. Evolution of sustainability in global green building rating tools. J. Clean. Prod. 2020, 259, 120912. [Google Scholar] [CrossRef]

- Gou, Z.; Xie, X. Evolving green building: Triple bottom line or regenerative design? J. Clean. Prod. 2017, 153, 600–607. [Google Scholar] [CrossRef]

- Ismaeel, W.S.E. Midpoint and endpoint impact categories in Green building rating systems. J. Clean. Prod. 2018, 182, 783–793. [Google Scholar] [CrossRef]

- Pomponi, F.; Moncaster, A. Embodied carbon mitigation and reduction in the built environment—What does the evidence say? J. Environ. Manag. 2016, 181, 687–700. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Orsini, F.; Marrone, P. Approaches for a low-carbon production of building materials: A review. J. Clean. Prod. 2019, 241, 118380. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Barreneche, C.; Miró, L.; Morera, J.M.; Bartolí, E.; Inés, F.A. Low carbon and low embodied energy materials in buildings: A review. Renew. Sustain. Energy Rev. 2013, 23, 536–542. [Google Scholar] [CrossRef]

- Malmqvist, T.; Nehasilova, M.; Moncaster, A.; Birgisdottir, H.; Rasmussen, F.N.; Wiberg, A.H.; Potting, J. Design and construction strategies for reducing embodied impacts from buildings—Case study analysis. Energy Build. 2018, 166, 35–47. [Google Scholar] [CrossRef] [Green Version]

- Rasmussen, F.N.; Birkved, M.; Birgisdóttir, H. Low-carbon design strategies for new residential buildings–lessons from architectural practice. Archit. Eng. Des. Manag. 2020, 16, 374–390. [Google Scholar] [CrossRef]

- Llatas, C.; Osmani, M. Development and validation of a building design waste reduction model. Waste Manag. 2016, 56, 318–336. [Google Scholar] [CrossRef]

- Gao, S.; Low, S.P.; Nair, K. Design for manufacturing and assembly (DfMA): A preliminary study of factors influencing its adoption in Singapore. Archit. Eng. Des. Manag. 2018, 14, 440–456. [Google Scholar] [CrossRef]

- Gao, S.; Jin, R.; Lu, W. Design for manufacture and assembly in construction: A review. Build. Res. Inf. 2020, 48, 538–550. [Google Scholar] [CrossRef]

- Gerth, R.; Boqvist, A.; Bjelkemyr, M.; Lindberg, B. Design for construction: Utilizing production experiences in development. Constr. Manag. Econ. 2013, 31, 135–150. [Google Scholar] [CrossRef]

- Wasim, M.; Han, T.M.; Huang, H.; Madiyev, M.; Ngo, T.D. An approach for sustainable, cost-effective and optimised material design for the prefabricated non-structural components of residential buildings. J. Build. Eng. 2020, 32, 101474. [Google Scholar] [CrossRef]

- Tan, T.; Lu, W.; Tan, G.; Xue, F.; Chen, K.; Xu, J.; Wang, J.; Gao, S. Construction-Oriented Design for Manufacture and Assembly Guidelines. J. Constr. Eng. Manag. 2020, 146, 1–12. [Google Scholar] [CrossRef]

- Lu, W.; Tan, T.; Xu, J.; Wang, J.; Chen, K.; Gao, S.; Xue, F. Design for manufacture and assembly (DfMA) in construction: The old and the new. Archit. Eng. Des. Manag. 2020. [Google Scholar] [CrossRef]

- Yuan, Z.; Sun, C.; Wang, Y. Design for Manufacture and Assembly-oriented parametric design of prefabricated buildings. Autom. Constr. 2018, 88, 13–22. [Google Scholar] [CrossRef]

- Pacheco, R.; Ordóñez, J.; Martínez, G. Energy efficient design of building: A review. Renew. Sustain. Energy Rev. 2012, 16, 3559–3573. [Google Scholar] [CrossRef]

- Akadiri, P.O.; Chinyio, E.A.; Olomolaiye, P.O. Design of a sustainable building: A conceptual framework for implementing sustainability in the building sector. Buildings 2012, 2, 126–152. [Google Scholar] [CrossRef] [Green Version]

- Cabeza, L.F.; Chàfer, M. Technological options and strategies towards zero energy buildings contributing to climate change mitigation: A systematic review. Energy Build. 2020, 219, 110009. [Google Scholar] [CrossRef]

- Vakili-Ardebili, A.; Boussabaine, A.H. Ecological building design determinants. Archit. Eng. Des. Manag. 2010, 6, 111–131. [Google Scholar] [CrossRef]

- Kneifel, J. Life-cycle carbon and cost analysis of energy efficiency measures in new commercial buildings. Energy Build. 2010, 42, 333–340. [Google Scholar] [CrossRef]

- Hertwich, E.G.; Ali, S.; Giacci, L.; Fishman, T.; Heeren, N.; Masanet, E.; Asghari, F.N.; Olivetti, E.; Pauliuk, S.; Tu, Q.; et al. Material efficiency strategies to reducing greenhouse gas emissions associated with buildings, vehicles, and electronics—A review. Environ. Res. Lett. 2019, 14, 43004. [Google Scholar] [CrossRef] [Green Version]

- Li, C.Z.; Lai, X.; Xiao, B.; Tam, V.W.Y.; Guo, S.; Zhao, Y. A holistic review on life cycle energy of buildings: An analysis from 2009 to 2019. Renew. Sustain. Energy Rev. 2020, 134, 110372. [Google Scholar] [CrossRef]

- Georgiadou, M.C.; Hacking, T.; Guthrie, P. A conceptual framework for future-proofing the energy performance of buildings. Energy Policy 2012, 47, 145–155. [Google Scholar] [CrossRef]

- Zabalza, I.; Scarpellini, S.; Aranda, A.; Llera, E.; Jáñez, A. Use of LCA as a tool for building ecodesign. A case study of a low energy building in Spain. Energies 2013, 6, 3901–3921. [Google Scholar] [CrossRef] [Green Version]

- Peuportier, B.; Thiers, S.; Guiavarch, A. Eco-design of buildings using thermal simulation and life cycle assessment. J. Clean. Prod. 2013, 39, 73–78. [Google Scholar] [CrossRef] [Green Version]

- Rockow, Z.R.; Ross, B.; Black, A.K. Review of methods for evaluating adaptability of buildings. Int. J. Build. Pathol. Adapt. 2019, 37, 273–287. [Google Scholar] [CrossRef]

- Asmone, A.S.; Chew, M.Y.L. Development of a design-for-maintainability assessment of building systems in the tropics. Build. Environ. 2020, 184, 107245. [Google Scholar] [CrossRef]

- Zhu, L.; Shan, M.; Hwang, B.G. Overview of Design for Maintainability in Building and Construction Research. J. Perform. Constr. Facil. 2018, 32, 1–9. [Google Scholar] [CrossRef]

- Ganisen, S.; Mohammed, A.H.; Nesan, L.J.; Mohammad, L.S.; Kanniyapan, G. The Identification of Design for Maintainability Imperatives to Achieve Cost Effective Building Maintenance: A Delphi Study. J. Teknol. 2015, 77, 75–88. [Google Scholar] [CrossRef] [Green Version]

- Manewa, A.; Siriwardena, M.; Ross, A.; Madanayake, U. Adaptable buildings for sustainable built environment. Built Environ. Proj. Asset Manag. 2016, 6, 139–158. [Google Scholar] [CrossRef]

- Conejos, S.; Langston, C.; Smith, J. AdaptSTAR model: A climate-friendly strategy to promote built environment sustainability. Habitat Int. 2013, 37, 95–103. [Google Scholar] [CrossRef] [Green Version]

- Heidrich, O.; Kamara, J.; Maltese, S.; Re Cecconi, F.; Dejaco, M.C. A critical review of the developments in building adaptability. Int. J. Build. Pathol. Adapt. 2017, 35, 284–303. [Google Scholar] [CrossRef] [Green Version]

- Gosling, J.; Sassi, P.; Naim, M.; Lark, R. Adaptable buildings: A systems approach. Sustain. Cities Soc. 2013, 7, 44–51. [Google Scholar] [CrossRef]

- Estaji, H. A Review of Flexibility and Adaptability in Housing Design. Int. J. Contemp. Archit. 2017, 4, 37–49. [Google Scholar]

- Conejos, S.; Langston, C.; Smith, J. Designing for better building adaptability: A comparison of adaptSTAR and ARP models. Habitat Int. 2014, 41, 85–91. [Google Scholar] [CrossRef]

- Salama, W. Design of concrete buildings for disassembly: An explorative review. Int. J. Sustain. Built Environ. 2017, 6, 617–635. [Google Scholar] [CrossRef]

- Kanters, J. Design for deconstruction in the design process: State of the art. Buildings 2018, 8, 150. [Google Scholar] [CrossRef] [Green Version]

- Eberhardt, L.C.M.; Birgisdóttir, H.; Birkved, M. Life cycle assessment of a Danish office building designed for disassembly. Build. Res. Inf. 2018, 6, 666–680. [Google Scholar] [CrossRef] [Green Version]

- Aye, L.; Ngo, T.; Crawford, R.H.; Gammampila, R.; Mendis, P. Life cycle greenhouse gas emissions and energy analysis of prefabricated reusable building modules. Energy Build. 2012, 47, 159–168. [Google Scholar] [CrossRef]

- Eckelman, M.J.; Brown, C.; Troup, L.N.; Wang, L.; Webster, M.D.; Hajjar, J.F. Life cycle energy and environmental benefits of novel design-for-deconstruction structural systems in steel buildings. Build. Environ. 2018, 143, 421–430. [Google Scholar] [CrossRef]

- Minunno, R.; O’Grady, T.; Morrison, G.M.; Gruner, R.L. Exploring environmental benefits of reuse and recycle practices: A circular economy case study of a modular building. Resour. Conserv. Recycl. 2020, 160, 104855. [Google Scholar] [CrossRef]

- Akanbi, L.A.; Oyedele, L.O.; Omoteso, K.; Bilal, M.; Akinade, O.O.; Ajayi, A.O.; Delgado, J.M.D.; Owolabi, H.A. Disassembly and deconstruction analytics system (D-DAS) for construction in a circular economy. J. Clean. Prod. 2019, 223, 386–396. [Google Scholar] [CrossRef]

- Denis, F.; Vandervaeren, C.; De Temmerman, N. Using network analysis and BIM to quantify the impact of Design for Disassembly. Buildings 2018, 8, 113. [Google Scholar] [CrossRef] [Green Version]

- Tingley, D.D.; Davison, B. Developing an LCA methodology to account for the environmental benefits of design for deconstruction. Build. Environ. 2012, 57, 387–395. [Google Scholar] [CrossRef]

- Wang, J.; Li, Z.; Tam, V.W.Y. Critical factors in effective construction waste minimization at the design stage: A Shenzhen case study, China. Resour. Conserv. Recycl. 2014, 82, 1–7. [Google Scholar] [CrossRef]

- Ajayi, S.O.; Oyedele, L.O.; Akinade, O.O.; Bilal, M.; Alaka, H.A.; Owolabi, H.A.; Kadiri, K.O. Attributes of design for construction waste minimization: A case study of waste-to-energy project. Renew. Sustain. Energy Rev. 2017, 73, 1333–1341. [Google Scholar] [CrossRef]

- Sfakianaki, E. Resource-efficient construction: Rethinking construction towards sustainability. World J. Sci. Technol. Sustain. Dev. 2015, 12, 233–242. [Google Scholar] [CrossRef]

- Benachio, G.L.F.; Freitas, M.C.D.; Tavares, S.F. Circular economy in the construction industry: A systematic literature review. J. Clean. Prod. 2020, 260, 121046. [Google Scholar] [CrossRef]

- Minunno, R.; O’Grady, T.; Morrison, G.M.; Gruner, R.L.; Colling, M. Strategies for applying the circular economy to prefabricated buildings. Buildings 2018, 8, 125. [Google Scholar] [CrossRef] [Green Version]

- Eberhardt, L.C.M.; Birkved, M.; Birgisdottir, H. Building design and construction strategies for a circular economy. Archit. Eng. Des. Manag. 2020, 0, 1–21. [Google Scholar] [CrossRef]

- Hossain, M.U.; Ng, S.T.; Antwi-Afari, P.; Amor, B. Circular economy and the construction industry: Existing trends, challenges and prospective framework for sustainable construction. Renew. Sustain. Energy Rev. 2020, 130, 109948. [Google Scholar] [CrossRef]

- Leising, E.; Quist, J.; Bocken, N. Circular Economy in the building sector: Three cases and a collaboration tool. J. Clean. Prod. 2018, 176, 976–989. [Google Scholar] [CrossRef]

- Gallego-Schmid, A.; Chen, H.M.; Sharmina, M.; Mendoza, J.M.F. Links between circular economy and climate change mitigation in the built environment. J. Clean. Prod. 2020, 260, 121115. [Google Scholar] [CrossRef]

- Buyle, M.; Galle, W.; Debacker, W.; Audenaert, A. Sustainability assessment of circular building alternatives: Consequential LCA and LCC for internal wall assemblies as a case study in a Belgian context. J. Clean. Prod. 2019, 218, 141–156. [Google Scholar] [CrossRef]

- Andersen, C.E.; Kanafani, K.; Zimmermann, R.K.; Rasmussen, F.N.; Birgisdóttir, H. Comparison of GHG emissions from circular and conventional building components. Build. Cities 2020, 1, 379. [Google Scholar] [CrossRef]

- Osobajo, O.A.; Oke, A.; Omotayo, T.; Obi, L.I. A systematic review of circular economy research in the construction industry. Smart Sustain. Built Environ. 2020. [Google Scholar] [CrossRef]

- Cottafava, D.; Ritzen, M. Circularity indicator for residentials buildings: Addressing the gap between embodied impacts and design aspects. Resour. Conserv. Recycl. 2020, 164, 105120. [Google Scholar] [CrossRef]

- Akanbi, L.A.; Oyedele, L.O.; Akinade, O.O.; Ajayi, A.O.; Delgado, M.D.; Bilal, M.; Bello, S.A. Salvaging building materials in a circular economy: A BIM-based whole-life performance estimator. Resour. Conserv. Recycl. 2018, 129, 175–186. [Google Scholar] [CrossRef]

- Saghafi, M.D.; Teshnizi, Z.S.H. Recycling value of building materials in building assessment systems. Energy Build. 2011, 43, 3181–3188. [Google Scholar] [CrossRef]

| Barrier | Geographical Scope | Contextual Scope | Publication |

|---|---|---|---|

| Clients | |||

| Lack of awareness | Ghana, Nigeria, Developing Countries, United Kingdom | Adoption of green building practice and certification. Use of alternative materials, circular economy and construction waste minimization. | [21,22,23,24,25] |

| Lack of demand | Nigeria, Italy, Ghana | Eco-design for building designers. Adoption of green certification and use of sustainable materials. | [18,21,26] |

| Government/Policy-Makers | |||

| Lack of suitable legislation | Italy, Ghana, Developing Countries, North-West Europe, Nigeria, United Kingdom, Taiwan | Eco-design for building designers. Adoption of green building practice and certification. Develop more adaptable building. Integrate circular economy and construction waste minimization. | [18,21,22,23,24,27,28,29] |

| Lack of support for eco-design | Ghana, Italy, Developing Countries | Eco-design for building designers. Adoption of green certification and circular economy. | [18,21,24] |

| Designers | |||

| Lack of suitable tools and methods | North-West Europe, Nigeria, Italy, France, Europe, United Kingdom | Eco-design and eco-design tools for building designers. Adoption of green building practices, circular economy, and life-cycle performance assessment. Use of sustainable and alternative materials | [16,18,25,26,27,30] |

| Lack of knowledge | North-West Europe, Malaysia, Ghana, Nigeria, Malaysia, United Kingdom, Slovenia, | Adoption of green building practice and certification. Use of sustainable and alternative materials. Eco-design in small and medium-sized enterprises (SMEs). Developing more adaptable buildings. Integrating circular economy and maintainability. | [17,21,22,24,25,27,28,31,32] |

| Lack of professional skills | Nigeria, Slovenia | Use of sustainable materials. Construction waste minimization. Eco-design in SME’s. | [17,23,26] |

| Lack of cooperation | Italy, Nigeria, Europe | Eco-design for building designers. Integrating construction waste minimization and life-cycle performance assessment. | [18,23,31] |

| The Building Sector | |||

| Lack of financial resources | Italy, Developing countries, Nigeria, North-West Europe, Malaysia, Slovenia, Europe, United Kingdom, | Eco-design for building designers and in SMEs. Use of sustainable and alternative materials. Integrating green building practices, circular economy, maintainability, life-cycle performance assessment, and construction waste minimization. Developing more adaptable buildings. | [17,18,22,24,25,27,30,32] |

| Lack of knowledge | Developing Countries, North-West Europe, Nigeria, United Kingdom | Adoption of green building practices and circular economy. | [22,24,27,28] |

| Lack of professional skills | Developing Countries, North-West Europe, Nigeria | Adoption of green building practices and circular economy. | [22,24,27] |

| Lack of material availability | North-West Europe, Nigeria, United Kingdom, Malaysia | Adoption of green building practices, circular economy, and maintainability. | [22,27,28,31] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ipsen, K.L.; Pizzol, M.; Birkved, M.; Amor, B. How Lack of Knowledge and Tools Hinders the Eco-Design of Buildings—A Systematic Review. Urban Sci. 2021, 5, 20. https://doi.org/10.3390/urbansci5010020

Ipsen KL, Pizzol M, Birkved M, Amor B. How Lack of Knowledge and Tools Hinders the Eco-Design of Buildings—A Systematic Review. Urban Science. 2021; 5(1):20. https://doi.org/10.3390/urbansci5010020

Chicago/Turabian StyleIpsen, Kikki Lambrecht, Massimo Pizzol, Morten Birkved, and Ben Amor. 2021. "How Lack of Knowledge and Tools Hinders the Eco-Design of Buildings—A Systematic Review" Urban Science 5, no. 1: 20. https://doi.org/10.3390/urbansci5010020