Investigation on Pore Structure and Permeability of Concrete–Rock Interfacial Transition Zones Based on Fractal Theory

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

- (1)

- The cleaned rock was placed into the molds and the raw materials were prepared strictly according to the C30 concrete mixing ratio. The weighed cement, sand, stones, admixtures, and water were poured into the concrete mixer and mixed for 60 s.

- (2)

- After mixing was completed, the concrete was poured sequentially into the steel molds. Then, the molds were placed on a vibrating table to remove air bubbles from the samples. Vibrating time should not exceed 30 s to avoid the effect of water secretion.

- (3)

- The composite specimen was dismantled within 24 h, put into a standard curing box for 28 days, and finally, a cube specimen of 100 × 100 × 100 mm was obtained.

- (4)

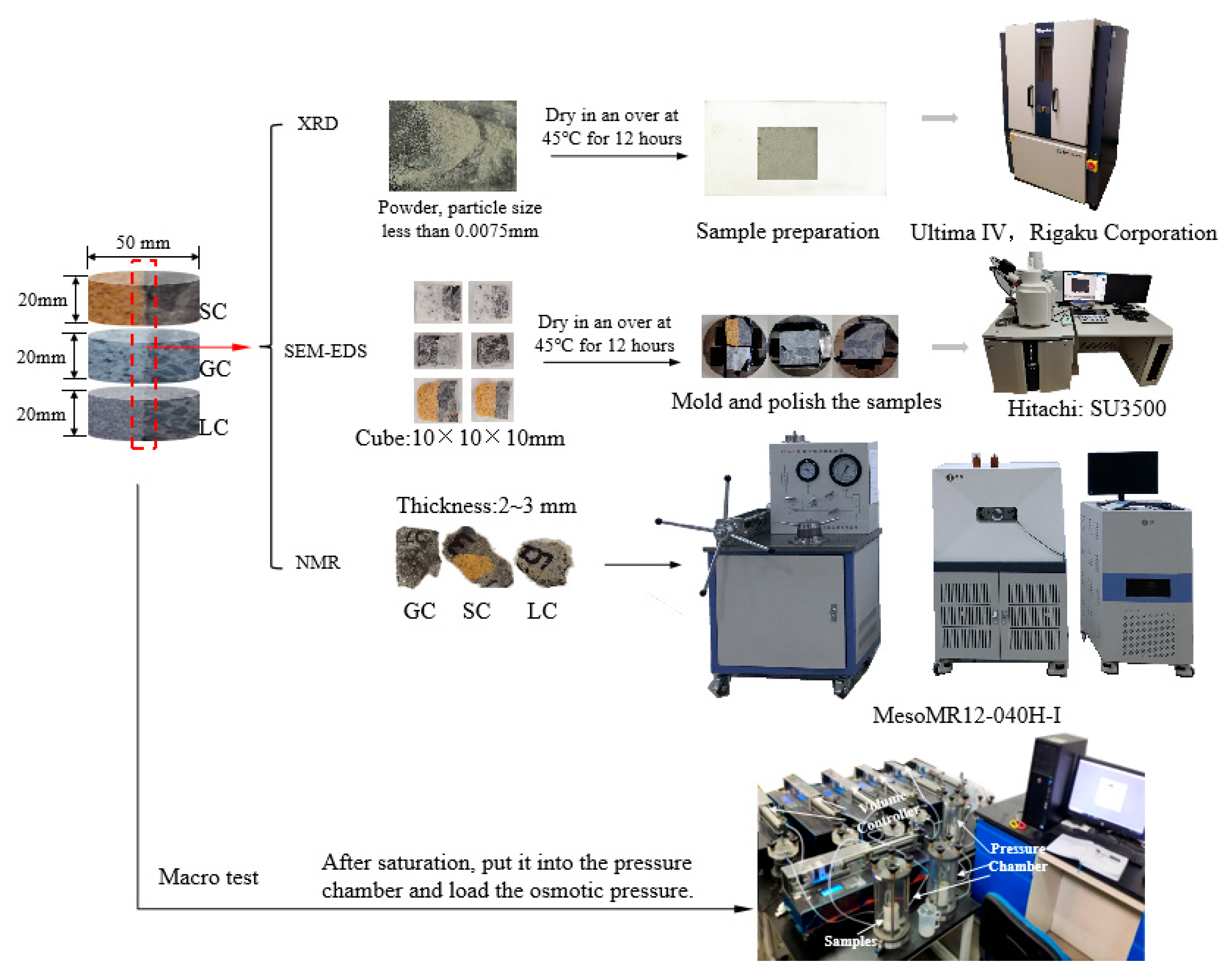

- According to the sample size required for the penetration test, a coring machine was used to take the core from the cube specimen. Finally, a cylindrical example of 50 × 100 mm was obtained. Figure 1 shows the fabrication process of the cylindrical concrete–rock mixed specimen.

2.2. Permeability Test and Procedure

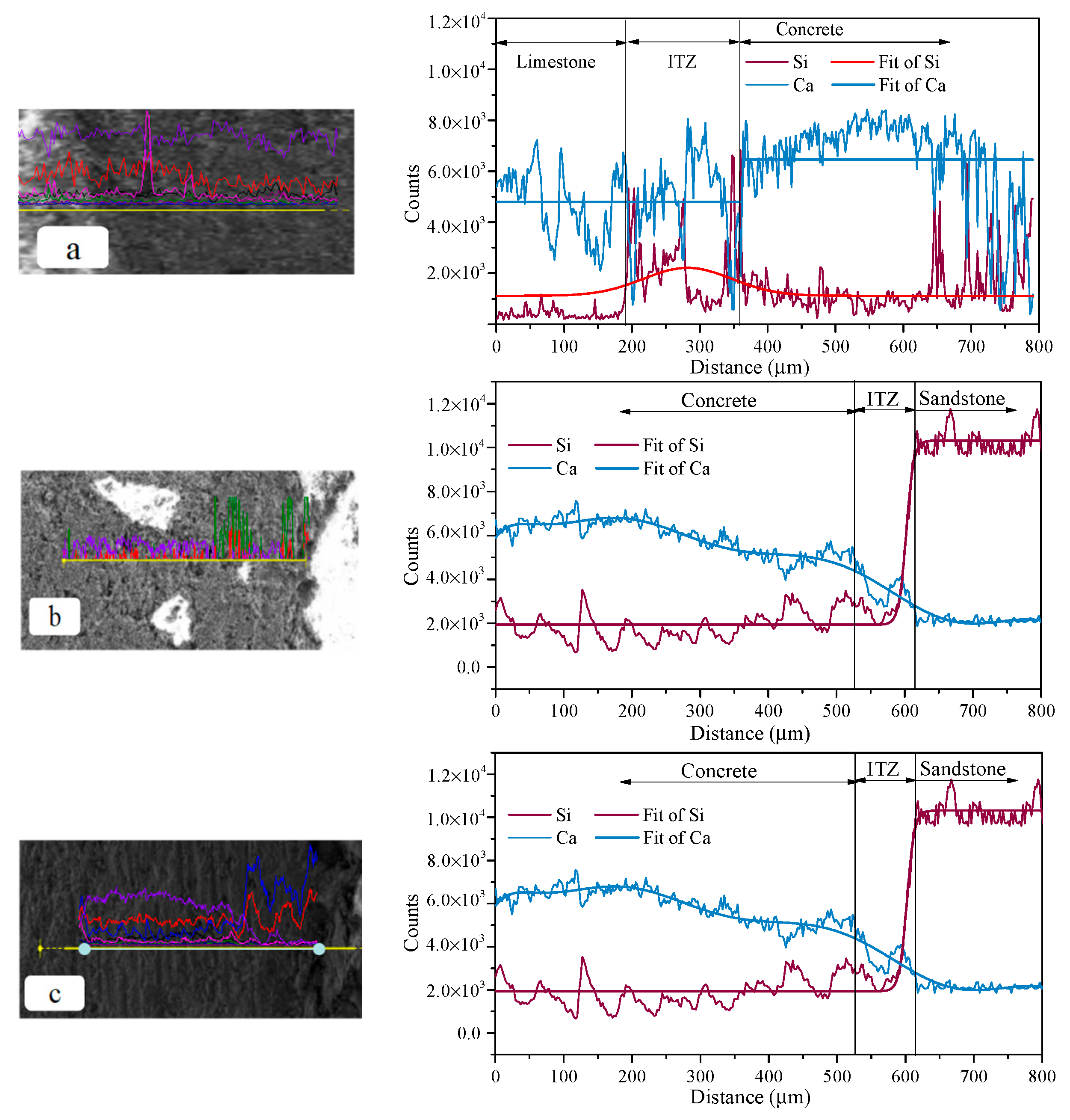

- The samples for the scanning electron microscope-energy spectrum analysis (SEM-EDS) were a cube of 10 × 10 ×10 mm, and the sample contained both rock and concrete. Then, the samples were dried in a drying oven at 45 °C for 12 h to a constant weight. The samples were scanned using a SU3500-HITACHI SEM-EDS at an accelerating voltage of 3000 V. The image was focused, adjusted, and photographed at different magnifications. Under the observation condition of magnification of 500, a regular line was drawn in the adjacent area of rock and concrete. The starting point of the standard line was inside the rock, and the endpoint was inside the concrete slurry. The length of the entire element distribution observation line was within 800 μm.

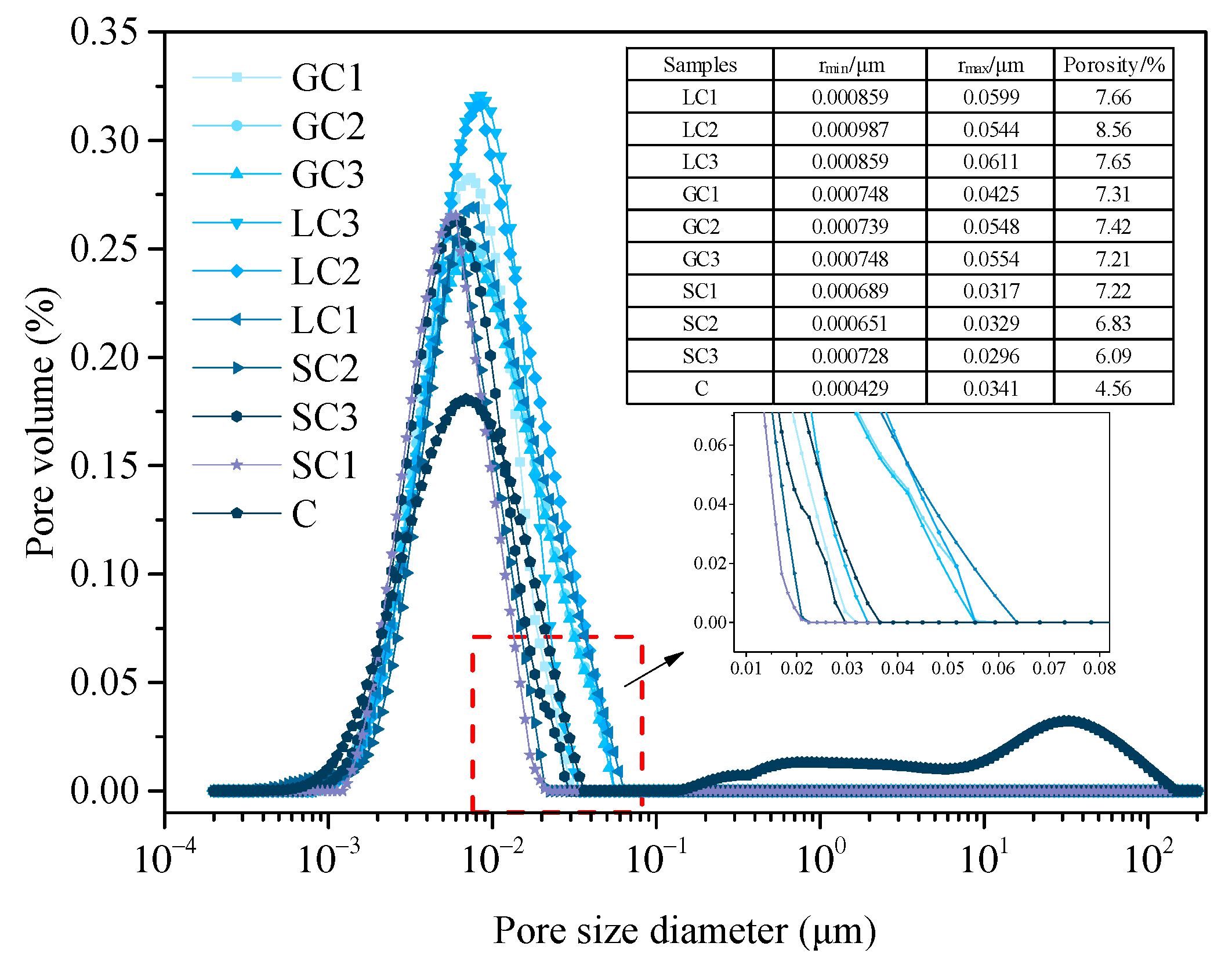

- The samples for the Nuclear Magnetic Resonance (NMR) were a 2~3 mm block mortar of ITZ, and the samples were saturated with vacuum-saturation equipment (type: MesoMR12-040H-I). Subsequently, the saturated samples were wrapped in plastic film and placed inside the sample chamber. After finding the appropriate center frequency, the proper relaxation time and echo time were selected according to the sample and the pore size distribution curve was obtained. Finally, the porosity and pore size distribution curve of the samples were obtained by inversion.

- The samples for the macro test were cylindrical specimens of 50 × 20 mm. Firstly, the samples were saturated with vacuum-saturation equipment. Subsequently, the saturated samples were placed inside the pressure chamber of cement-based materials steady-state permeation test equipment. According to the project operation environment, the seepage pressure was set at 2 MPa until the test ended.

3. Results

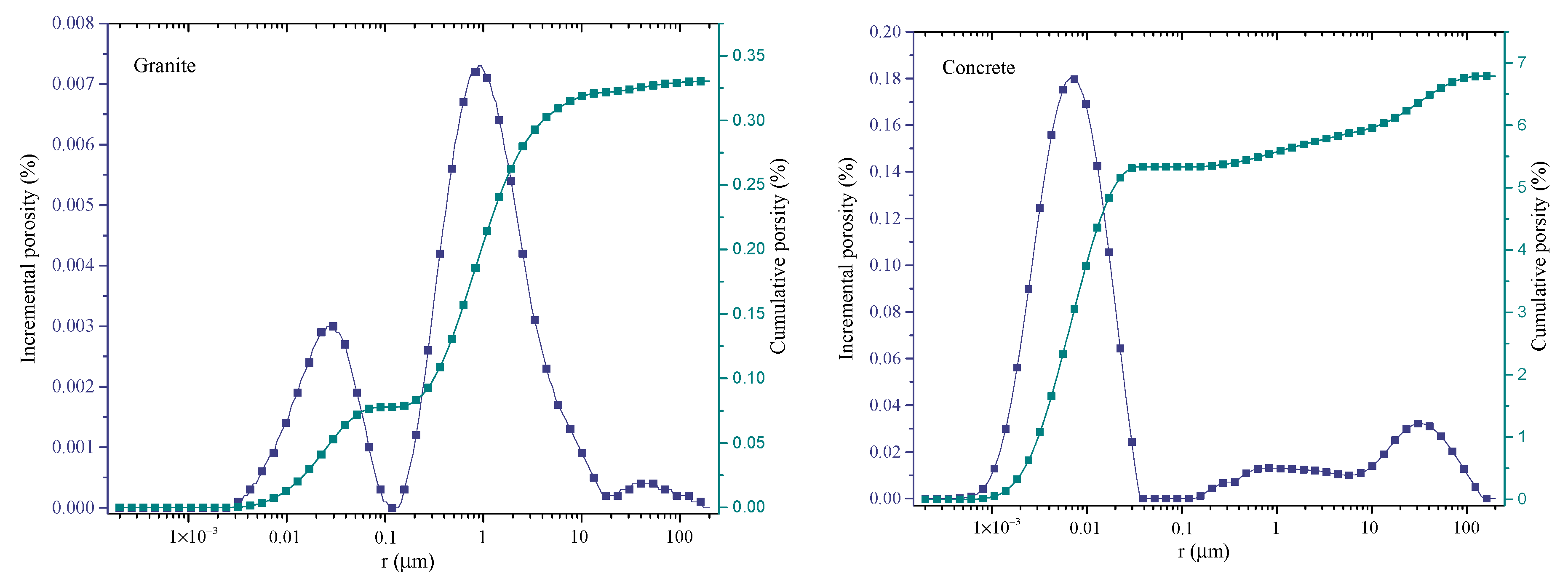

3.1. Pore-Structure of Bedrocks and Concrete

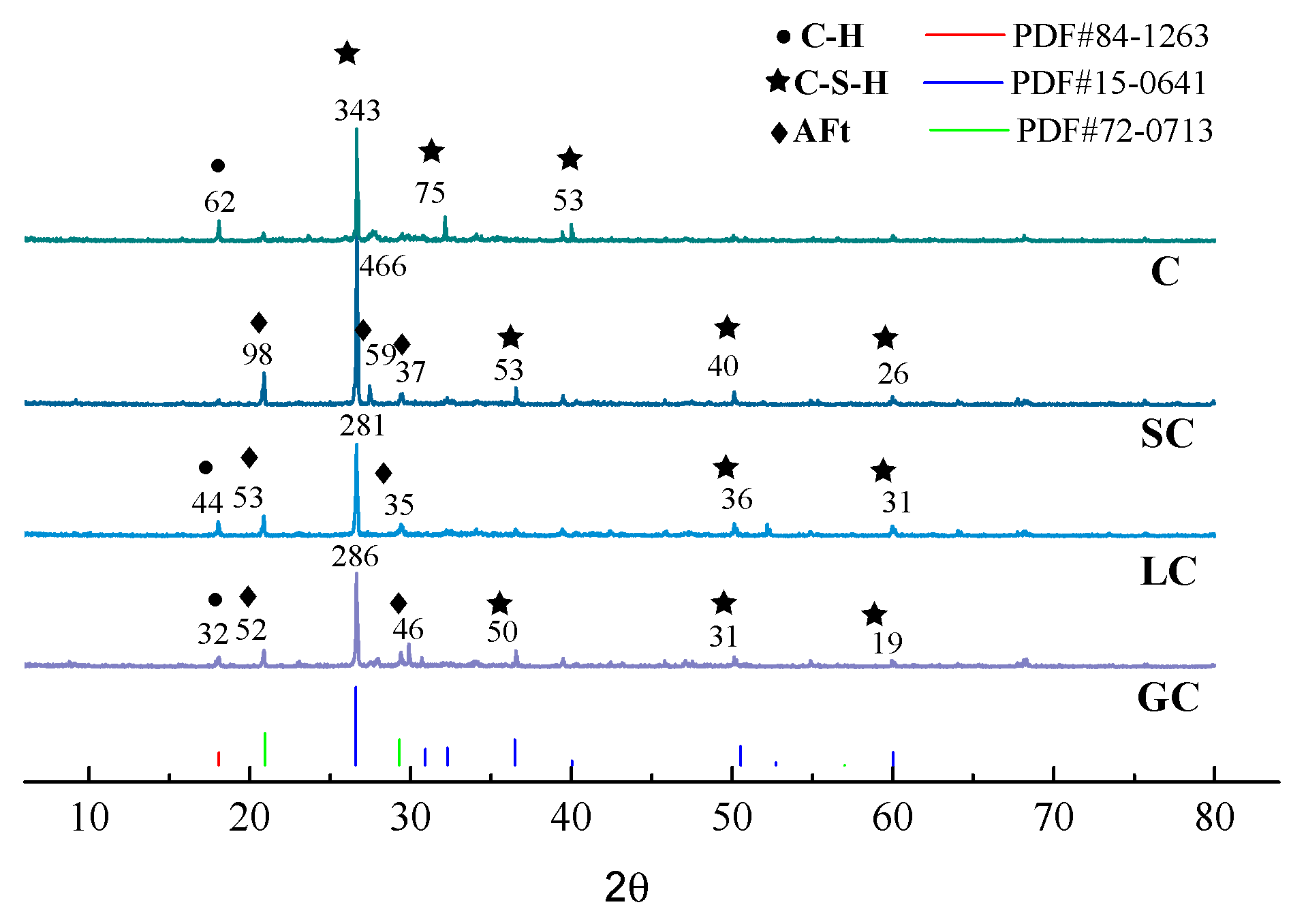

3.2. Calcium Compounds of ITZ

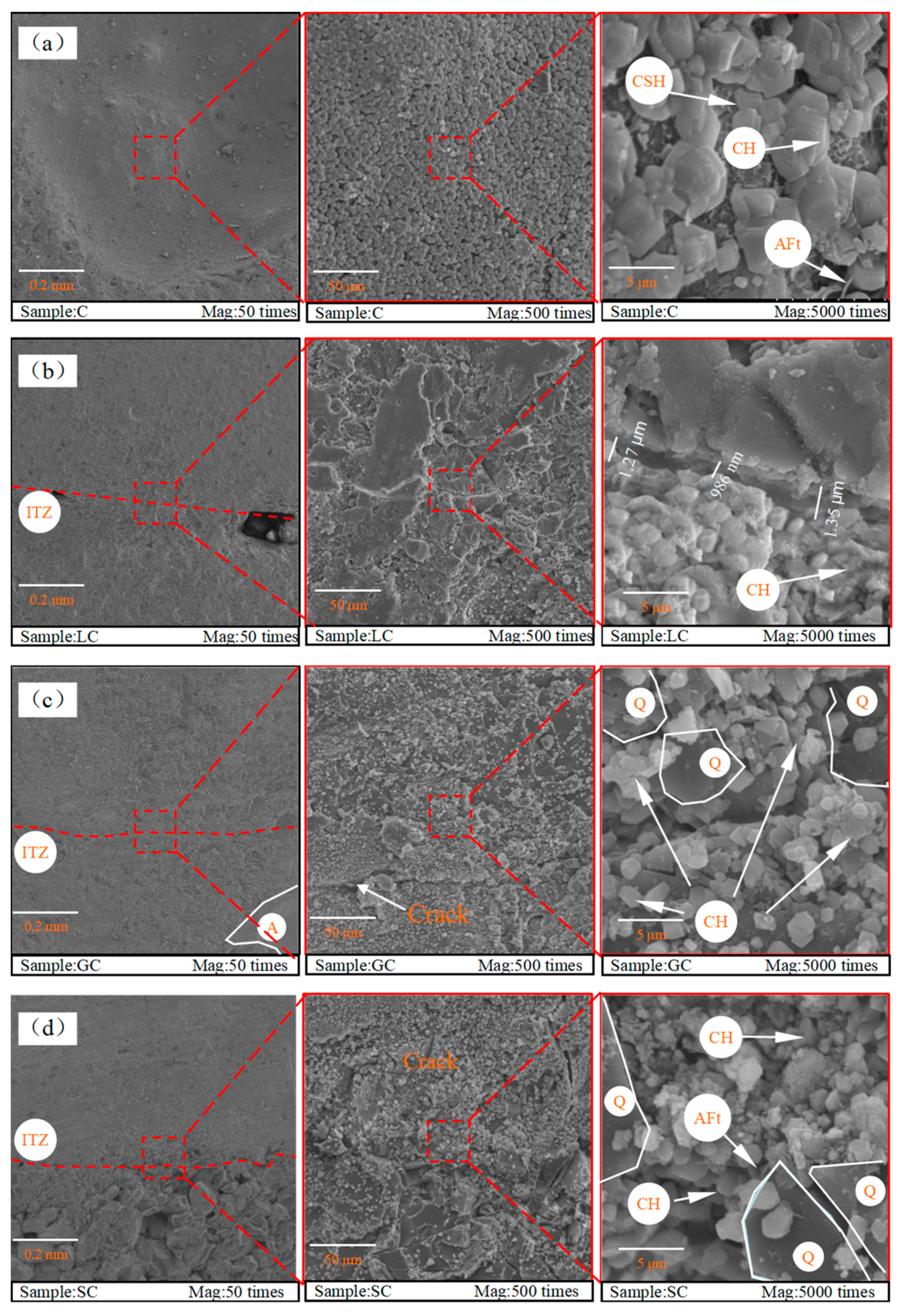

3.3. Thickness of ITZ

3.4. Pore Structure of ITZ

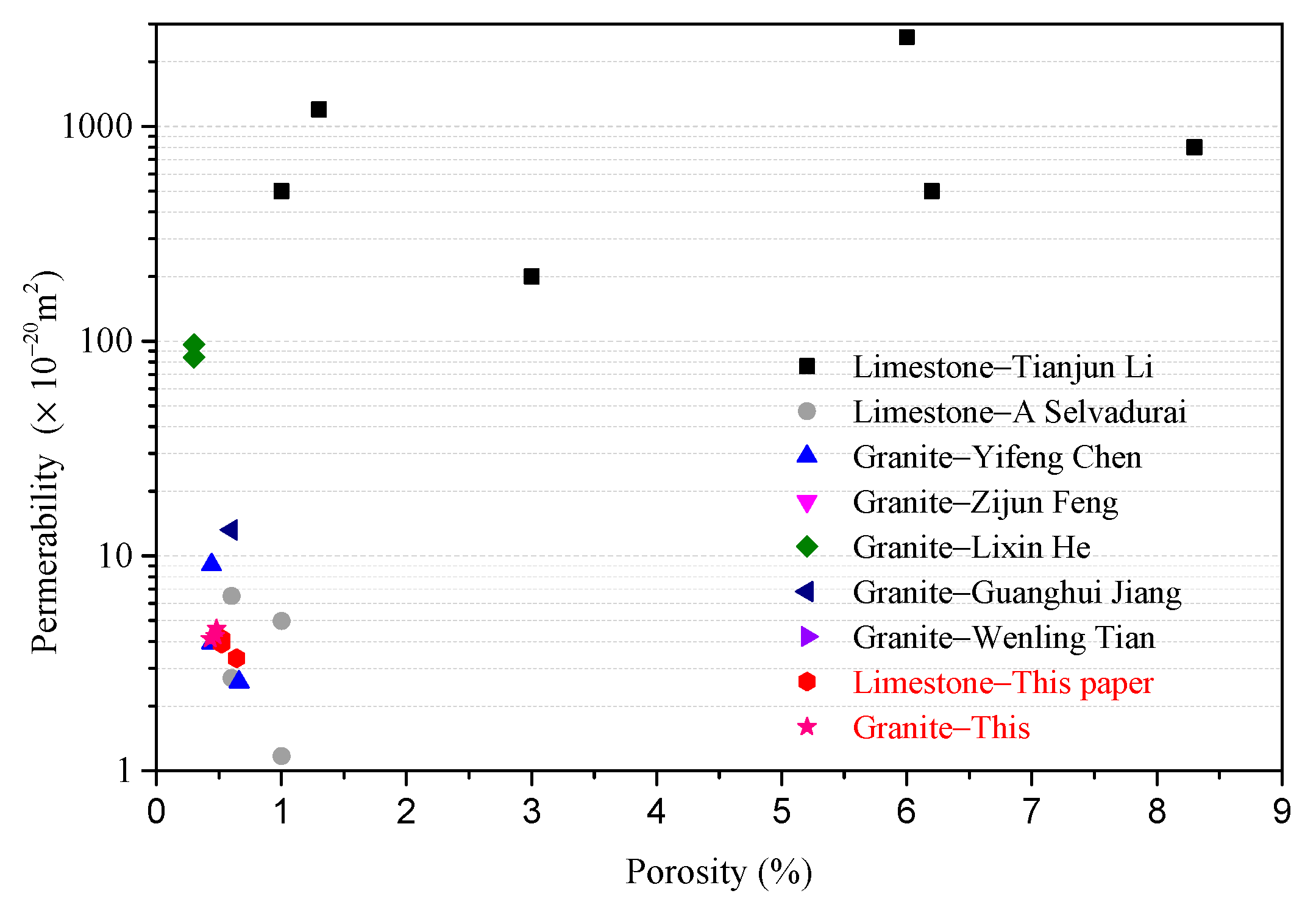

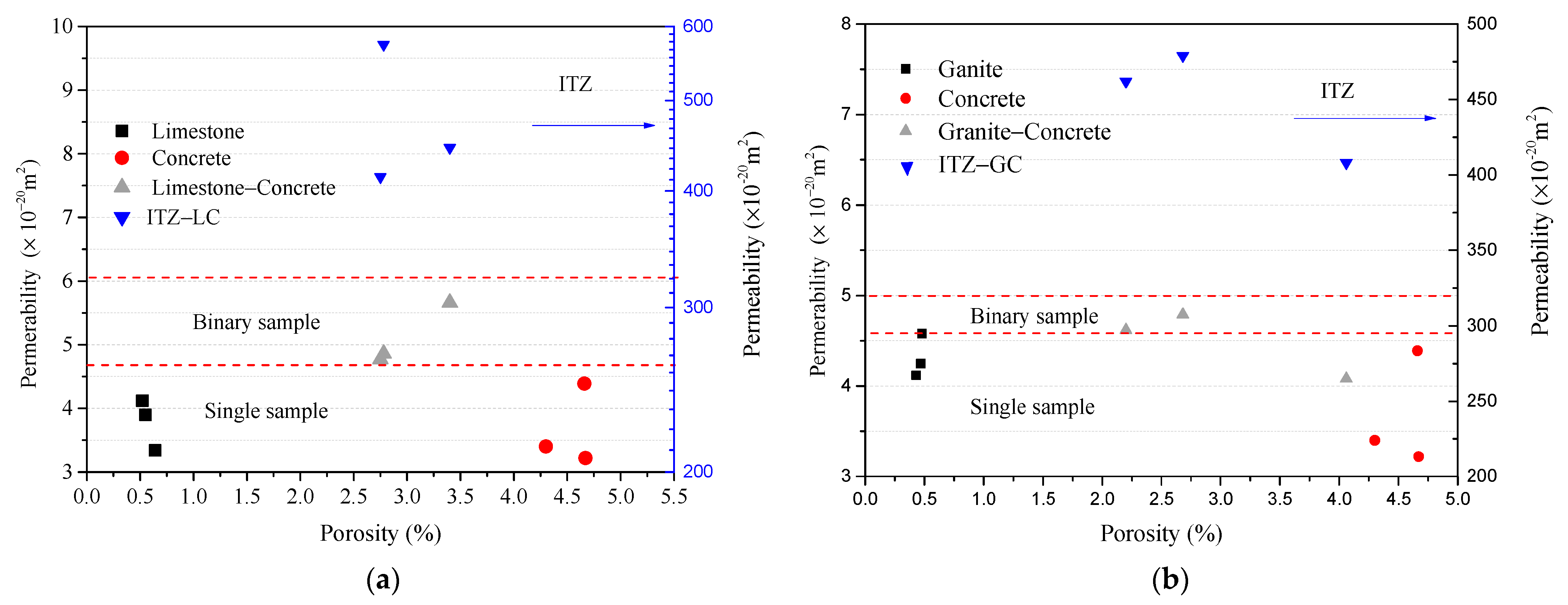

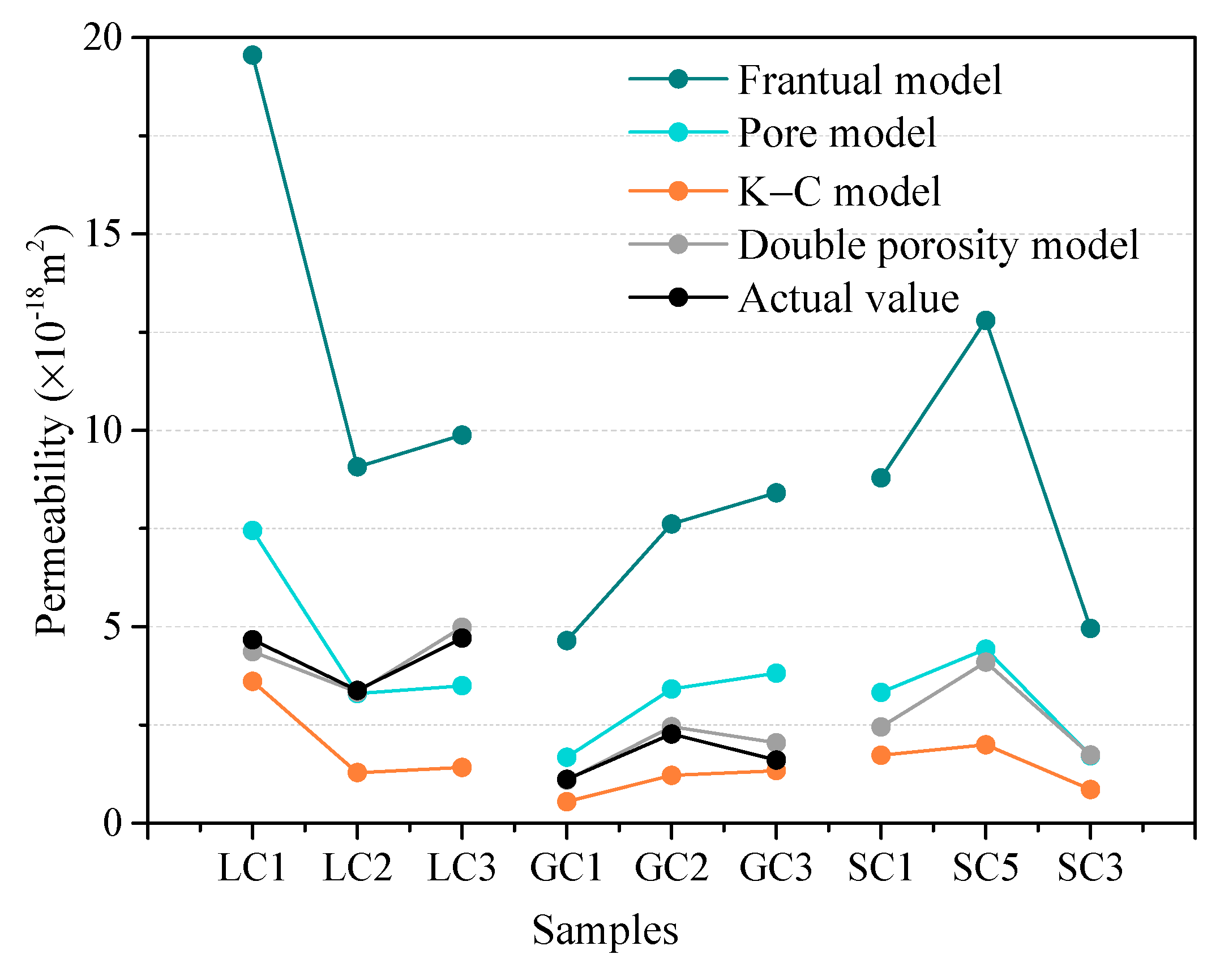

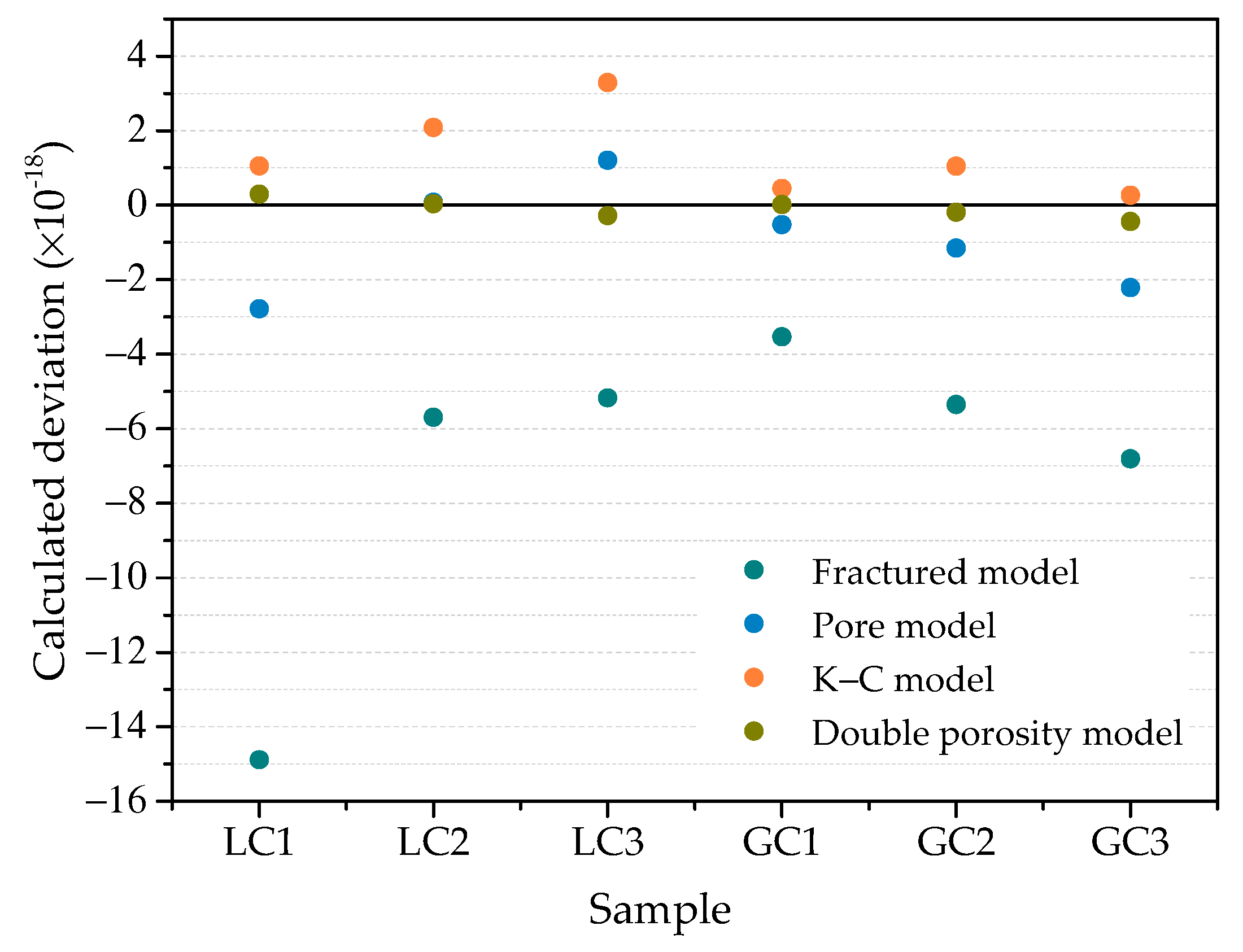

3.5. Permeability of ITZ

4. ITZ Permeability Model Based on the Fractional Theory

5. Conclusions

- (1)

- The main hydration products in the concrete–rock ITZ are CSH gel, CH, and Aft. The CSH gel content in different ITZs is between 72.5 and 75.1%, less than the cement slurry in the concrete, which is 88%. The sandstone–concrete ITZ has the highest CSH content and lowest CH content. In contrast, the limestone–concrete ITZ has the highest CH content and lowest CSH content. The CSH content is closely related to the rock particle size. The ITZ formed by coarse-grained rocks has high CSH content.

- (2)

- The thickness of concrete–rock ITZ is between 95 and 155 μm, the porosity is between 6.09 and 8.59%, and the pore size distribution is between 0.698 and 61.6 nm. Compared with the cement slurry–aggregate ITZ, the concrete–rock ITZ has more micro-cracks and larger thickness, while its range of pore size decreases. The difference in the micro-morphology and phase content leads to the difference in the thickness in the ITZ.

- (3)

- The porosity and pore size distribution properties of bedrock have significant effects on the microstructure characteristics of the ITZ. The microstructure of the sandstone–concrete ITZ is the densest, followed by granite–concrete ITZ, and the limestone–concrete ITZ is the loosest. Macro-pores increase the roughness of the interface, which will limit the shrinkage and deformation of cement slurry in the hardening process, reduce the number of cracks in the ITZ area, and form a better structural interface.

- (4)

- The impermeability of sandstone and concrete binary structure is not affected by the existence of a bonding interface. However, when limestone and granite (low porosity) are used as bedrocks, the ITZ has a significantly higher permeability. The ITZ permeability between 4.08 × 10−18 m2 and 5.74 × 10−18 m2 was two orders of magnitude larger than the permeability coefficient of rock and concrete.

- (5)

- The fractal permeability model in this study relates to the micropore structure. The proposed model provides a perfect prediction with experimental data and those predicted from the other models. It is pointed out that the contribution of microcracks to the permeability of the ITZ cannot be ignored.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lizarazo, M.; Higuera, C.; Claisse, P. Measuring the effect of the ITZ on the transport related properties of mortar using electrochemical impedance. Constr. Build. Mater. 2014, 52, 9–16. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, C.; Liao, L.; Wang, C. Numerical study of the effect of ITZ on the failure behaviour of concrete by using particle element modelling. Constr. Build. Mater. 2018, 170, 776–789. [Google Scholar] [CrossRef]

- Zhu, Z.; Provis, J.; Chen, H. Quantification of the influences of aggregate shape and sampling method on the overestimation of ITZ thickness in cementitious materials. Powder Technol. 2018, 326, 168–180. [Google Scholar] [CrossRef]

- Patel, R.A.; Quoc Tri, P.; Seetharam, S.C.; Perko, J.; Jacques, D.; Maes, N.; De Schutter, G.; Ye, G.; Van Breugel, K. Diffusivity of saturated ordinary Portland cement-based materials: A critical review of experimental and analytical modelling approaches. Cem. Concr. Res. 2016, 90, 52–72. [Google Scholar] [CrossRef]

- Nemati, K.M.; Gardoni, P. Microstructural and statistical evaluation of interfacial zone percolation in concrete. Strength Fract. Complex. 2005, 3, 191–197. [Google Scholar]

- Wang, J.; Guo, Z.; Yuan, Q.; Zhang, P.; Fang, H. Effects of ages on the ITZ microstructure of crumb rubber concrete. Constr. Build. Mater. 2020, 254, 111329. [Google Scholar] [CrossRef]

- Qiu, J.; Zhou, Y.; Guan, X.; Zhu, M. The influence of fly ash content on ITZ microstructure of coal gangue concrete. Constr. Build. Mater. 2021, 298, 1–11. [Google Scholar] [CrossRef]

- Nežerka, V.; Bílý, P.; Hrbek, V.; Fládr, J. Impact of silica fume, fly ash, and metakaolin on the thickness and strength of the ITZ in concrete. Cem. Concr. Compos. 2019, 103, 252–262. [Google Scholar] [CrossRef]

- Bílý, P.; Nežerka, V.; Hrbek, V.; Fládr, J. Validation of micromechanical model for prediction of itz thickness of high-strength concrete containing secondary cementitious materials. Mater. Sci. Forum 2020, 995, 143–148. [Google Scholar] [CrossRef]

- He, S.; Yang, E. Strategic strengthening of the interfacial transition zone (ITZ) between microfiber and cement paste matrix with carbon nanofibers (CNFs). Cem. Concr. Compos. 2021, 119, 104019. [Google Scholar] [CrossRef]

- Hosan, A.; Shaikh, F.U.A.; Sarker, P.; Aslani, F. Nano- and micro-scale characterisation of interfacial transition zone (ITZ) of high volume slag and slag-fly ash blended concretes containing nano SiO2 and nano CaCO3. Constr. Build. Mater. 2021, 269, 121311. [Google Scholar] [CrossRef]

- Lin, J.; Chen, H.; Zhao, Q.; Li, M. Statistical analysis of the critical percolation of ITZ around polygonal aggregates in three-phase concrete materials. Physica A 2021, 572, 125878. [Google Scholar] [CrossRef]

- Bentz, D.P. Influence of internal curing using lightweight aggregates on interfacial transition zone percolation and chloride ingress in mortars. Cem. Concr. Compos. 2009, 31, 285–289. [Google Scholar] [CrossRef]

- Lyu, K.; She, W. Determination of aggregate surface morphology at the interfacial transition zone (ITZ). J. Vis. Exp. 2019. [Google Scholar] [CrossRef] [PubMed]

- Skalny, J. Challenges for cement research—Are we ready. Am. Ceram. Soc. Bull. 1984, 63, 1138. [Google Scholar]

- Wakeley, L.D.; Roy, D.M. A method for testing the permeability between grout and rock. Cem. Concr. Res. 1982, 12, 533–534. [Google Scholar] [CrossRef]

- Jiang, G.; Zuo, J.; Ma, T.; Wei, X. Experimental investigation of wave velocity-permeability model for granite subjected to different temperature processing. Geofluids 2017, 2017, 6586438. [Google Scholar] [CrossRef] [Green Version]

- Yang, C. Influence of aggregate content on the percolated interfacial transition zone of cement-based materials by using accelerated chloride migration test. J. Chin. Inst. Eng. 2006, 29, 159–164. [Google Scholar] [CrossRef]

- Snyder, K.A.; Winslow, D.N.; Bentz, D.P.; Garboczi, E.J. Effects of interfacial zone percolation on cement-based composite transport properties. MRS Online Proc. Libr. 1991, 245, 265–270. [Google Scholar] [CrossRef]

- Bentz, D.P.; Hwang, J.T.G.; Hagwood, C.; Garboczi, E.J.; Snyder, K.A.; Buenfeld, N.; Scrivener, K.L. Interfacial zone percolation in concrete: Effects of interfacial zone thickness and aggregate shape. Mater. Res. Soc. Symp. Proc. 1994, 370, 437. [Google Scholar] [CrossRef] [Green Version]

- Zheng, J.; Zhou, X. Percolation of ITZs in concrete and effects of attributing factors. J. Mater. Civ. Eng. 2007, 19, 784–790. [Google Scholar] [CrossRef]

- Zheng, J.; Zhou, X. Effective medium method for predicting the chloride diffusivity in concrete with ITZ percolation effect. Constr. Build. Mater. 2013, 47, 1093–1098. [Google Scholar] [CrossRef]

- Kim, S.U.; Kim, J.S.; Kang, J.W.; Han, T.S. Construction of virtual interfacial transition zone (ITZ) samples of hydrated cement paste using extended stochastic optimization. Cem. Concr. Compos. 2019, 102, 84–93. [Google Scholar] [CrossRef]

- Li, K.; Stroeven, M.; Stroeven, P.; Sluys, L.J. Effects of technological parameters on permeability estimation of partially saturated cement paste by a DEM approach. Cem. Concr. Compos. 2017, 84, 222–231. [Google Scholar] [CrossRef]

- Li, K.; Stroeven, P.; Stroeven, M.; Sluys, L.J. A numerical investigation into the influence of the interfacial transition zone on the permeability of partially saturated cement paste between aggregate surfaces. Cem. Concr. Res. 2017, 102, 99–108. [Google Scholar] [CrossRef]

- Jia, B.; Cui, X. Pore pressure dependent gas flow in tight porous media. J. Pet. Sci. Eng. 2021, 205, 108835. [Google Scholar] [CrossRef]

- Jia, B.; Xian, C.-G. Permeability measurement of the fracture-matrix system with 3D embedded discrete fracture model. Pet. Sci. 2022. [Google Scholar] [CrossRef]

- Sun, X.; Zhang, B.; Dai, Q.; Yu, X. Investigation of internal curing effects on microstructure and permeability of interface transition zones in cement mortar with SEM imaging, transport simulation and hydration modeling techniques. Constr. Build. Mater. 2015, 76, 366–379. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, G.; Tong, Y.; Gu, C. Prediction on permeability of engineered cementitious composites. Crystals 2021, 11, 526. [Google Scholar] [CrossRef]

- Tran, T.T.; Pham, D.T.; Vu, M.N.; Truong, V.Q.; Ho, X.B.; Tran, N.L.; Nguyen-Sy, T.; To, Q.D. Relation between water permeability and chloride diffusivity of concrete under compressive stress: Experimental investigation and mesoscale lattice modelling. Constr. Build. Mater. 2021, 267, 121164. [Google Scholar] [CrossRef]

- Yu, P.; Duan, Y.H.; Chen, E.; Tang, S.W.; Wang, X.R. Microstructure-based fractal models for heat and mass transport properties of cement paste. Int. J. Heat Mass Transf. 2018, 126, 432–447. [Google Scholar] [CrossRef]

- Jin, S.; Zhang, J.; Han, S. Fractal analysis of relation between strength and pore structure of hardened mortar. Constr. Build. Mater. 2017, 135, 1–7. [Google Scholar] [CrossRef]

- Tang, S.W.; He, Z.; Cai, X.H.; Cai, R.J.; Zhou, W.; Li, Z.J.; Shao, H.Y.; Wu, T.; Chen, E. Volume and surface fractal dimensions of pore structure by NAD and LT-DSC in calcium sulfoaluminate cement pastes. Constr. Build. Mater. 2017, 143, 395–418. [Google Scholar] [CrossRef]

- Wang, L.; Zeng, X.; Yang, H.; Lv, X.; Guo, F.; Shi, Y.; Hanif, A. Investigation and application of fractal theory in cement-based materials: A review. Fractal Fract. 2021, 5, 247. [Google Scholar] [CrossRef]

- Meng, Q.; Qin, Q.; Yang, H.; Zhou, H.; Wu, K.; Wang, L. Fractal characteristics of the pore structure of coral powder-cement slurry under different fractal models. Fractal Fract. 2022, 6, 145. [Google Scholar] [CrossRef]

- Shan, J.; Zhang, Y.; Wu, S.; Lin, Z.; Li, L.; Wu, Q. Pore characteristics of pervious concrete and their influence on permeability attributes. Constr. Build. Mater. 2022, 327, 126874. [Google Scholar] [CrossRef]

- Wang, B.; Guo, J.; Liu, J.; Wang, Q. Prediction method of permeability of textile-reinforced concrete based on fractal dimension theory. Constr. Build. Mater. 2022, 327, 126868. [Google Scholar] [CrossRef]

- Dai, Q.; Wang, G.; Zhao, X.; Han, Z.; Lu, K.; Lai, J.; Wang, S.; Li, D.; Li, Y.; Wu, K. Fractal model for permeability estimation in low-permeable porous media with variable pore sizes and unevenly adsorbed water lay. Mar. Pet. Geol. 2021, 130, 105135. [Google Scholar] [CrossRef]

- Li, R.; Chen, Z.; Wu, K.; Liu, X.; Dou, L.; Yang, S.; Xu, J. A fractal model for gas-water relative permeability curve in shale rocks(Article). J. Nat. Gas Sci. Eng. 2020, 81, 103417. [Google Scholar] [CrossRef]

- Wen, F.; Fan, H.; Zhai, S.; Zhang, K.; Liu, F. Pore characteristics analysis and numerical seepage simulation of antifreeze permeable concrete. Constr. Build. Mater. 2020, 255, 119310. [Google Scholar] [CrossRef]

- Jullien, M.; Raynal, J.; Kohler, É.; Bildstein, O. Physicochemical reactivity in clay-rich materials: Tools for safety assessment (Article). Oil Gas Sci. Technol. 2005, 60, 107–120. [Google Scholar] [CrossRef] [Green Version]

- Zhu, J.; Bao, W.; Peng, Q.; Deng, X. Influence of substrate properties and interfacial roughness on static and dynamic tensile behaviour of rock-shotcrete interface from macro and micro views. Int. J. Rock Mech. Min. Sci. 2020, 132, 104350. [Google Scholar] [CrossRef]

- Wang, Y.; Lu, B.; Hu, X.; Liu, J.; Zhang, Z.; Pan, X.; Xie, Z.; Chang, J.; Zhang, T.; Nehdi, M.L.; et al. Effect of CO2 surface treatment on penetrability and microstructure of cement-fly ash–slag ternary concrete. Cem. Concr. Compos. 2021, 123, 1–12. [Google Scholar] [CrossRef]

- Rao, G.A.; Prasad, B.R. Influence of the roughness of aggregate surface on the interface bond strength. Cem. Concr. Res. 2002, 32, 253–257. [Google Scholar] [CrossRef]

- Shi, Y.; Lv, X.; Zhou, S.; Liu, Z.A.; Yang, M.; Liu, C.; Lu, C. Mechanical properties, durability, and ITZ characteristics of full-grade dam concrete prepared by aggregates with surface rust stains. Constr. Build. Mater. 2021, 305, 1–14. [Google Scholar] [CrossRef]

- Hussin, A.; Poole, C. Petrography evidence of the interfacial transition zone (ITZ) in the normal strength concrete containing granitic and limestone aggregates. Constr. Build. Mater. 2011, 25, 2298–2303. [Google Scholar] [CrossRef]

- He, J.; Lei, D.; Xu, W. In-situ measurement of nominal compressive elastic modulus of interfacial transition zone in concrete by SEM-DIC coupled method. Cem. Concr. Compos. 2020, 114, 103779. [Google Scholar] [CrossRef]

- Xie, Y.; Corr, D.; Jin, F.; Zhou, H.; Shah, S. Experimental study of the interfacial transition zone (ITZ) of model rock-filled concrete (RFC). Cem. Concr. Compos. 2015, 55, 223–231. [Google Scholar] [CrossRef]

- Petrounias, P.; Giannakopoulou, P.P.; Rogkala, A.; Stamatis, P.M.; Tsikouras, B.; Papoulis, D.; Lampropoulou, P.; Hatzipanagiotou, K. The influence of alteration of aggregates on the quality of the concrete: A case study from serpentinites and andesites from central macedonia. Geosciences 2018, 8, 115. [Google Scholar] [CrossRef] [Green Version]

- Wu, K.; Shi, H.; Xu, L.; Ye, G.; De Schutter, G. Microstructural characterization of ITZ in blended cement concretes and its relation to transport properties. Cem. Concr. Res. 2016, 79, 243–256. [Google Scholar] [CrossRef]

- Liu, Y.; Shen, P.; He, Y.; Wang, F. Research progress of special aggregate concrete. Bull. Chin. Ceram. Soc. 2021, 40, 2831–2855. [Google Scholar] [CrossRef]

- Li, T.; Huang, Z.; Feng, Y.; Chen, X.; Ma, Q.; Liu, B.; Guo, X. Reservoir characteristics and evaluation of fluid mobility in organic-rich mixed siliciclastic-carbonate sediments: A case study of the lacustrine Qiketai Formation in Shengbei Sag, Turpan-Hami Basin, Northwest China. J. Pet. Sci. Eng. 2020, 185, 106667. [Google Scholar] [CrossRef]

- Selvadurai, A.; Głowacki, A. Estimates for the local permeability of the cobourg limestone. J. Rock Mech. Geotech. Eng. 2018, 10, 1009–1019. [Google Scholar] [CrossRef]

- Selvadurai, A.; Głowacki, A. Stress-induced permeability alterations in an argillaceous limestone. Rock Mech. Rock Eng. 2017, 50, 1079–1096. [Google Scholar] [CrossRef]

- Chen, Y.; Hu, S.; Wei, K.; Hu, R.; Zhou, C.; Jing, L. Experimental characterization and micromechanical modeling of damage-induced permeability variation in Beishan granite. Int. J. Rock Mech. Min. Sci. 2014, 71, 64–76. [Google Scholar] [CrossRef]

- Feng, Z.; Zhao, Y.; Liu, D. Permeability evolution of thermally cracked granite with different grain sizes. Rock Mech. Rock Eng. 2021, 54, 1953–1967. [Google Scholar] [CrossRef]

- He, L.; Yin, Q.; Jing, H. Laboratory investigation of granite permeability after high-temperature exposure. Processes 2018, 6, 36. [Google Scholar] [CrossRef] [Green Version]

- Tian, W.; Yang, S.; Elsworth, D.; Wang, J.; Li, X.-Z. Permeability evolution and crack characteristics in granite under treatment at high temperature. Int. J. Rock Mech. Min. Sci. 2020, 134, 104461. [Google Scholar] [CrossRef]

- Yu, B.; Cheng, P. A fractal permeability model for bi-dispersed porous media. Int. J. Heat Mass Transf. 2002, 45, 2983–2993. [Google Scholar] [CrossRef]

- Xu, P.; Yu, B. The scaling laws of transport properties for fractal-like tree networks. J. Appl. Phys. 2006, 100, 104906. [Google Scholar] [CrossRef] [Green Version]

- Monachesi, L.B.; Guarracino, L. A fractal model for predicting water and air permeabilities of unsaturated fractured rocks. Transp. Porous Media 2011, 90, 779–789. [Google Scholar] [CrossRef]

- Yu, B. Analysis of flow in fractal porous media. Appl. Mech. Rev. 2008, 61, 0508011–05080119. [Google Scholar] [CrossRef]

- Xu, P.; Yu, B. Developing a new form of permeability and Kozeny–Carman constant for homogeneous porous media by means of fractal geometry. Adv. Water Resour. 2008, 31, 74–81. [Google Scholar] [CrossRef]

- Gérard, B.; Marchand, J. Influence of cracking on the diffusion properties of cement-based materials. Cem. Concr. Res. 2000, 30, 37–43. [Google Scholar] [CrossRef]

- Wong, H.S.; Buenfeld, N.R.; Hill, J.; Harris, A.W. Mass transport properties of mature wasteform grouts. Adv. Cem. Res. 2007, 19, 35–46. [Google Scholar] [CrossRef] [Green Version]

- Wong, H.S.; Zobel, M.; Buenfeld, N.R.; Zimmerman, R.W. Influence of the interfacial transition zone and microcracking on the diffusivity, permeability and sorptivity of cement-based materials after drying. Mag. Concr. Res. 2009, 61, 571–589. [Google Scholar] [CrossRef] [Green Version]

| Material | Water | Cement | Crush Stone | Sand | Admixtures |

|---|---|---|---|---|---|

| Concrete | 0.36 | 1 | 2.824 | 1.392 | 0.005 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yue, J.; Sheng, J.; Wang, H.; Hu, Y.; Zhang, K.; Luo, Y.; Zhou, Q.; Zhan, M. Investigation on Pore Structure and Permeability of Concrete–Rock Interfacial Transition Zones Based on Fractal Theory. Fractal Fract. 2022, 6, 329. https://doi.org/10.3390/fractalfract6060329

Yue J, Sheng J, Wang H, Hu Y, Zhang K, Luo Y, Zhou Q, Zhan M. Investigation on Pore Structure and Permeability of Concrete–Rock Interfacial Transition Zones Based on Fractal Theory. Fractal and Fractional. 2022; 6(6):329. https://doi.org/10.3390/fractalfract6060329

Chicago/Turabian StyleYue, Juan, Jinchang Sheng, Huimin Wang, Yunjin Hu, Kailai Zhang, Yulong Luo, Qing Zhou, and Meili Zhan. 2022. "Investigation on Pore Structure and Permeability of Concrete–Rock Interfacial Transition Zones Based on Fractal Theory" Fractal and Fractional 6, no. 6: 329. https://doi.org/10.3390/fractalfract6060329