A Lorentz Force Actuated Continuous Deformable Polymer Mirror for Wavefront Control †

Abstract

:1. Introduction

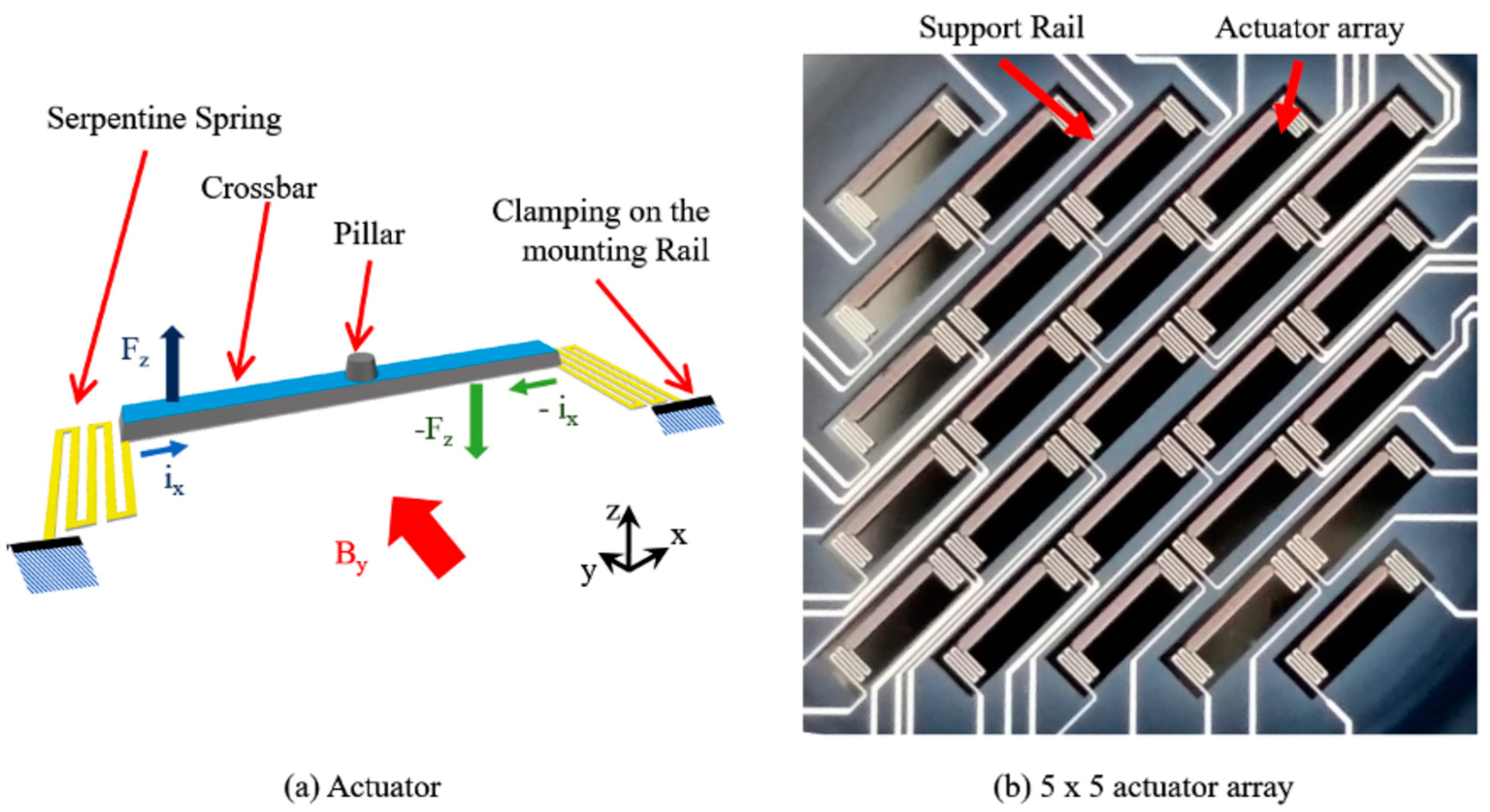

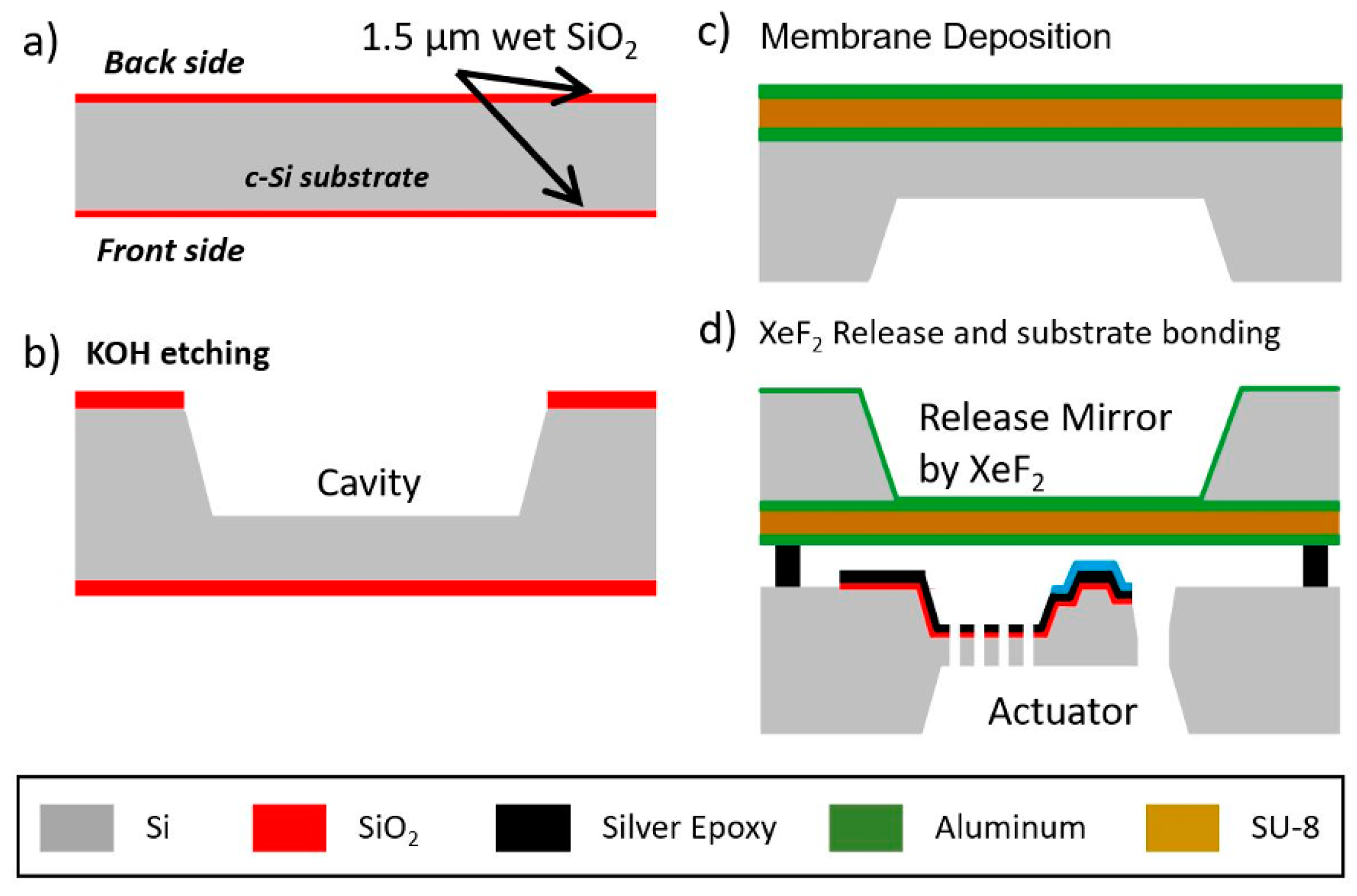

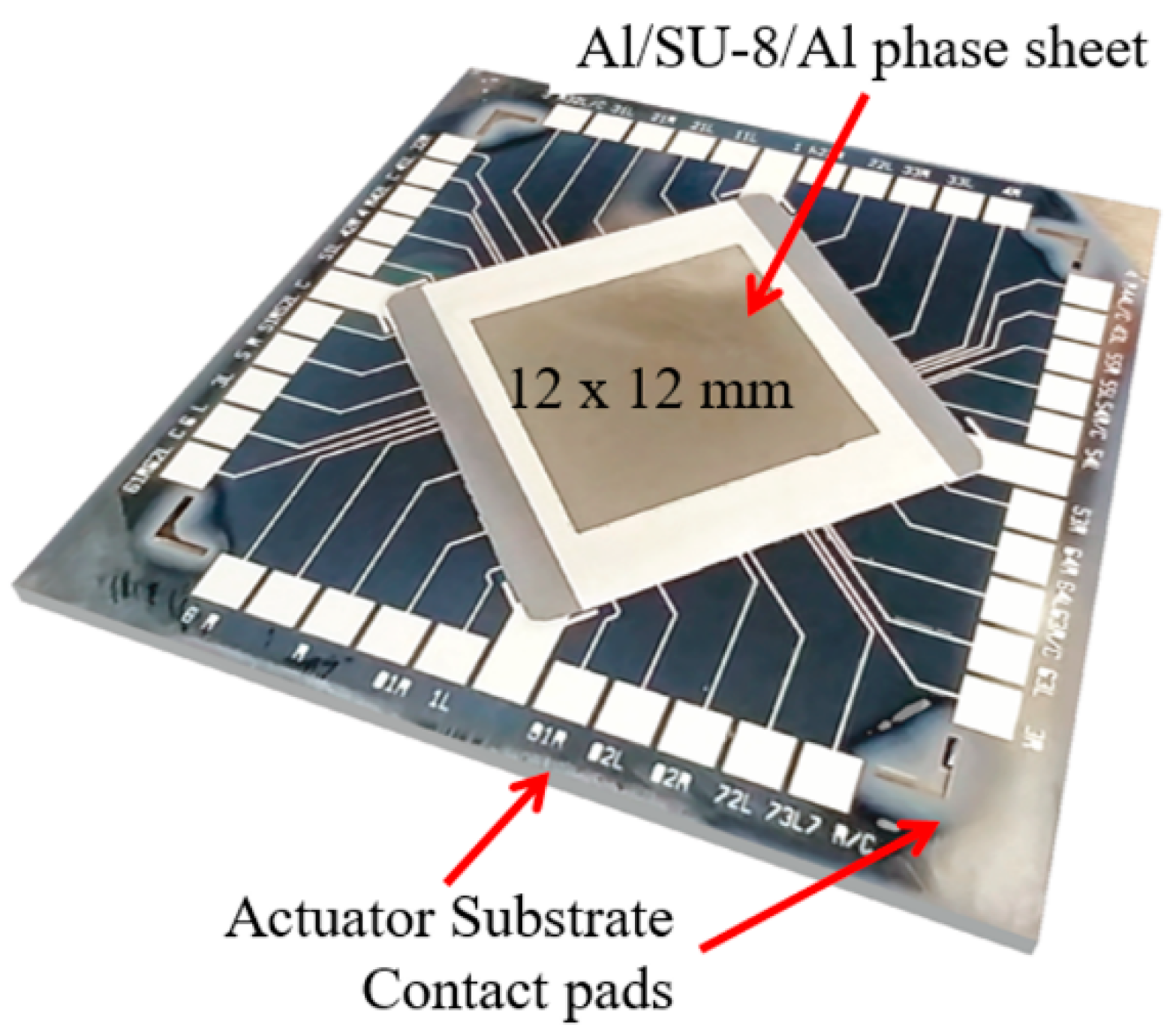

2. Design and Fabrication

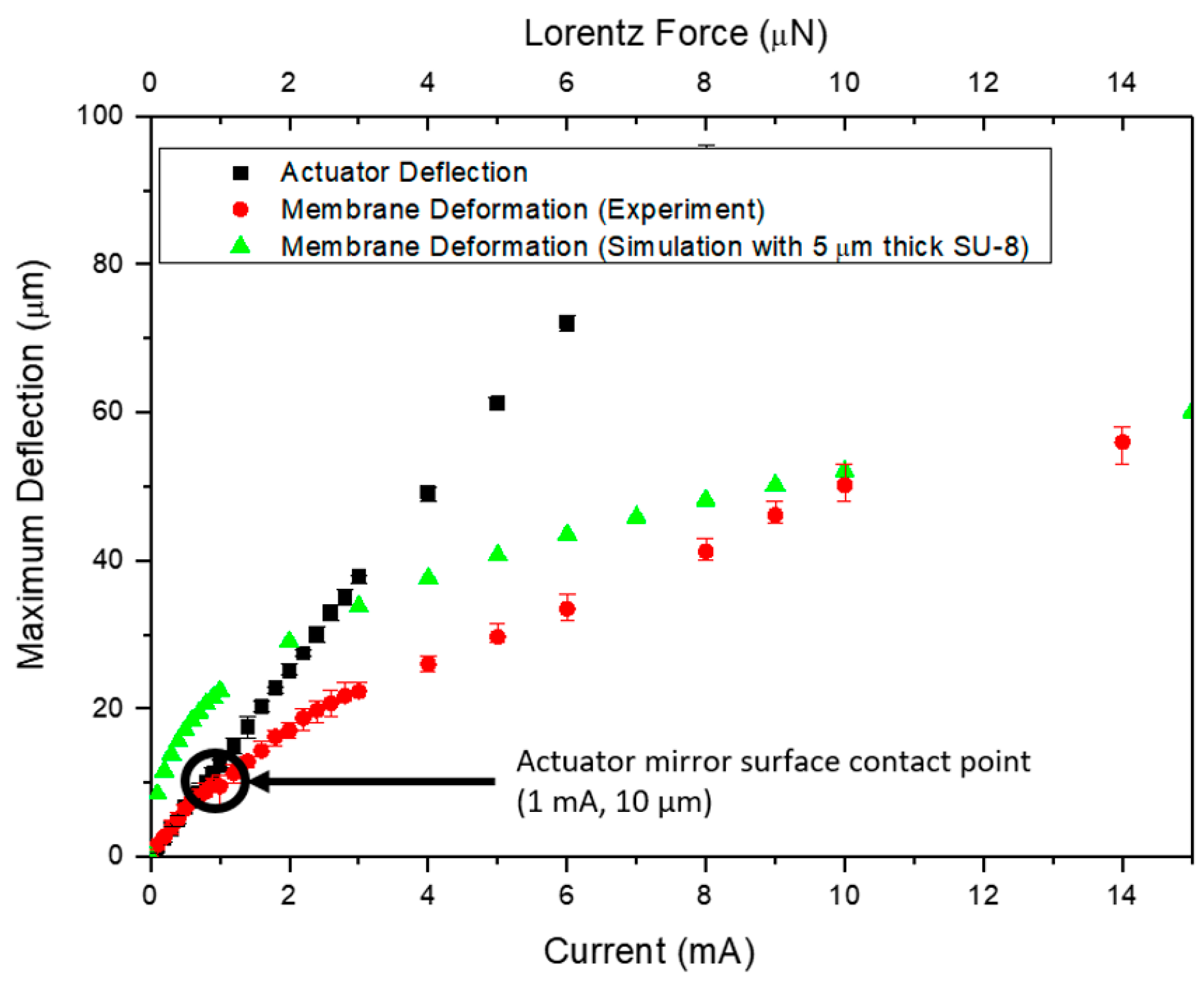

3. Result and Discussion

Acknowledgments

Conflicts of Interest

References

- Madec, P.-Y. Overview of deformable mirror technologies for adaptive optics and astronomy. Proc. SPIE 8447 Adapt. Opt. Syst. III 2012, 844705. [Google Scholar] [CrossRef]

- Wallace, B.P.; Hampton, P.J.; Bradley, C.H.; Conan, R. Evaluation of a MEMS deformable mirror for an adaptive optics test bench. Opt. Express 2006, 14, 10132–10138. [Google Scholar] [CrossRef] [PubMed]

- Perreault, A.; Bifano, T.G.; Levine, B.M.; Horenstein, M.N. Adaptive optic correction using microelectromechanical deformable mirrors. Opt. Eng. 2002, 41, 561–566. [Google Scholar] [CrossRef]

- Bifano, T. Shaping light: MOEMS deformable mirrors for microscopes and telescopes. Proc. MEMS Adapt. Opt. IV 2010, 7595, 759502. [Google Scholar] [CrossRef]

- Vera-Díaz, F.A.; Doble, N. The Human Eye and Adaptive Optics in Topics in Adaptive Optics; InTech Open Access Publisher: Rijeka, Croatia, 2012; pp. 119–150. [Google Scholar] [CrossRef]

- Liang, J.; Williams, D.R.; Miller, D.T. Supernormal vision and high-resolution retinal imaging through adaptive optics. J. Opt. Soc. Am. 1997, 14, 2884–2892. [Google Scholar] [CrossRef] [PubMed]

- Wilson, K.E.; Wright, M.W.; Lee, S.; Troy, M. Adaptive optics for daytime deep space laser communications to Mars. In Proceedings of the Digest of the LEOS Summer Topical Meetings, San Diego, CA, USA, 25–27 July 2005. [Google Scholar] [CrossRef]

- Fugate, R.Q. Laser beacon adaptive optics for power beaming applications. In Proceedings of the SPIE 2121, Laser Power Beaming, Los Angeles, CA, USA, 1 May 1994; pp. 68–76. [Google Scholar]

- Friese, C.; Zappe, H. Deformable Polymer Adaptive Optical Mirrors. J. Microelectromech. Syst. 2008, 17, 11–19. [Google Scholar] [CrossRef]

- Lin, P.-Y.; Hsieh, H.-T.; Su, G.-D.J. Design and fabrication of a large-stroke MEMS deformable mirror for wavefront control. J. Opt. 2011, 13, 055404. [Google Scholar] [CrossRef]

- Ma, J.; Liu, Y.; Chen, C.; Li, B.; Chu, J. Deformable mirrors based on piezoelectric unimorph microactuator array for adaptive optics correction. Opt. Commun. 2011, 284, 5062. [Google Scholar] [CrossRef]

- Park, B.; Afsharipour, E.; Chrusch, D.; Shafai, C.; Andersen, D.; Burley, G. Large Displacement Bi-Directional Out-of-Plane Lorentz Actuator Array for Surface Manipulation. J. Micromech. Microeng. 2017, in press. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, B.; Afsharipour, E.; Shafai, C. A Lorentz Force Actuated Continuous Deformable Polymer Mirror for Wavefront Control. Proceedings 2017, 1, 554. https://doi.org/10.3390/proceedings1040554

Park B, Afsharipour E, Shafai C. A Lorentz Force Actuated Continuous Deformable Polymer Mirror for Wavefront Control. Proceedings. 2017; 1(4):554. https://doi.org/10.3390/proceedings1040554

Chicago/Turabian StylePark, Byoungyoul, Elnaz Afsharipour, and Cyrus Shafai. 2017. "A Lorentz Force Actuated Continuous Deformable Polymer Mirror for Wavefront Control" Proceedings 1, no. 4: 554. https://doi.org/10.3390/proceedings1040554