Magnetomotive and Tension-Based Tuning of a Micromechanical Resonator †

Abstract

:1. Introduction

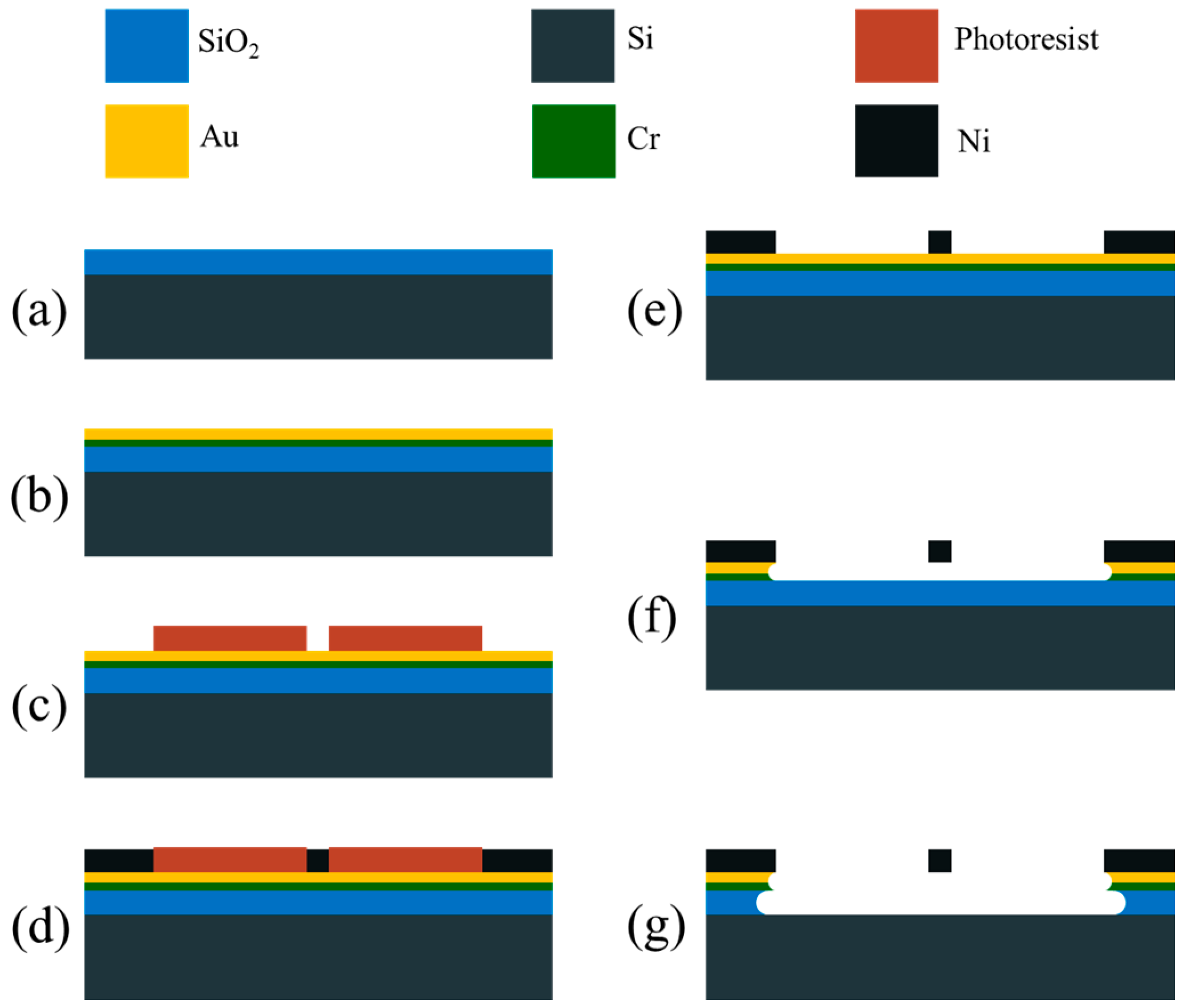

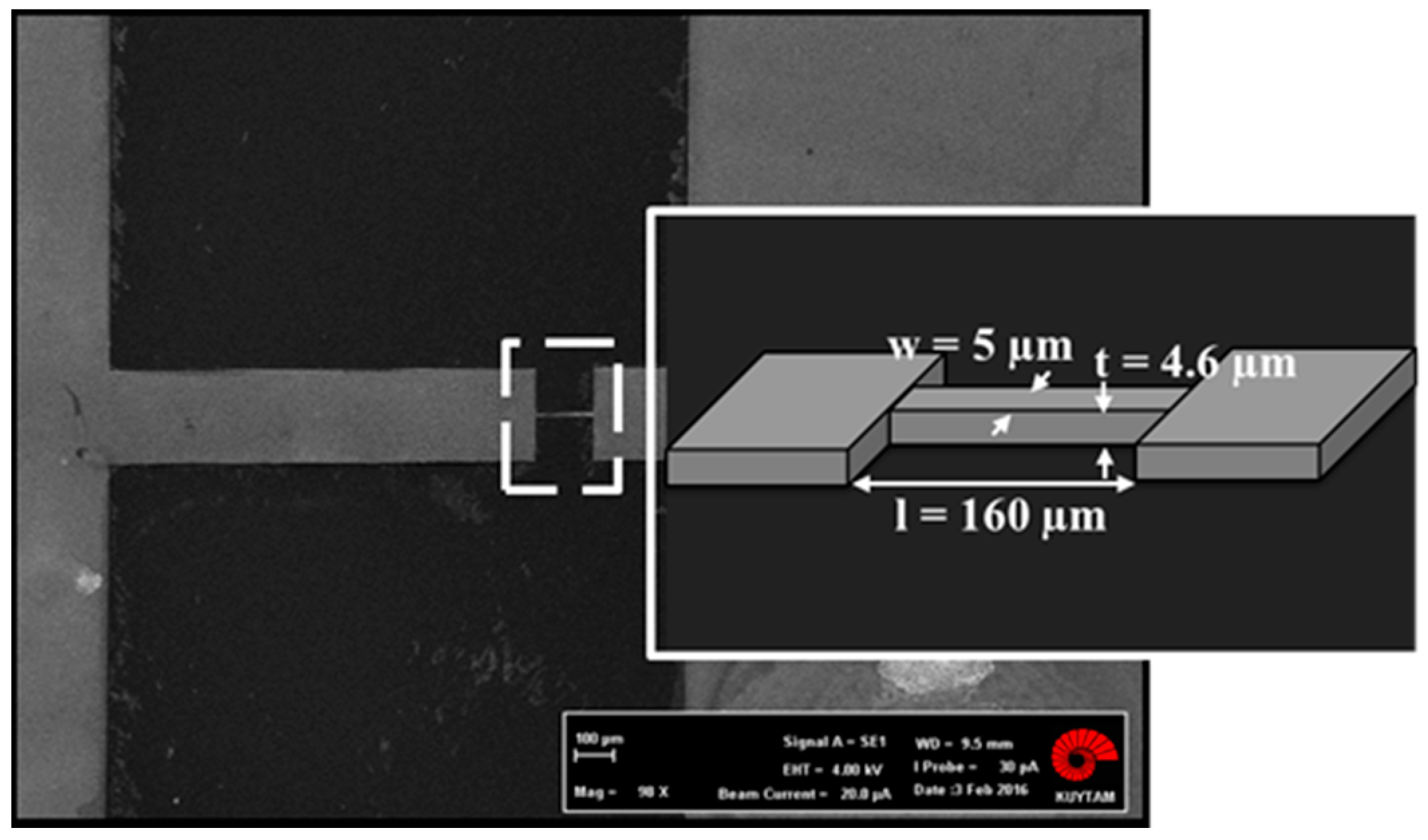

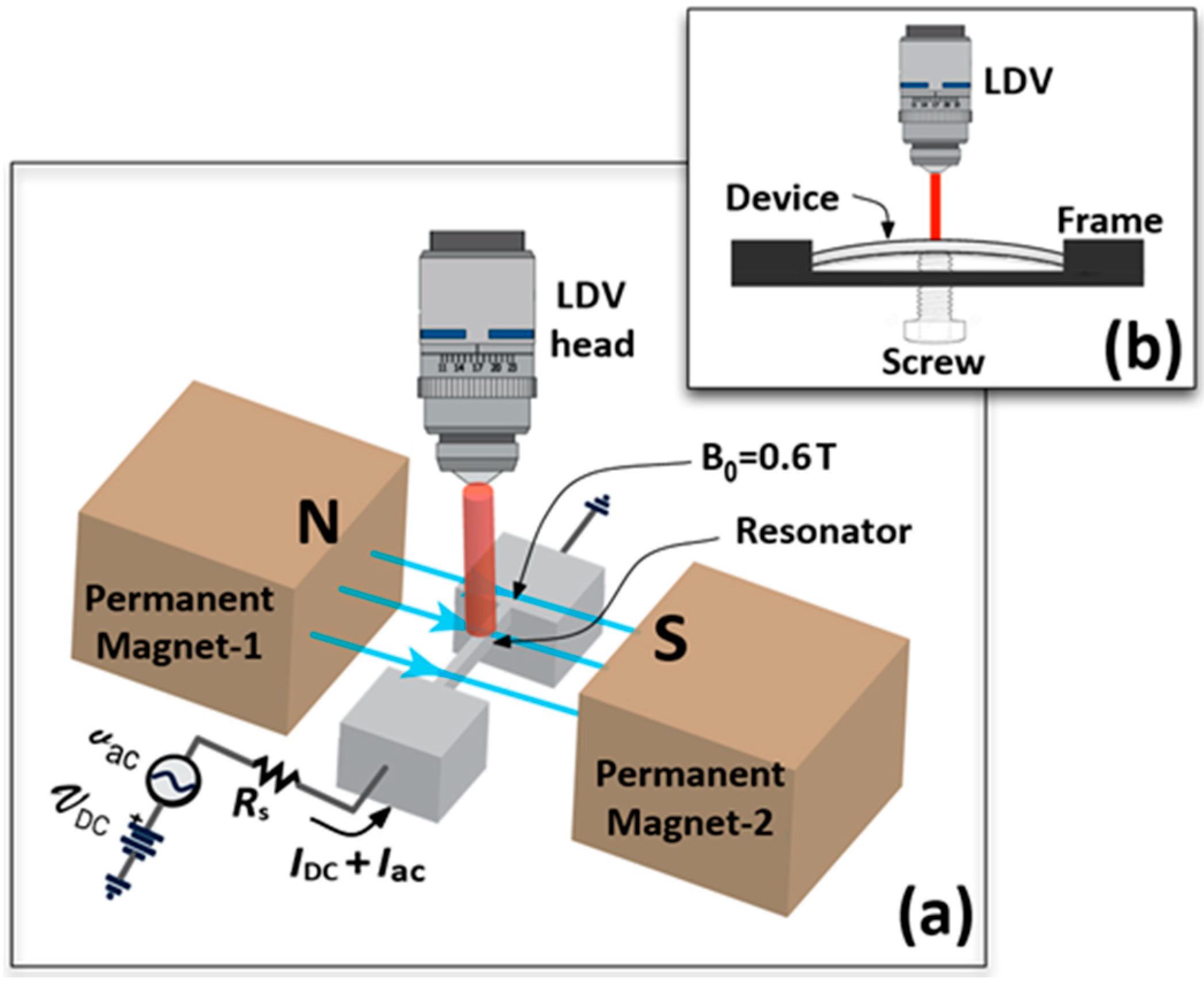

2. Materials and Methods

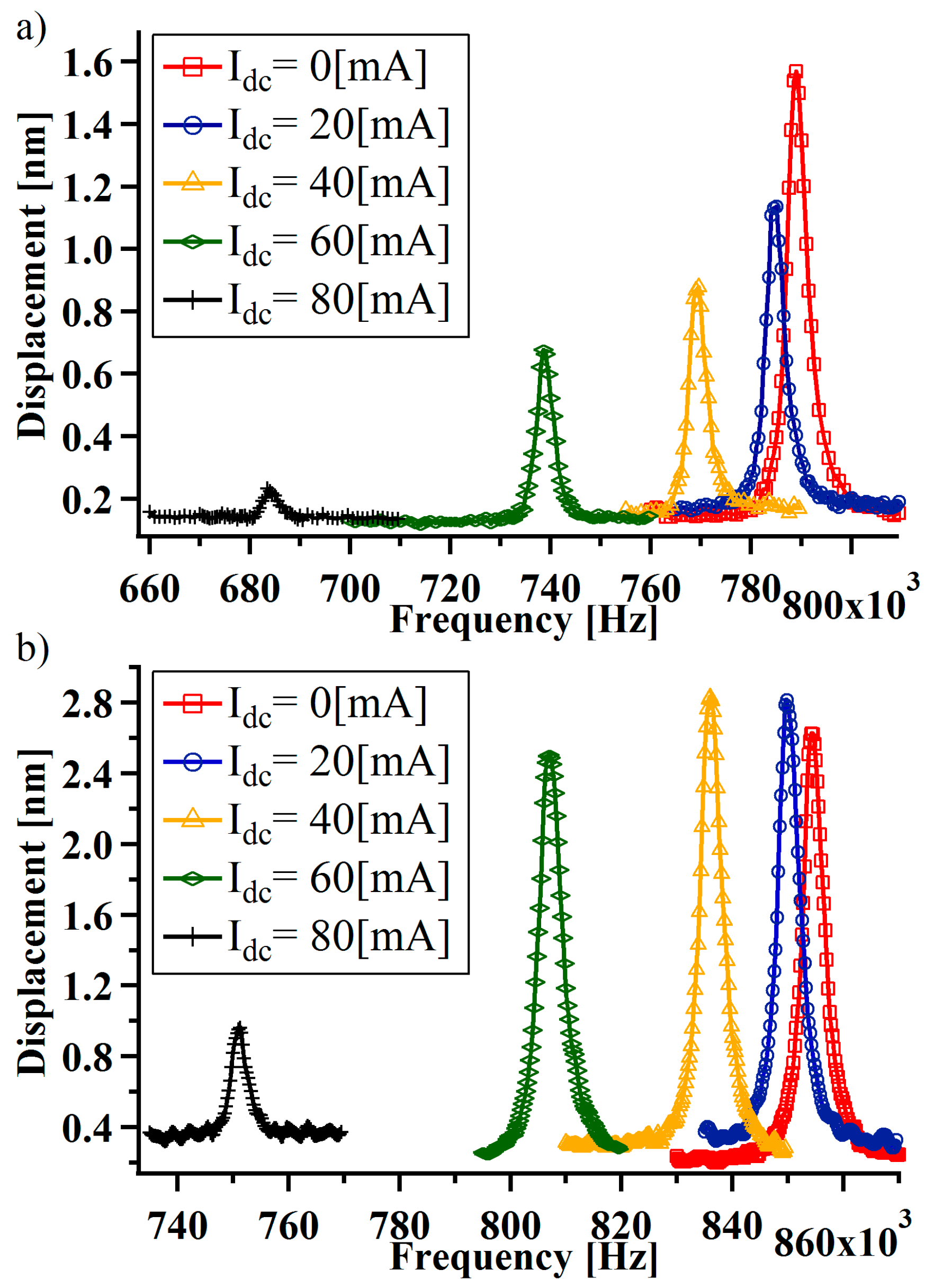

3. Results and Discussion

Acknowledgments

Conflicts of Interest

References

- Scheibner, D.; Mehner, J.; Reuter, D.; Gessner, T.; Dötzel, W. A spectral vibration detection system based on tunable micromechanical resonators. Sens. Actuators A Phys. 2005, 123, 63–72. [Google Scholar] [CrossRef]

- Verbridge, S.S.; Shapiro, D.F.; Craighead, H.G.; Parpia, J.M. Macroscopic tuning of nanomechanics: Substrate bending for reversible control of frequency and quality factor of nanostring resonators. Nano Lett. 2007, 7, 1728–1735. [Google Scholar] [CrossRef] [PubMed]

- Ning, Z.Y.; Shi, T.W.; Fu, M.Q.; Guo, Y.; Wei, X.L.; Gao, S.; Chen, Q. Transversally and axially tunable carbon nanotube resonators in situ fabricated and studied inside a scanning electron microscope. Nano Lett. 2014, 14, 1221–1227. [Google Scholar] [CrossRef] [PubMed]

- Remtema, T.; Lin, L. Active frequency tuning for micro resonators by localized thermal stressing effects. Sens. Actuators A Phys. 2001, 91, 326–332. [Google Scholar] [CrossRef]

- Dominik, V.S.; Artur, E.; Robert, H.B. Tunable coupled nanomechanical resonators for single-electron transport. New J. Phys. 2002, 4, 86. [Google Scholar]

- Ekinci, K.L.; Roukes, M.L. Nanoelectromechanical systems. Rev. Sci. Instrum. 2005, 76, 061101. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bicer, M.; Yalcinkaya, A.D.; Alaca, B.E. Magnetomotive and Tension-Based Tuning of a Micromechanical Resonator. Proceedings 2017, 1, 572. https://doi.org/10.3390/proceedings1040572

Bicer M, Yalcinkaya AD, Alaca BE. Magnetomotive and Tension-Based Tuning of a Micromechanical Resonator. Proceedings. 2017; 1(4):572. https://doi.org/10.3390/proceedings1040572

Chicago/Turabian StyleBicer, Mahmut, Arda D. Yalcinkaya, and B. Erdem Alaca. 2017. "Magnetomotive and Tension-Based Tuning of a Micromechanical Resonator" Proceedings 1, no. 4: 572. https://doi.org/10.3390/proceedings1040572