Hydropower Potential Assessment in Water Supply Systems †

Abstract

:1. Introduction

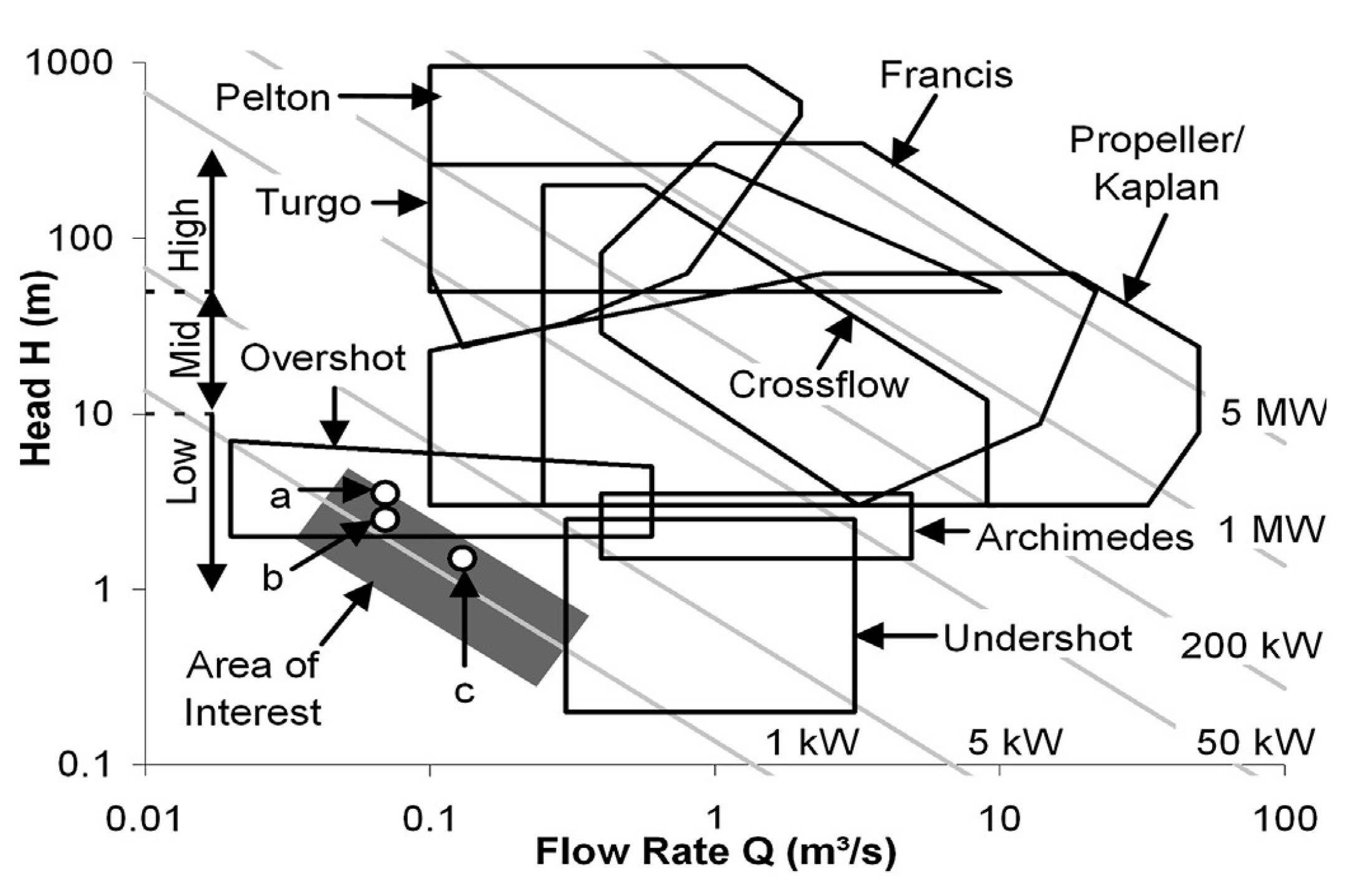

2. Materials and Methods

2.1. Supply Flow

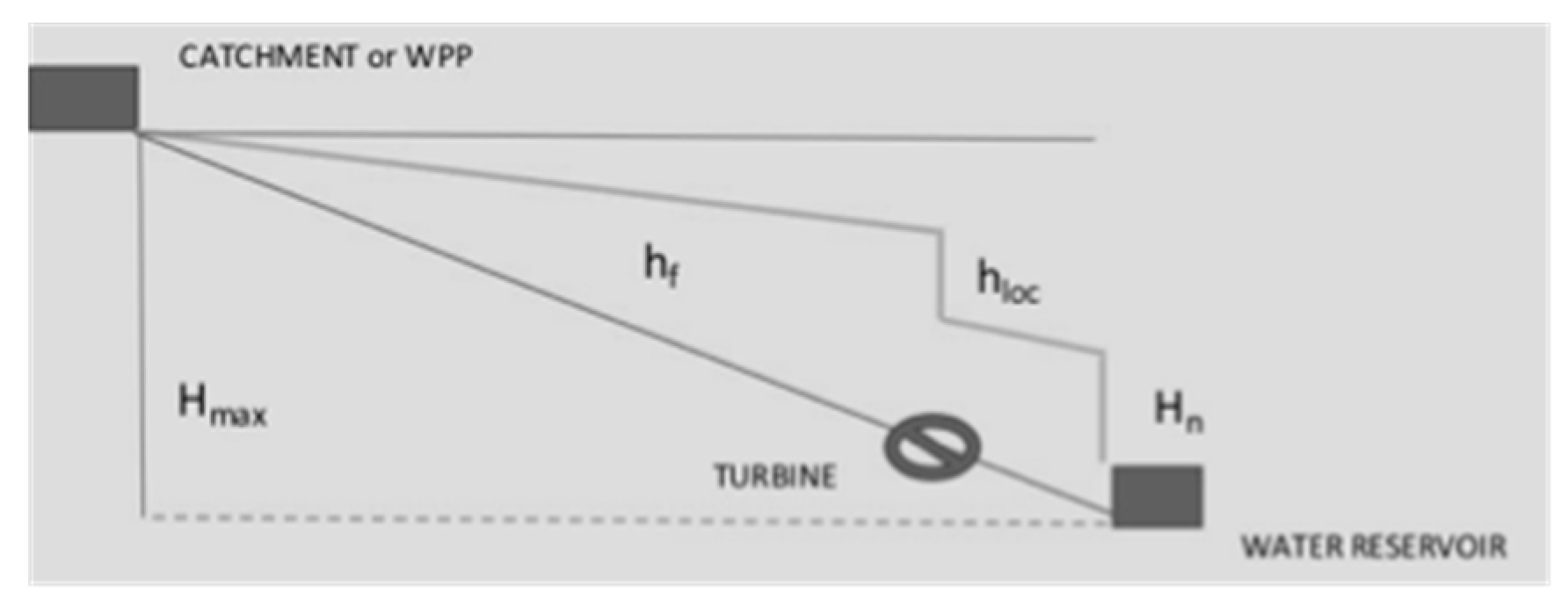

2.2. Head Measurement

2.3. Pipe Design

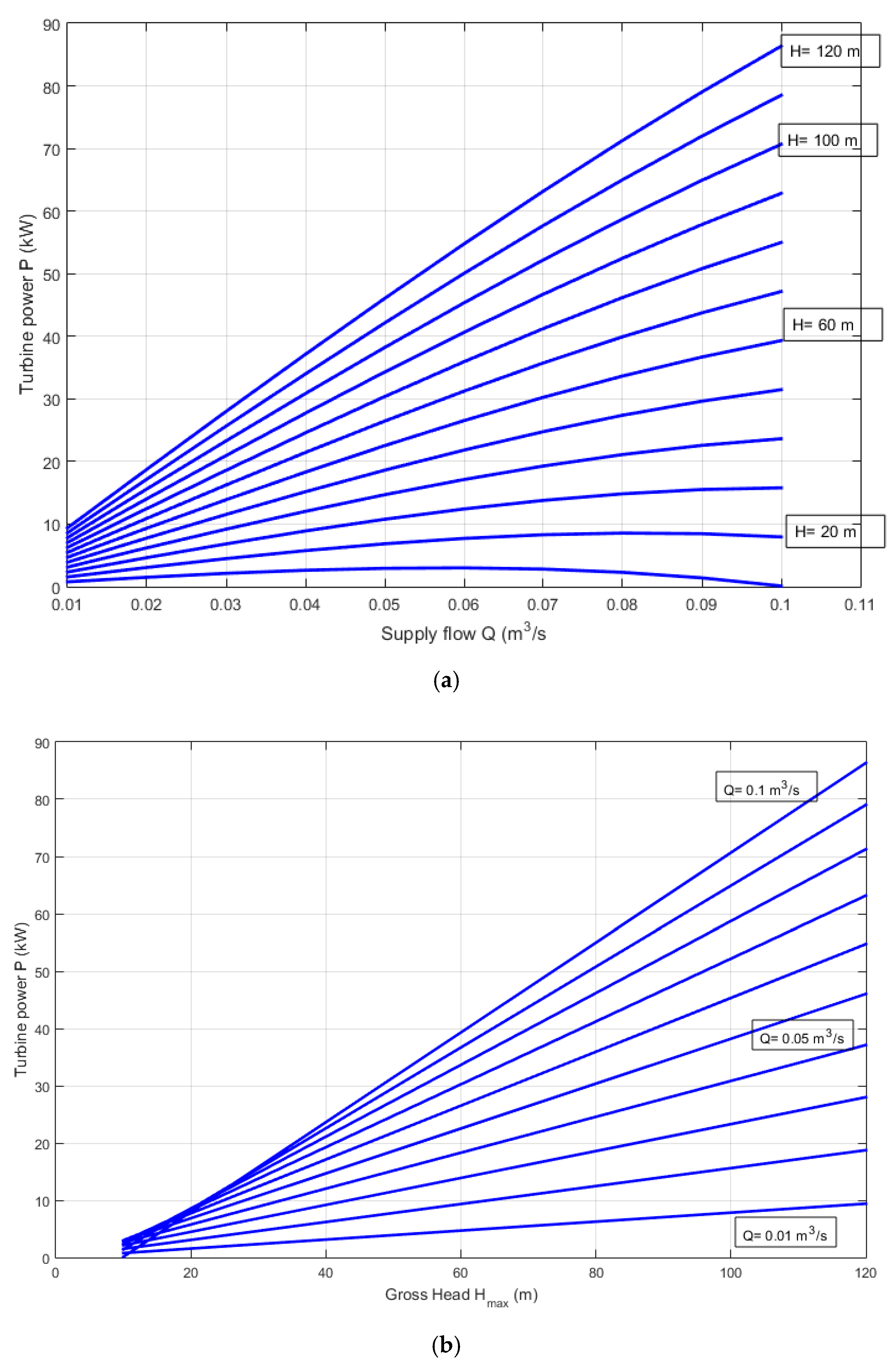

2.4. Power Generate in a Turbine

3. Results and Discussion

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Du, J.; Yang, H.; Shen, Z.; Chen, J. Micro hydro power generation from water supply system in high rise buildings using pump as turbines. Energy 2017, 137, 431–440. [Google Scholar] [CrossRef]

- Binama, M.; Su, W.-T.; Li, X.-B.; Li, F.-C.; Wei, X.-Z.; An, S. Investigation on pump as turbine (PAT) technical aspects for micro hydropower schemes: A state-of-the-art review. Renew. Sustain. Energy Rev. 2017, 79, 148–179. [Google Scholar] [CrossRef]

- Williamson, S.J.; Stark, B.H.; Booker, J.D. Low head pico hydro turbine selection using a multi-criteria analysis. Renew. Energy 2014, 61, 43–50. [Google Scholar] [CrossRef]

- Bousquet, C.; Samora, I.; Manso, P.; Rossi, L.; Heller, P.; Schleiss, A.J. Assessment of hydropower potential in wastewater systems and application to Switzerland. Renew. Energy 2017, 113, 64–73. [Google Scholar] [CrossRef]

- Nasir, B.A. Design Considerations of Micro-hydro-electric Power Plant. Energy Procedia 2014, 50, 19–29. [Google Scholar] [CrossRef]

- INEbase/Agricultura y Medio Ambiente/Agua /Estadística Sobre el Suministro y Saneamiento del Agua/Últimos Datos. Available online: http://www.ine.es/dyngs/INEbase/es/operacion.htm?c=Estadistica_C&cid=1254736176834&menu=ultiDatos&idp=1254735976602 (accessed on 1 June 2018).

- CEDEX. Guía Técnica Sobre Tuberías para Transporte de agua a Presión; Ministerio de Fomento y Ministerio de Medio Ambiente: Madrid, Spain, 2003; ISBN 84-7790-384-0. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gómez-Llanos, E.; Arias-Trujillo, J.; Durán-Barroso, P.; Ceballos-Martínez, J.M.; Torrecilla-Pinero, J.A.; Urueña-Fernández, C.; Candel-Pérez, M. Hydropower Potential Assessment in Water Supply Systems. Proceedings 2018, 2, 1299. https://doi.org/10.3390/proceedings2201299

Gómez-Llanos E, Arias-Trujillo J, Durán-Barroso P, Ceballos-Martínez JM, Torrecilla-Pinero JA, Urueña-Fernández C, Candel-Pérez M. Hydropower Potential Assessment in Water Supply Systems. Proceedings. 2018; 2(20):1299. https://doi.org/10.3390/proceedings2201299

Chicago/Turabian StyleGómez-Llanos, Eva, Juana Arias-Trujillo, Pablo Durán-Barroso, José M. Ceballos-Martínez, Jesús A. Torrecilla-Pinero, Carlos Urueña-Fernández, and Miguel Candel-Pérez. 2018. "Hydropower Potential Assessment in Water Supply Systems" Proceedings 2, no. 20: 1299. https://doi.org/10.3390/proceedings2201299