Development of Triboelectric Devices for Human–Machine Interface Applications †

Abstract

:1. Introduction

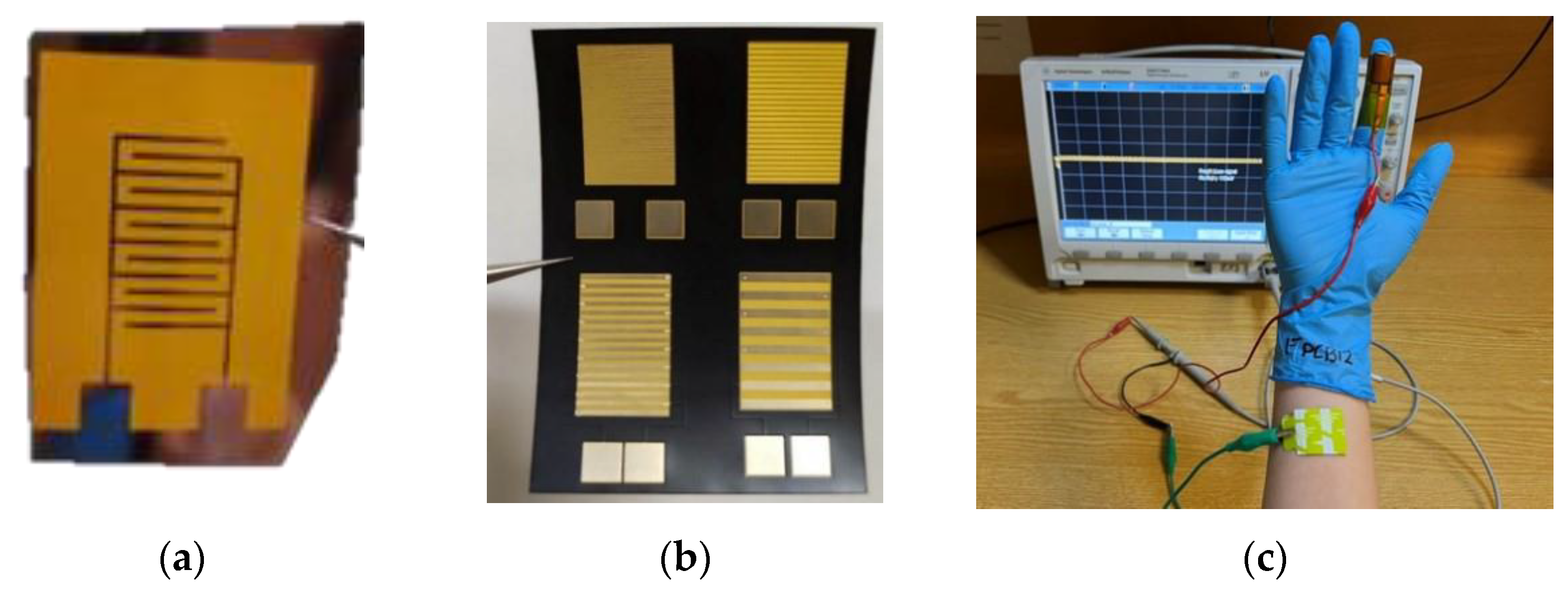

2. Materials and Methods

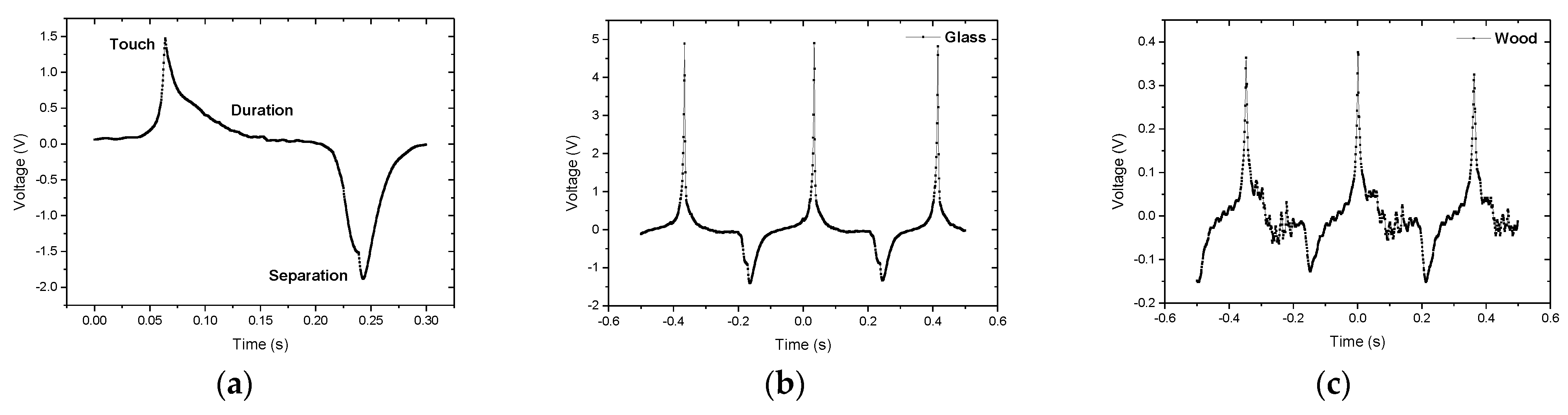

3. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhu, P.; Peng, H.; Rwei, A.Y. Flexible, wearable biosensors for digital health. Med. Nov. Technol. Devices 2022, 14, 100118. [Google Scholar] [CrossRef]

- Nan, X.; Wang, X.; Kang, T.; Zhang, J.; Dong, L.; Dong, J.; Xia, P.; Wei, D. Review of Flexible Wearable Sensor Devices for Biomedical Application. Micromachines 2022, 13, 1395. [Google Scholar] [CrossRef] [PubMed]

- Prajapati, S.; Padhan, B.; Amulyasai, B.; Sarkar, A. Nanotechnology-based sensors. In Biopolymer-Based Formulations: Biomedical and Food Applications; Elsevier: Amsterdam, The Netherlands, 2020; pp. 237–262. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Anastasopoulos, A.; Zacharia, V.; Bardakas, A.; Tsamis, C. Development of Triboelectric Devices for Human–Machine Interface Applications. Proceedings 2024, 97, 7. https://doi.org/10.3390/proceedings2024097007

Anastasopoulos A, Zacharia V, Bardakas A, Tsamis C. Development of Triboelectric Devices for Human–Machine Interface Applications. Proceedings. 2024; 97(1):7. https://doi.org/10.3390/proceedings2024097007

Chicago/Turabian StyleAnastasopoulos, Andreas, Vasiliki Zacharia, Achilleas Bardakas, and Christos Tsamis. 2024. "Development of Triboelectric Devices for Human–Machine Interface Applications" Proceedings 97, no. 1: 7. https://doi.org/10.3390/proceedings2024097007