Investigating the Effects of Annealing on the Mechanical Properties of FFF-Printed Thermoplastics

Abstract

:1. Introduction

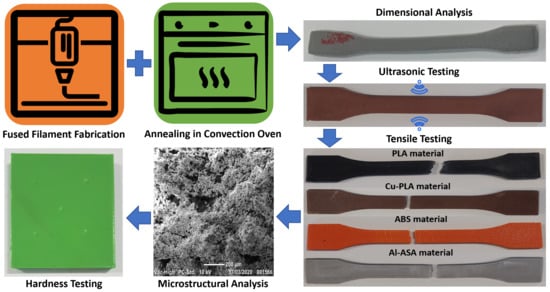

2. Materials and Manufacturing Process

3. Experimental Methodology

3.1. Dimensional Analysis

3.2. Ultrasonic Testing

3.3. Tensile Testing

3.4. Microstructural Analysis

3.5. Hardness Testing

- HR = Rockwell number

- e = depth of impression after removal of the major load, in units of 0.002 mm.

4. Experimental Results and Discussions

4.1. Results from Dimensional Analysis

4.2. Results from Ultrasonic Testing

4.3. Results from Tensile Testing

4.4. Results from Microstructural Analysis

4.5. Results from Hardness Testing

5. Conclusions

- Annealing can adversely affect the dimensional tolerances of FFF-printed parts. Therefore, it is crucial to take the relevant shrinkage/expansion into consideration when designing parts to be printed by FFF and subjected to annealing afterward.

- Ultrasonic testing was used to assess the crystallinity of the annealed and unannealed samples. This NDT was able to accurately show lower transmission times of sound waves for samples annealed at higher temperatures compared to the unannealed ones.

- Tensile testing showed positive results on the semi-crystalline materials (PLA and Cu-PLA). However, the results for the amorphous materials (ABS and Al-ASA) were not comparable with the semi-crystalline materials. Therefore, a strong case should be made to anneal ABS and Al-ASA material for a small increment in tensile strength.

- The microstructural analysis supported the results obtained through ultrasonic and tensile testing. It showed a high percentage of voids for samples with high transmission times and lower fracture load values.

- Testing the materials for Rockwell hardness (scale L) showed that Al-ASA has the highest hardness value (50.2 HRL), PLA is second (48 HRL), Cu-PLA (41.2 HRL) is third and ABS (39.1 HRL) has the lowest hardness values. The maximum values for all the materials were obtained at the highest annealing temperatures specified in this work.

Author Contributions

Funding

Conflicts of Interest

References

- Standard, A.S.T.M. Standard Terminology for Additive Manufacturing Technologies; ASTM International F2792-12a: West Conshohocken, PA, USA, 2012. [Google Scholar]

- Butt, J. A Novel Additive Manufacturing Process for the Production of Metal Parts. Ph.D. Thesis, Anglia Ruskin University, Cambridge, UK, 2016. [Google Scholar]

- Butt, J.; Mebrahtu, H.; Shirvani, H. Metal rapid prototyping technologies. In Advances in Engineering Research; Petrova, V.M., Ed.; Nova Science Publishers, Inc.: New York, NY, USA, 2017; Chapter 2; Volume 14, pp. 13–52. [Google Scholar]

- Butt, J.; Shirvani, H. Experimental analysis of metal/plastic composites made by a new hybrid method. Addit. Manuf. 2018, 22, 216–222. [Google Scholar] [CrossRef]

- Butt, J.; Shirvani, H. Additive, subtractive, and hybrid manufacturing processes. In Advances in Manufacturing and Processing of Materials and Structures; CRC Press: Boca Raton, FL, USA, 2018; pp. 187–218. [Google Scholar]

- Gao, J. Production of multiple material parts using a desktop 3D printer. In Advances in Manufacturing Technology XXXI: Proceedings of the 15th International Conference on Manufacturing Research, Incorporating the 32nd National Conference on Manufacturing Research, University of Greenwich, London, UK, 5–7 September 2017; IOS Press: Amsterdam, The Netherlands, 2017; Volume 6, p. 148. [Google Scholar]

- Charbonnier, B.; Menezo, S.; O’Brien, P.; Lebreton, A.; Fedeli, J.M.; Bakir, B.B. Silicon photonics for next generation FDM/FDMA PON. J. Opt. Commun. Netw. 2012, 4, A29–A37. [Google Scholar] [CrossRef]

- Butt, J.; Onimowo, D.A.; Gohrabian, M.; Sharma, T.; Shirvani, H. A desktop 3D printer with dual extruders to produce customised electronic circuitry. Front. Mech. Eng. 2018, 13, 528–534. [Google Scholar] [CrossRef]

- Ning, F.; Cong, W.; Qiu, J.; Wei, J.; Wang, S. Additive manufacturing of carbon fiber reinforced thermoplastic composites using fused deposition modeling. Compos. Part B Eng. 2015, 80, 369–378. [Google Scholar] [CrossRef]

- Ning, F.; Cong, W.; Hu, Y.; Wang, H. Additive manufacturing of carbon fiber-reinforced plastic composites using fused deposition modeling: Effects of process parameters on tensile properties. J. Compos. Mater. 2017, 51, 451–462. [Google Scholar] [CrossRef]

- Liu, Z.; Lei, Q.; Xing, S. Mechanical characteristics of wood, ceramic, metal and carbon fiber-based PLA composites fabricated by FDM. J. Mater. Res. Technol. 2019, 8, 3741–3751. [Google Scholar] [CrossRef]

- Sa’ude, N.; Masood, S.H.; Nikzad, M.; Ibrahim, M.; Ibrahim, M.H.I. Dynamic mechanical properties of copper-ABS composites for FDM feedstock. Int. J. Eng. Res. Appl. 2013, 3, 1257–1263. [Google Scholar]

- Sanchez, D.M.; de la Mata, M.; Delgado, F.J.; Casal, V.; Molina, S.I. Development of carbon fiber acrylonitrile styrene acrylate composite for large format additive manufacturing. Mater. Des. 2020, 1941, 108577. [Google Scholar] [CrossRef]

- Yang, C.; Tian, X.; Li, D.; Cao, Y.; Zhao, F.; Shi, C. Influence of thermal processing conditions in 3D printing on the crystallinity and mechanical properties of PEEK material. J. Mater. Process. Technol. 2017, 248, 1–7. [Google Scholar] [CrossRef]

- Liao, Y.; Liu, C.; Coppola, B.; Barra, G.; Di Maio, L.; Incarnato, L.; Lafdi, K. Effect of porosity and crystallinity on 3D printed PLA properties. Polymers 2019, 11, 1487. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.K.; Kim, Y.R.; Kim, S.H.; Kim, J.H. Investigation of the internal stress relaxation in FDM 3D printing: Annealing conditions. J. Korean Soc. Manuf. Process Eng. 2018, 17, 130–136. [Google Scholar] [CrossRef]

- Beniak, J.; Holdy, M.; Križan, P.; Matúš, M. Research on parameters optimization for the Additive Manufacturing process. Transp. Res. Procedia 2019, 40, 144–149. [Google Scholar] [CrossRef]

- Slavković, V.; Grujović, N.; Dišić, A.; Radovanović, A. Influence of annealing and printing directions on mechanical properties of PLA shape memory polymer produced by fused deposition modeling. In Proceedings of the 6th International Congress of Serbian Society of Mechanics Mountain Tara, Mountain Tara, Serbia, 19–21 June 2017; pp. 19–21. [Google Scholar]

- Singh, S.; Singh, M.; Prakash, C.; Gupta, M.K.; Mia, M.; Singh, R. Optimization and reliability analysis to improve surface quality and mechanical characteristics of heat-treated fused filament fabricated parts. Int. J. Adv. Manuf. Technol. 2019, 102, 1521–1536. [Google Scholar] [CrossRef]

- Wach, R.A.; Wolszczak, P.; Adamus-Wlodarczyk, A. Enhancement of mechanical properties of FDM-PLA parts via thermal annealing. Macromol. Mater. Eng. 2018, 303, 1800169. [Google Scholar] [CrossRef]

- Somireddy, M.; Singh, C.V.; Czekanski, A. Analysis of the material behavior of 3D printed laminates via FFF. Exp. Mech. 2019, 59, 871–881. [Google Scholar] [CrossRef]

- Rodríguez-Panes, A.; Claver, J.; Camacho, A.M. The influence of manufacturing parameters on the mechanical behaviour of PLA and ABS pieces manufactured by FDM: A comparative analysis. Materials 2018, 11, 1333. [Google Scholar] [CrossRef] [Green Version]

- García-Domínguez, A.; Claver, J.; Camacho, A.M.; Sebastián, M.A. Considerations on the Applicability of Test Methods for Mechanical Characterization of Materials Manufactured by FDM. Materials 2020, 13, 28. [Google Scholar] [CrossRef] [Green Version]

- Cuan-Urquizo, E.; Barocio, E.; Tejada-Ortigoza, V.; Pipes, R.B.; Rodriguez, C.A.; Roman-Flores, A. Characterization of the mechanical properties of FFF structures and materials: A review on the experimental, computational and theoretical approaches. Materials 2019, 12, 895. [Google Scholar] [CrossRef] [Green Version]

- Alsoufi, M.S.; Elsayed, A.E. Warping deformation of desktop 3D printed parts manufactured by open source fused deposition modeling (FDM) system. Int. J. Mech. Mechatron. Eng. 2017, 17, 7–16. [Google Scholar]

- Torres, J.; Cotelo, J.; Karl, J.; Gordon, A.P. Mechanical property optimization of FDM PLA in shear with multiple objectives. JOM 2015, 67, 1183–1193. [Google Scholar] [CrossRef]

- Keleş, Ö.; Blevins, C.W.; Bowman, K.J. Effect of build orientation on the mechanical reliability of 3D printed ABS. Rapid Prototyp. J. 2017, 23, 320–328. [Google Scholar] [CrossRef]

- Garg, A.; Bhattacharya, A.; Batish, A. Failure investigation of fused deposition modelling parts fabricated at different raster angles under tensile and flexural loading. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2017, 231, 2031–2039. [Google Scholar] [CrossRef]

- BS EN ISO 527-2:2012. Plastics—Determination of Tensile Properties–Part 2: Test Conditions for Moulding and Extrusion Plastics; British, European and International Standard: London, UK, 2012. [Google Scholar]

- BS EN ISO 2039-2: 2000 BS 2782-3: Method 365C:1992. Plastics—Determination of hardness—Part 2: Rockwell Hardness; British, European and International Standard: London, UK, 2000. [Google Scholar]

- Hart, K.R.; Dunn, R.M.; Sietins, J.M.; Mock, C.M.H.; Mackay, M.E.; Wetzel, E.D. Increased fracture toughness of additively manufactured amorphous thermoplastics via thermal annealing. Polymer 2018, 144, 192–204. [Google Scholar] [CrossRef]

- Wang, L.; Gramlich, W.M.; Gardner, D.J. Improving the impact strength of Poly (lactic acid) (PLA) in fused layer modeling (FLM). Polymer 2017, 114, 242–248. [Google Scholar] [CrossRef]

- Wang, L.; Gardner, D.J. Contribution of printing parameters to the interfacial strength of polylactic acid (PLA) in material extrusion additive manufacturing. Progr. Addit. Manuf. 2018, 3, 165–171. [Google Scholar] [CrossRef]

- Harris, A.M.; Lee, E.C. Improving mechanical performance of injection molded PLA by controlling crystallinity. J. Appl. Polym. Sci. 2008, 107, 2246–2255. [Google Scholar] [CrossRef]

- Benwood, C.; Anstey, A.; Andrzejewski, J.; Misra, M.; Mohanty, A.K. Improving the impact strength and heat resistance of 3D printed models: Structure, property, and processing correlationships during fused deposition modeling (FDM) of poly (lactic acid). ACS Omega 2018, 3, 4400–4411. [Google Scholar] [CrossRef]

- Butt, J.; Hewavidana, Y.; Mohaghegh, V.; Sadeghi-Esfahlani, S.; Shirvani, H. Hybrid manufacturing and experimental testing of glass fiber enhanced thermoplastic composites. J. Manuf. Mater. Process. 2019, 3, 96. [Google Scholar] [CrossRef] [Green Version]

- Tabi, T.; Sajó, I.E.; Szabó, F.; Luyt, A.S.; Kovács, J.G. Crystalline structure of annealed polylactic acid and its relation to processing. Express Polym. Lett. 2010, 4, 659–668. [Google Scholar] [CrossRef]

- Song, Y.; Li, Y.; Song, W.; Yee, K.; Lee, K.Y.; Tagarielli, V.L. Measurements of the mechanical response of unidirectional 3D-printed PLA. Mater. Des. 2017, 123, 154–164. [Google Scholar] [CrossRef]

- Rangisetty, S.; Peel, L.D. The effect of infill patterns and annealing on mechanical properties of additively manufactured thermoplastic composites. In Proceedings of the ASME 2017 Conference on Smart Materials, Adaptive Structures and Intelligent Systems, Burlington, VT, USA, 18–20 September 2017. [Google Scholar]

- Xinhua, L.; Shengpeng, L.; Zhou, L.; Xianhua, Z.; Xiaohu, C.; Zhongbin, W. An investigation on distortion of PLA thin-plate part in the FDM process. Int. J. Adv. Manuf. Technol. 2015, 79, 1117–1126. [Google Scholar] [CrossRef]

- Gordeev, E.G.; Galushko, A.S.; Ananikov, V.P. Improvement of quality of 3D printed objects by elimination of microscopic structural defects in fused deposition modeling. PLoS ONE 2018, 13, e0198370. [Google Scholar] [CrossRef]

- Wittbrodt, B.; Pearce, J.M. The effects of PLA color on material properties of 3-D printed components. Addit. Manuf. 2015, 8, 110–116. [Google Scholar] [CrossRef] [Green Version]

- Pérez, M.; Medina-Sánchez, G.; García-Collado, A.; Gupta, M.; Carou, D. Surface quality enhancement of fused deposition modeling (FDM) printed samples based on the selection of critical printing parameters. Materials 2018, 11, 1382. [Google Scholar] [CrossRef] [Green Version]

- Singh, D.; Singh, R.; Boparai, K.S. Investigations on hardness of investment-casted implants fabricated after vapour smoothing of FDM replicas. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 1–12. [Google Scholar] [CrossRef]

- Pei, E.; Lanzotti, A.; Grasso, M.; Staiano, G.; Martorelli, M. The impact of process parameters on mechanical properties of parts fabricated in PLA with an open-source 3-D printer. Rapid Prototyp. J. 2015, 21, 604–617. [Google Scholar]

- Zurita Hurtado, O.J.; Di Graci Tiralongo, V.C.; Aguirre, C.; Cristina, M. Effect of surface hardness and roughness produced by turning on the torsion mechanical properties of annealed AISI 1020 steel. Rev. Fac. Ing. Univ. Antioq. 2017, 84, 55–59. [Google Scholar] [CrossRef]

| # | Material | Nozzle Temperature (°C) | Bed Temperature (°C) | Glass Transition Temperature (°C) | Annealing Temperatures (°C) |

|---|---|---|---|---|---|

| 1 | 3D Filaprint PLA | 210 | 60 | 60–65 | 70, 80, 90 |

| 2 | FilaPrint metal copper PLA | 200 | 60 | 60–65 | 70, 80, 90 |

| 3 | 3D Filaprint ABS | 240 | 95 | 105 | 105, 115, 125 |

| 4 | ASA extrafill aluminium | 250 | 100 | 100 | 70, 80, 90, 105, 115 * |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Butt, J.; Bhaskar, R. Investigating the Effects of Annealing on the Mechanical Properties of FFF-Printed Thermoplastics. J. Manuf. Mater. Process. 2020, 4, 38. https://doi.org/10.3390/jmmp4020038

Butt J, Bhaskar R. Investigating the Effects of Annealing on the Mechanical Properties of FFF-Printed Thermoplastics. Journal of Manufacturing and Materials Processing. 2020; 4(2):38. https://doi.org/10.3390/jmmp4020038

Chicago/Turabian StyleButt, Javaid, and Raghunath Bhaskar. 2020. "Investigating the Effects of Annealing on the Mechanical Properties of FFF-Printed Thermoplastics" Journal of Manufacturing and Materials Processing 4, no. 2: 38. https://doi.org/10.3390/jmmp4020038