Vat Photopolymerization Additive Manufacturing of Functionally Graded Materials: A Review

Abstract

:1. Introduction

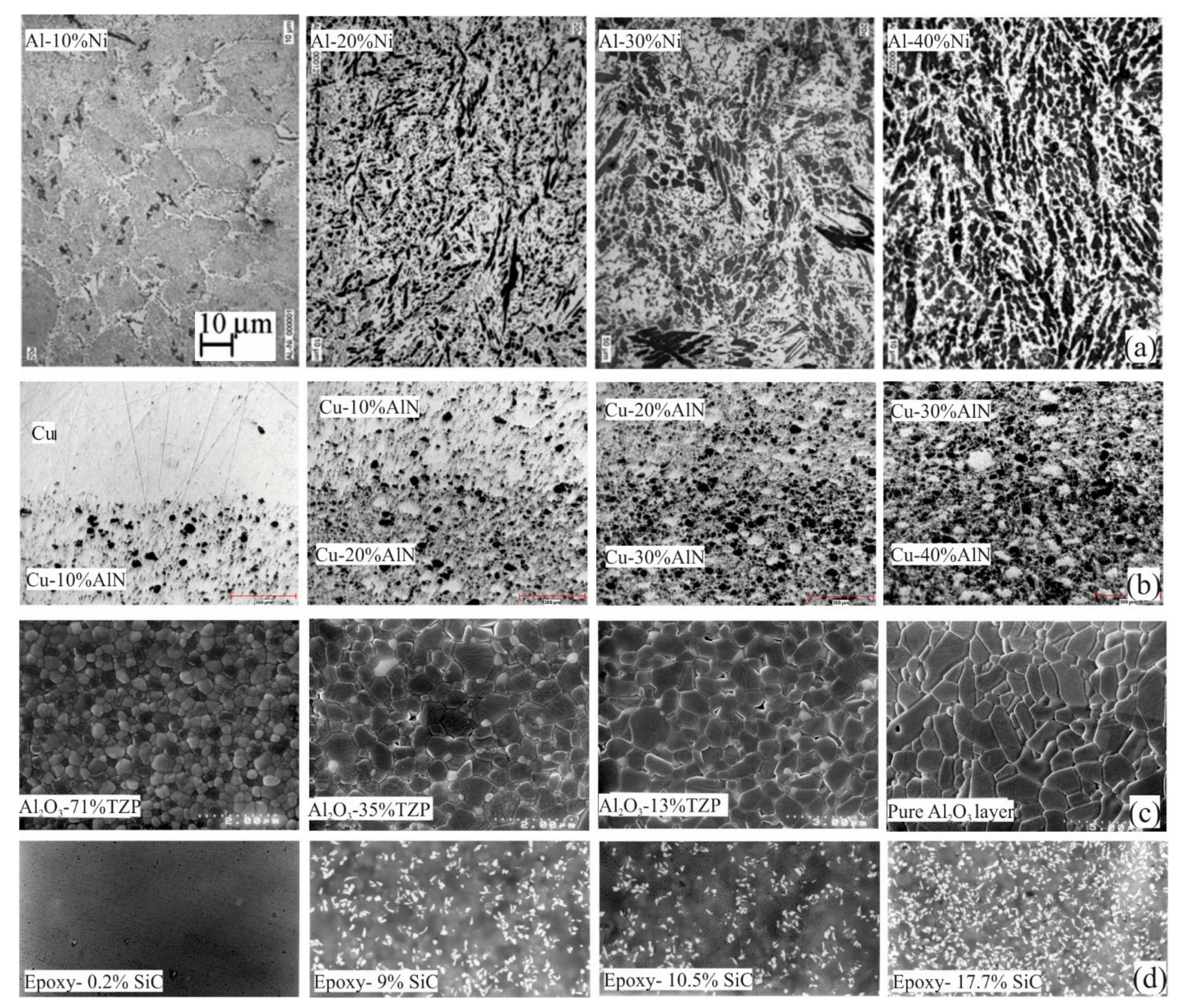

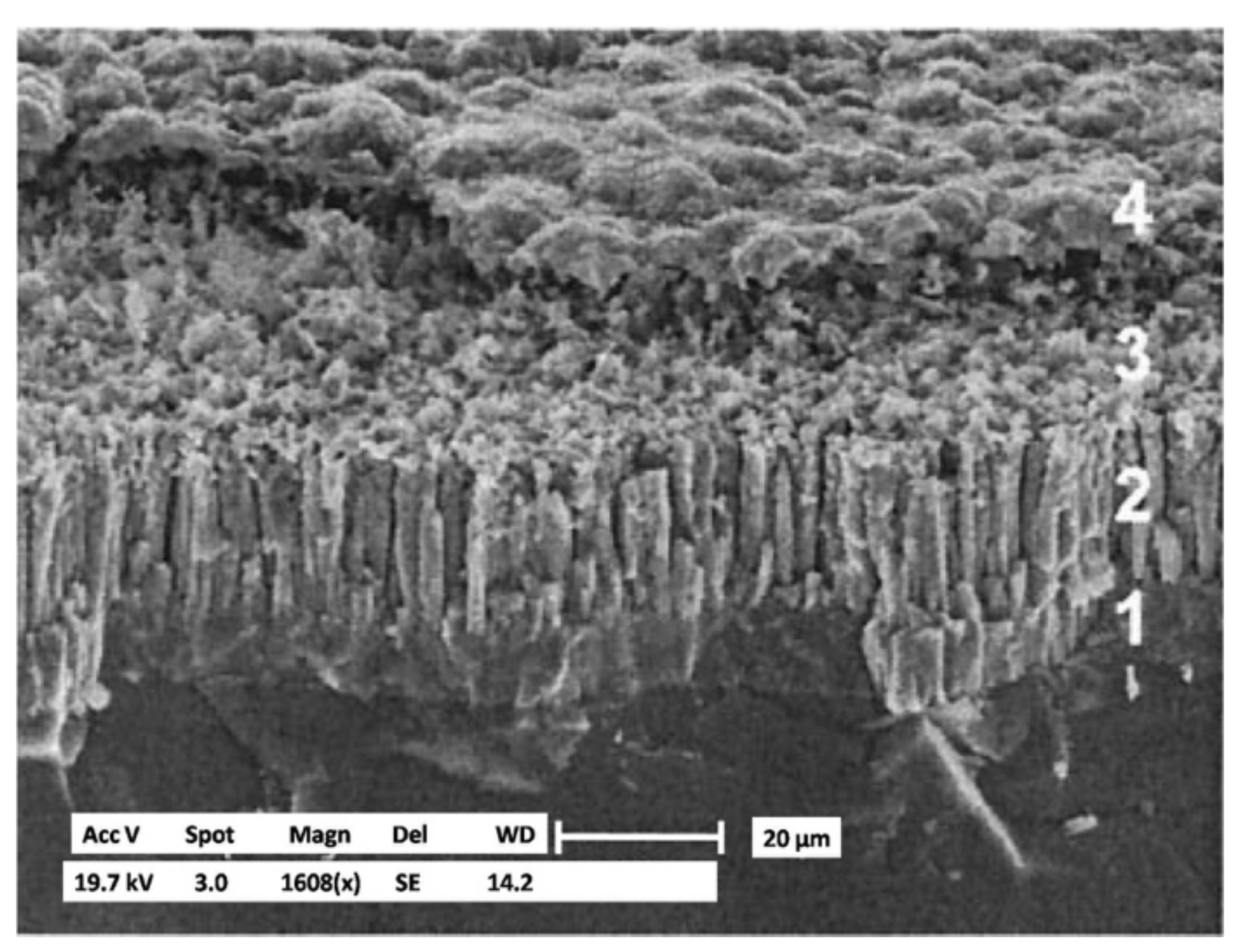

2. Background

- FGMs can behave as an interface layer that creates a strong bond between two dissimilar and incompatible materials

- FGMs can offer reduced interlayer residual stresses that occur due to thermal expansion coefficient difference and stress singularities due to elastic mismatch

- FGMs can alter crack propagation mechanisms and reduce crack driving forces with toughening mechanisms such as crack bridging or crack shielding [36].

- Metal-Metal (e.g., Al-Cu, Al-Ni, Al-Ti, Mo-Ti)

- Metal-Ceramic (e.g., Al-SiC, Al-Al2O3, Ni-ZrO2)

- Ceramic-Ceramic (e.g., SiC-Carbon, Al2O3-ZrO2, Carbon-Carbon)

- Ceramic-Polymer (e.g., Glass-Epoxy, Carbon-Epoxy)

- Due to thermal mismatch, a higher attention should be given in case the FGM is composed of two dissimilar materials in terms of layer boundary cracking during sintering.

- The optimized manufacturing parameters should be obtained for different materials.

- The methodology and equipment should be adapted so that a cost-effective mass production is possible.

3. Conventional Manufacturing of FGMs

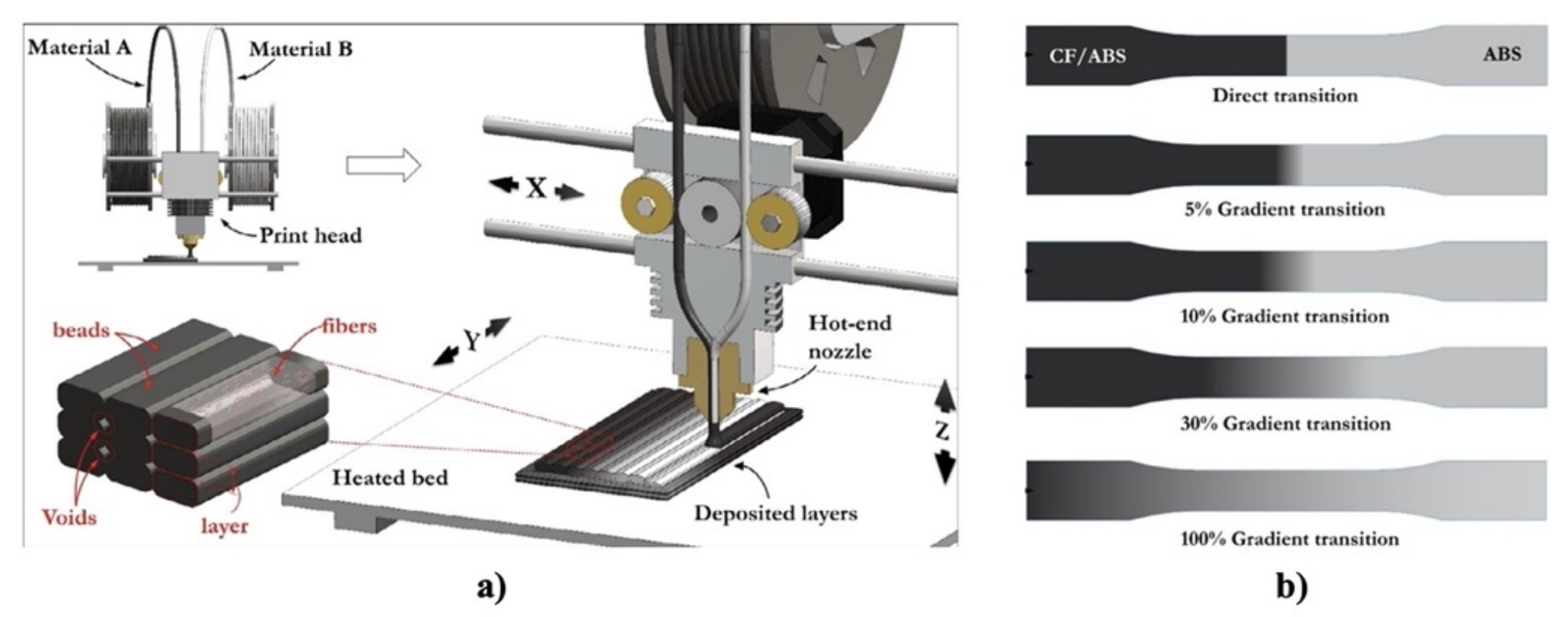

4. Additive Manufacturing of Functionally Graded Materials

- Development of techniques with low cost and high automation degree

- Manufacturing custom and complex shapes

- Development of gradient with high precision and control

- Improved processing mechanisms for mass production

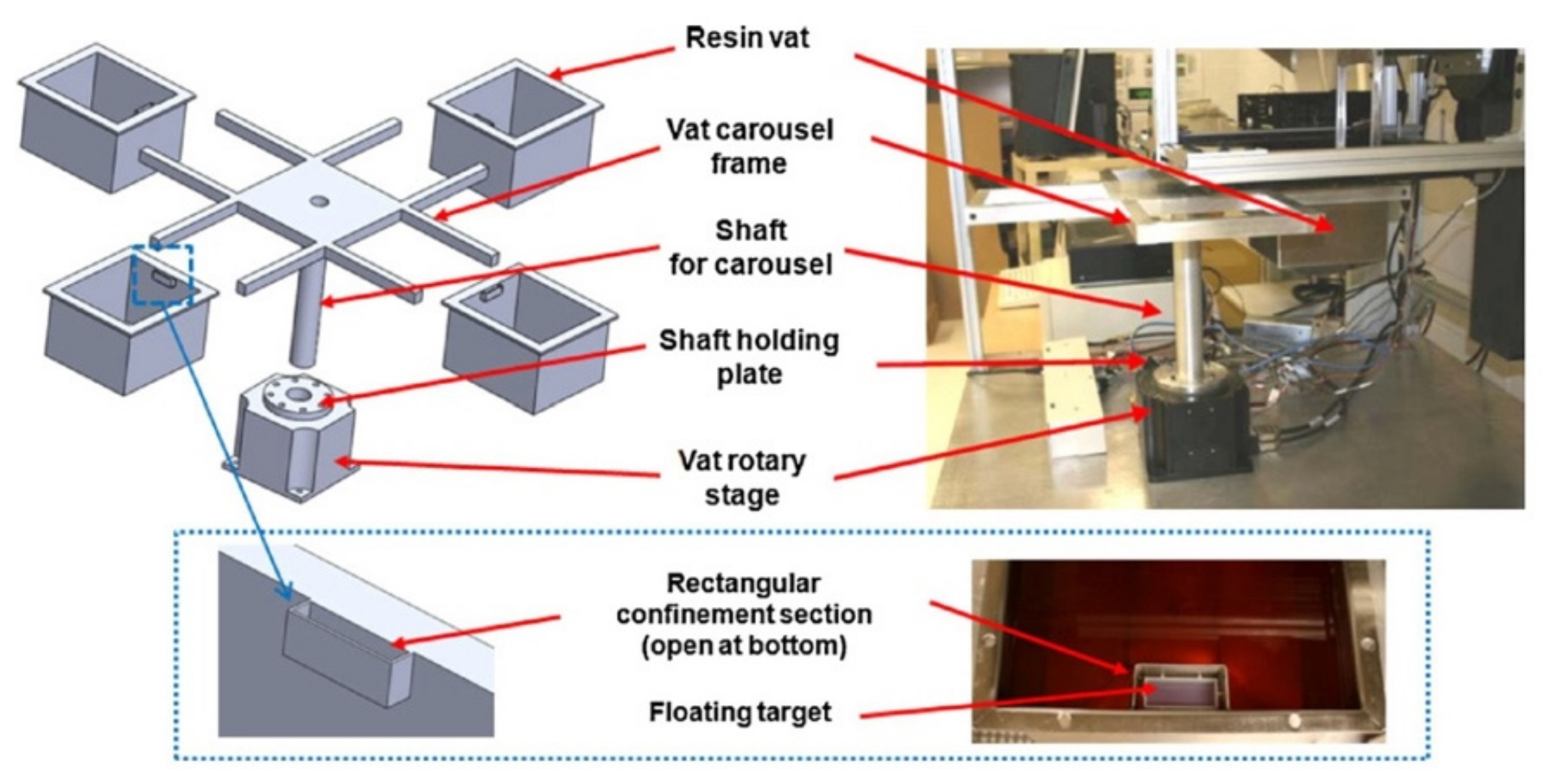

5. Vat Photopolymerization Additive Manufacturing of Functionally Graded Materials

6. Future Aspects

- Lack of guidelines and standards for the selection of best AM method in terms of characterization of grading in materials

- Scatter of measured properties between batches and type of machines

- Low tolerance control and material defects

- Low speed, accuracy, and surface quality

- Lack of microstructure-process-property relations for current AM methodologies

- Commercial methodologies for the mass production via AM methods

- Software that will allow the design of FGMs from preparation of CAD to slicing and exporting with predefined material properties in different directions.

- New design of hardware setup (e.g., new extruder design for FFF method)

- Thermo-mechanical characterization especially for the transition interfaces

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Markovic, S.; Lukić, M.J.; Skapin, S.D.; Stojanović, B.; Uskoković, D. Designing, fabrication and characterization of nanostructured functionally graded HAp/BCP ceramics. Ceram. Int. 2015, 41, 2654–2667. [Google Scholar] [CrossRef] [Green Version]

- Ahankari, S.S.; Kar, K.K. Functionally graded composites: Processing and applications. In Composite Materials: Processing, Applications, Characterizations; Springer: Berlin/Heidelberg, Germany, 2016; pp. 116–168. ISBN 9783662495148. [Google Scholar]

- Naebe, M.; Shirvanimoghaddam, K. Functionally graded materials: A review of fabrication and properties. Appl. Mater. Today 2016, 5, 223–245. [Google Scholar] [CrossRef]

- Jha, D.K.; Kant, T.; Singh, R.K. A critical review of recent research on functionally graded plates. Compos. Struct. 2013, 96, 833–849. [Google Scholar] [CrossRef]

- Bever, M.B.; Duwez, P.F. Gradients in composite materials. Mater. Sci. Eng. 1972, 10, 1–8. [Google Scholar] [CrossRef]

- Shen, M.; Bever, M.B. Gradients in polymeric materials. J. Mater. Sci. 1972, 7, 741–746. [Google Scholar] [CrossRef]

- Koizumi, M. FGM activities in Japan. Compos. Part B Eng. 1997, 28, 1–4. [Google Scholar] [CrossRef]

- Saleh, B.; Jiang, J.; Fathi, R.; Al-hababi, T.; Xu, Q.; Wang, L.; Song, D.; Ma, A. 30 Years of functionally graded materials: An overview of manufacturing methods, applications, and future challenges. Compos. Part B Eng. 2020, 201, 108376. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, F.; Huang, Z.; Jia, M.; Chen, G.; Ye, Y.; Lin, Y.; Liu, W.; Chen, B.; Shen, Q.; et al. Additive manufacturing of functionally graded materials: A review. Mater. Sci. Eng. A 2019, 764, 138209. [Google Scholar] [CrossRef]

- Besisa, D.H.A.; Ewais, E.M.M. Advances in functionally graded ceramics—Processing, sintering properties and applications. In Advances in Functionally Graded Materials and Structures; Ebrahimi, F., Ed.; InTechOpen: London, UK, 2016; pp. 1–31. ISBN 978-953-51-2274-6. [Google Scholar]

- Kieback, B.; Neubrand, A.; Riedel, H. Processing techniques for functionally graded materials. Mater. Sci. Eng. A. 2003, 362, 81–105. [Google Scholar] [CrossRef]

- Li, Y.; Feng, Z.; Hao, L.; Huang, L.; Xin, C.; Wang, Y.; Bilotti, E.; Essa, K.; Zhang, H.; Zheng, L.; et al. A review on functionally graded materials and structures via additive manufacturing: From multi-scale design to versatile functional properties. Adv. Mater. Technol. 2020, 5, 1900981. [Google Scholar] [CrossRef]

- Loh, G.H.; Pei, E.; Harrison, D.; Monzón, M.D. An overview of functionally graded additive manufacturing. Addit. Manuf. 2018, 23, 34–44. [Google Scholar] [CrossRef] [Green Version]

- Scheithauer, U.; Weingarten, S.; Johne, R.; Schwarzer, E.; Abel, J.; Richter, H.J.; Moritz, T.; Michaelis, A. Ceramic-based 4D components: Additive manufacturing (AM) of ceramic-based functionally graded materials (FGM) by thermoplastic 3D printing (T3DP). Materials 2017, 10, 1368. [Google Scholar] [CrossRef] [Green Version]

- Gibson, I.; Rosen, D.; Stucker, B.; Khorasani, M. Additive Manufacturing Technologies, 3rd ed.; Springer Nature: Cham, Switzerland, 2021; ISBN 978-1-4939-2112-6. [Google Scholar]

- Chen, Y.; Liou, F. Additive manufacturing of metal functionally graded materials: A review, solid freeform fabrication. In Proceedings of the 29th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, Austin, TX, USA, 13–15 August 2018. [Google Scholar]

- Choy, S.Y.; Sun, C.N.; Leong, K.F.; Tan, K.E.; Wei, J. Functionally graded material by additive manufacturing. In Proceedings of the 2nd International Conference on Progress in Additive Manufacturing (Pro-AM 2016), Singapore, 16–19 May 2016; pp. 206–211. [Google Scholar]

- Hasanov, S.; Gupta, A.; Alifui-Segbaya, F.; Fidan, I. Hierarchical homogenization and experimental evaluation of functionally graded materials manufactured by the fused filament fabrication process. Compos. Struct. 2021, 275, 114488. [Google Scholar] [CrossRef]

- Chartrain, N.A.; Williams, C.B.; Whittington, A.R. A review on fabricating tissue scaffolds using vat photopolymerization. Acta Biomater. 2018, 74, 90–111. [Google Scholar] [CrossRef]

- Wang, J.; Das, S.; Rai, R.; Zhou, C. Data-driven simulation for fast prediction of pull-up process in bottom-up stereolithography. Comput. Aided Des. 2018, 99, 29–42. [Google Scholar] [CrossRef]

- Wu, X.; Lian, Q.; Li, D.; Jin, Z. Biphasic osteochondral scaffold fabrication using multi-material mask projection stereolithography. Rapid Prototyp. J. 2019, 25, 277–288. [Google Scholar] [CrossRef]

- Choi, W.J.; Kim, C.H.; Wicker, R. Multi-material stereolithography. J. Mater. Process. Technol. 2011, 211, 318–328. [Google Scholar] [CrossRef]

- Short, M.P.; Ballinger, R.G. A functionally graded composite for service in high-temperature lead- and lead-bismuth–cooled nuclear reactors–I: Design. Nucl. Technol. 2012, 177, 366–381. [Google Scholar] [CrossRef]

- Zhao, J.; Ai, X.; Deng, J.; Wang, J. Thermal shock behaviors of functionally graded ceramic tool materials. J. Eur. Ceram. Soc. 2004, 24, 847–854. [Google Scholar] [CrossRef]

- Tang, S.; Wang, R.; Liu, P.; Niu, Q.; Yang, G.; Liu, W.; Liu, D. Preparation of WC-TiC-Ni3Al-CaF2 functionally graded self-lubricating tool material by microwave sintering and its cutting performance. High Temp. Mater. Proc. 2020, 39, 45–53. [Google Scholar] [CrossRef]

- Mahamood, R.M.; Akinlabi, E.T.; Shukla, M.; Pityana, S. Functionally graded material: An overview. In Proceedings of the World Congress on Engineering, London, UK, 4–6 July 2012. [Google Scholar]

- Rajput, R.K. A Textbook of Manufacturing Technology: Manufacturing Processes, 2nd ed.; Laxmi Publications: New Delhi, India, 2007; ISBN 9788131802441. [Google Scholar]

- Vereschaka, A.A.; Grigoriev, S.N.; Sitnikov, N.N.; Batako, A.D. Delamination and longitudinal cracking in multi-layered composite nano-structured coatings and their influence on cutting tool life. Wear 2017, 390–391, 209–219. [Google Scholar] [CrossRef]

- Wan, Y.; Yue, Y.; Zhong, Z. Multilayered piezomagnetic/piezoelectric composite with periodic interface cracks under magnetic or electric field. Eng. Fract. Mech. 2012, 84, 132–145. [Google Scholar] [CrossRef]

- Mahamood, R.M.; Akinlabi, E.T. Functionally Graded Materials, 1st ed.; Springer International Publishing AG: Cham, Switzerland, 2017; ISBN 9783319537566. [Google Scholar]

- Pompe, W.; Worch, H.; Epple, M.; Friess, W.; Gelinsky, M.; Greil, P.; Hempel, U.; Scharnweber, D.; Schulte, K. Functionally graded materials for biomedical applications. Mater. Sci. Eng. A 2003, 362, 40–60. [Google Scholar] [CrossRef]

- Miao, X.; Sun, D. Graded/Gradient porous biomaterials. Materials 2010, 3, 26–47. [Google Scholar] [CrossRef] [Green Version]

- Bhavar, V.; Kattire, P.; Thakare, S.; Patil, S.; Singh, R.K.P. A Review on functionally gradient materials (FGMs) and their applications. IOP Conf. Ser. Mater. Sci. Eng. 2017, 229, 012021. [Google Scholar] [CrossRef]

- Udupa, G.; Rao, S.S.; Gangadharan, K.V. Functionally graded composite materials: An overview. Procedia Mater. Sci. 2014, 5, 1291–1299. [Google Scholar] [CrossRef]

- Anne, G.; Hecht-Mijic, S.; Richter, H.; Van der Biest, O.; Vleugels, J. Strength and residual stresses of functionally graded Al2O3/ZrO2 discs prepared by electrophoretic deposition. Scr. Mater. 2006, 54, 2053–2056. [Google Scholar] [CrossRef]

- Jin, Z.H.; Batra, R.C. Some basic fracture mechanics concepts in functionally graded materials. J. Mech. Phys. Solids. 1996, 44, 1221–1235. [Google Scholar] [CrossRef]

- Kaya, C. Al2O3–Y-TZP/Al2O3 functionally graded composites of tubular shape from nano-sols using double-step electrophoretic deposition. J. Eur. Ceram. Soc. 2003, 23, 1655–1660. [Google Scholar] [CrossRef]

- El-Galy, I.M.; Saleh, B.I.; Ahmed, M.H. Functionally graded materials classifications and development trends from industrial point of view. SN Appl. Sci. 2019, 1, 1378–1401. [Google Scholar] [CrossRef] [Green Version]

- Parihar, R.S.; Setti, S.G.; Sahu, R.K. Recent advances in the manufacturing processes of functionally graded materials: A review. Sci. Eng. Compos. Mater. 2018, 25, 309–336. [Google Scholar] [CrossRef]

- El-Wazery, M.S.; El-Desouky, A.R. A review on functionally graded ceramic-metal materials. Mater. Environ. Sci. 2015, 6, 1369–1376. [Google Scholar]

- Rajan, T.P.D.; Pillai, R.M.; Pai, B.C. Functionally graded Al–Al3Ni in situ intermetallic composites: Fabrication and microstructural characterization. J. Alloys Compd. 2008, 453, L4–L7. [Google Scholar] [CrossRef]

- Chmielewski, M.; Pietrzak, K. Metal-ceramic functionally graded materials–manufacturing, characterization, application. Bull. Pol. Acad. Sci. Tech. Sci. 2016, 64, 151–160. [Google Scholar] [CrossRef] [Green Version]

- Krumova, M.; Klingshirn, C.; Haupert, F.; Friedrich, K. Microhardness studies on functionally graded polymer composites. Compos. Sci. Technol. 2001, 61, 557–563. [Google Scholar] [CrossRef]

- Sarathchandra, D.T.; Subbu, S.K.; Venkaiah, N. Functionally graded materials and processing techniques: An art of review. Mater. Today Proc. 2018, 5, 21328–21334. [Google Scholar] [CrossRef]

- Matsuo, S.; Watari, F.; Ohata, N. Fabrication of functionally graded dental composite resin post and core by laser lithography and finite element analysis of its stress relaxation effect on tooth root. Dental Mater. J. 2001, 20, 257–274. [Google Scholar] [CrossRef]

- Watari, F.; Yokoyama, A.; Omori, M.; Hirai, T.; Kondo, H.; Uo, M.; Kawasaki, T. Biocompatibility of materials and development to functionally graded implant for biomedical application. Compos. Sci. Technol. 2004, 64, 893–908. [Google Scholar] [CrossRef]

- Lu, L.; Chekroun, M.; Abraham, O.; Maupin, V.; Villain, G. Mechanical properties estimation of functionally graded materials using surface waves recorded with a laser interferometer. NDT E Int. 2011, 44, 169–177. [Google Scholar] [CrossRef] [Green Version]

- Müller, E.; Drasar, C.; Schilz, J.; Kaysser, W.A. Functionally graded materials for sensor and energy applications. Mater. Sci. Eng. A 2003, 362, 17–30. [Google Scholar] [CrossRef]

- Niino, M.; Kisara, K.; Mori, M. Feasibility study of FGM technology in space solar power systems (SPSS). Mater. Sci. Forum. 2005, 492, 163–168. [Google Scholar] [CrossRef]

- Coomar, N.; Kadoli, R. Comparative analysis of steady state heat transfer in a TBC and functionally graded air-cooled gas turbine blade. Sadhana 2010, 35, 1–17. [Google Scholar] [CrossRef]

- Nayak, P.; Armani, A. Optimal three-dimensional design of functionally graded parts for additive manufacturing using Tamura–Tomota–Ozawa model. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2021, 235, 1993–2006. [Google Scholar] [CrossRef]

- Kou, X.Y.; Parks, G.T.; Tan, S.T. Optimal design of functionally graded materials using a procedural model and particle swarm optimization. Comput. Aided Des. 2010, 44, 300–310. [Google Scholar] [CrossRef]

- Molla, T.T.; Liu, J.Z.; Schaffer, G.B. Computational design of functionally graded materials from sintered powders. Integr. Mater. Manuf. Innov. 2019, 8, 82–94. [Google Scholar] [CrossRef]

- Correia, V.M.F.; Madeira, J.F.A.; Araújo, A.L.; Soares, C.M.M. Multiobjective optimization of functionally graded material plates with thermo-mechanical loading. Compos. Struct. 2019, 207, 845–857. [Google Scholar] [CrossRef]

- Jain, M.; Sadangi, R.K.; Cannon, W.R.; Kear, B.H. Processing of functionally graded WC/Co/diamond nanocomposites. Scr. Mater. 2001, 44, 2099–2103. [Google Scholar] [CrossRef]

- Jung, Y.; Park, S.; Choi, S. Effect of CH4 and H2 on CVD of SiC and TiC for possible fabrication of SiC/TiC/C FGM. Mater. Lett. 1997, 30, 339–345. [Google Scholar] [CrossRef]

- Wan, B.Q.; Sun, X.Y.; Ma, H.T.; Feng, R.F.; Li, Y.S.; Yang, Q. Plasma enhanced chemical vapor deposition of diamond coatings on Cu–W and Cu–WC composites. Surf. Coat. Technol. 2015, 284, 133–138. [Google Scholar] [CrossRef]

- Seifried, S.; Winterer, M.; Hahn, H. Nanocrystalline gradient films through chemical vapor synthesis. Scr. Mater. 2001, 44, 2165–2168. [Google Scholar] [CrossRef]

- EL-Wazery, M.S.; EI-Desouky, A.R. Fabrication and characteristics of 8YSZ/Ni functionally graded materials by applying spark plasma sintering procedure. Int. J. Appl. Sci. Eng. 2014, 12, 313–332. [Google Scholar] [CrossRef]

- Ubeyli, M.; Balci, E.; Sarikan, B.; Oztas, M.K.; Camuscu, N.; Yildirim, R.O.; Keles, O. The ballistic performance of SiC–AA7075 functionally graded composite produced by powder metallurgy. Mater. Des. 2014, 56, 31–36. [Google Scholar] [CrossRef]

- Calis, N.; Kushan, S.R.; Kara, F.; Mandal, H. Functionally graded SiAlON ceramics. J. Eur. Ceram. Soc. 2004, 24, 3387–3393. [Google Scholar] [CrossRef]

- Milosan, I.; Bedo, T.; Gabor, C.; Munteanu, D.; Pop, M.A.; Catana, D.; Cosnita, M.; Varga, B. Characterization of aluminum alloy–silicon carbide functionally graded materials developed by centrifugal casting process. Appl. Sci. 2021, 11, 1625. [Google Scholar] [CrossRef]

- Watanabe, Y.; Kim, I.S.; Fukui, Y. Microstructures of functionally graded materials fabricated by centrifugal solid-particle and in-situ methods. Met. Mater. Int. 2005, 11, 391–395. [Google Scholar] [CrossRef]

- Kunimine, T.; Shibuya, M.; Sato, H.; Watanabe, Y. Fabrication of copper/diamond functionally graded materials for grinding wheels by centrifugal sintered casting. J. Mater. Process Technol. 2015, 217, 294–301. [Google Scholar] [CrossRef]

- Ewais, E.M.M.; Besisa, D.H.A.; Zaki, Z.I.; Kandil, A.T. Tailoring of functionally graded zirconia-mullite/alumina ceramics. J. Eur. Ceram. Soc. 2012, 32, 1561–1573. [Google Scholar] [CrossRef]

- Sarraute, S.; Smensen, O.T.; Hansen, E.R. Fabrication process for barium titanate-ferrite functionally graded ceramics. J. Eur. Ceram. Soc. 1998, 18, 759–764. [Google Scholar] [CrossRef]

- Homa, J. Rapid prototyping of high-performance ceramics opens new opportunities for the CIM industry. Powder Inject. Mold. Int. 2012, 6, 65–68. [Google Scholar]

- Chartier, T.; Badev, A. Rapid prototyping of ceramics. In Handbook of Advanced Ceramics: Materials, Applications, Processing, and Properties, 2nd ed.; Somiya, S., Ed.; Oxford Academic Press: Oxford, UK, 2013; pp. 489–524. ISBN 978-0-12-385469-8. [Google Scholar]

- Travitzky, N.; Bonet, A.; Dermeik, B.; Fey, T.; Filbert-Demut, I.; Schlier, L.; Schlordt, T.; Greil, P. Additive manufacturing of ceramic-based materials. Adv. Eng. Mater. 2014, 16, 729–754. [Google Scholar] [CrossRef]

- Wang, J.C.; Dommati, H.; Hsieh, S.J. Review of additive manufacturing methods for high-performance ceramic materials. Int. J. Adv. Manuf. Technol. 2019, 103, 2627–2647. [Google Scholar] [CrossRef]

- Halloran, J.W. Ceramic stereolithography: Additive manufacturing for ceramics by photopolymerization. Annu. Rev. Mater. Res. 2016, 46, 19–40. [Google Scholar] [CrossRef]

- Zanchetta, E.; Cattaldo, M.; Franchin, G.; Schwentenwein, M.; Homa, J.; Brusatin, G.; Colombo, P. Stereolithography of SiOC ceramic microcomponents. Adv. Mater. 2016, 28, 370–376. [Google Scholar] [CrossRef] [PubMed]

- Hasanov, S.; Alkunte, S.; Rajeshirke, M.; Gupta, A.; Huseynov, O.; Fidan, I.; Alifui-Segbaya, F.; Rennis, A. Review on Additive Manufacturing of Multi-Material Parts: Progress and Challenges. J. Manuf. Mater. Process. 2022, 6, 4. [Google Scholar] [CrossRef]

- Al-saedi, D.S.J.; Masood, S.H.; Faizan-ur-rab, M.; Alomarah, A.; Ponnusamy, P. Mechanical properties and energy absorption capability of functionally graded F2BCC lattice fabricated by SLM. Mater. Des. 2018, 144, 32–44. [Google Scholar] [CrossRef]

- Choy, S.Y.; Sun, C.; Leong, K.F.; Wei, J. Compressive properties of functionally graded lattice structures manufactured by selective laser melting. Mater. Des. 2017, 172, 251–258. [Google Scholar] [CrossRef]

- Niendorf, T.; Leuders, S.; Riemer, A.; Brenne, F.; Tröster, T.; Richard, H.A.; Schwarze, D. Functionally graded alloys obtained by additive manufacturing. Adv. Eng. Mater. 2014, 16, 857–861. [Google Scholar] [CrossRef]

- Mumtaz, K.A.; Hopkinson, N. Laser melting functionally graded composition of Waspaloy and Zirconia powders. J. Mater. Sci. 2007, 42, 7647–7656. [Google Scholar] [CrossRef] [Green Version]

- Gualtieri, T.; Bandyopadhyay, A. Additive manufacturing of compositionally gradient metal-ceramic structures: Stainless steel to vanadium carbide. Mater. Des. 2018, 139, 419–428. [Google Scholar] [CrossRef]

- Bandyopadhyay, P.P.; Balla, V.K.; Bose, S.; Bandyopadhyay, A. Compositionally graded aluminum oxide coatings on stainless steel using laser processing. J. Am. Ceram. Soc. 2007, 90, 1989–1991. [Google Scholar] [CrossRef]

- Sheydaeian, E.; Toyserkani, E. Additive manufacturing functionally graded titanium structures with selective closed cell layout and controlled morphology. Int. J. Adv. Manuf. Technol. 2018, 96, 3459–3469. [Google Scholar] [CrossRef]

- Levy, A.; Miriyev, A.; Elliott, A.; Babu, S.S.; Frage, N. Additive manufacturing of complex-shaped graded TiC/steel composites. Mater. Des. 2017, 118, 198–203. [Google Scholar] [CrossRef] [Green Version]

- Leu, M.C.; Deuser, B.K.; Tang, L.; Landers, R.G.; Hilmas, G.E.; Watts, J.L. Freeze-form extrusion fabrication of functionally graded materials. CIRP Ann. 2012, 61, 223–226. [Google Scholar] [CrossRef]

- Singh, N.; Singh, R.; Ahuja, I.P.S. On development of functionally graded material through fused deposition modelling assisted investment casting from Al2O3/SiC reinforced waste low density polyethylene. Trans. Indian Inst. Met. 2018, 71, 2479–2485. [Google Scholar] [CrossRef]

- Kumar, S. Development of functionally graded materials by ultrasonic consolidation. CIRP J. Manuf. Sci. Technol. 2010, 3, 85–87. [Google Scholar] [CrossRef]

- Hasanov, S.; Gupta, A.; Nasirov, A.; Fidan, I. Mechanical characterization of functionally graded materials produced by the fused filament fabrication process. J. Manuf. Process. 2020, 58, 923–935. [Google Scholar] [CrossRef]

- Pagac, M.; Hajnys, J.; Ma, Q.P.; Jancar, L.; Jansa, J.; Stefek, P.; Mesicek, J. A Review of vat photopolymerization technology: Materials, applications, challenges, and future trends of 3D printing. Polymers 2021, 13, 598–618. [Google Scholar] [CrossRef] [PubMed]

- Lantada, A.D.; Romero, A.B.; Schwentenwein, M.; Jellinek, C.; Homa, J.; García-Ruíz, J.P. Monolithic 3D labs- and organs-on-chips obtained by lithography-based ceramic manufacture. Int. J. Adv. Manuf. Technol. 2017, 93, 3371–3381. [Google Scholar] [CrossRef] [Green Version]

- Hull, C.W. Apparatus for Production of Three-Dimensional Objects by Stereolithography. U.S. Patent 638,905, 11 March 1984. [Google Scholar]

- Peele, B.N.; Wallin, T.J.; Zhao, H.; Shepherd, R.F. 3D printing antagonistic systems of artificial muscle using projection stereolithography. Bioinspir. Biomim. 2015, 10, 055003. [Google Scholar] [CrossRef]

- Leigh, S.J.; Purssell, C.P.; Bowen, J.; Hutchins, D.A.; Covington, J.A.; Billson, D.R. A miniature flow sensor fabricated by micro-stereolithography employing a magnetite/acrylic nanocomposite resin. Sens. Actuators A Phys. 2011, 168, 66–71. [Google Scholar] [CrossRef]

- Melchels, F.P.; Feijen, J.; Grijpma, D.W. A review on stereolithography and its applications in biomedical engineering. Biomaterials 2010, 31, 6121–6130. [Google Scholar] [CrossRef] [Green Version]

- He, Y.; Wu, Y.; Fu, J.Z.; Gao, Q.; Qiu, J.J. Developments of 3D printing microfluidics and applications in chemistry and biology: A review. Electroanalysis 2016, 28, 1658–1678. [Google Scholar] [CrossRef]

- Tian, X.; Jin, J.; Yuan, S.; Chua, C.K.; Tor, S.B.; Zhou, K. Emerging 3D-Printed electrochemical energy storage devices: A critical review. Adv. Energy Mater. 2017, 7, 1700127. [Google Scholar] [CrossRef]

- Huang, J.; Qin, Q.; Wang, J. A review of stereolithography: Processes and systems. Processes 2020, 8, 1138. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, S.; Zhao, Y.; Duan, W.; Liu, B.; Wang, T.; Wang, G. Digital light processing 3D printing of AlSi10Mg powder modified by surface coating. Add. Manuf. 2017, 39, 101897. [Google Scholar] [CrossRef]

- Schwentenwein, M.; Homa, J. Additive Manufacturing of Dense Alumina Ceramics. Int. J. Appl. Ceram. Technol. 2014, 12, 1–7. [Google Scholar] [CrossRef]

- Scheithauer, U.; Schwarzer, E.; Moritz, T.; Michaelis, A. Additive Manufacturing of Ceramic Heat Exchanger: Opportunities and Limits of the Lithography-Based Ceramic Manufacturing (LCM). J. Mater. Eng. Perform. 2018, 24, 14–20. [Google Scholar] [CrossRef]

- Bai, X.; Ding, G.; Zhang, K.; Wang, W.; Zhou, N.; Fang, D.; He, R. Stereolithography additive manufacturing and sintering approaches of SiC ceramics. Open Ceram. 2021, 5, 1000046. [Google Scholar] [CrossRef]

- Huang, X.; Dai, H.; Hu, Y.; Zhuang, P.; Shi, Z.; Ma, Y. Development of a high solid loading β-TCP suspension with a low refractive index contrast for DLP-based ceramic stereolithography. J. Eur. Ceram. Soc. 2021, 41, 3743–3754. [Google Scholar] [CrossRef]

- Santoliquido, O.; Camerota, F.; Ortona, A. The influence of topology on DLP 3D printing, debinding and sintering of ceramic periodic architectures designed to replace bulky components. Open Ceram 2021, 5, 100059. [Google Scholar] [CrossRef]

- Altun, A.A.; Ertl, F.; Marechal, M.; Makaya, A.; Sgambati, A.; Schwentenwein, M. Additive manufacturing of lunar regolith structures. Open Ceram. 2021, 5, 100058. [Google Scholar] [CrossRef]

- Kirihara, S. Stereolithographic additive manufacturing of ceramic components with functionally modulated structures. Open Ceram. 2021, 5, 100068. [Google Scholar] [CrossRef]

- Preobrazhenskiy, I.I.; Tikhonov, A.A.; Evdokimov, P.V.; Shibaev, A.V.; Putlyaev, V.I. DLP printing of hydrogel/calcium phosphate composites for the treatment of bone defects. Open Ceram. 2021, 6, 100115. [Google Scholar] [CrossRef]

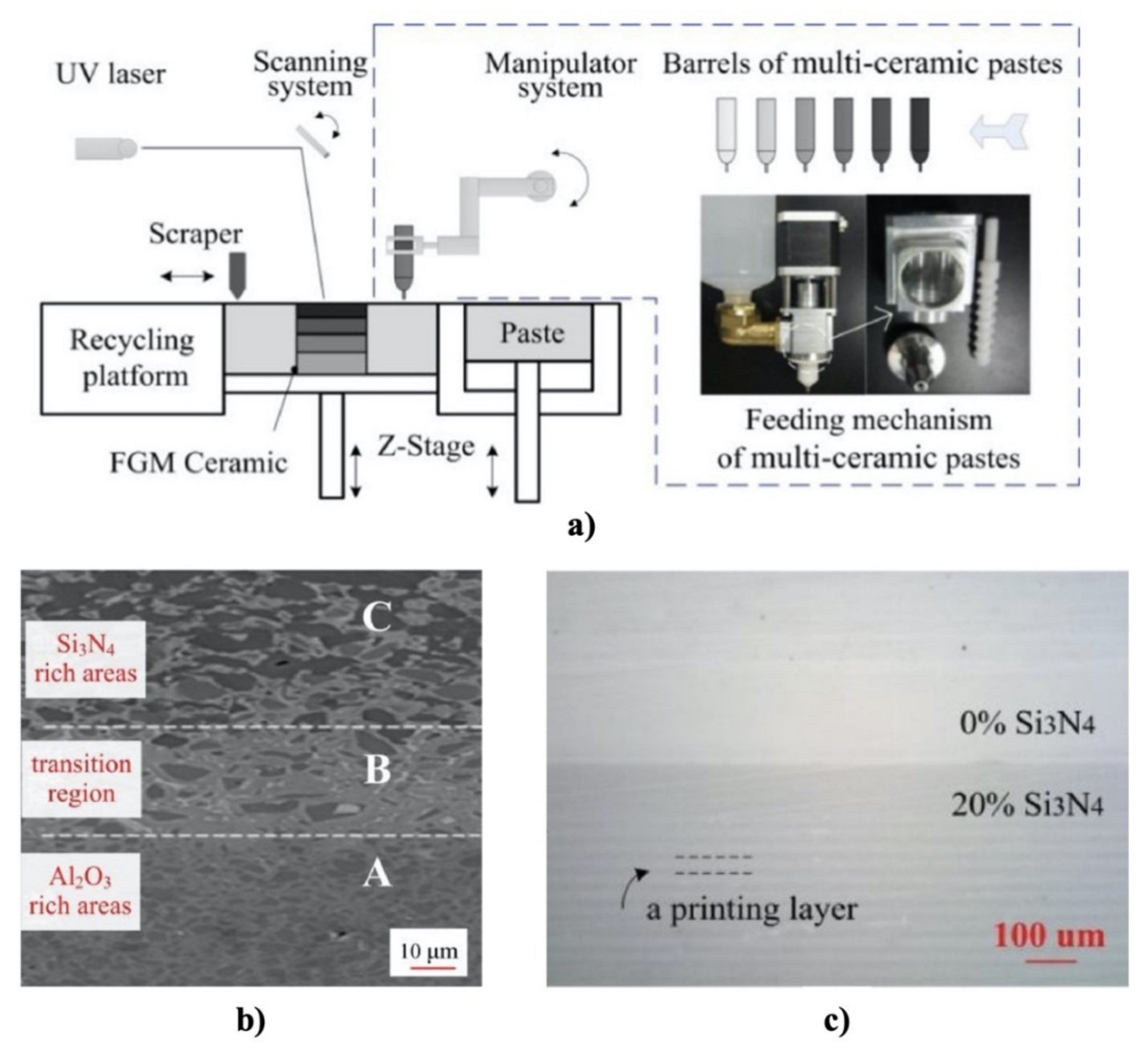

- Xing, H.; Zoua, B.; Liu, X.; Wang, X.; Huang, C.; Hu, Y. Fabrication strategy of complicated Al2O3-Si3N4 functionally graded materials by stereolithography 3D printing. J. Eur. Ceram. Soc. 2020, 40, 5797–5809. [Google Scholar] [CrossRef]

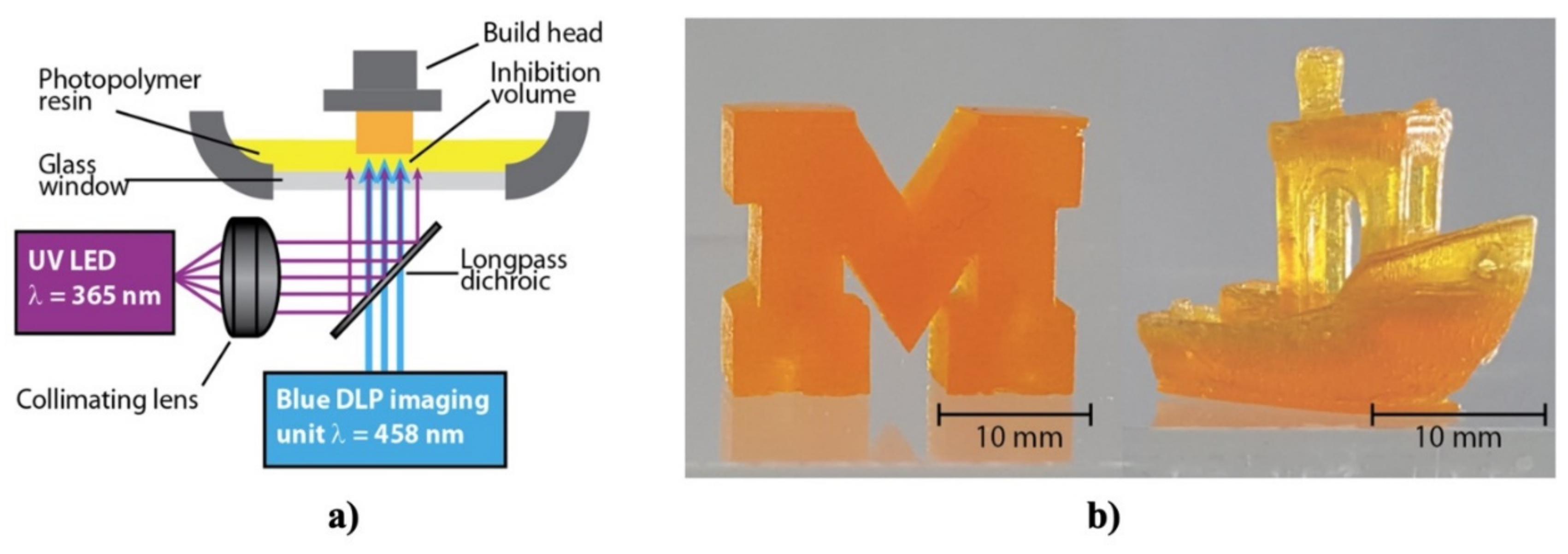

- de Beer, M.P.; van der Laan, H.L.; Cole, M.A.; Whelan, R.J.; Burns, M.A.; Scott, T.F. Rapid, continuous additive manufacturing by volumetric polymerization inhibition patterning. Sci. Adv. 2019, 5, aau8723. [Google Scholar] [CrossRef] [PubMed] [Green Version]

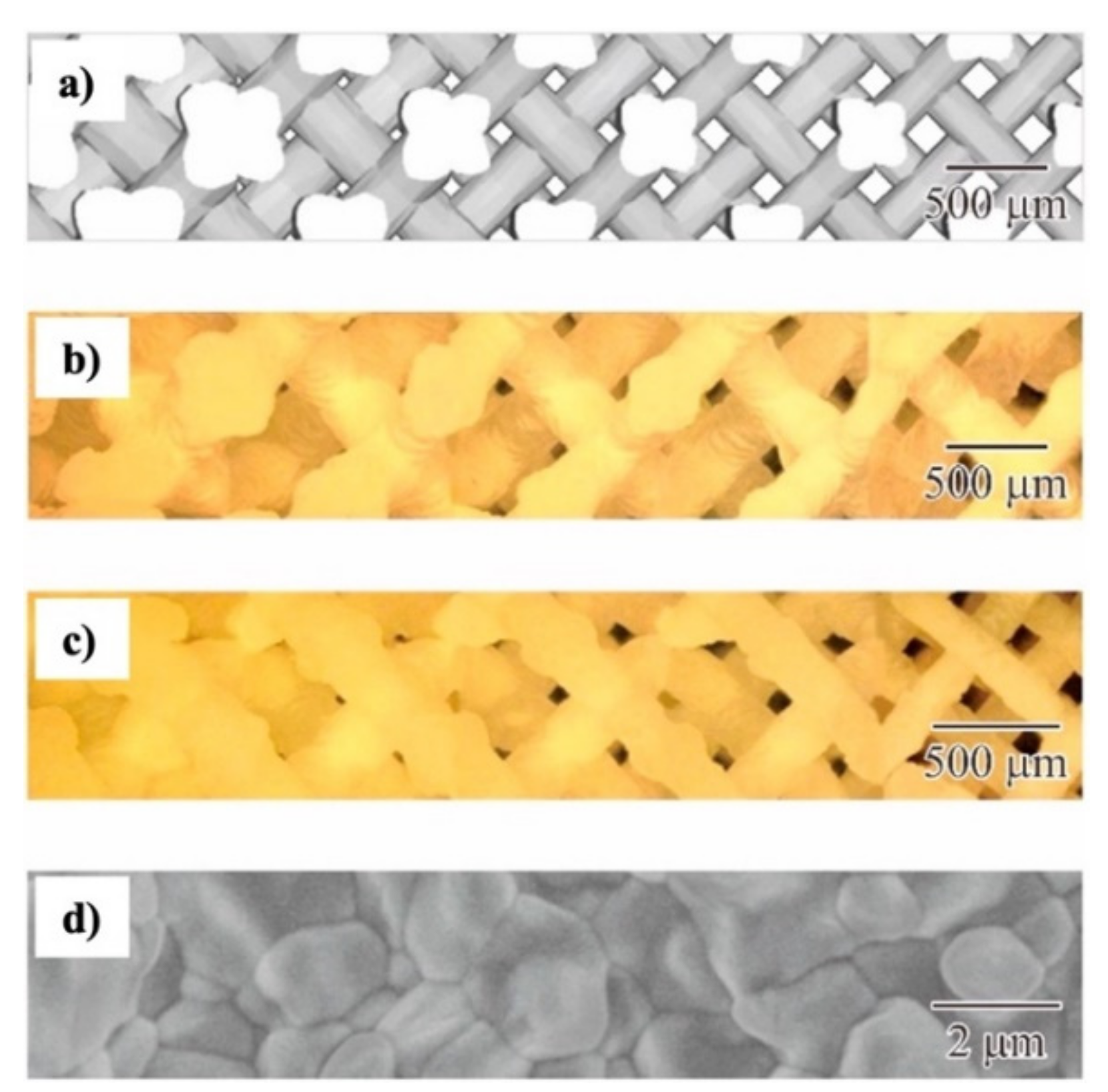

- Liu, T.; Guessasma, S.; Zhu, J.; Zhang, W.; Belhabib, S. Functionally graded materials from topology optimization and stereolithography. Eur. Polymer. J. 2018, 108, 199–211. [Google Scholar] [CrossRef]

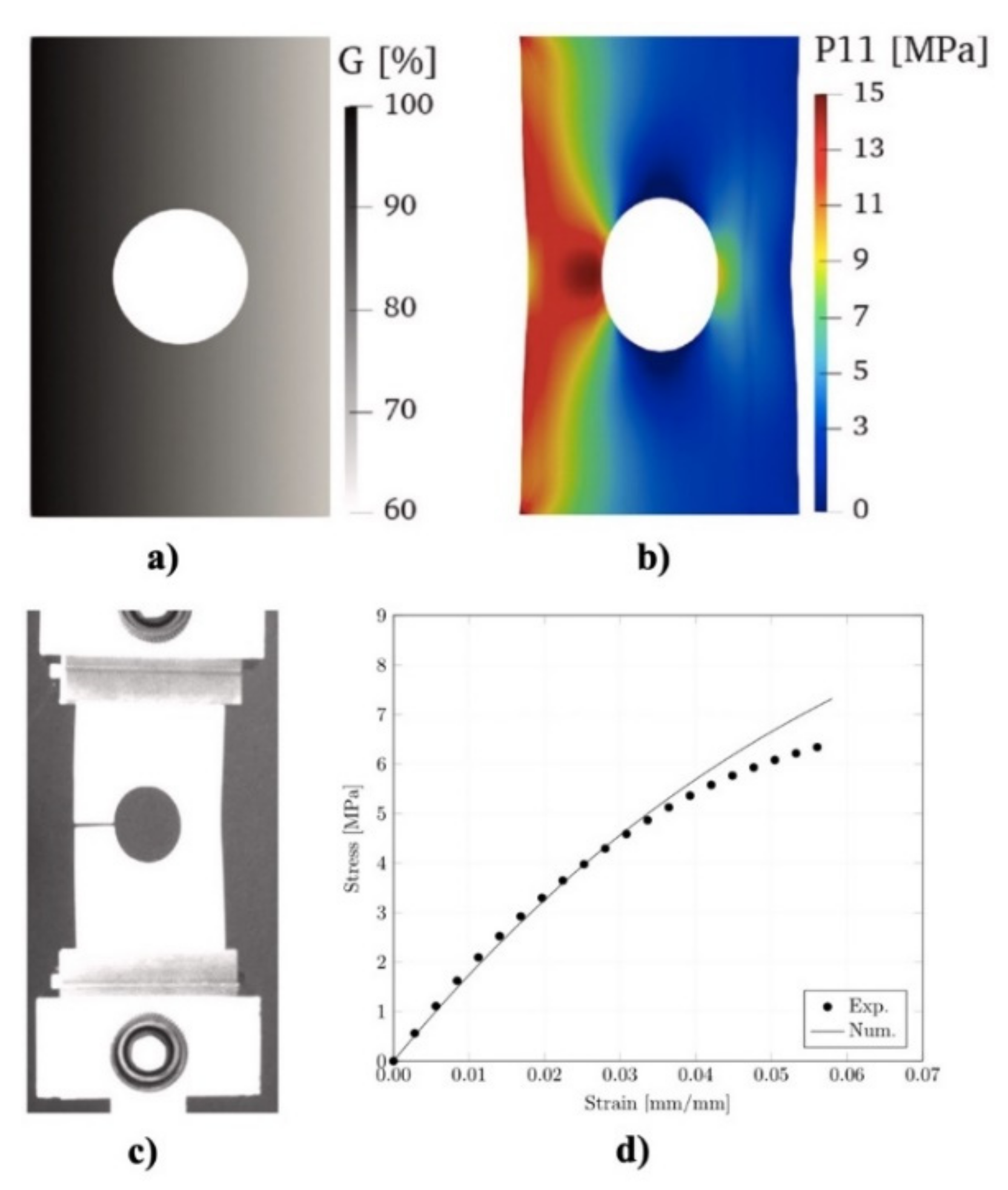

- Valizadeh, I.; Aboud, A.A.; Dorsam, E.; Weeger, O. Tailoring of functionally graded hyperelastic materials via grayscale mask stereolithography 3D printing. Addit. Manuf. 2021, 47, 102108. [Google Scholar] [CrossRef]

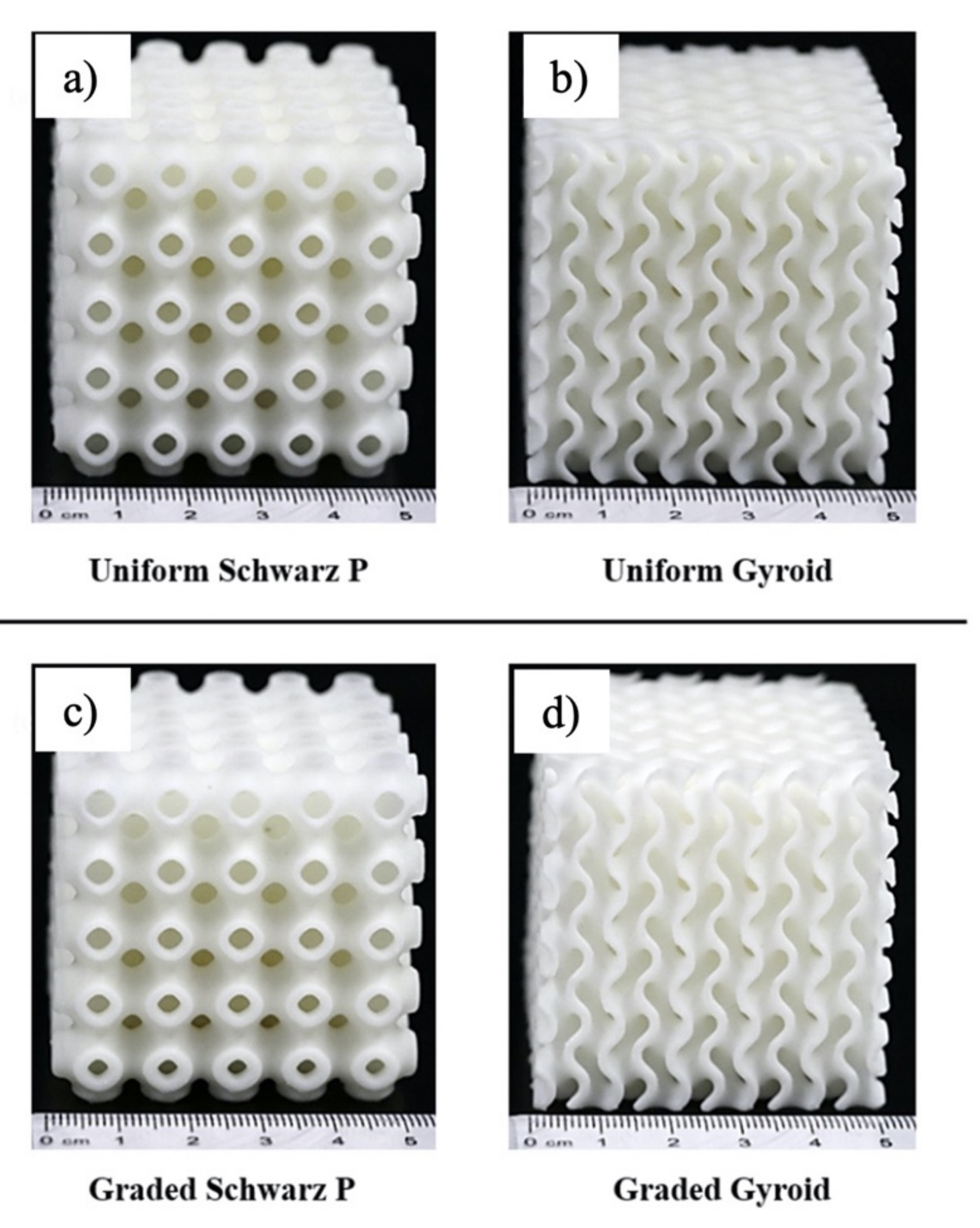

- Yu, S.; Sun, J.; Bai, J. Investigation of functionally graded TPMS structures fabricated by additive manufacturing. Mater. Des. 2019, 182, 108021. [Google Scholar] [CrossRef]

- Gonzalez, P.; Schwarzer, E.; Scheithauer, U.; Kooijmans, N.; Moritz, T. Additive manufacturing of functionally graded ceramic materials by stereolithography. J. Vis. Exp. 2019, 143, e57943. [Google Scholar] [CrossRef]

- Ge, Q.; Sakhaei, A.H.; Lee, H.; Dunn, C.K.; Fang, N.X.; Dunn, M.L. Multimaterial 4D printing with tailorable shape memory polymers. Sci. Rep. 2016, 6, 31110. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Peterson, G.I.; Schwartz, J.J.; Zhang, D.; Weiss, B.M.; Ganter, M.A.; Storti, D.W.; Boydston, A.J. Production of materials with spatially-controlled cross-link density via vat photopolymerization. ACS. Appl. Mater. Interfaces 2016, 8, 29037–29043. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Z.; Wu, J.; Mu, X.; Chen, H.; Qi, H.J.; Fang, D. Origami by frontal photopolymerization. Sci. Adv. 2017, 3, e1602326. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kowsari, K.; Akbari, S.; Wang, D.; Fang, N.X.; Ge, Q. High-efficiency high-resolution multimaterial fabrication for digital light processing-based three-dimensional printing. 3D Print Addit. Manuf. 2018, 5, 185–193. [Google Scholar] [CrossRef]

- Kuang, X.; Wu, J.; Chen, K.; Zhao, Z.; Ding, Z.; Hu, F.J.; Fang, D.; Qi, H.F. Grayscale digital light processing 3D printing for highly functionally graded materials. Sci. Adv. 2019, 5, aav5790. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Safaee, S.; Chen, R. Investigation of a magnetic field-assisted digital-light-processing stereolithography for functionally graded materials. Procedia Manuf. 2019, 34, 731–773. [Google Scholar] [CrossRef]

- Vijayavenkataraman, S.; Kuan, L.Y.; Lu, W.F. 3D-printed ceramic triply periodic minimal surface structures for design of functionally graded bone implants. Mater. Des. 2020, 191, 108602. [Google Scholar] [CrossRef]

- Zhou, C.; Chen, Y.; Yang, Z.; Khoshnevis, B. Digital material fabrication using mask-image-projection-based stereolithography. Rapid Prototyp. J. 2013, 19, 153–165. [Google Scholar] [CrossRef]

- Cho, H.S.; Park, W.S.; Choi, B.W.; Leu, M.C. Determining optimal parameters for stereolithography processes via genetic algorithm. J. Manuf. Syst. 2000, 19, 18–27. [Google Scholar] [CrossRef]

- Chockalingam, K.; Jawahar, N.; Chandrasekar, U.; Ramanathan, K.N. Establishment of process model for part strength in stereolithography. J. Mater. Process. Technol. 2008, 208, 348–365. [Google Scholar] [CrossRef]

- Canellidis, V.; Giannatsis, J.; Dedoussis, V. Genetic-algorithm-based multi-objective optimization of the build orientation in stereolithography. Int. J. Adv. Manuf. Technol. 2009, 45, 714–730. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nohut, S.; Schwentenwein, M. Vat Photopolymerization Additive Manufacturing of Functionally Graded Materials: A Review. J. Manuf. Mater. Process. 2022, 6, 17. https://doi.org/10.3390/jmmp6010017

Nohut S, Schwentenwein M. Vat Photopolymerization Additive Manufacturing of Functionally Graded Materials: A Review. Journal of Manufacturing and Materials Processing. 2022; 6(1):17. https://doi.org/10.3390/jmmp6010017

Chicago/Turabian StyleNohut, Serkan, and Martin Schwentenwein. 2022. "Vat Photopolymerization Additive Manufacturing of Functionally Graded Materials: A Review" Journal of Manufacturing and Materials Processing 6, no. 1: 17. https://doi.org/10.3390/jmmp6010017